Slim precision ball bearings move high-tech in space

- Details

- Hits: 967

In the area of precision bearings, the Rodriguez GmbH with their Kaydon “Realislim” Thin section bearingsn a key technology for the Aerospace available. These specialized rolling bearings contributed to the success of the Mars mission in 2021 by allowing NASA's Perseverance rover to carry out its tasks efficiently and reliably. The Precision ball bearings but are also suitable for other applications in the demanding industry.

Contents

- Precision ball bearings: Compact, precise, light

- Bearing requirements in aerospace

- Frequently asked questions

Precision ball bearings: Compact, precise, light

Kaydon thin section bearings are known for their compact design and light weight. They offer the precision and performance required for use in space. Their reliability has been proven over decades, making them an ideal choice for this demanding application, not for the first time.

Kaydon thin section bearings are known for their compact design and light weight. They offer the precision and performance required for use in space. Their reliability has been proven over decades, making them an ideal choice for this demanding application, not for the first time.

From robot arms to tool carousels

These thin section bearings, which are based on several designs, are used in a wide range of applications Rover Persevance, as in the mainrobotic arm, the sample collection tower, the tool carousel and the sample handling assembly. The Kaydon bearings are critical to the rover's movement mechanisms, enabling precise manipulation of instruments and helping to collect valuable data.

By adapting different models of Kaydon thin section bearings to the specific requirements of the Mars mission Optimum functionality was achieved with minimized size and weight. For space missions where every gram counts, this is of utmost importance, as is reliability. After all, repair or replacement is not an option on Mars.

Thin section bearings on Mars mission

The choice of Kaydon thin section bearings for the Mars mission is based on their proven performance in previous projects, including Phoenix Mars Lander Mission in 2008. At that time, the compact, high-performance bearings even met NASA's extreme criteria. For this mission, the handheld robotic arm was optimized so that it could be remotely controlled in space directly from Earth.

The focus was on maximum precision and strict weight reduction from the previous model. By consistently saving materials, the weight was reduced by 26 kg to 14 kg be reduced. For the hollow shaft of the drive, a bearing that fits into the outer diameter of the joint was required, with the inside Cables should be conducted.

The Robot was used on Mars, among other things, to take soil samples. The bearings must be able to absorb very high forces, because breaking through the ice layer and digging to a depth of around 50 cm requires a force of more than 45 kg. A special version of the thin section bearing qualified for this requirement Ultra slim-Series: These special bearings are made from heat treated 440C stainless steel. The material has also been honed, which ensures an extremely smooth surface and better running behavior.

The additional heat treatment allows use in extreme cold. The robot arm joints maintain temperatures of up to -108°C was standing. The bearings are lubricated with a special lubricant with low outgassing. This does not become too tough in extreme cold and does not evaporate in the thin atmosphere on Mars.

Precision products on the ISS

In the demanding environment of space, Kaydon thin section bearings have established themselves as reliable components in a wide range of other applications.

A notable example of this is their use in a robotic arm on the outer wall of the International Space Station (ISS), which hovers about 400 km above the Earth's surface. This robot is known as Caesar (Compliant Assistance and Exploration Space Robot) and was developed by the German Aerospace Center (DLR). It has an extendable arm that is 3 m long and is flexibly controlled by seven joints.

The Reali-Slim thin section bearings from Kaydon are used in these joints. They carry radial and axial loads efficiently and are very space-saving. The previous project Rokviss (Robotic Components Verification on the ISS), also managed by DLR, relied on the performance of Kaydon's thin-ring angular contact ball bearings between 2005 and 2010, thus enabling smooth and precise movements in space.

Bearing requirements in aerospace

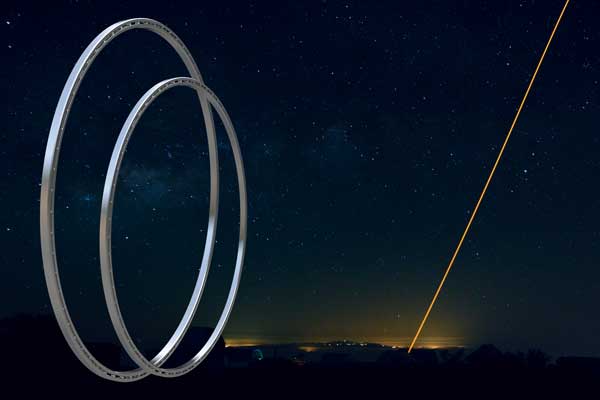

In the aerospace industry, Kaydon thin section bearings offer innovative solutions to other challenges: an outstanding example of this is their application in one Micro Laser Communication Terminal, which was developed by a German technology company.

In the aerospace industry, Kaydon thin section bearings offer innovative solutions to other challenges: an outstanding example of this is their application in one Micro Laser Communication Terminal, which was developed by a German technology company.

This terminal, designed for the Communication between small flying objects, features a high-precision coarse alignment unit protected by a compact glass dome. The azimuth axis required ball bearings that were not only precise and fast, but also light and compact to meet the demanding requirements for precision with minimal friction and low weight.

With his know-how as a provider of first-class drive solutions, Rodriguez made a decisive contribution: the ultra-slim thin section bearings met all expectations. These bearings measuring 60 x 66 x 2,5 mm are made from high quality stainless steel manufactured. They proved to be an ideal solution for applications that require both excellent precision and high corrosion resistance.

Their now proven application in laser communication terminals has not only proven their reliability, but has also contributed significantly to improving the alignment accuracy of the systems.

Consulting - engineering - tailor-made suit

With their extensive expertise in adapting solutions for specific applications, they offer Rodriguez experts Tailor-made advice and support in the selection. Their in-depth knowledge enables them to precisely optimize Kaydon thin section bearings according to individual customer needs.

Specialized design adjustments include fine-tuning preloads, applying specialty greases or providing grease-free bearings, and implementing anti-corrosion coatings. In addition, the use of high quality materials for rolling elements and cages, such as PEEK, stainless steel and Teflon, the functionality and longevity of the bearings in demanding environments.

Rodriguez thin section bearings

The compactness and lightweight of Kaydon thin section bearings often not only meet the requirements of the aerospace or robotics era better than conventional ball bearings. With the all-rounders in minimal cross-sections offered by Rodriguez, space and weight can be saved by more than 80% in many applications - with high performance and precision. Here you will find new developments, information and other applications for thin section bearings.

Frequently asked questions

What is a precision bearing?

A precision bearing is a high-precision component used in mechanical systems of machines to provide low-friction movement between two parts. It is characterized by very tight tolerances in production, which ensures high running accuracy, rigidity and reliability during rotary or linear movement.

Where are precision bearings used?

Precision bearings are required in various applications where devices and systems precision, low friction and longevity require. Examples include aerospace, machine tool construction, etc Medical Technology or found in high-speed applications.

You might also be interested in...

linear guide | Precise, light, durable

Ball screw drive | Rotating ball screw

Miniature and other profile rail guide for various uses

Hard chrome-plated h6 guide shafts from our own production

Ready-to-install slew drives in a particularly flat design

The author Nicole Dahlen is Managing Director Sales, Marketing and Organization at Rodriguez GmbH in Eschweiler.