Distance sensors | Distance, path, distance & Co.

- Details

- Hits: 7190

Distance sensors, distance sensors, thickness gauges, etc. are among the distance sensors. In our article we highlight the latest developments from manufacturers, current applications, the status of development and trends in this area. Here you can also find answers to frequently asked questions about sensors for dimensional measurements Path, distance, thickness, position, etc.

Contents

- Distance sensors 2024 – The most important things in brief

- Distance sensor innovations

- New sensor class simplifies positioning tasks significantly

- Interferometer for ultra-precise length and angle measurement

- Cable encoders, cable sensors and cable displacement sensors

- Magnetic, configurable and precise angle sensors

- Laser distance sensors for machines and systems

- Confocal sensors for precise distance and thickness measurements

- IO-Link sensors deliver the most extensive diagnostic data

- Precise distance and thickness meter for various surfaces

- Position sensor for mobile hydraulics meets the highest EMC requirements

- Intelligent position measuring system for absolute linear feedback

- Sensors for wind turbines and generators – onshore and offshore

- Distance sensors archive

- FAQ

Distance sensors 2024 – The most important things in brief

The distance sensors are in recent years more accurate, smaller and more versatile become. Modern distance sensors use a variety of technologies such as laser distance sensors, infrared and radar or ultrasonic distance sensors to be used in a wide range of applications - from industrial automation to vehicle assistance systems Robotic.

A current trend in the development of distance sensors is the integration of KI and machine learning. This allows the sensors to better interpret complex environments and deliver more precise measurement results. This is particularly important in dynamic and unstructured environments such as autonomous navigation.

Another trend is the increasing networking of distance sensors as part of the Internet of Things (IoT). By connecting to IoT platforms, the sensors can provide real-time data for Predictive Maintenance, real-time monitoring and improved process control is essential.

The further developments regarding Energy Efficiency and miniaturization enable their use in portable and battery-operated devices as well as in applications where space is limited.

Distance sensor innovations

Distance sensors precisely measure the distance between the sensor and the measurement object and are used, among other things, to determine positions, avoid collisions and optimize automation processes. We present the new products to you here.

New sensor class simplifies positioning tasks significantly

April 24.04.2024, 2 | The smart XNUMXD profile sensors from the OX series offer precise and fast positioning tasks in automation Baumer an innovative solution: These sensors, still considered an insider tip, represent an economical and efficient alternative to traditional smart vision sensors and multi-sensor solutions.

April 24.04.2024, 2 | The smart XNUMXD profile sensors from the OX series offer precise and fast positioning tasks in automation Baumer an innovative solution: These sensors, still considered an insider tip, represent an economical and efficient alternative to traditional smart vision sensors and multi-sensor solutions.

Smart 2D profile sensors are particularly suitable for tasks in which workpieces or tools have specific features such as edges, gaps, or certain shapes using height profile can be recorded precisely. The main advantage of this technology is the rapid and reliable acquisition of position data, which leads to higher throughput and increased productivity. Compared to contrast-based methods, these sensors enable shorter cycle times and higher object speeds.

Another significant advantage of the OX series is its Ease of use. The sensors are easy to parameterize and configure via an intuitive web interface, which enables quick commissioning. The integrated functional toolbox processes profile data directly in the sensor, meaning no complex post-processing of the data is required. Additionally, the independent acquisition of height profiles eliminates the need for special lighting, which is often critical in contrast-based approaches.

In summary, the smart 2D profile sensors of the OX series from Baumer offer an economical and effective solution wherever positioning tasks can be solved by evaluating height or distance information. This makes them ideal for applications such as edge detection and positioning robots or Tools.

Application example from robotics

The fully automated assembly system for electroplating racks presented here was developed by the Swiss automation specialist Roth technology developed. Robots fill the empty hooks with parts. The inaccurate electroplating frames are a big challenge because every specimen is different. This task is no problem for the new OX series, as the video shows you.

Interferometer for ultra-precise length and angle measurement

19.01.2024/XNUMX/XNUMX | They are suitable for high-precision distance, angle or other distance measurements interferometer excellent because, based on the superposition of waves, they meet the requirements for extreme precision, for example in production measurement technology, Research or space travel. In this article we will introduce you to some Product news from different manufacturers.

19.01.2024/XNUMX/XNUMX | They are suitable for high-precision distance, angle or other distance measurements interferometer excellent because, based on the superposition of waves, they meet the requirements for extreme precision, for example in production measurement technology, Research or space travel. In this article we will introduce you to some Product news from different manufacturers.

Cable encoders, cable sensors and cable displacement sensors

28.03.2022 | draw-wire encoder are precise measuring instruments that offer reliable and accurate distance measurement using a simple but effective principle. Their easy handling and high flexibility make them ideal for use in the Industrial automationin vehicle systems and in construction technology. Discover cable pull encoders to improve accuracy and efficiency in these areas.

28.03.2022 | draw-wire encoder are precise measuring instruments that offer reliable and accurate distance measurement using a simple but effective principle. Their easy handling and high flexibility make them ideal for use in the Industrial automationin vehicle systems and in construction technology. Discover cable pull encoders to improve accuracy and efficiency in these areas.

Magnetic, configurable and precise angle sensors

March 25.03.2021, XNUMX | A angle sensor often has to function reliably even under harsh operating conditions. These sensors provide accurate angle data that is used in applications in Mobile work machines, Automotive engineering and Industrial automation are needed. Discover how angle sensors work and their technological advantages using the example of some applications in our article.

March 25.03.2021, XNUMX | A angle sensor often has to function reliably even under harsh operating conditions. These sensors provide accurate angle data that is used in applications in Mobile work machines, Automotive engineering and Industrial automation are needed. Discover how angle sensors work and their technological advantages using the example of some applications in our article.

Laser distance sensors for machines and systems

02.02.2021 | Baumer offers various versions of laser distance sensors for distance measurement, distance measurement and position measurement of a wide range of objects. The portfolio of laser distance sensors is divided into standard, performance and high performance laser distance sensors. Below we present the new developments for laser distance measurement.

02.02.2021 | Baumer offers various versions of laser distance sensors for distance measurement, distance measurement and position measurement of a wide range of objects. The portfolio of laser distance sensors is divided into standard, performance and high performance laser distance sensors. Below we present the new developments for laser distance measurement.

Confocal sensors for precise distance and thickness measurements

08.05.2020 | Micro-Epsilon introduces a new generation of confocal sensors. They are suitable for measuring the thickness of transparent materials and for precise distance measurement. The Sensors Confocal DT IFS 2407-3 and 2404 / 90-2 open up new applications on curved surfaces and in confined spaces for series applications. Together with the Confoca lDT controllers, measuring rates of up to 70 kHz are achieved.

08.05.2020 | Micro-Epsilon introduces a new generation of confocal sensors. They are suitable for measuring the thickness of transparent materials and for precise distance measurement. The Sensors Confocal DT IFS 2407-3 and 2404 / 90-2 open up new applications on curved surfaces and in confined spaces for series applications. Together with the Confoca lDT controllers, measuring rates of up to 70 kHz are achieved.

The technology of the Confocal DT IFS2407-3 enables a high level Tilt angle of up to ± 30°. This means that curved and structured surfaces are recorded precisely. The large measuring range is 3 mm, the numerical aperture (NA) is 0,43 and the high base distance is 28 mm. With the large tilt angle, these confocal sensors are predestined for geometry tests in coordinate measuring machines. Users receive stable and highly accurate results on surfaces of gears or external threads.

For the exact recording of paths, distances, positions and thicknesses in confined spaces the IFS2404 / 90-2 was designed. It offers a measuring range of 2 mm with a resolution of 0,040 µm. The sensor has a beam path of 90 °. The design with radial beam path allows space-saving integration with a reduced installation depth. This sensor is mainly used in series production.

Micro-Epsilon also offers for the confocal sensor customized versions. Other designs, special cable lengths, vacuum-compatible materials or extended fastening options are conceivable here.

IO-Link sensors deliver the most extensive diagnostic data

03.02.2020/XNUMX/XNUMX | With the fully digital inductive IO-Link sensors Alphaprox from Baumer can generate the most comprehensive diagnostic data on the market. In addition to sensor temperature, operating time and operating voltage, the sensors also record boot cycles, switching frequency and distance values.

03.02.2020/XNUMX/XNUMX | With the fully digital inductive IO-Link sensors Alphaprox from Baumer can generate the most comprehensive diagnostic data on the market. In addition to sensor temperature, operating time and operating voltage, the sensors also record boot cycles, switching frequency and distance values.

This information can easily be called up via the IO-Link interface and stored in the steering digitally processed. In addition, the sensors have a kind of memory.

Frequency distribution of process and diagnostic data

The histogram function of the IO-Link sensors allows the frequency distribution of the process and diagnostic data to be evaluated over a relevant period of time. For the Condition monitoring information about the status of devices, machines and systems can be collected and evaluated very easily. This data forms the basis for predictive maintenance or predictive maintenance. Through specific analyzes of the collected process and diagnostic data, the effectiveness of the systems can be increased in a targeted manner and processes in the applications can be optimized.

The inductive ones distance sensors Alphaprox primarily deliver a micrometer-precise digital distance value. With a switching frequency of 1,25 kHz and a cycle time of 0,6 ms, Baumer inductive sensors are the fastest on the market. Thanks to the extensive diagnostic data, the sensor age can be determined very precisely by recording the boot cycles or the previous operating time. This allows the machine operator to draw predictive conclusions for his applications as to when a component needs to be replaced or serviced. Machine downtimes in the automation system can be optimally planned.

The sensors have a unique histogram function for logging diagnostic and process data. In the event of undesirable machine conditions, operators can more easily understand the errors. That shortens it Troubleshooting. The evaluation of trends is also easily possible with the IO-Link function and control. An increase in the sensor temperature can indirectly indicate that a machine component in the vicinity of the sensor is overheating or that the immediate ambient temperature is rising. This can be an advance warning of an impending machine failure.

Reading tip: Distance and other optical sensors

Reading tip: Distance and other optical sensors

In addition to the voltage supply and the temperatures, the measured value stands for Distance and frequency available for evaluation as a histogram. In order not to falsify the statistics in the process when commissioning the sensor or replacing it, the statistics can be reset at any time. About the user-friendly Interface every system manufacturer can read out the data for his histogram analysis intuitively and as required. The IO-Link sensor converts units internally and outputs the values in the desired unit to the controller.

Such inductive sensors with the most comprehensive diagnostic data are available from Baumer in sizes 6,5 mm to M30 with a detection range of up to 18 mm when flush mounted. Most of this diagnostic data is also with the Baumer Ultrasonic sensors UR18 and U500 available.

Precise distance and thickness meter for various surfaces

13.01.2020/XNUMX/XNUMX | The distance and distance sensor offers the highest precision thickness Gauge “Confocal DT IFS2407-3” (picture above) from Micro-Epsilon when measuring Surfaces. This confocal sensor for distance and thickness measurements works at a maximum tilt angle of ±30 degrees. Therefore, stable measurement signals are achieved and highly accurate results are output even on curved surfaces. The confocal-chromatic sensors count in the optical Measurement Technology to the most demanding measuring systems.

You will be precise Distance measurement on different surfaces and for non-contact thickness measurement used for transparent materials. State-of-the-art technology enables the thickness gauge to have a high tilt angle. As a result, curved and structured ones can be recorded reliably and precisely.

The sensor has a large measuring range of 3 mm, a numerical aperture (NA) of 0,43 and a high basic distance of 28 mm. In connection with the large tilt angle, these sensors are suitable for geometry tests in Coordinate measuring machines. Particularly on surfaces such as gear wheels or external threads, there are stable and highly accurate results.

Through non-contact measuring principles the sensor does not act on the target. The measurement is therefore wear-free. This means that the values are recorded much faster than tactile measurement methods can. Together with the Confocal DT controllers, measurement rates of up to 70 KHz can be achieved.

Position sensor for mobile hydraulics meets the highest EMC requirements

Sep 30.09.2019, XNUMX | For position detection directly in the pressure range of hydraulic or pneumatic cylinders Novotechnik the displacement transducers of the new TM1 series were developed. They reliably record the position and speed of mobile machines, even in harsh environmental conditions, with a resolution of 0,1 mm.

Sep 30.09.2019, XNUMX | For position detection directly in the pressure range of hydraulic or pneumatic cylinders Novotechnik the displacement transducers of the new TM1 series were developed. They reliably record the position and speed of mobile machines, even in harsh environmental conditions, with a resolution of 0,1 mm.

The successors to the TIM series are suitable for measuring lengths to 2000 mm and are optimized for use in applications with the highest EMC requirements. They comply with EN 13309 for construction machinery and ISO 14982 for agricultural and forestry machinery, are protected against HF fields up to 11452 V/m in accordance with ISO 2-200 and therefore exceed the E1 requirements of the German Federal Motor Transport Authority. The measurement signal can be as an analog current or voltage signal or via fieldbusinterfaces (CAN open, CAN SAE J1939).

The IP6K9K sensors offer a pressure resistance of up to 350 bar, pressure peaks up to 450 bar, a high temperature resistance from -40° to +105 °C and, thanks to the non-contact, wear-free measuring principle, a very long service life. The connector system allows quick installation in closed or one-sided open cylinders without soldering, crimping or screwing: The contact carrier of the M12 connector is already at the signalcables of the sensor connected; it is routed to the outside through a hole in the cylinder.

Intelligent position measuring system for absolute linear feedback

July 16.07.2019, XNUMX | With the BMP series Balluff a new intelligent displacement sensor in the program, which, in addition to the absolute position signal for the stroke of a piston via IO-Link, can also provide information about the sensor status and the current environmental conditions. He monitors e.g. B. the sensor temperature, the number of starts and issues warnings when an adjustable limit value is exceeded.

July 16.07.2019, XNUMX | With the BMP series Balluff a new intelligent displacement sensor in the program, which, in addition to the absolute position signal for the stroke of a piston via IO-Link, can also provide information about the sensor status and the current environmental conditions. He monitors e.g. B. the sensor temperature, the number of starts and issues warnings when an adjustable limit value is exceeded.

A pair of internal counter permanently records the operating hours over the entire service life, since the last maintenance and the last switch-on. This means that any necessary replacement can be planned for the next service interval.

The integrated IO-Link interface also offers flexibility; It enables, for example, quick format changes through time-saving parameterization functions. The magnetic and therefore non-contact, wear-free sensor continuously determines the absolute position of a piston, is compatible with almost all cylinder types and is quickly installed.

Exact execution of a defined piston stroke

Preferred areas of application can be found where the exact design of a defined piston stroke plays a key role in determining process and product quality, for example in assembly, handling and factory automation.

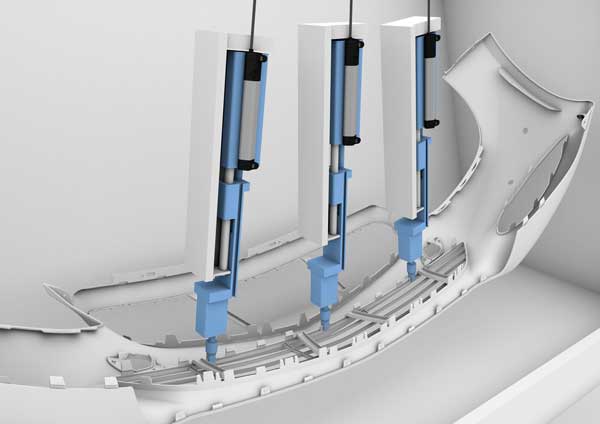

Typical application examples for the magnetic field position measuring systems can be found at joining processes. When it comes to joining composite materials together with minimal effort, ultrasonic welding is usually the method of choice, e.g. in the production of complex components such as dashboards, instrument panels or bumpers and headlights in the automotive industry. The BMP position sensor is ideal for positioning the sonotrode precisely for the joining process.

Right on Pneumatic cylinder mounted on the feed unit, it monitors its axial movement and thus continuously checks the piston stroke. In this way, the sonotrode is always fed precisely with an accuracy of 100 µm with every movement. Thanks to the absolute measurement, it is always known where the piston is. This ensures products of high, reproducible quality and stabilizes the process.

Sensors for wind turbines and generators – onshore and offshore

05.02.2019 | Micro-Epsilon offers a wide range of modern sensors for Wind Turbines. For the safe plant operation Numerous measurement methods and sensor models are available in the test bench and in series use onshore and offshore.

FAQ

What is a distance sensor?

A distance sensor measures the distance or distance between an object and the sensor. There are different names, types and measurement principles.

What types of distance sensors are there?

The distance sensors include Waysensors or displacement transducers, Positionssensors, Distancesensors, Thickknife and Removalsmesser. There are non-contact measuring and contact distance sensors. Non-contact distance sensors include laser distance sensors, infrared sensors, confocal sensors, capacitive sensors, radar sensors, eddy current sensors, ultrasonic sensors and interferometers. Contact distance sensors are cable sensors, inductive displacement sensors or magnetic sensors.

Where are distance sensors used?

Distance sensors are used in numerous applications, including automation technology, automotive technology, robotics and in Safety Technology. They offer a precise and often non-contact way to detect the position, distance or presence of objects.

How can you measure very small distances?

To measure very small distances, high-precision sensors and measuring instruments are used. Various methods are used in applications such as semiconductor manufacturing, microscopy, materials testing and precision engineering where accuracy is important Micrometer range or below is required. Common methods include:

- Laser-Interferometers use the interference of laser light to measure microscopic changes in distance. They offer high accuracy and resolution.

- capacitive Sensors measure changes in electrical capacity caused by small changes in distance. They are suitable for very precise close-range measurements.

- Confocal Chromatic Sensors use light with different wavelengths to determine the exact position of a point. They are particularly precise for micrometer measurements.

- Optical Micrometers measure small distances using precise light beam techniques.

- Piezoelectric Sensors can measure small movements very precisely because they react to pressure and convert it into an electrical signal.

Source: This article is based on information from the following companies: AB Jödden, Baumer, IFM Electronic, Micro-Epsilon, Novotechnik, GDP.

You might also be interested in...

Thermal Imaging Camera | Innovations for industrial applications

Baumer Group builds new innovation center in Frauenfeld

Laser distance sensor for machines and systems

gripper | pneumatic, electrical, magnetic

Robust high-resolution GigE camera recognizes the finest details

Optimize weld seam with calculation and profile measurement

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.