Push pull M12 connector now standardized thanks to IEC 61076-2-010?

- Details

- Hits: 10965

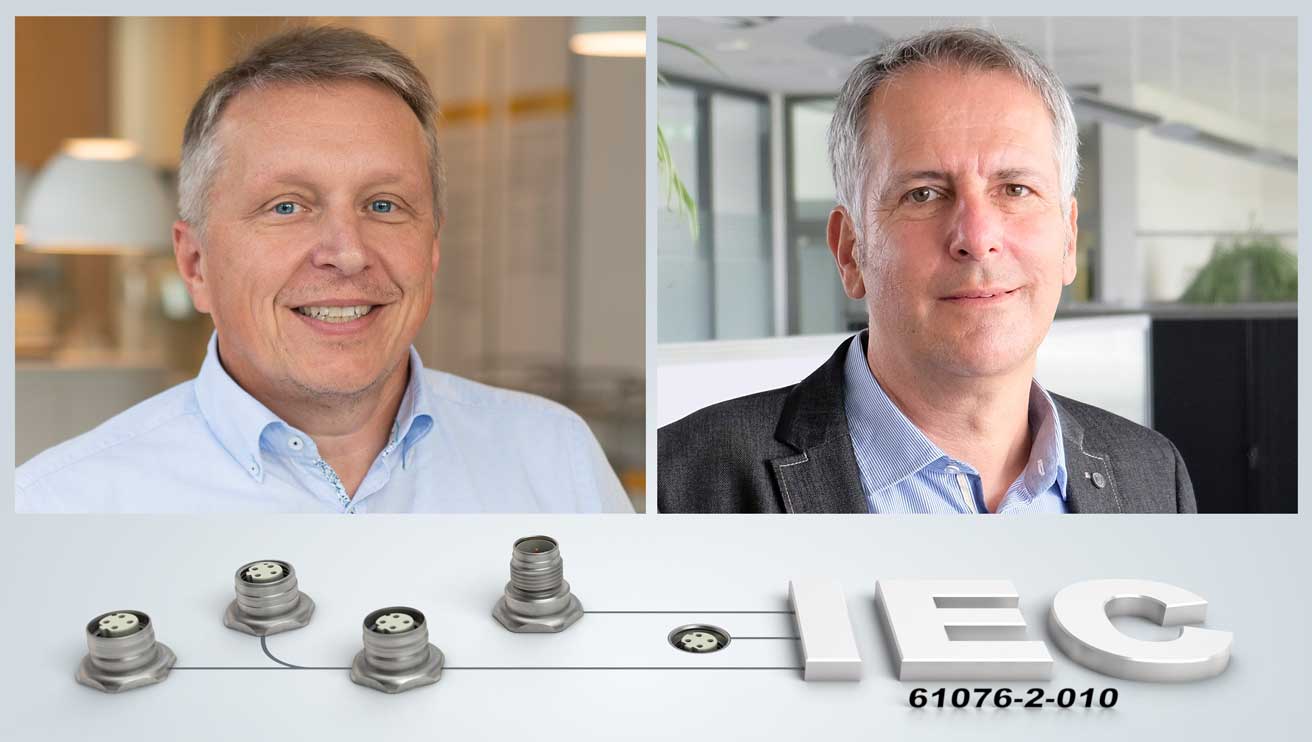

So far they have followed Connectors manufacturer at M12 connector with Push Pull Locking different approaches. Now there is a new norm that can bring them together. Dirk-Peter Post from Harting and Jürgen Sahm from Phoenix Contact explain in an interview the state of affairs and the potential of IEC 61076-2-010 to finally set an industry standard.

Contents

- Current status of M12 connector

- Concepts and standards for push-pull connectors

- Potential for unity on the push-pull connector

With IEC 61076-2-010, the industry finally has an industry-wide uniform system. Say that Dirk Peter Post, Head of Global Product Management Circular Interface Connectors at Harting Electronics and Jurgen Sahm, Senior Specialist Product Marketing Circular Connectors at Phoenix Contact.

Harting, Phoenix Contact, Murrelektronik, Molex, Binder, Conec, Escha and Weidmüller only announced a new standard for them in early summer Push-pull locking the M12Connectors want to establish themselves in the market. The goal of cross-manufacturer compatibility will soon be implemented with the standard published in 2020.

Current status of M12 connector

Jurgen Sahm: “This topic has been discussed in the market for years. Various proprietary solutions have led to selective successes, but a market standard could not be achieved in the past. The desire for a uniform, standardized system has never died down and is more relevant today than ever. The new approach to M12 connectors with push-pull fast locking now offers the potential for a manufacturer-independent market standard. The scope of a uniform technology is immense and significant for many branches of industry. "

What are the advantages of a push-pull locking system for an M12 connector?

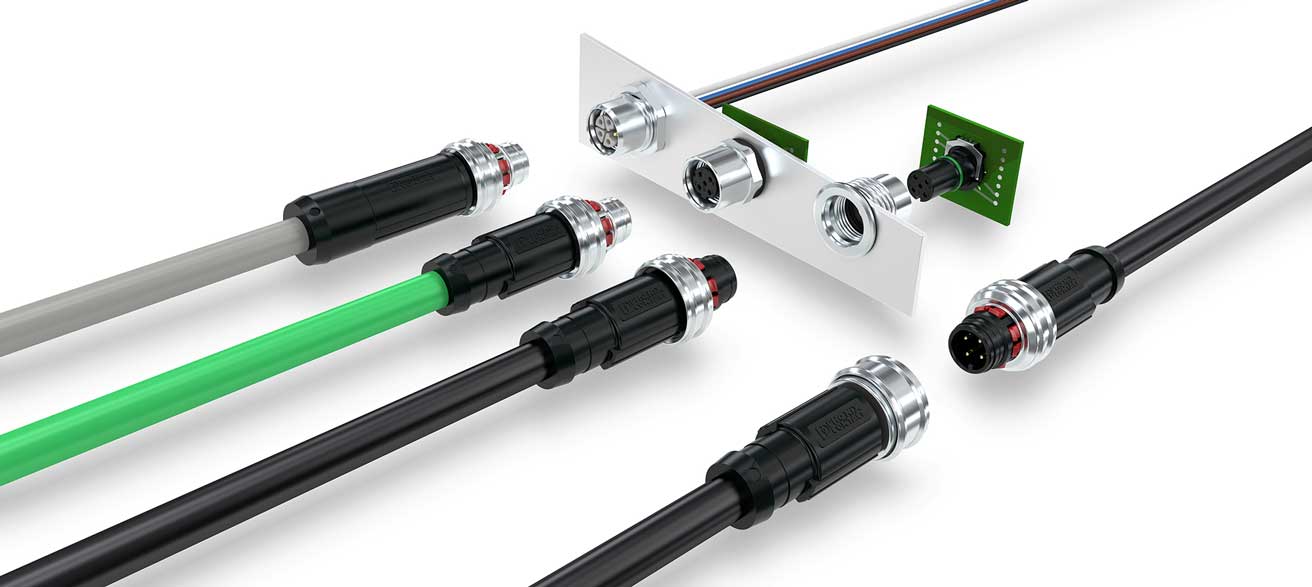

Dirk Peter Post: “The locking by means of push pull brings a high time savings of around 80 percent when connecting the Automation services, since screwing is no longer necessary. Extrapolated to the year, enormous savings potential can be realized in assembly. Due to the improved handling, device ports can also be arranged more compactly, which is the desire for miniaturization and more economical cabling corresponds. In addition to saving time, there is no need to check the correct tightening torque of the lock using a torque wrench. The user receives acoustic feedback, which indicates that the lock is correct. Thus we have a simple, quick and safe locking. "

Jurgen Sahm: “There is a standard that describes all the embodiments for an M12 push pull standard. The IEC 61076-2-010 includes an internal and an external locking by means of push-pull. It thus contains all the variants that are required for a integrated system solution find application in the field of automation. Thus, the IEC 61076-2-010 can be seen as an extension of the proven M12 connector standard with screw locking, as it is described in the basic standard IEC 61076-2-101.

With Kuka from the Harting connector to robot connectivity

With Kuka from the Harting connector to robot connectivity

The trick is that the only change to the established M12 connector is that the M12 thread is supplemented by a groove and at the same time the proven properties of the M12 full thread are retained. As a result, the devices can be universally equipped using a so-called M12 duo port and can be connected in the future either with push-pull or with the M12 screw connectors that are widespread on the market. So both connections are possible. Even extensions of the Lines through flying push-pull couplings can be assembled with commercially available standard components."

Concepts and standards for push-pull connectors

Are there any other concepts and standards for the M12 connector with push pull?

Dirk Peter Post: “In addition to IEC 61076-2-010, there is also the IEC 61076 2 012, which describes a push-pull internal lock. The IEC 61076-2-012 arose from concepts of existing, non-standardized PP industrial connectors that were designed in the M12 format. That is why there is no homogeneous integration into the M12 connector world. "

How do these standards differ in further comparison?

Jurgen Sahm: “Although both standards serve the same purpose of Quick lock serve, they are very different. The IEC 61076-2-010 is based on the full thread from the original standard IEC 61076-2-101. It therefore leaves the world standard for automation components in its familiar form untouched. In contrast, in IEC 61076-2-012, the thread was interrupted by three segments. The thread interruptions are necessary so that the three locking hooks of the cable connector can dip through the thread into the locking position. Such systems require that the angle allocation between the push-pull mechanism and the contact carrier is adhered to very precisely when integrating the device. Otherwise the push-pull connector would be blocked and could no longer be plugged into the port.

Single Pair Ethernet | for IIot and Industry 4.0

Single Pair Ethernet | for IIot and Industry 4.0

The solution based on IEC 61076-2-010 does not require an interruption of the thread because the locking contour was placed at the beginning of the M12 thread. It can be used as a puncture in a simple manner Thread production in the standard process will be realized. This makes design-in particularly easy for the device manufacturer. The device connectors are designed to be rotationally symmetrical, just like the tried and tested M12 connector standard. The push-pull mechanism of the device port does not have to be aligned with the coding of the M12 contact carrier.

That gives the device manufacturer one high degree of freedom for simple and economical design of the cable outlets of the ports. The M12 basic standard -101 and the push-pull standard -010 are also consistent with regard to the design-in requirements. You work in lockstep, so to speak. This goes so far that a conventional M12 port with standard thread can be exchanged for a compatible duo port with push pull - without any structural changes in the device design and subsequently with existing device concepts.

There are also other advantages: For example, the push-pull locking elements in Metal or Plastic are executed. The inexpensive push-pull connectors made of plastic can be used in extended applications such as the agricultural or chemical industry. "

Potential for unity on the push-pull connector

Dirk Peter Post: “Yes, there are. The eight specialized in M12 connectors Manufacturers Weidmüller, Escha, Conec, Murrelektronik, Molex, Binder, Harting and Phoenix Contact have spoken out in favor of supporting IEC 61076-2-010. The main reasons for this are the manufacturer-independent functional reliability and economic manufacturability due to the proximity to the basic standard -101 and easy integration into the device without major design-in effort. The fast and widespread availability of the new push-pull system and investment security thanks to broad support from manufacturers also play a major role.

Ergonomic computer workstation in the office and home office

Ergonomic computer workstation in the office and home office

For these reasons, the DNA of the M12 connector basic standard (-101) flows unchanged into the 010 and becomes one with the know-how of the above-mentioned M12 connector manufacturers new global standard updated.

Because the manufacturers have committed themselves not only normatively but also in practice to a secure interchangeability of the push-pull system across manufacturers, the user can choose from a broad, technically mature product portfolio with all the advantages of the M12 connector standard Multi sourcing serve."

Jurgen Sahm: “Proprietary solutions with increased design-in effort have no chance in industry these days. Simple, standardized solutions that are consistent System topology follow are the order of the day. The eight manufacturers have committed themselves to this overarching idea. The message is that the M12 standard norm and the push-pull norm largely overlap and all in the industrial wiring Variants required with M12 included. Simple puncture means there is no need to change the design-in process. The step to push-pull is that simple.”

You might also be interested in...

Ethernet switches | The data driver in the network

Charging plug, charging cable | For the electric car

Single Pair Ethernet | for IIot and Industry 4.0

industrial housing | Indoor and outdoor control boxes

Electrical Wires | From cable to assembly