For precise movement

Electric linear motor innovations such as ball screws, trapezoidal screws, rack and pinion drives, linear modules and actuators for positioning and strokes

Image: Rodriguez

For precise movement

Electric linear motor innovations such as ball screws, trapezoidal screws, rack and pinion drives, linear modules and actuators for positioning and strokes

Image: Rodriguez

The linear actuator is a sub-area of Linear Technology and essential in modern drive technology. From linear motors, linear axles, linear units, positioning and spindle drives to electric cylinders, pneumatic cylinders and hydraulic cylinders: These technologies move your automation and production systems straight and precisely. Discover the subtleties and potential of these drive types in our comprehensive overview.

Linear motors, drives and actuators have evolved significantly further developed: They are becoming smaller and more efficient without losing performance. This allows for use in compact and restricted spaces. The accuracy of the linear drives has improved, they position faster and more precisely. Many linear drives today have integrated control elements that reduce installation effort and increase performance.

The trend goes to smart linear drives: With embedded intelligence, Sensors and feedback systems, these drives can be adapted to their environment in real time. There is also a trend towards the development of even more efficient linear drives that consume less energy. Modern linear actuator systems are becoming IoT-enabled, allowing for remote monitoring, Predictive Maintenance and data analysis possible. Manufacturers are adapting linear drives more and more specifically to the requirements of the application. You can see how all these developments are reflected in new products in the following new products for 2023:

Hydraulic cylinders play a central role in many technical systems. In this comprehensive overview, we not only offer the latest innovations in the industry but also basic knowledge. You will also receive practical tips Troubleshooting with defective hydraulic cylinders and exciting insights into them Applications of linear actuatore.

The requirements for Pneumatic cylinder are constantly increasing in terms of design, stroke, maintenance and energy efficiency. SMC offers ISO cylinders from the CP96 series according to DIN ISO 21287, double-acting in four new versions. This pneumatic special cylinder with energy return and the compact cylinder offer a reduction in compressed air consumption by up to 48% - a world first.

The Linear motor, an integral part of modern Drive Technology, has made remarkable progress in recent years. This development goes hand in hand with the innovations Linear actuator and Electric cylinder. Our comprehensive overview presents the latest features and technology trends.

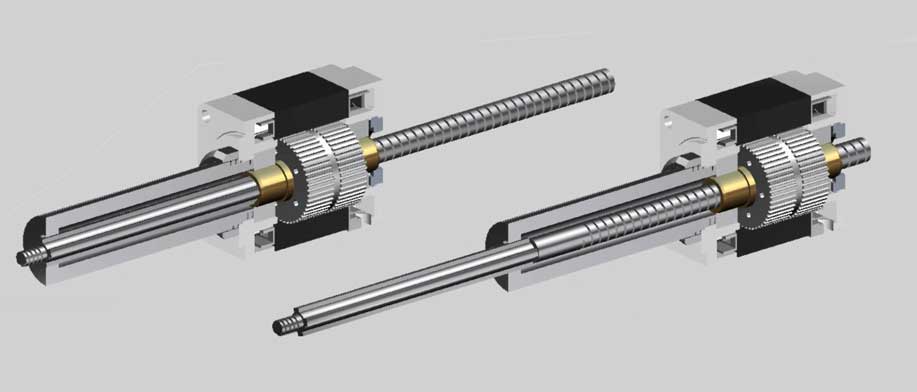

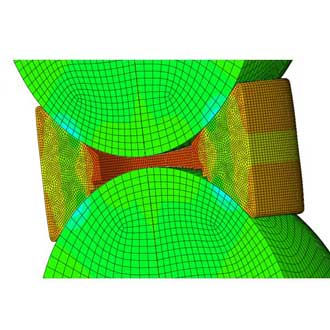

The Ball Screw converts a rotary movement into a longitudinal movement. It causes less friction than others Linear Drives, like the trapezoidal thread spindle. It offers high efficiency, which means a longer service life. The specialists know how these properties can be exceeded in detail.

In certain applications are Lead Screws an extremely economical alternative to the more precise ones ball screws. Dr. Tretter has included them in its broad product portfolio and covers a very wide range of diameters and pitches with the trapezoidal thread spindles.

Linear drives can be found in many industries: from small, spectacular miniature drives in medical technology to powerful hydraulic cylinders in hydroelectric power plants. Let yourself be inspired:

The Lifting column has become indispensable in modern technology, be it in the field of Medical Technology, in furniture design or in the Industrial automation. Recognized experts in this field present in-depth knowledge and reliable information about how it works, areas of application and New developments around lifting columns.

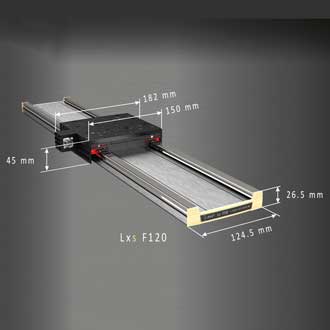

The Linear axis is a core building block in the Automation and precision metrology. We present new developments to you here various companies before, their functions and areas of application. Find out how you can generate advantages in your design with these linear axes.

A modern one Linear unit allows precise and repeatable movements. It not only increases efficiency, but also the accuracy of various movement processes. Find out more about new developments with linear units in this article different manufacturers and what benefits each offers.

Ob Positioning or called otherwise Actuator: Both cannot be missing in modern times Drive Technology. With our overview you can find out more about new features and innovations. Various manufacturers report on the subtleties and advantages of their current developments and how these influence the state of the art. Learn more about the future of precise motion control.

The MK Technology Group presents alongside its Conveyor technology modules for feeding and linking also its system solutions for workpiece transport. The focus is on the modular transfer system “Versamove” and the storage-capable pallet circulation system “SPU 2040”. A selection of belt conveyors and, for the first time, Emma's efficient hinged belt conveyor systems will also be on display.

If the customer speaks happily and happily about their supplier, they have probably done everything right and delivered the right product. This is also made clear by the following user reports:

The Drylin-Technology from Igus presents lubricant-free linear axes, driven by spindles, toothed belts or racks. Both manual handwheel variants and electrical solutions are available. From standard models to specialized versions, such as lightweight plastic axles or robust stainless steel modules for high loads, the Motion Plastics specialist covers a wide range.

How fit Plastic and heavy load together? Igus knows it and offers one for this Spindle nut in the new thread nut design. The polymer nut Dry spin JGRM made of injection molding is therefore a cost-effective alternative to the ball screw nut for the ball screw. Together with one Screw it moves heavy loads wear-resistant and lubricant-free.

koco Motion offers besides Stepper Motors and DC motors also linear drives. These are available in 8 Nema sizes from Nema 6 to Nema 34 in different motor lengths and the resulting feed forces. The linear actuators are precise, easy to control, cost-effective and space-saving. They are suitable for use in numerous applications that require precise positioning.

stepper motor linear actuators are on the rise, especially if they can eliminate the need for complex pneumatic cylinders. At Koco Motion, their share of total sales has increased disproportionately in recent years. Reason enough to take a look behind the scenes of the extensive portfolio, which is available in standard and customer-specific versions - the latter with an increasing trend in an immense selection.

The “Kannmotion” drive platform from Koco Motion and Adlos has been expanded to include some features. The cooperation partners recently demonstrated what is possible with this using a coin sorter. The servo system can Motion is a platform for customer-specific applications based on integrated stepper motor controls.

Schaeffler offers with the product line INA high-precision linear drives that are used particularly in the automotive and manufacturing industries. The portfolio also includes linear axes, linear guides, spindle drives such as ball screws. With the takeover of Ewellix (formerly SKF) in 2022, the product range will be greatly expanded to include actuators, lifting columns and roller screw drives.

Schaeffler sets new standards in things Linear unit and Linear motor. While the linear drives offer high percentage performance improvements, customer-specific linear modules increase the range. Find out what advantages you can generate in practice with the innovative linear drives.

There are numerous linear actuator manufacturers worldwide, each with their own specializations and technical characteristics. Here are some prominent manufacturers:

In the electric linear drive a Electric motor for that one driving element like a spindle turns. This rotational movement is converted into a straight-line movement by mechanical mechanisms such as screws or belts, which can be achieved, for example: B. moves a carriage back and forth. There are also direct electric linear drives such as the linear motor, which do not require such mechanisms and generate linear movements directly. Alternatively, be at Hydraulic System- Or PneumaticsCylinder media are pressurized, which then move a piston or piston rod and thus perform mechanical work.

An electric linear drive is a component that converts electrical energy into linear motion. An electric motor is used that creates a straight-line movement via mechanical mechanisms such as spindles or belts. In contrast to pneumatic or hydraulic drives, it does not require any liquids or gases, just an electrical power source.

In the electromechanical linear drives are rotary actuators or simple Engines connected to mechanics that convert the rotary movement into a linear movement or simply back and forth movement. Such components can be pulleys, threaded spindles, racks etc. Also Transmission, which typically multiply the torque, can be combined with mechanics to convert rotary motion into linear motion.

At a electromechanical cylinder the mechanics are located in a housing. This screw drive converts the introduced motor torque into a linear movement. Together with one Servomotor the user receives an intelligent linear drive.

There are different types of linear actuators based on different technologies:

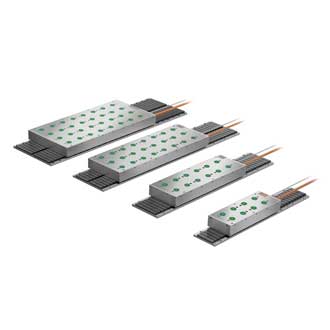

A linear motor is particularly suitable for applications that... fast and precise require linear movements. With direct drive, there are no mechanical transmission elements such as gears or belts. This makes the linear motor less susceptible to wear and easier to maintain. The high dynamics are reflected in high acceleration and speed. The linear motor provides accurate motion control and high repeatability.

Sources: This article is based on information from the following companies: August Steinmeyer, Baumeister+Schack, Bosch Rexroth, Hunger Hydraulik, Igus, Jenny Science, Koco Motion, NSK, Schaeffler.