for power transmission

Save total cost of ownership with efficient gear wheels, drive chains, conveyor chains, toothed racks and toothed belts

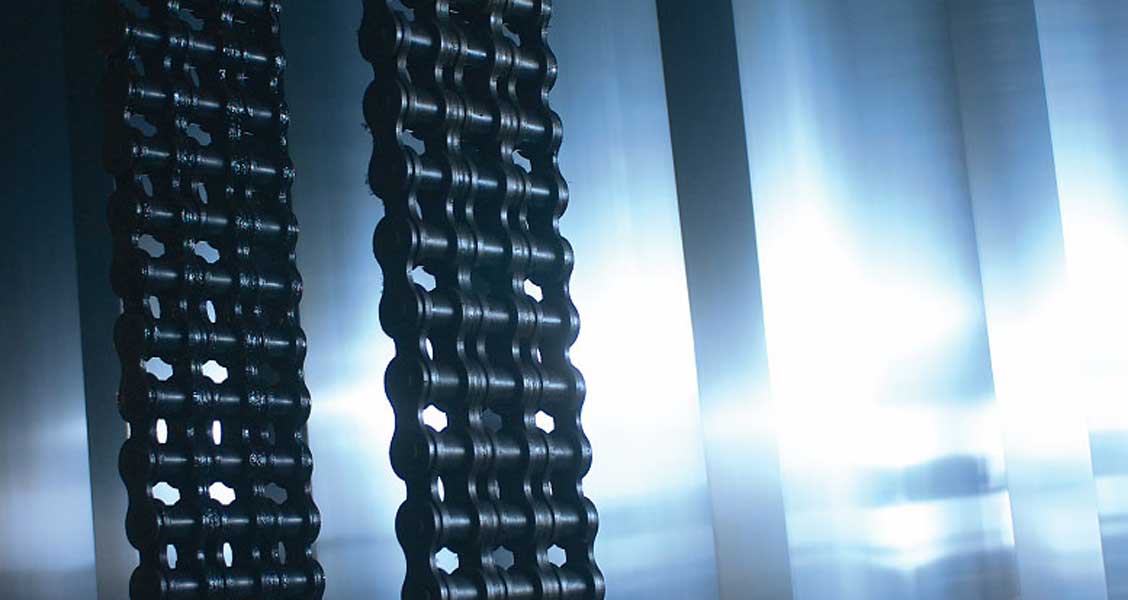

Image: Tsubaki

for power transmission

Save total cost of ownership with efficient gear wheels, drive chains, conveyor chains, toothed racks and toothed belts

Image: Tsubaki

This is a construction site. We optimize for you!

Here you will find products and applications for Drive elements, part of the Drive Technology. This includes components such as racks, drive chains and also gears, clutches and brakes. Learn how to use efficient drive elements to reduce TCO costs in applications food technology to Automobile Can save manufacturing.

Contents

Drive chains, sprockets, belts, conveyor chains, shafts, toothed wheels, toothed racks, toothed belts transfer movements, forces and torques from the drive into the machine. With these products of the Drive Technology it depends on the service life, strength, load capacity, etc. Because if they fail, the machine comes to a standstill. The drive elements are therefore maintenance-intensive and often have a decisive influence on the TCO costs (Total Cost of Ownership). We have many great success stories in which replacing a drive element increases machine running times many times over.

In the following, we present new and further developments in the field of drive elements. Click on the links to get to Transmission, Couplings and Brakeswhich we will deal with separately in a menu.

When it comes to a lack of service life, excessive wear and tear and unreliability of drive chains, it is advisable to think outside the box and ask an alternative supplier. In the present case, a Dutch steel mill was able to increase the productivity of its heat treatment in the long term. How? Because Tsubkaki has replaced his failure-prone lifting chains with high-tech chains with a service life of up to 15 years.

A manufacturer of insulating glass fiber wool found out that premature wear of the chain installed in a conveyor system was responsible for the deteriorating product quality. He replaced the chain with a premium chain from the leading manufacturer of drive technology products, Tsubaki. This not only solved the quality problems, but also tripled the service life of the system.

A manufacturer of insulating glass fiber wool found out that premature wear of the chain installed in a conveyor system was responsible for the deteriorating product quality. He replaced the chain with a premium chain from the leading manufacturer of drive technology products, Tsubaki. This not only solved the quality problems, but also tripled the service life of the system.

While machine parts must be protected against contamination and the influence of aggressive media, care must be taken that e.g. B. the worker is not injured on rotating parts such as shafts or spindles. This is done through appropriate protective measures such as bellows. For special applications, Steinbock is now presenting a bellows with Velcro or zip.

While machine parts must be protected against contamination and the influence of aggressive media, care must be taken that e.g. B. the worker is not injured on rotating parts such as shafts or spindles. This is done through appropriate protective measures such as bellows. For special applications, Steinbock is now presenting a bellows with Velcro or zip.