for drives and other systems

Pneumatic components such as compressors, clamping technology, pneumatic cylinders, valves or systems for compressed air treatment

for drives and other systems

Pneumatic components such as compressors, clamping technology, pneumatic cylinders, valves or systems for compressed air treatment

for drives and other systems

Pneumatic components such as compressors, clamping technology, pneumatic cylinders, valves or systems for compressed air treatment

One with the medium of air Power Type and thus realize movement, this is possible with the Pneumatics. We present new pneumatic developments such as pneumatic cylinders, compressors, pneumatic valves, etc. for your design!

Contents

As a specialty of Fluid Technology is in contrast to Hydraulic System in pneumatics, compressed air is used to generate movements. The fluidic principle is similar, but instead of liquids in hydraulics, there is gaseous fluid Air for use. The Compressed air system consists of the compressor to generate the compressed air, the compressed air preparation via z. B. Filters with subsequent compressed air distribution via the compressed air network consisting of pipes, hoses and valves and finally the applications. There, pneumatic cylinders convert the compressed air acting on the pistons into mechanical work order, which gives the application its movements. The greatest advantage of pneumatics over hydraulics is the medium of air itself, it is dry and clean, inexpensive and less prone to failure.

Find out about news like Pneumatics Cylinders, for compressed air treatment, avoidance of leaks and tools etc. With these systems you can really save compressed air in your pneumatic construction!

Applied Research

Logistics

gas springs are important components eg in the Automobile- or furniture industry where controlled movements of loads are required. You will also be in the Medical Technology and used in aviation. will be one Gas Spring incorrectly calculated, this can lead to dangerous and expensive damage to a machine or plant. Below you will find information on how to calculate, design and order gas springs online.

gas springs are important components eg in the Automobile- or furniture industry where controlled movements of loads are required. You will also be in the Medical Technology and used in aviation. will be one Gas Spring incorrectly calculated, this can lead to dangerous and expensive damage to a machine or plant. Below you will find information on how to calculate, design and order gas springs online.

The requirements for Pneumatic cylinder are constantly increasing in terms of design, hub, maintenance and energy efficiency. SMC offers ISO cylinders from the CP96 series in accordance with DIN ISO 21287, specifically double-acting in four new versions. They include an ISO standard and compact version, an ISO-based version with energy return and an energy-efficient compact cylinder. This special pneumatic cylinder with energy recovery and the compact cylinder offer a reduction in compressed air consumption of up to 48% - one world first.

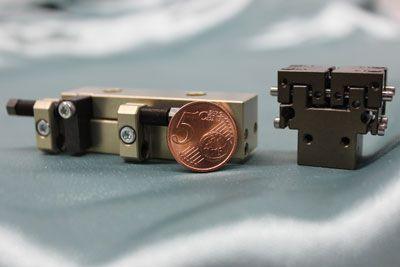

The pneumatic linear unit LSM-3 from Friedemann Wagner is a precise and repeatable mini linear slide for the pneumatic automation of especially small workpieces. The load to be moved is safely guided and carried by 2 guide carriages with sealed recirculating ball guides.

The pneumatic linear unit LSM-3 from Friedemann Wagner is a precise and repeatable mini linear slide for the pneumatic automation of especially small workpieces. The load to be moved is safely guided and carried by 2 guide carriages with sealed recirculating ball guides.

Airpower presents the pneumatic swivel drive "Twintorque", which is suitable for all areas of application where the highest quality and reliability are required. It is certified according to SIL3 according to the international standard IEC61508: 2010 and is suitable for all types of fittings. Swivel angles of 90 ° and 180 ° are available, with all other desired nominal swivel angles (e.g. 45 ° 120 °, 135 °, 145 °) can be adjusted using two additional adjusting screws in the drive cover.

Airpower presents the pneumatic swivel drive "Twintorque", which is suitable for all areas of application where the highest quality and reliability are required. It is certified according to SIL3 according to the international standard IEC61508: 2010 and is suitable for all types of fittings. Swivel angles of 90 ° and 180 ° are available, with all other desired nominal swivel angles (e.g. 45 ° 120 °, 135 °, 145 °) can be adjusted using two additional adjusting screws in the drive cover.

An compressors or Compressor compresses and compresses air, water or oil according to the displacement principle or according to the turbo principle. Whether e.g. B. screw compressors, piston compressors or rotary compressors are used and regardless of the principle, they all have in common that they energy efficient have to be. This will become mandatory from July 2023 IE4 Binding energy efficiency level. We present innovations and use cases to you:

SMC presents the improved Soft start valve AV-A series for the Pneumatics. The valves are very compact and offer a flow rate up to 2,2 times higher. They require 80% less energy than the previous models. The range of possible uses of the revised soft start valves increases significantly with the flow rate of up to 13.400 l / min.

IMI Precision Engineering has presented the world's only "Fail Freeze" proportional valve (pressure-maintaining in the event of a fault in the supply voltage) that is certified according to Atex (IS) for use in hazardous environments. The valve of the 422IS series allows the use of flammable gases as a control medium instead of compressed air. This makes compressed air generation at remote locations unnecessary.

IMI Precision Engineering has presented the world's only "Fail Freeze" proportional valve (pressure-maintaining in the event of a fault in the supply voltage) that is certified according to Atex (IS) for use in hazardous environments. The valve of the 422IS series allows the use of flammable gases as a control medium instead of compressed air. This makes compressed air generation at remote locations unnecessary.

If users combine the pressure control valve ASR and the flow control valve ASQ from SMC Pneumatics on the cylinder of their electric drives, they can reduce their own air consumption by 40%. The response time during the return stroke can also be shortened considerably.

If users combine the pressure control valve ASR and the flow control valve ASQ from SMC Pneumatics on the cylinder of their electric drives, they can reduce their own air consumption by 40%. The response time during the return stroke can also be shortened considerably.

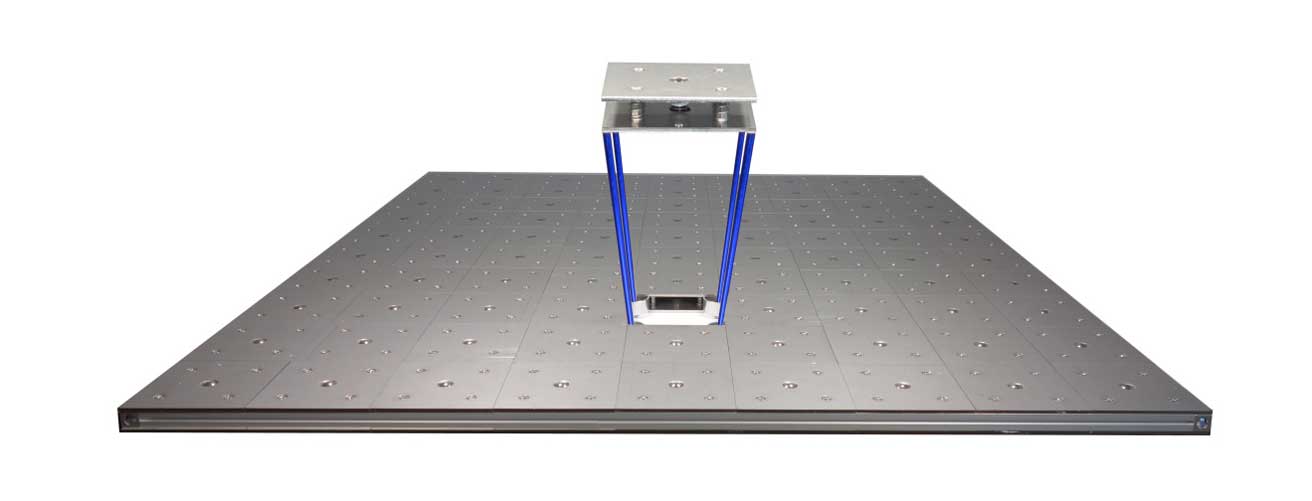

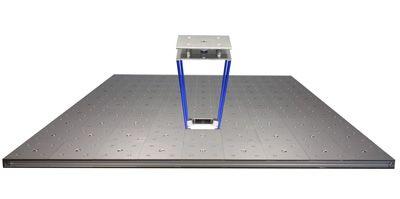

Loads of up to 4000 kg per m² can be conveyed gently and practically frictionless on a film of air on the "fixed sliding" ball transfer unit from Orimair. This is particularly advantageous for soft and sensitive surfaces, since the load is absorbed over a large area and not at points. Conveyor tables or vacuum tables of any size can be built with the elements using the mosaic method.

Loads of up to 4000 kg per m² can be conveyed gently and practically frictionless on a film of air on the "fixed sliding" ball transfer unit from Orimair. This is particularly advantageous for soft and sensitive surfaces, since the load is absorbed over a large area and not at points. Conveyor tables or vacuum tables of any size can be built with the elements using the mosaic method.

A spring tappet compensates for height and level differences when mounting the suction cup directly. The internal air duct simplifies the tubing. Furthermore, the spring plunger ensures that the suction cup is gently placed on the workpiece. The new anti-twist spring plungers from Fipa reliably protect against dirt thanks to the internal spring.

A spring tappet compensates for height and level differences when mounting the suction cup directly. The internal air duct simplifies the tubing. Furthermore, the spring plunger ensures that the suction cup is gently placed on the workpiece. The new anti-twist spring plungers from Fipa reliably protect against dirt thanks to the internal spring.

IMI Precision Engineering introduces the new 51D electronic pressure switch from IMI Norgren. This is suitable for all standard pneumatic applications in which it works precisely with an overall accuracy of ± 2%. The pressure switch can be used in pressure ranges from -1 to 10 bar and -1 to 1 bar and has two electrical outputs (2 x PNP and 2 x NPN).

IMI Precision Engineering introduces the new 51D electronic pressure switch from IMI Norgren. This is suitable for all standard pneumatic applications in which it works precisely with an overall accuracy of ± 2%. The pressure switch can be used in pressure ranges from -1 to 10 bar and -1 to 1 bar and has two electrical outputs (2 x PNP and 2 x NPN).