Plug-and-play thermal imaging camera for outdoor, glass and more

- Details

- Hits: 15295

Online Thermal imager Systems for industrial applications are a specialty of Optris. From condition monitoring in outdoor areas to quality assurance in the Glass manufacturing the areas of application are diverse. the infrared cameras are constantly being further developed and adapted to the requirements of the systems and applications. Below we present the new developments:

Contents

- Infrared camera with incredible 8 µm optics

- IR camera optimizes 3D printing processes from Fraunhofer ILT

- Infrared camera in a protective housing for hot and cold outdoor areas

- Bottom up thermal imaging inspection system for glass tempering

- Thermal imaging camera with car hotspot finder

- Thermal imaging camera measures glass temperature during glass hardening

- IR camera for laser processing below 1900 °C

- IR camera with cooling housing, air purge attachment and shutter

- Archive for thermal imaging cameras news

- FAQ

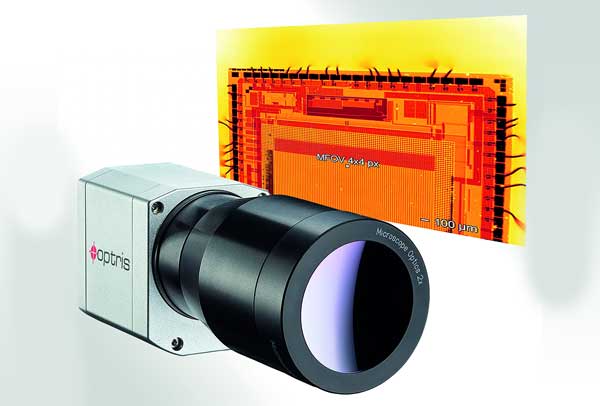

Infrared camera with incredible 8 µm optics

03.02.2024/640/XNUMX | The structures of electronic assemblies are becoming ever smaller and are very compact. So that the infrared camera PI XNUMXi from Optris measures temperatures precisely and geometrically, even in chip-level structures, it has been equipped with the new Microscope optics MO2X equipped with 2x magnification.

03.02.2024/640/XNUMX | The structures of electronic assemblies are becoming ever smaller and are very compact. So that the infrared camera PI XNUMXi from Optris measures temperatures precisely and geometrically, even in chip-level structures, it has been equipped with the new Microscope optics MO2X equipped with 2x magnification.

High temperatures have a negative effect on the lifespan of Electronic components and assemblies. The accelerated aging of many semiconductor materials at elevated temperatures may be caused by a poor electrical connection due to the increased contact resistance. However, elevated temperatures can also occur within complex semiconductor components such as processors.

The geometric resolution of the thermal imaging camera is an incredible 8 µm with the new optics. 4x4 pixels are required for exact temperature measurement (MFOV). This means you can now create objects with a Size of only 34 µm measure. This means that even tiny structures can be analyzed at chip level. The thermal resolution reaches a very good value of 80 mK. The focus of the optics allows you to work at a distance of 15 mm from the object being measured.

The optics on the PI series cameras are easily interchangeable. This means that the system can be used flexibly for various measuring tasks. A high quality one Microscope stand with fine adjustment is included in delivery. Using it, microelectronic assemblies can be examined very easily. The maximum resolution of the IR camera is 640 x 480 pixels at a frame rate of 32 Hz. The PI 640i with 640 x 120 pixels is impressive even at a frame rate of 125 Hz. The license-free analysis software PIX Connect is also included in the scope of delivery, alternatively a Complete SDK available.

IR camera optimizes 3D printing processes from Fraunhofer ILT

04.12.2023/XNUMX/XNUMX | Of the 3D Print of metals is becoming increasingly popular. In particular, powder bed-based laser beam melting or Laser powder bed fusion (LPBF) allows delicate and very complex structures and always opens up new applications. The quality of the process depends heavily on the right temperatures. To measure this, the scientists use Fraunhofer ILT an infrared camera from Optris.

04.12.2023/XNUMX/XNUMX | Of the 3D Print of metals is becoming increasingly popular. In particular, powder bed-based laser beam melting or Laser powder bed fusion (LPBF) allows delicate and very complex structures and always opens up new applications. The quality of the process depends heavily on the right temperatures. To measure this, the scientists use Fraunhofer ILT an infrared camera from Optris.

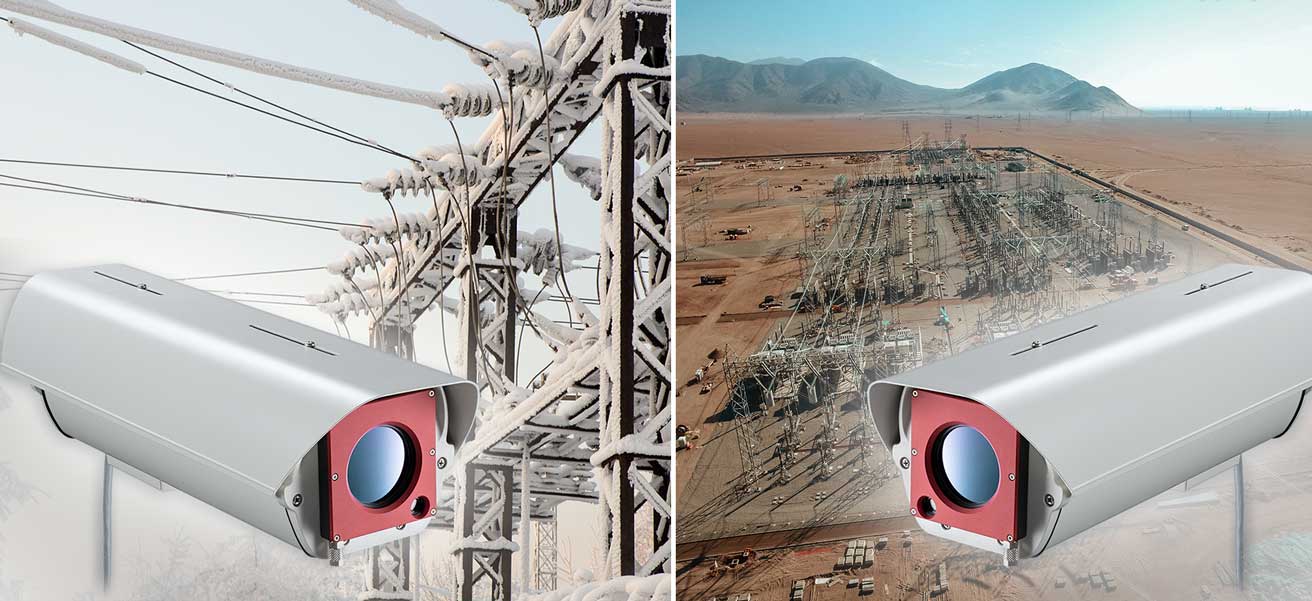

Infrared camera in a protective housing for hot and cold outdoor areas

11.11.2023/XNUMX/XNUMX | the Thermal imager Use under adverse environmental conditions is possible with the Outdoor protective housing by Optris. Very low or high temperatures, dust and humidity place high demands on the Electronics. Special measures are therefore often required to protect sensitive devices. This also applies to the thermal imaging cameras of the PI and Xi series from Optris.

11.11.2023/XNUMX/XNUMX | the Thermal imager Use under adverse environmental conditions is possible with the Outdoor protective housing by Optris. Very low or high temperatures, dust and humidity place high demands on the Electronics. Special measures are therefore often required to protect sensitive devices. This also applies to the thermal imaging cameras of the PI and Xi series from Optris.

So that they can easily withstand adverse conditions, the specialist for non-contact thermography has developed a new outdoor housing that optimally protects the sensitive devices. Compact, the housing offers the possibility for the first time Thermal imaging camera and HD video camera to be integrated together in one system. A compact USB server is also integrated into it.

Purging attachment protects against dust and moisture

The IP66 housing Can be used without any problems in damp and dusty environments. An electric heating element is integrated for using the infrared camera at very low temperatures. This switches on automatically below +15 °C. A fan distributes the warm air evenly throughout the thermal imaging camera housing. This means that the thermal imaging camera can also be used down to -40 °C. In return, temperatures up to +50 °C are possible in warmer areas.

The optionally available air purge attachment continuously flushes the protective window of the housing with compressed air. This prevents dust or condensing moisture from collecting there. The infrared camera therefore always has optimal visibility and measures reliably.

Video and infrared camera for combined condition monitoring

Together with the optional video camera with a resolution of 1280 x 720 pixels, combined optical and thermal condition monitors or implement fire protection applications in the best possible way.

The one in the housing is used to transfer images from thermal imaging cameras and video cameras USB server at. Here the results of both cameras are combined into one stream. The data information is transmitted via an Ethernet cable. This allows for convenient camera integration into existing video control systems.

On the trail of temperatures with new apps

09.11.2022 | Dr. Ulrich Kienitz, Managing Director of Optris GmbH, Berlin, invites you to visit the App Store at SPS 2022. The guide offers demo software and many new products such as thermal imaging cameras and pyrometers.

Optris exhibits at the Hannover Messe 2023.

Bottom up thermal imaging inspection system for glass tempering

09.05.2022 | For the high energy efficiency in Buildings become default Low-E glass window and facade elements used. Designed as multi-pane insulating glass, the windows have a coated side with a very low emissivity. This is a major challenge for infrared measuring devices. Because they traditionally measure the glass temperature from above when the panes are moved out of the furnace during the glass tempering process.

The new bottom up system solves this problem while tracking one new approach: By installing two thermal imaging cameras below the prestressing line, they always measure the temperature on the uncoated glass side with high emissivity (1600 pixel scan line resolution and max. field of view of 111° / 4,3 m scan width). Both infrared cameras are protected in the event of glass breakage by a CTlaser 4M pyrometer from Optris in the digitally controlled optics protection system (DCLP - two automatic shutters).

The Bottom Up Glass Inspection System for Glass Tempering Lines is easy to install because it already pre-assembled is. The thermal imaging camera system is suitable for the tightest of installation spaces. It can be precisely positioned mechanically. The old, bulky line scanners previously used are no longer necessary. The scan line can be precisely aligned using the software supplied.

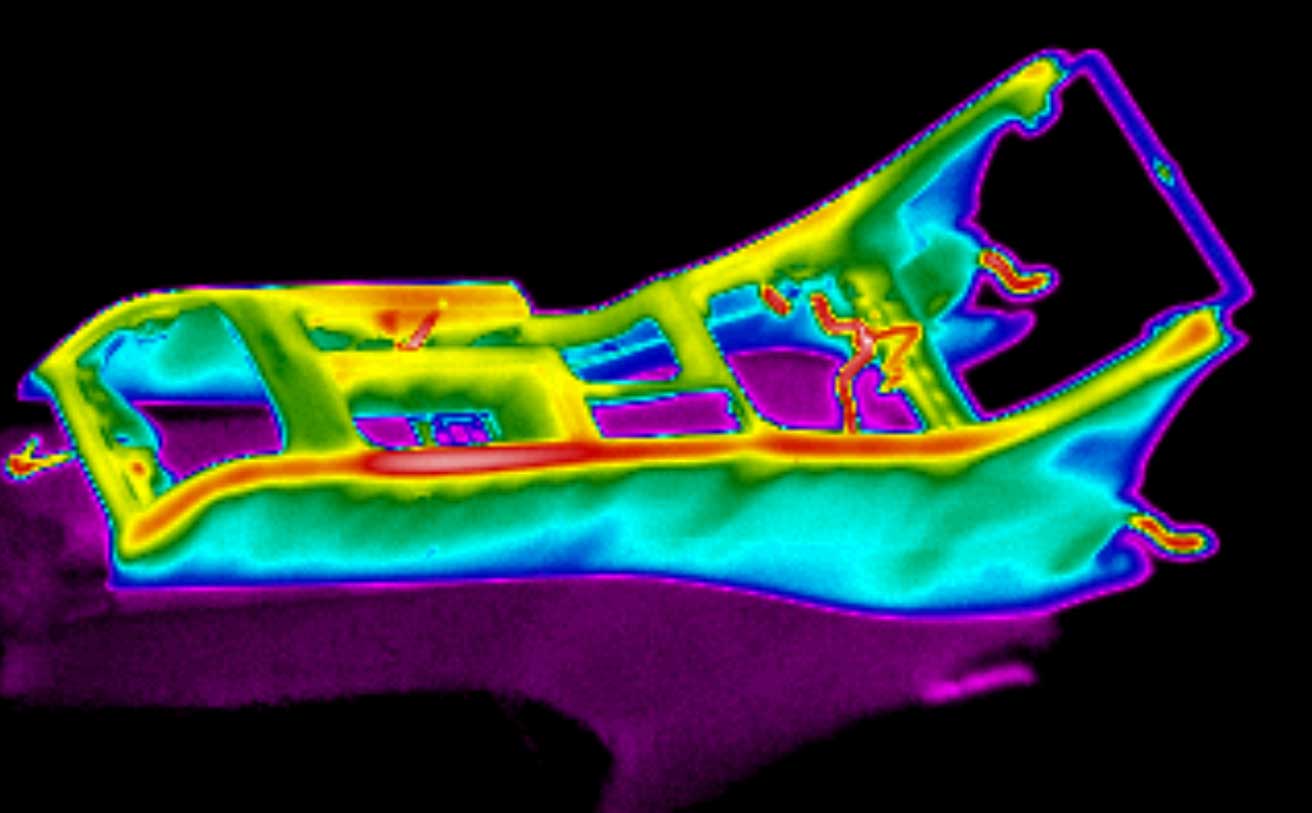

Thermal imaging camera with car hotspot finder

31.05.2021/XNUMX/XNUMX | "In addition to the usual use of an IR camera with PC and software, the thermal imaging camera also works fully autonomously as a smart, target-seeking pyrometer with analog or alarm output," explains Torsten Czech, Head of Marketing at Optris.

31.05.2021/XNUMX/XNUMX | "In addition to the usual use of an IR camera with PC and software, the thermal imaging camera also works fully autonomously as a smart, target-seeking pyrometer with analog or alarm output," explains Torsten Czech, Head of Marketing at Optris.

The thermal imaging cameras of the Xi 410 series have a Fast Ethernet interface. The infrared cameras can be conveniently supplied via PoE. This enables uncomplicated installation of the thermal imaging cameras even over greater distances to the PC.

Thanks to the integrated in the infrared cameras Auto hotspot finder function the temperature of moving objects is measured reliably. The thermal imaging device does not have to be readjusted. In the event of a problem with the connected PC or failure of the network connection, the camera also creates the thermal image fully autonomously and ensures a seamless and reliable alarm in the event of a problem being detected.

Thanks to this property, the Xi 410 thermal imaging device is ideally suited for all safety-related applications such as preventive Fire protection or the condition monitoring on machines and systems.

OEM cameras with motor focus

In addition to the Ethernet interface The Xi 410 thermal imaging camera has a USB 2.0 port for quick configuration of important parameters. It also has a direct 0/4-20 mA analog output. Up to 9 freely definable measuring fields of the thermal imaging camera can be further processed as analog outputs (either 0/4-20 mA or 0-10 V) via an external process interface. Over Relais These can be issued as an alarm - ideal for use as OEM cameras.

The thermal imaging cameras of the Xi 410 series are, like the other two series of the Xi series, also equipped with a motorized focus. This allows convenient focusing from a distance using the free PIX Connect software.

The Resolution of the thermal imaging cameras is 382 pixels x 240 pixels at a frame rate of 25 Hz. The Xi 410 was designed for Measurement of temperatures calibrated from -20 ° to 900 ° C. When ordering a thermal imaging camera, customers receive a ready-to-use package Including mounting nut, mounting bracket, software, Ethernet and USB connection cable.

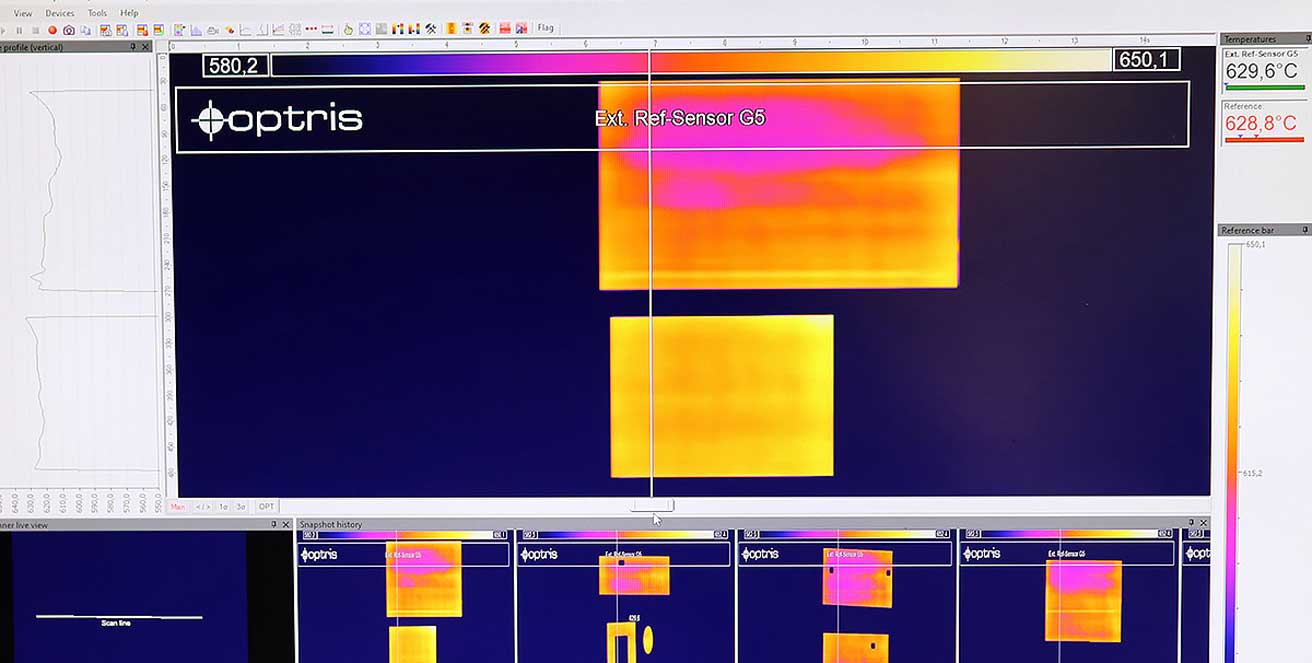

Thermal imaging camera measures glass temperature during glass hardening

24.03.2021/XNUMX/XNUMX | The physical properties of Flat glass can be changed through targeted heat treatment. For example, single-pane safety glass (ESG) is produced by thermal toughening. The glass panes are heated evenly in an oven to a temperature of more than 600 °C. They are then suddenly cooled down in a cooling section by blowing air on them. Optris has developed an infrared system to monitor the glass temperature and temperature distribution during this process.

In the process of Tempering In order to achieve the desired quality of the glass panes, the temperature in the oven determined for the respective type of glass and glass thickness must be precisely maintained. In addition to the exact temperature, it is also important to ensure that the temperature distribution within the glass panes is as homogeneous as possible. Optris has the complete thermal imaging camera system for quality assurance of this application TD GIS 640 R developed. Based on the PI 640 thermal imaging camera, it can be precisely adapted to any glass tempering system thanks to selectable optics with different opening angles.

Monitor glass temperature on window glass

For energy-efficient buildings today, the so-called Low-E glass for windows and facade components used as standard. The windows are designed as multi-pane insulating glass. They consist of a coated side with a very low emissivity. The coating ensures reduced heat radiation in winter and less heating of the rooms due to solar radiation from outside in summer.

For energy-efficient buildings today, the so-called Low-E glass for windows and facade components used as standard. The windows are designed as multi-pane insulating glass. They consist of a coated side with a very low emissivity. The coating ensures reduced heat radiation in winter and less heating of the rooms due to solar radiation from outside in summer.

The low emissivity of the insulating glass windows poses a major challenge for the infrared measurement technology used. The new thermal imaging camera system Top Down GIS 640 R was specially configured for this. A thermal imaging camera type PI 640 is installed at the oven exit for measurements above the glass on the coated side. It measures the temperature distribution of the individual glass panes in high resolution and very quickly across the entire width of the system. Below the glass on the uncoated side, a pyrometer type CT G5L reproducibly measures the exact glass temperature.

Maintenance intervals extended considerably

The individual pixels of the infrared camera image are referenced to this measured value. This allows an automated emissivity correction for standard glass and Low-E glass. In addition to the temperature distribution, the IR system also determines the glass surface. The pyrometer and thermal imaging camera are equipped with digitally controlled optics protection. These shutters significantly reduce the need for cleaning the optics. There is no need for additional and time-consuming blowing with compressed air.

The individual pixels of the infrared camera image are referenced to this measured value. This allows an automated emissivity correction for standard glass and Low-E glass. In addition to the temperature distribution, the IR system also determines the glass surface. The pyrometer and thermal imaging camera are equipped with digitally controlled optics protection. These shutters significantly reduce the need for cleaning the optics. There is no need for additional and time-consuming blowing with compressed air.

Optris offers this for simple electrical installations on a glass tempering system Top Down GIS 640 R System pre-assembled. The complete system consists of a thermal imaging camera, pyrometer, shutter and a compact switch cabinet with electronic and control components as well as cables.

Compared to the ones often used so far Line scanners With the camera-based GIS 640 R system, the exact alignment of the scan line can be conveniently carried out in the software. The exact mechanical positioning of the infrared system above the furnace is not required. This reduces the effort for installation and commissioning to a minimum.

Infrared heater for efficient heat processes in industry

Infrared heater for efficient heat processes in industry

Glass temperature monitoring in glass production

The following video shows how the Quality Assurance during all production phases in the Glass manufacturing with infrared Measurement Technology can be implemented by Optris.

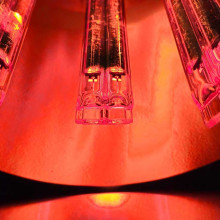

IR camera for laser processing below 1900 °C

19.11.2019 | When measuring the temperature in processes where lasers are used, the IR camera be insensitive to the scattered light of the laser. The new PI 08M from Optris is ideal for such applications because it has a very narrow-band spectral sensitivity at 800 nm.

19.11.2019 | When measuring the temperature in processes where lasers are used, the IR camera be insensitive to the scattered light of the laser. The new PI 08M from Optris is ideal for such applications because it has a very narrow-band spectral sensitivity at 800 nm.

Most industrial processing lasers like NIR or CO2-Laser operate outside of this range, so the detector is protected against stray laser light without additional filters. Typical applications are laser welding, laser soldering or laser hardening processes where temperatures play an important role.

With the wavelength range of 800 nm, the PI 08M is the measurement error minimal even with unknown or changing emissivities. At high temperatures, this is only 1,5% of the measured value; below 1500 °C even only 1%. The measuring range extends from 575° to 1900 °C. Inside the new IR camera is a highly dynamic CMOS detector with an optical resolution of up to 764 x 480 pixels, which can be operated at a maximum image frequency of 1 kHz. This means that the thermal imaging cameras from Optris are also suitable for very fast processes.

Fastest 3D stereo camera and image processing in one device

Fastest 3D stereo camera and image processing in one device

The PI 08M from Optris can be easily integrated into a wide variety of applications. A real-time analog output provides an output signal of 0 to 10 V. The temperature is averaged over an area of 8 x 8 pixels - the position of this area can be freely selected. Also included is a Software Development Kit included, which makes all functions available to the user.

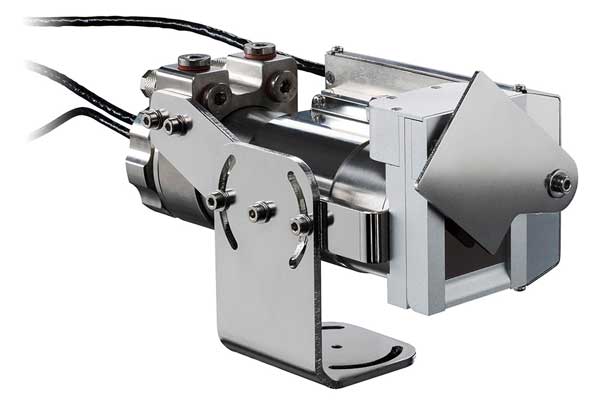

IR camera with cooling housing, air purge attachment and shutter

08.04.2019/XNUMX/XNUMX | the infrared cameras of Compact Line Xi 80 and Xi 400 by Optris have been supplemented with new industrial accessories for use under extreme conditions. The system has a modular structure, so the water cooling housing, the Purging attachment and the shutter can be used individually or in combination.

08.04.2019/XNUMX/XNUMX | the infrared cameras of Compact Line Xi 80 and Xi 400 by Optris have been supplemented with new industrial accessories for use under extreme conditions. The system has a modular structure, so the water cooling housing, the Purging attachment and the shutter can be used individually or in combination.

The out Stainless steel shutter basically serves to protect the optics from dirt and incident objects. This is particularly important when the thermal imager is measuring up and the measurement objects are above it, as in glass industry. With a response time of just 100 ms, the IR camera is optimally protected against falling broken glass. In addition, the shutter can be used in discontinuous processes so that the optics are only exposed to the ambient conditions during the measurement process.

In order to be able to use the compact thermal imaging camera under extreme conditions in industry, there is a Water Cooling made of stainless steel and an air purge attachment made of anodised aluminum are available. Cooling allows use in hot environments up to 250°C. The air purge attachment protects against air particles and prevents condensation on the optics. It can be screwed on in 4 positions, whereby the direction of the air flow can be individually adjusted to the application. A silicon window is integrated in the Purging Attachment, which can be replaced in the event of mechanical damage without complex assembly steps.

Archive for thermal imaging cameras news

- Thermal imaging camera with microscope optics for electronics developers

- IR camera with robust accessories for the glass industry

- Thermal imager detects molding-related errors in injection molding

- Special wavelength range reduces measurement errors below 2000 °C

- Line camera for the production of glass sheets and glass container

- Outdoor protective housing for IR cameras in dusty and humid environments

- Thermal imaging camera with telephoto optics for small objects at a great distance

- 1800 degrees Celsius for metals - trade fair statement

- Thermal imaging camera prevents spread of Ebola fever

- Thermal imaging camera with safety driving circuit for process automation

- Smallest thermal imaging camera for research and development

Thermal imaging camera with microscope optics for electronics developers

22.11.2018/XNUMX/XNUMX | Optris shows how easy the Thermal imager pi 640 can be converted into a microscope optic with a standard optic. The new microscope lenses were specially developed for the requirements of the electronics industry.

IR camera with robust accessories for the glass industry

20.11.2018/2014/2016 | Optris has XNUMX and XNUMX with the PI 450 G7 and PI 640 G7 two special infrared cameras brought to market for the glass industry. In order to meet the industry-specific requirements, a laminar air purge was developed in addition to the robust cooling jacket. The first well-known customers are using the system for 24/7 line scan applications.

20.11.2018/2014/2016 | Optris has XNUMX and XNUMX with the PI 450 G7 and PI 640 G7 two special infrared cameras brought to market for the glass industry. In order to meet the industry-specific requirements, a laminar air purge was developed in addition to the robust cooling jacket. The first well-known customers are using the system for 24/7 line scan applications.

"The overall system offers easy integration and offers the best price-performance ratio for a measuring point on the market," explains Ingo Stahlkopf, Glass Application Specialist at Optris.

In the float process, the temperature profile of the entire glass width must be recorded at various points, e.g. B. through slots a few millimeters wide at the zone transitions in the cooling oven. Compared to conventional systems, the manufacturer offers special thermal imaging cameras in one cooling jacket, which works flawlessly in ambient temperatures up to 315 °C. A laminar air purge can now be integrated between the cooling housing and the application, which prevents dirt deposits on the camera optics with a flexibly adjustable air flow. "The cooling system works so well that the air purge can even be touched," describes Ingo Stahlkopf.

"The Linescan system only needs one computer," it says Torsten Czech, Head of Product Management at Optris to the point. Compared to other solutions on the market, no additional server units, software licenses or maintenance contracts are required. When mounted, the infrared cameras can be focused from the outside and the included, free PIX Connect software can be adapted to the glass application from the PC. Thanks to its folding mechanism, the Laminar Airpurge enables maintenance of the infrared devices without complete disassembly.

Thermal imager detects molding-related errors in injection molding

01.11.2017 | Uncontrolled and unstable processes are the most frequently encountered cost guzzlers in injection molding. 60 to 70% of all part-related defects are caused by the Temperature control of the injection molds. With the thermal imaging cameras from Optris and the online quality monitoring system “IR-Thermo Control” from Willi Steinko and Plexpert, thermal errors in injection molding processing can be detected inline as they occur on the website.

In combination with the "PI Connect" software, the data is transferred to IR thermal control. On this basis, fitters, process engineers and those responsible for quality can quickly, reliably and purposefully produce high-quality components with the shortest possible cycle times. The time and energy savings achieved lead to a reduction in unit costs in the production of the molded parts.

Most common thermal problems and their causes

| appearance | Thermal problem assignment | Most common cause |

| Dimensional problems, lack of mechanical properties | Excessive temperature deviations on the tool wall | Asymetric tempering channel layout, insufficient heat dissipation, bridging of tempering channels |

| Molding default | Excessive temperature deviations on the mold wall, partially or over the entire molded part | Asymetric tempering channel layout, insufficient heat dissipation, bridging of tempering channels |

| Surface markings by gloss and matte spots, burr formation | Thermal impressions of inserts and ejector pins, domes, retainers, ribs and breakthroughs | Insufficient heat dissipation, insufficient insulation of hot runner systems and HK nozzles, non-tempered parts of molded parts |

| Significantly too long cooling times / cycle times | Poorly designed mold temperature control, high pressure losses within the temperature control system, hotspots on the molded part | Clogged cooling ducts, inadequate technical condition of the tempering and cooling units, aggressive water condition, untreated or insufficiently treated water |

The IR-Thermo Control System supplies this important data and shows short-term effects as well as trends such as a gradual increase in temperature in the serial process. The simple installation within 5 minutes on any injection molding machine enables maximum flexibility and availability of the system.

The IR-Thermo Control System supplies this important data and shows short-term effects as well as trends such as a gradual increase in temperature in the serial process. The simple installation within 5 minutes on any injection molding machine enables maximum flexibility and availability of the system.

Temperature deviation via reference image method

The process-oriented user guidance facilitates the definition of control limits and automatically provides temperature deviations via a reference image method. Any differences that occur are immediately visible. The IR-Thermo Control quality module creates an image of the molded part in each cycle. A reference image is generated from the first GUT part.

Each subsequent shot is compared with the reference image. If a deviation occurs anywhere, an alarm is issued. These technologies are found e.g. B. Application in 2K injection molding and in the combination of foam and compact injection molding (Krallmann Pilot Werkzeug GmbH).

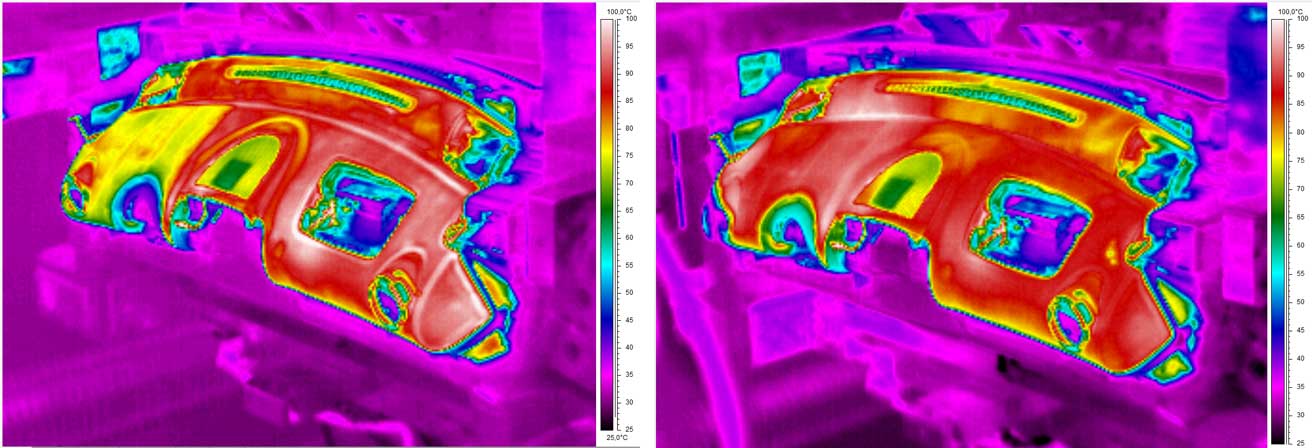

In another example from automotive sector Disturbances occurring in the process are directly visible. The following application shows a thermal weak point that occurs during production in such a way that the area on the left (left image) has a lower surface temperature than the area on the right. As a result, the component was made almost 2,5 mm shorter. The reason for the dimensional deviation was that the required holding pressure could not be effective. The mold temperature control was then adjusted in this area and thus optimized (picture on the right).

No other technical instrument reveals thermal inadequacies as clearly as this plug and work system IR thermal control. For example, excessive temperature differences on injection molded parts and tools are displayed in a way that is understandable for everyone. This means that the previous laying on of hands to locate hot, warm or cold zones on the component or the tool surface is finally a thing of the past.

Special wavelength range reduces measurement errors below 2000 °C

28.04.2017/XNUMX/XNUMX | The new thermal imaging camera PI 05M from Optris has a continuous measuring range from 900° to 2000 °C. It has a resolution of 764 x 480 pixels and measures in the wavelength range from 500 to 540 nm. It supplements the PI 1M with a measuring range from 0,85 to 1,1 µm and is suitable for use in the metal industry. Due to the special spectral range, it minimizes measurement errors with unknown or changing emissivities.

28.04.2017/XNUMX/XNUMX | The new thermal imaging camera PI 05M from Optris has a continuous measuring range from 900° to 2000 °C. It has a resolution of 764 x 480 pixels and measures in the wavelength range from 500 to 540 nm. It supplements the PI 1M with a measuring range from 0,85 to 1,1 µm and is suitable for use in the metal industry. Due to the special spectral range, it minimizes measurement errors with unknown or changing emissivities.

“With the PI 05M, we have developed another compact thermal imaging camera for the global metal industry that is particularly suitable for measuring the temperature of molten metal,” explains Dr.-Ing. Ulrich Kienitz, CEO of Optris GmbH.

With the PI 05M you can Surfaces up to 2000 °C measure – consistently from 900 °C. With an image frequency of 1 kHz, measurements can be taken at an optical resolution of 72 x 56 pixels, with this area of over 4000 pixels being freely positionable. There is also a direct real-time analogue output with a freely positionable 8 x 8 pixel region. These options offer optimal adaptation to the respective application.

Thermal imaging camera innovations for industrial applications

Thermal imaging camera innovations for industrial applications

The camera measures infrared radiation in the Spectral range between 500 and 540 nm and is therefore suitable for all laser processing processes, since thermal radiation above 540 nm is blocked very well. The diode lasers commonly used in the metal sector in the 900 to 1030 nm range or the Nd:YAG laser at 1064 nm therefore have no disruptive effect on the measurement. The camera works here without any additional filters. Basically, this short-wave measurement of metal surfaces has the advantage that measurement errors are greatly minimized in the case of unknown or changing emissivities.

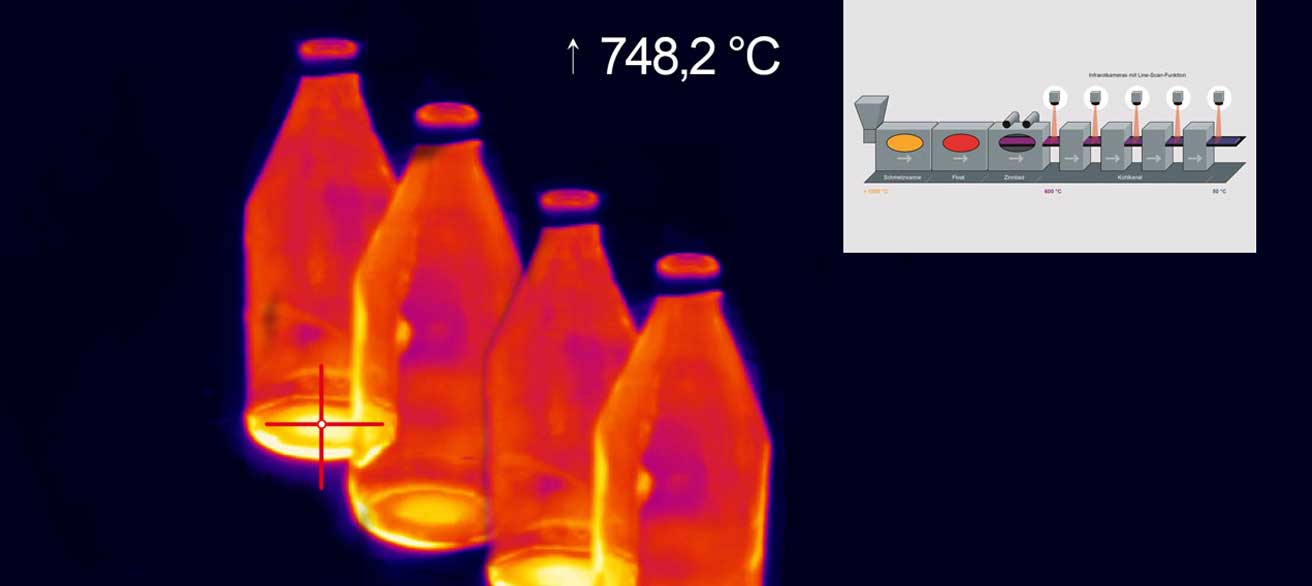

Line camera for the production of glass sheets and glass container

28.09.2016/XNUMX/XNUMX | For the glass industry, Optris presents the Thermal imaging camera 640 G7. With its 7,9 µm filter, it is suitable for measuring glass and offers even more application options thanks to the VGA resolution. The "PI Connect" software enables it to be used as a line scan camera, which is elementary when checking the temperature of ribbons and panes of glass.

Temperature control is of crucial importance in the glass industry and is carried out in almost all process steps. In closed and hot areas, temperatures can sometimes only be determined using a room sensor. The compact infrared thermometers and cameras can also be used in cramped environments with high temperatures. The camera is in the cooling process at the flat glass manufacture used as well as in container glass production.

When measuring temperatures precisely, the emissivity an essential factor. Glass has emissivities of approx. 0,85 in the long-wave range. At higher process temperatures, it is typically measured at 5,0 µm or 7,9 µm, since the emissivity is ≥0,95 in these spectral ranges. The main advantage of 7,9 µm is the lower angle dependency of the emissivity.

Outdoor protective housing for infrared cameras in dusty and humid environments

17.06.2016/XNUMX/XNUMX | In addition to the cooling housings, Optris now also offers specially designed protective housings for outdoor use. The infrared cameras of the Optris PI series can thus year-round outdoors used under harsh conditions. As a special feature, the outdoor protective housing has an air purge attachment. Large outdoor areas can be integrated into the control system via the USB server gigabit, which can also be integrated into the housing.

17.06.2016/XNUMX/XNUMX | In addition to the cooling housings, Optris now also offers specially designed protective housings for outdoor use. The infrared cameras of the Optris PI series can thus year-round outdoors used under harsh conditions. As a special feature, the outdoor protective housing has an air purge attachment. Large outdoor areas can be integrated into the control system via the USB server gigabit, which can also be integrated into the housing.

The outdoor protective housing is with the Degree of protection IP 66 classified and is made of robust sheet steel. The camera lens is effectively protected from external influences by the anti-reflective coated germanium window or a resilient protective film. In addition, the outdoor protective housing is equipped with a blow-out attachment that continuously protects the protective window from contamination and allows the thermal imaging cameras to work even in dusty and humid environments.

By being integrated into an Abus housing PTC heating element, which switches on automatically at temperatures below 15 °C, as well as the fan unit, which ensures even temperature distribution, the thermal imaging camera is always kept at the optimal operating temperature. This results in an application range of -40° to +30 °C. The online USB cameras can be converted to Ethernet via the USB server Gigabit, which can also be integrated, and can therefore be integrated into a process system over long distances. The dimensions of the housing are 390 x 150 x 112 m.

Thermal imaging camera with telephoto optics for small objects at a great distance

21.04.2016/XNUMX/XNUMX | The VGA thermal imaging camera PI 640 from Optris has been supplemented by another interchangeable lens. Four lenses are now available for the different measurement tasks and customer requirements. In addition to the 33°, 60° and 90° optics, measurements can now also be carried out with a 15° telephoto lens.

21.04.2016/XNUMX/XNUMX | The VGA thermal imaging camera PI 640 from Optris has been supplemented by another interchangeable lens. Four lenses are now available for the different measurement tasks and customer requirements. In addition to the 33°, 60° and 90° optics, measurements can now also be carried out with a 15° telephoto lens.

The PI 640 is in industrial use across all sectors worldwide. In addition to the surface to be measured is the Size of the measuring spot of crucial importance. The telephoto lens now makes it possible to measure the temperature of extremely small objects from greater distances. For example, at a distance of 5 m, the thermal imaging camera can measure the exact temperature of 6 mm2 measure small objects.

The Objectives were designed and developed in Germany. The various components, including the germanium lenses commonly used in the long-wave infrared measurement range (LWIR), are manufactured and assembled at the Berlin company headquarters and the respective optics are calibrated to the thermal imaging cameras. The license-free software is included in the scope of delivery.

1800 degrees Celsius for metals - trade fair statement

15.04.2015 | Dr.-Ing. Ulrich Kienitz, Managing Director of Optris GmbH, Berlin, presents the new developments in infrared technology at the Hanover Fair 2015.

Thermal imaging camera prevents spread of Ebola fever

19.09.2014/XNUMX/XNUMX | Virus epidemics like that H1N1 virus 2009/2010 and the Ebola virus 2014 are highly dangerous and create a worldwide demand for appropriate screening techniques that enable rapid and non-contact identification of travelers who may be infected with fever. With its "PI 160" "PI 160" thermal imaging camera, Optris offers a cost-effective and easy-to-use control system for detecting people with increased body temperature.

“In places with a high concentration of people, such as airports, people can be scanned quickly and across the board so that, in the event of suspicion, they can be discreetly pulled out for individual examination,” explains Dr.-Ing. Ulrich Kienitz, Managing Director of Optris GmbH, the advantages of the application.

The entire system consists of the fast thermal imaging camera PI 160 as well as the comprehensive software package "PI Connect". The high-tech devices are easy to install, operate and can be used on the go. The temperature resolution of 0,1 °C detects the smallest temperature changes that generate an automatic alarm.

Thermal imaging camera with safety driving circuit for process automation

10.11.2014/XNUMX/XNUMX | The new process interface (PIF) from Optris enables automated process monitoring in which the hardware of the PI infrared cameras is combined with all cable connections and the free "PI Connect" analysis software are permanently monitored during operation. The control of the external computer in this monitoring process is unique on the market. The developers have transferred the principle of the safety driving circuit, as known from railway vehicles, to the thermal imaging camera system.

10.11.2014/XNUMX/XNUMX | The new process interface (PIF) from Optris enables automated process monitoring in which the hardware of the PI infrared cameras is combined with all cable connections and the free "PI Connect" analysis software are permanently monitored during operation. The control of the external computer in this monitoring process is unique on the market. The developers have transferred the principle of the safety driving circuit, as known from railway vehicles, to the thermal imaging camera system.

When integrating the thermal imaging cameras into a safety-relevant, automated process, a continuous process monitoring can be guaranteed in 24/7 operation. To ensure this, six fail-safe states are monitored in the industrial PIF: malfunction of the thermal imaging camera, malfunction of the software, failure of the power supply or interruption of the USB line, failure of the PIF power supply, interruption of the connection cable between the camera and PIF and a cable break on the fail-safe cable. These are output via a Relais, that at one steering, e.g. B. one SPS, has been connected. The status is also displayed on the device by an LED.

For integration into the process, the industrial process interface 3 analogue/ alarm outputs, 2 analogue inputs, 1 digital input and 3 alarm relays. This enables monitoring of multiple measurement zones in the camera's field-of-view (FoV). In addition, functions of the camera can be easily controlled remotely.

Smallest thermal imaging camera for research and development

09.04.2014 | Dr.-Ing. Ulrich Kienitz, Managing Director of Optris GmbH, Berlin, presented us at the Hannover Messe 2014 with the smallest thermal imaging camera on the market, which is ideal for R&D.

FAQ

What is a thermal imaging camera?

An Thermal imaging camera is an infrared camera for non-contact temperature measurement of a specific measurement object. It can be used to show the distribution and change of temperatures. The evaluation of the data is based on infrared radiation. The thermal radiation emitted by the measurement object is focused on an infrared detector. The resolution (in pixels) of thermal imaging cameras is much lower than that of visual cameras. Thermal imaging cameras are suitable for displaying temperature distributions or temperature changes in larger areas.

How does an IR camera work?

An infrared camera, also known as an IR camera or thermal imaging camera, captures thermal images by recording the infrared radiation (heat radiation) emitted by objects. How it works can be explained in just a few steps:

- detection of infrared radiation: Any object whose temperature is above absolute zero emits infrared radiation. The IR camera is equipped with a sensor that detects this radiation.

- Create a thermal image: The captured infrared radiation is converted into an electronic signal. This signal is then processed to produce a thermal image that represents the temperature differences of the observed scene in different colors.

- Presentation and analysis: The thermal image is displayed on the camera display and can be used for further analyzes such as temperature measurements, pattern recognition or diagnostics.

Where are thermal imaging cameras used?

Thermal imaging cameras are used in many areas, e.g. B. in the Buildingsthermography, in the preventive maintenance of machines, in the Medical Technology or in the Safety Technology.

How far can thermal imaging cameras see?

The range of a thermal imaging camera depends on several factors:

- SensorResolution and sensitivity: Higher resolutions and more sensitive sensors can detect finer temperature differences from greater distances.

- Objectsize and TemperatureDifference: Larger and warmer objects can be detected from a further distance than smaller or less warm objects.

- optics the camera: Lenses with a longer focal length enable a better view of distant objects.

- Atmospherice Conditions: Humidity, smoke, fog and other atmospheric disturbances may reduce range.

In general, thermal imaging cameras can detect objects at several hundred meters, but in some cases, especially with powerful cameras and under ideal conditions, the range can be several kilometers.

You might also be interested in...

Infrared camera optimizes Laser Powder Bed Fusion 3D printing

Infrared heater for efficient heat processes in industry

Control Fair 2024 | The industry is already looking forward to Stuttgart

Optical measurement technology know-how directly from the manufacturer Optris

Learn everything about infrared camera measurement technology at Optris

Webinar: Contactless temperature measurement technology metal

Lorenz-Oliver Riegel is a PR + content specialist at Optris GmbH, Berlin.