for industrial applications

Dimensional, electrical, mechanical, optical measurement variables, temperature measurement technology, CAQ software, materials testing - for QA in production

Image: Blum Novotest

for industrial applications

Dimensional, electrical, mechanical, optical measurement variables, temperature measurement technology, CAQ software, materials testing - for QA in production

Image: Blum Novotest

For the comprehensive digitalization and automation of production processes, it is essential to have precise Real-time measurements to capture, transport, analyze and put back into the smarter cycle Quality Assurance attributed. Intelligent Sensors need appropriate evaluation units to ensure precise monitoring and control of complex processes in product development. But the Measurement Technology is much larger. Testing technology, measuring transducers, measuring devices, measuring systems – you can find it all here.

The former control department for quality assurance in Industry 3.0 operations and the good old caliper have long since been replaced by a high-tech and automated one Quality management, which ensures the necessary accuracy in Industry 4.0 manufacturing. Analogue measuring devices of yesteryear have been replaced by digital measuring technology and sensors. Integrated into the components and machines, these measurements are directly integrated into the process in real time and send the data obtained to the company for evaluation steering and their downstream software tools.

Quality Assurance is a critical factor for success in the manufacturing industry and beyond. At a time when precision and reliability are not only desired but expected, modern measurement technology stands out as a key area for innovation. With advances in digital image processing, the integration of Artificial intelligence for data analysis or the introduction of autonomous sensor systems, for example, enable unprecedented accuracy in monitoring and controlling production processes, reduce rejects and improve efficiencies.

By understanding current trends and technologies in quality assurance and measurement technology, companies can not only... Increase product quality, but also gain a decisive competitive advantage. Thanks to the countless data generated, corrective interventions can be made in the manufacturing process without having to interrupt production. Wear and other properties that endanger downtime are nipped in the bud as part of condition monitoring through permanent measurements and testing.

In addition to the intelligent measuring device, there is a lot to evaluate the individual measurement communication technology and data processing necessary. This means that measurement technology is moving more and more in this direction Industry 4.0. Below you will find new features:

Thermometer, thermocouple, spectrometer, image processing, oscilloscope, transmitter, pendulum impact mechanism, 3D coordinate measuring machine, measuring probe, infrared camera, pyrometer, measuring transducer, industrial scale, load cell, moisture meter, laser vibrometer, calibrators, interferometer, measuring machine, angle measuring device, flow meter, temperature measuring device, laser microscope, stereo microscope, multimeter , data logger, data splitter, micrometer screw, load cell, vibration meter, vibration meter, pressure measurement technology, torque measuring shaft, speed meter, measuring amplifier, length measuring machine, tension meter, gauges, measuring mandrel, tachometer, edge distance measuring device, precision measuring device, roughness meter, tolerance meter, fit meter, light measuring device, measuring table, dial indicator, spectrophotometer, radiation pyrometer , coating thickness gauge, distance meter, profile projector, depth gauge, 2D scanner, 3D scanner, lots of sensors and much more. Today we measure everything that can be measured in some form.

We have detailed articles based on a wealth of information about the following measuring devices and quality assurance systems Manufacturer of innovative measurement technology compiled:

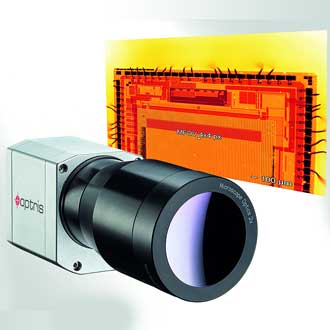

Here you will find new developments from industrial image processing for quality assurance in mechanical and plant engineering as well as for special industries. We provide information about image processing systems such as Embedded vision, Gig-E and 3D camera, Frame grabber, CMOS sensors and much more. The components and measurement methods for image processing are used, among other things, to avoid errors or determine position and orientation in Industry 4.0 production.

CAQ uses computer support to support and improve quality assurance in production in a wide range of industries. The quality management processes are with CAQ software and CAQ systems designed and optimized with and without a cloud connection in the form of a CAQ solution - with the aim of sustainably producing high-quality products in efficient business processes. The article introduces you to some CAQ systems.

Perschmann Calibration makes this easier Calibrate. With the new portal Trendic hub Users receive direct online access to the calibration database. Here, calibration data can be managed in an audit-proof manner and the respective measuring device can be managed securely.

In view of increasingly individual customer requirements and smaller batch sizes, food and beverage manufacturers in high-wage countries are left with only one sufficient solution Process automation competitive. A performant and robust sensors is necessary here so that the systems become transparent. The is an unbeatable helper for the phase separation of food, water and cleaning liquid conductivity sensor “Combilyz”.

Current sensors measure currents. Discover the latest developments in the field in this article Current Sensor, including advanced Hall sensors. We introduce you to market innovations and show their possible applications. Find out how modern current sensors from various companies improve accuracy and efficiency in various industries Automotive and increase industry.

Distance sensors, distance sensors, thickness gauges, etc. are among the distance sensors. In our article we highlight the latest developments from manufacturers, current applications, the status of development and trends in this area. Here you can also find answers to frequently asked questions about sensors for dimensional measurements Path, distance, thickness, position, etc.

Level sensors are used for continuous measurement of the levels of liquids, bulk solids and other media. Discover the latest developments in capacitive level sensors Level sensor and ultrasonic level sensor. You can find current information in our article Market innovations, diverse Fields of application and insights into the current state of the art as well as the latest Trends.

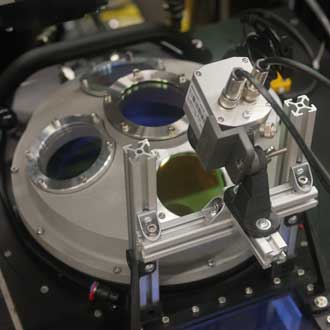

They are suitable for high-precision path, angle or other distance measurements interferometer excellent because, based on the superposition of waves, they meet the requirements for extreme precision, for example in production measurement technology, Research or space travel. In this article we will introduce you to some new products from different manufacturers and give you a little basic knowledge.

A pair of capacitive sensor is used wherever precise measurement results are required. Due to the very good temperature stability, the capacitive measuring principle is particularly suitable for applications in which temperature fluctuations appear. Capacitive sensors measure vibrations, deflection, expansion, path, deflection, deformation, thickness and much more.

In modern manufacturing technology, measuring machines ensure that precision and efficiency in quality assurance and production monitoring are improved. We report here on innovative measurement technologies like this 3D coordinate measuring machine or a measuring machine Gear measurement and show how these technologies can improve your measurement results.

coming soon

Cable pull transmitter, also known as Cable pull sensor or Cable displacement sensor, are precise measuring instruments that offer reliable and accurate distance measurement through a simple but effective principle: a rope is extended in proportion to the movement of the measurement object. Their easy handling and high flexibility make them ideal for use in the Industrial automation, in vehicle systems and in construction technology.

An ultrasonic sensor takes millimeter-precise measurements of the distance of objects or the fill levels of media such as liquids. It uses ultrasonic waves as a displacement sensor. When measuring distance, the measuring principle of sound transit time measurement is often used high-frequency sound pulses for use. Objects can be made of metal, non-metal, transparent, powdery or liquid.

An angle gauge is a measuring instrument that is used to measure the angle between two reference points or surfaces to measure or check. It is used to determine the exact orientation, tilt or tilt angle of an object. Typical applications of angle measuring devices can be found in construction, mechanical engineering, architecture and manufacturing. We present two new developments to you.

An angle sensor often has to function reliably even under harsh operating conditions. These sensors provide accurate Angle data, which are used in applications in Mobile work machines, automotive technology and industrial automation are needed. Discover how angle sensors work and their technological advantages using the example of some applications in our article. Learn how they increase efficiency and accuracy across various industries.

Modern flow meters, especially with integrated ultrasound technology, ensure reliable and precise liquid, gas and other media monitoring. We provide you with, among other things, innovative Ultrasonic flow meter or mass flow rate measuring devices that can also be used in potentially explosive areas.

An accelerometer or accelerometer precisely measures acceleration forces and is used in applications that require motion analysis and control. They measure static or dynamic personnel and can Direction and acceleration capture. Discover new products, applications and basic knowledge in this article.

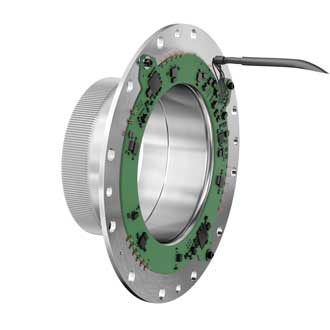

Encoders act as measurement sensors for precise Speed measurement and Position detection in manufacturing processes, mobile machines and industrial drive technology. Here the protractors convert rotational movement into digital signals. The rotary encoders work with wear-free scanning, which is carried out optoelectronic or magnetically. There are incremental encoders and absolute encoders.

Torques can be measured precisely with a torque sensor. In the automotive industry, manufacturing engineering and aerospace, they play a crucial role in monitoring and controlling Rotary movements. Find out more about how they work, types and applications as well as new developments.

The torque measuring shaft is a special sensor technology for measuring the torque in rotating systems such as drive shafts, Engines or gearboxes. They are used in automobiles and industrial drives. Our article presents the latest developments and technologies that enable this measuring waves make it more efficient and user-friendly.

In industry, speed sensors record and monitor the Speeds of drives based on the principle of an inductive sensor or a magnetic sensor. Discover the latest developments in speed sensors, also known as tachometers. Our article introduces new speed sensor innovations, explains a wide range of possible uses and answers the most important questions about these precise measuring devices.

In industry, a wide range of pressure sensors are used to regulate the mechanical measurement of pressure and sometimes also temperature. Analogue and increasingly digital, they are suitable for Pneumatics, Hydraulic System or are electrically designed. With IO Link a pressure sensor qualifies for Industry 4.0 applications Dual channel principle it is even more flexible.

In addition to acceleration sensors, industrial vibration measurement and vibration measurement are particularly important Laser vibrometer for use. The data obtained is often fed into a control system that enables real-time monitoring and analysis. This can be used for preventative maintenance and improving operational efficiency.

Devices like data logger and Data splitter play a central role in modern data collection, processing and analysis. Find out through new innovations how these technologies increase the efficiency of measurement data acquisition, improve the accuracy of data analysis and thus make a decisive contribution to optimizing industrial processes.

The range of measuring transducers for industrial applications includes temperature transmitters and pressure transmitters. In our article we introduce you to the latest innovations Measurement variable converter that make these devices more efficient and versatile in use. Find out how modern measuring transducers are now also used with communication capabilities in various industrial areas.

Measuring amplifiers play a major role in the signal processing under increasing digitalization and automation - even more so when they are used in Industry 4.0 production. For example, today, depending on the application, sensors are used without integrated evaluation electronics in the housing and the digital evaluation of the signals is transmitted to intelligent measuring amplifiers. Below you will find new developments relating to the measuring amplifier.

In the interaction of lidar, laser triangulation and time-of-flight technologies, 3D sensors unfold their full potential spatial data precisely zu the erfass. In our article we highlight new 3D sensor developments and the dynamic applications of these state-of-the-art sensors. Learn how these new developments are transforming the 3D capture landscape.

Not a cloud in the sky and it becomes dangerous: the natural UV radiation from solar energy, but also the UV radiation from artificial sources, have different effects on human skin depending on the wavelength range. Ahlborn offers a global radiation sensor with which the Measure solar radiation leaves and a measuring head for UVE rays.

Discover the fascinating world of the lidar sensor, a part of the optical sensors. Find out everything about the current state of technology and future trends in our article. We will introduce you to new products from various manufacturers as well as the diverse possible applications of lidar sensors.

Stereo microscope, laser microscope or high-speed microscope are used in industrial applications Quality control. They are also indispensable in research and development, where they provide detailed insights into the microstructure and composition of materials. In this article, learn how these modern magnification tools are redefining the boundaries of visual analysis and in which areas of application they are particularly effective.

Are you ready for the latest developments in the field of optical sensors for measuring Distance, presence, position etc. In our article you will find out everything about the state of the art, various applications and you will get answers to your questions about optical sensors. Read how an optical sensor can meet your needs.

In our current article we look at the latest spectrometer developments and trends as well as their growing importance in industry and research. Find out how modern spectrometers do this Spectrum and the wavelength analyze light more precisely than ever and thus contribute to innovative applications in various specialist areas.

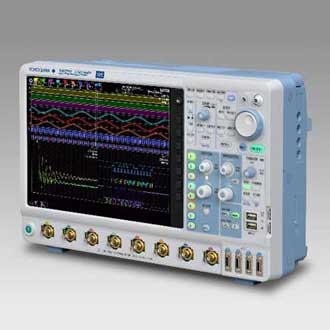

Which oscilloscope is right for my work? Digital oscilloscopes offer advanced analysis capabilities, while analog oscilloscopes remain irreplaceable for certain applications. Find out here what an oscilloscope can do and how to choose the right model for your needs Measurement tasks find and which ones New Products there is on the market.

The latest developments in temperature sensing focus on sensor materials and measurement accuracy as well IO-Link Integration and multifunction. This article also shows how the latest sensors are used in industrial and technological contexts. Find out how advanced temperature sensors from various manufacturers improve precision in critical areas Applications increase.

In our article we highlight the latest developments and technologies in the Temperature measurement and regulation, including Thermocouple, thermometer, thermostat and temperature sensor. Learn how these instruments are used in various industries to ensure precision and efficiency in temperature monitoring.

Thermal imaging cameras are used for non-contact temperature measurement in research & development as well as in production. The infrared cameras have to meet a wide range of requirements, from use in the high four-digit temperature range to the highest resolutions for microthermography to communication capability for Industry 4.0 applications.

Hardness testing is most often used, especially for metals material mechanically tested shall be. In our current article we present the latest advances in Vickers, Knoop and Brinell hardness testing methods. We also answer your questions about this area of materials science.

In our article on materials testing, we highlight the latest trends and developments in the areas of destructive and non-destructive material testing. Learn how to use these methods in industry, from quality control to research. We answer key questions and show how modern technologies such as Generative artificial intelligence increase efficiency and precision in material testing.

The notched-bar impact test is a material testing procedure with which comparatively quickly and with little effort toughness of materials can be determined. With the new HIT450P pendulum impact tester for notched-bar impact bending tests on metals, Zwick Roell is introducing a device that has been optimally tailored to the test.

With the new “DQ-Road” measuring system from Dqdt, fuel consumption in series vehicles can be determined under real road conditions - regardless of the vehicle type. The ensures secure data processing CAN bus technology from Microcontroller.

The GPS-supported gyro system “Adma” from Genesys was made specifically for driving dynamics- And Driver assistancedeveloped and built for measurements in the automotive sector. With the Automotive Dynamic Motion Analyzer (Adma), all motion states such as acceleration, speed, position, rotational speed, position and slip angle of the vehicle can be recorded with high precision while in motion.

Before the dummy is placed in the crash vehicle, various points and angles must be determined so that the dummy is positioned in the vehicle in accordance with the design. One of these values is the H point (hip point). Aicon 3D Systems now offers the solution for the crash test Move Inspect DPS for seat pre-adjustment and determination of the H-point for various test scenarios.

IMC test + measurement is expanding its Cansasflex series with new highly insulated measurement modules and connection boxes for safe measurements in HV environments, especially on electric cars and hybrid vehicles. The new four-channel Measuring module “Hiso-HV4” is suitable for measuring high differential voltages of up to 800 V. This can be used, for example, to record HV voltages along the electrical drive train.

The efficient control of machines and systems in battery cell production requires many sensors that work with different measuring methods. The sensor technology of Pepperl + Fuchs is standard equipment in the automotive industry. Based on decades of experience, the company offers all relevant measuring devices for battery manufacturing from a single source.

In order to help hydrogen (H2) achieve a breakthrough as an alternative fuel, we need attractive fuels Hydrogen cars and high-performance commercial vehicles that can be refueled in a comprehensive filling station infrastructure. The construction of the corresponding hydrogen filling stations requires a lot of measurement technology to ensure safety when refueling with hydrogen. Wika offers the complex instrumentation for this, such as valves, temperature or pressure sensors.

The Center for Wind Power Drives CWD The measurement campaign for a wind turbine is the most powerful to date Wind turbine (WAE) on its 4 MW system test bench. As part of the Certbench joint project, Enercon's E115 system with a nominal output of 3,2 MW was measured over a period of six weeks using the hardware-in-the-loop (Hil) system for rotor emulation.

The global hydrogen economy is in full swing and is an important part of the energy transition. Jumo would like to participate in this development and is positioning itself with its Measurement Technology as a system and solution provider for the Hydrogen production. pressure- And Temperature Sensors, conductivity sensors or Pressure Transmitters ensure quality here.

Freudenberg Sealing Technologies (FST) has a material testing procedure and a simulation method for Elastomeric materials developed to improve the performance and service life of components in offshore wind turbines. Material simulation analyzes how materials behave over the lifespan of a turbine.

With customer-specific optimized concepts for standard compliance Illumination of workplaces in accordance with EN 12464-1/-2 R. Stahl for consistent planning security. In particular, the company can support the switch to energy-efficient and long-lasting LED technology with in-depth expertise.

Energy harvesting pioneer enocean presents a new multisensor. In the manufacturer's PTM form factor for maintenance-free wireless switches and sensors, this delivers Sensor module Data for building automation and the Internet of Things (IoT). The integrated solar cell generates all the energy required for operation.

Because global confectionery consumption is constantly growing, manufacturers of Chocolate & Co. set up their production facilities quickly, flexibly, economically and safely so that they remain competitive. A powerful, state-of-the-art industrial scale and inspection solution from Minebea Intec can help to increase efficiency in the confectionery industry.

Made possible with its “Dylight” X-ray inspection systems Minebea Intec the safe and reliable one Inspection of raw materials and packaged products in the food industry. The continuous development of the systems not only increases efficiency, but also flexibility in the selection of possible packaging materials.

In July 2018 brought Minebea Mitsumi in Japan that Mimamori bed sensor system on the market. The innovative technology was aimed particularly at care facilities. The project was launched in May 2017 and promises significant benefits in the healthcare sector for the European market as well. The bed sensor system records patient movements, vital data and behavior patterns without contact and is so far unique.

The coronavirus pandemic led to an increased need for measurement technology that can be used to quickly and reliably determine body temperature. Optris ppresents a new IR camera for this purpose Measure fever. With the PI 450i, the surface temperature of people's faces can be measured even as they pass by, using software support based on infrared measurement technology.

The Femsense technology from Steady sense continuously records body temperature in a simple, exact and hygienic way. It can be used, for example, to determine ovulation when a child is about to be born, or it can record dangerous temperature increases after the operation.

With that of dr Catherine Philip The developed digital laser microscope can be used to examine deeper layers of tissue, such as those found in: B. can be found in the thyroid gland of patients. For her outstanding dissertation, Dr. Philip with that Bertha Benz Prize 2020 honored.

People move less and less. Fraunhofer Researchers have now developed an interactive learning system that is intended to motivate more movement in a playful way: a sensor mat with a Activity monitor combined. With the system, children and adults can keep fit and build up knowledge at the same time. The solution records the intensity of movement and displays it immediately.

Jumo, a global company, is characterized by its expertise as a system and solution provider in industrial measurement technology and automation. With an extensive portfolio that includes high-precision sensors and automation components for temperature, liquid analysis, pressure, level, flow and humidity, the company also develops tailor-made solutions.

In addition to extensive safety precautions, handling hydrogen also requires measurement expertise. This applies to the production of hydrogen from ultra-pure water as well as to feeding the electrolyzer or monitoring the electrolytic conductivity. Digital, explosion-proof pressure- And Temperature Sensors from Jumo ensure the monitoring and security of the thermodynamic processes.

The MinebeaMitsumi Daughter Minebea Intec is a leading provider of weighing and inspection technologies. The comprehensive portfolio is aimed at increasing efficiency and quality in production and packaging. The offering includes a wide range of precision scales, industrial scales, bench and floor scales, inspection systems such as metal detectors, X-ray machines and software solutions for data collection and analysis.

The load cell is small, inconspicuous and yet indispensable in many industries: Built in industrial scales e.g. For example, in numerous areas of industry such as goods receiving and shipping, it ensures that the contents or filling levels of containers, tanks and silos as well as vehicles are precisely determined. Read about the innovations Minebea Intec for industrial weighing.

Optris specializes in the development and manufacture of non-contact temperature measuring devices and offers an extensive portfolio of infrared thermometers, thermal imaging cameras and thermographic solutions for industry and research. The diverse range of pyrometers and thermal imaging cameras aims to enable precise and reliable temperature monitoring in a wide range of applications.

Optis offers several compact and high-performance infrared thermometer versions for industrial temperature measurement. These can be operated via PC and via app. Below we will introduce you to the new developments of these infrared thermometers, including, among others color pyrometer CS Cision, the Pyrometer CT Laser 4M and CT 4M for high-speed applications as well as the CS Micro for the OEM sector.

Online thermal imaging camera systems for industrial applications are an Optris specialty. The areas of application are diverse, from condition monitoring in outdoor areas to quality assurance in glass production. The infrared cameras are constantly being further developed and adapted to the requirements of the systems and applications.

The inventor of the proximity switch Pepperl + Fuchs is at the same time a pioneer and innovator in sensor technology and explosion protection. The extensive portfolio of sensors for industry includes inductive, capacitive, ultrasonic, photoelectric and magnetic field sensors as well as rotary encoders and identification systems. These sensors are used in a number of industries including factory and process automation.

Acceleration sensors and inclination sensors from the IMU F99 series from Pepperl+Fuchs were specifically developed for dynamic applications such as those found in wind power or construction machinery. Both Inertial measuring systems offer 360 degree measurement in three axes. Read how an acceleration sensor in a wind turbine and an inclination sensor in an excavator demonstrate their advantages.

Inductive sensors from Pepperl+Fuchs are used in a wide variety of applications and sectors in the process industry and industrial automation. No matter whether for Position detection the metal objects or as proximity switch in the machine tool, an inductive sensor from the manufacturer reliably detects metallic objects even with a large switching distance.

Level sensors, also known as Level gauge or Level sensors are required for level measurement in many applications, such as the process industry, food industry, chemical industry, water and wastewater treatment and many more. Pepperl+Fuchs has a solution for every application.

In the meantime it is Ultrasonic sensor technology arrived in all industrial areas. Their USP features are reliability, versatility, precision and robustness. Even under the harshest environmental conditions, ultrasonic sensors are insensitive to contamination because the sensor surface cleans itself through vibration.

Pepperl+Fuchs offers based on 2D and 3D Cameratechnological diverse options for detection, identification, positioning and measurement in factory automation. The "Smartrunner" technology combines the powerful light section process with a vision sensor including LED lighting. This is what the 2D vision is based on Sensors "Matcher" and "Detector".

Turck offers an extensive portfolio of sensors for industrial applications. The range includes inductive, capacitive, magnetic field-based, optoelectronic and ultrasonic sensors as well as pressure sensors. Many of these sensors are IO-link capable and therefore support Industry 4.0 applications. These products are used in a variety of industries to automate processes and monitor machine functions.

Turck offers non-contact and conventional encoders in various designs. The encoder are incremental, absolute with hollow shaft or solid shaft in sizes from 24 to 102 mm diameter. They are vibration-resistant, robust and work even in demanding environments. Here we present to you the new developments such as the Profinet absolute rotary encoders.

Inductive sensors from Turck detect without contact based on the wear-free functional principle metal objects. The Uprox sensors are characterized by their special coil concept. The Factor 1 sensors offer the largest switching distance on metals. A new inductive sensor based on Uprox technology has now been developed in a cuboid shape for logistics and another for the first time for carbon detection.

Turck's extensive portfolio of temperature sensors also in combination with humidity measurement or Vibration measurement offers a wide selection for a wide variety of applications. The comfortable temperature sensor series TS+ e.g. B. is very flexible, easy to assemble and quick to put into operation. The new temperature/vibration sensor CMVT with IO-Link also offers results with high accuracy.

Different measuring principles are used to record limit levels or measure fill levels. Turck offers a comprehensive portfolio for various media and environmental conditions. This also includes the ultrasonic level sensor and the radar sensor for level measurement. IO-Link interfaces make the sensors IIoT suitable.

The golden rule of measurement technology is: “Measure as accurately as necessary, not as accurately as possible.” This rule highlights the importance of appropriateness and efficiency in measurement technology. It's about finding the balance between the required accuracy for the application and the effort required to achieve that accuracy.

Metrology encompasses a wide range of methods, devices and technologies used to determine various physical, chemical or electrical quantities. It plays a crucial role in almost all technical and scientific areas, from quality control in production to research and development. Elements of measurement technology include:

DIN 1319 is one fundamental norm series, which deals with the basics of measurement technology. The implementation specifies terms, definitions and general principles for measuring, the properties of measuring devices and measuring systems and for dealing with measurement uncertainties.