Rodriguez GmbH | The in-house pavers

- Details

- Hits: 3808

Linear Technology and Precision bearings for industrial applications reliably and quickly is a major challenge in times of supply bottlenecks. Good to be there with a partner like that Rodriguez GmbH works together in Eschweiler. Here, over the years, a flexible in-house production built up. Rotary and linear components can be manufactured quickly and customer-specifically in the extensive machine park. Information and other news can be found below:

Contents

- Who is Rodriguez?

- What's going on at Rodriguez GmbH?

- The year 2022 was extremely successful

- SKF thrust bearings Super Precision Bearings now at Rodriguez

- Nicole Dahlen is the new managing director of Rodriguez

- Quality instead of roller bearings and linear technology Mass – Interview

- development scout as guest – reportage

- From dealer to developer and manufacturer - interview

- 25 years drive technology from Eschweiler

Who is Rodriguez?

In 1984 Gunther Schulz founded the German subsidiary of GmbH RA Rodriguez, Inc. founded in New York due to the successful sale of high-quality drive elements such as the Kaydon Thin section bearings. In addition to building up the global export business, he established the company as a high-performance system supplier, for example for linear guides. Since the takeover in 2008, the company has operated under Rodriguez GmbH. Two sales offices in France and Portugal support the Eschweiler in looking after customers and prospects in southern Europe. The Company is a renowned employer based on strict quality and performance standards. The contact is always professional, respectful and constructive, which underlines the satisfaction among employees and customers.

High level of vertical integration and short decision-making processes

The proportion of in-house production at Rodriguez GmbH is currently approx 50% with an upward trend. The demand for high vertical integration is reinforced by short decision-making paths between sales, development and design. All process steps are covered in the company from development and production to assembly and quality assurance. Rodriguez is thus much more flexible than his competitors and with the same high standards.

The proportion of in-house production at Rodriguez GmbH is currently approx 50% with an upward trend. The demand for high vertical integration is reinforced by short decision-making paths between sales, development and design. All process steps are covered in the company from development and production to assembly and quality assurance. Rodriguez is thus much more flexible than his competitors and with the same high standards.

Also, Rodriguez has focused on custom precision roller bearing and Linear Technology-System solutions specialized. The so-called Value Added Products (VAP) are based on many years of engineering know-how and special knowledge of mechanics. Of course, the drive specialist offers a comprehensive all-round service for its high-quality roller bearings and linear technology.

However, the customer-specific machine elements have another added value: With them, conversion parts can be saved, tolerances reduced and assembly times shortened. This saves significant costs for development, procurement and administration and enables customers to focus on their Core competencies to concentrate.

Development of in-house production at Rodriguez GmbH

Beginning of the 90 years Rodriguez added linear components to the product portfolio. Almost at the same time, Eschweiler started its own production. Because they also wanted to be more flexible and able to act when it came to individual developments. Initially, the focus was on the assembly of hardened and ground shafts.

Beginning of the 90 years Rodriguez added linear components to the product portfolio. Almost at the same time, Eschweiler started its own production. Because they also wanted to be more flexible and able to act when it came to individual developments. Initially, the focus was on the assembly of hardened and ground shafts.

Linear housings, shaft blocks, shaft supports and round guides were soon added. Today, in 2023, production has modern CNC lathes and milling machines that can be used, among other things, to machine shafts with outside diameters of up to 100 mm. Machines, measuring center, quality assurance and the know-how of the employees are all geared towards the hard turning of workpieces. About 15 years ago Rodriguez GmbH has invested in its own machining centers and an expansion of the machine park. From then on, roller bearings could also be machined and manufactured.

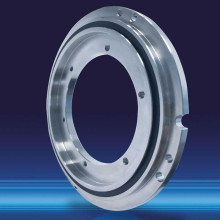

today Slewing rings with outside diameters of up to 1400 mm and the much sought-after slewing rings with smaller diameters leave the company. advanced Tools and innovative devices keep the production facilities state-of-the-art. A great clean room system of clean room class 4 according to DIN EN ISO 14644-1 is also part of the equipment. Here you can find components for the Semiconductor Technology manufacture and assemble.

Status of production technology 2023 in Eschweiler

The machine park for the areas of linear and precision bearing technology is continuously modernized and expanded. With the replacement of an older system by the Biglia B750 YS lathe in 2021, the machining times and thus the profitability were increased. The other new machines and devices also include the high-performance DMG Mori NZX2000 CNC lathe and the fully automatic Silvercut RSP 400N cutting system. The latter manufactures guide rails, spindles, tubes and other rod materials using the wet cut-off process. Lightweight robot from Universal Robots also increase capacities.

The measuring room is another example of the continuous improvement of equipment at the customer's service. It was used to test and maintain the required tolerances of precision bearings and linear guide set up in the µ range. There is also a new 3D measuring machine for checking rolling bearings with outside diameters of up to 1500 mm. A tactile system can be used to measure the contour and roughness of ball raceways.

The measuring room is another example of the continuous improvement of equipment at the customer's service. It was used to test and maintain the required tolerances of precision bearings and linear guide set up in the µ range. There is also a new 3D measuring machine for checking rolling bearings with outside diameters of up to 1500 mm. A tactile system can be used to measure the contour and roughness of ball raceways.

On another test bench and with mobile devices hardness tests be made. There is also a high-resolution length measuring bench and roundness testers for the μm range. Since 2021, series products from in-house production can be checked on the 3D measuring machine Wenzel SF 55. The new Keyence VHX microscope enables detailed residual dirt analyzes and roughness measurements.

These means enable the Eschweiler specialists to ensure the dimensional accuracy of, for example, machined Shafts and ball screws or milled parts such as bearing housings and shaft supports. Apart from individual components, complex customer-specific systems can also be controlled. In the future, Rodriguez GmbH will further expand its vertical range of production and thus respond to customer requests even better and more flexibly. There is already a vision for this expansion plans.

Rodriguez exhibits at the Hannover Messe 2023.

What's going on at Rodriguez GmbH?

Rodriguez GmbH has many years of experience in the field of roller bearings and linear technology and has become one in recent years important player developed in this area. Thanks to their innovative products and their high quality, they are able to meet the ever-changing demands of the market. Find out more about the company from Eschweiler.

The year 2022 was extremely successful

16.12.2022 | The year 2022 was extremely successful for Rodriguez. The provider of machine element solutions was able to increase its order intake and sales with a forecast of around 34 million euros.

16.12.2022 | The year 2022 was extremely successful for Rodriguez. The provider of machine element solutions was able to increase its order intake and sales with a forecast of around 34 million euros.

"A focus again this year was on the expansion of in-house production," comments Gunther Schulz, managing partner at Rodridguez. "We have continued to invest in new machines with which we can offer our customers even more flexibility and quality".

At the same time, constant evolution is taking place within the company: digitized processes, systems and strategies ensure greater efficiency and innovation. In 2022 is also the decision for a new one ERP system like.

In 2022, Rodriguez was also successful in the consulting program eco profit participated in order to improve the sustainability and efficiency of the company. The company has taken many important steps towards sustainability and efficiency. The Marbach site celebrated its 25th anniversary. Rodriguez customers in southern Germany, Austria and Switzerland are looked after from here.

Despite the restrictions caused by the corona pandemic, numerous trade fairs were able to take place, at which Rodriguez maintained an exchange with customers and partners. Internally, some initiatives were able to pick up speed again, such as a health day and a summer party as well as the company sports group, which met regularly again.

Rodriguez has set himself ambitious goals for the coming year: the implementation of the ERP system and the further implementation of the digitization strategy as well as the expansion of in-house production. With the construction of a new buildings production areas and offices with a focus on manufacturing are expanded to approx. 2900 m². Rodriguez is therefore well positioned and future-oriented in the new year.

SKF thrust bearings Super Precision Bearings now at Rodriguez

15.06.2020/XNUMX/XNUMX | Rodriguez has expanded its machine element offerings. The provider is now selling SKF High-precision warehouse within Germany. These high-precision axial angular contact ball bearings and axial cylindrical roller bearings were designed for use in machine tools. The SKF Thrust bearings complement the existing portfolio and are also predestined for MRO (maintenance, repair and operations).

15.06.2020/XNUMX/XNUMX | Rodriguez has expanded its machine element offerings. The provider is now selling SKF High-precision warehouse within Germany. These high-precision axial angular contact ball bearings and axial cylindrical roller bearings were designed for use in machine tools. The SKF Thrust bearings complement the existing portfolio and are also predestined for MRO (maintenance, repair and operations).

"We are very excited to partner with SKF," says Gunther Schulz managing partner of Rodriguez GmbH. “With her, we can expand our business field. So we are not only positioned even more broadly for the machine tool industry, but can also serve the need for spare parts and service at short notice.”

In the Machine Tools is the Storage of spindles, turntables or rotary tables are critical to the success of an optimal power absorption and power transmission. Rodriguez can now best meet such requirements with a comprehensive portfolio of precise rolling bearings.

Very stiff and extremely precise axial bearings

The High precision bearings the SKF range Super precision bearings fit perfectly into this special range: They support high speeds and loads and run as stiffly and extremely precisely as possible. In addition, such a machine element generates little heat and a low noise and vibration level. There's also a long service life, long maintenance intervals and low energy consumption.

"With our high-precision bearings, manufacturers of original devices and end users can further optimize the parameters of their systems and applications," says Jurgen Schaefer at SKF. "Thanks to our partnership with Rodriguez, even more users can now benefit from these sophisticated solutions."

Nicole Dahlen is the new managing director of Rodriguez

07.02.2019 | Nicole Dahlen has been with us since the end of last year Managing director Sales, marketing and organization at Rodriguez GmbH in Eschweiler. The manager has been with the company for 29 years and most recently held the position of Director Sales + Marketing. She has also been an authorized signatory since 2015.

07.02.2019 | Nicole Dahlen has been with us since the end of last year Managing director Sales, marketing and organization at Rodriguez GmbH in Eschweiler. The manager has been with the company for 29 years and most recently held the position of Director Sales + Marketing. She has also been an authorized signatory since 2015.

In the course of her 29 years with the company, Nicole Dahlen has passed through all departments and is therefore not only familiar with a special field, but has one holistic view on the company. Last but not least, the new managing director experienced and shaped the development from dealer to manufacturer of customer-specific system solutions, which was important for Rodriguez - from changing the company locations to setting up and expanding in-house production.

"I've grown with the company and am therefore very familiar with the internal processes as well as the objectives and the strategy," says Nicole Dahlen, who has attended external technical and commercial training courses as well as management programs throughout her career. “Rodriguez can look back on very successful years. I would like to continue this positive development with new impulses and enable further growth.”

Nicole Dahlen thus reinforces Gunther Schulz in company management. The managing partner founded Rodriguez in 1984 and developed it into an internationally well-positioned company that preferably offers linear technology and precision bearings from its own production. "I've been working closely with Mr. Schulz for many years, so I'm familiar with his goals and values in corporate management," says Nicole Dahlen. "I'm really looking forward to the new challenges."

Class instead of roller bearings and linear technology mass - interview

26.04.2017 | Interview with Gunther Schulz, Managing Director, Rodriguez GmbH, Eschweiler, among other things, with questions about the constantly growing production, profitability and corporate philosophy. The interview was given at the Hanover Fair.

We asked Mr. Schuz the following questions:

- How is Rodriguez doing economically almost ten years after you bought the company?

- You have invested a great deal in production in recent years: How is that paying off today?

- What trends are you observing in your specialist field of precision bearings, particularly thin section bearings?

- What is going on in this regard with linear technology?

- What percentage of sales does your "Value Added Products" business unit generate and which target markets is it aimed at?

- What highlights do you present here at the Hannover Messe?

development scout as guest – reportage

02.11.2012/XNUMX/XNUMX | We visited Rodriguez GmbH, a leading manufacturer and distributor of linear technology and roller bearings, in Eschweiler to learn more about their economic situation, new products, future plans and trends. The managers and employees enthusiastically reported to us about the company's progress and explained to us what the problems were Value Addedproducts.

From dealer to developer and manufacturer - interview

29.05.2012 | Precision in motion – this is the slogan of Rodriguez GmbH. In Eschweiler, it was recognized that automated motion sequences require ever more precise components. The young, old company developed from a pure dealer to a developer and manufacturer. Young-old because Managing Director Gunther Schulz bought the company in mid-2008. That was just two months before the crisis hit. developmentscout spoke to the "young entrepreneur" about current and past events. In our interview we share interesting insights and get an impressive assessment of the transformation in the industry. We asked the following questions:

Rodriguez has developed in recent years from a pure dealer to the developer and manufacturer of bearing solutions and linear technology. Where is the company today?

They bought the company Rodriguez in the middle of 2008 almost three years ago. Was that a good decision from today's perspective?

Gunther Schulz: This is a mixed feeling. Unfortunately, we had only two months of normalcy between the purchase of the company and the arrival of the crisis, which was immediately accompanied by a decline in business. It followed 2009's low point with a staggering 45 percent sales slump. At that time, I often thought I had not made the right decision. With hindsight, however, I find that it was 100% correct. It's a lot of fun again and I would do it again.

What is the current business situation of Rodriguez?

Gunther Schulz: The current business situation is very good, albeit different in our three core business areas. As far as linear technology is concerned, the economy started to grow strongly in the first quarter of last year, when we almost returned to the level of mid-2008 and now we are above it. In the rotative area, ie rolling bearings, the recovery started much later and we have not quite reached the pre-crisis level.

Which novelties did you present at the Hanover Fair this year?

Gunther Schulz: We have put our focus on in-house production and have shown that we are not only a dealer in rolling bearings, but are increasingly developing and manufacturing them ourselves. We have specialized in customer-specific products. We want to create added value for our customers by combining different components according to the 'value added product' principle. In many cases, we are already using our own production capacities for this purpose, which we are expanding more and more. This year we have again invested heavily in new machines for all production areas.

They offer precision bearings and linear technology for a wide range of industrial sectors. That is what many do. What makes Rodriguez special?

Gunther Schulz: Due to our flat hierarchies, we can be very flexible and offer short reaction times. Fast processing of quotations, problem solving and order delivery - these are our strengths in addition to the innovative technology that we take for granted. Our focus is on service, advice and customer proximity.

What do the major energy policy changes mean for Rodriguez, will you cut off a piece of the pie?

Gunther Schulz: Of course. We have developed some interesting and new applications for solar energy tracking systems for the solar industry. For this we are currently testing prototypes for our customers, who mainly come from France and Spain. For bearings in wind turbines, our bearings are not big enough.

What goals has Rodriguez set himself?

Gunther Schulz: A big goal is to reach the sales volume of 2008 again as fast as possible. We will not quite make it this year, because our third area, automotive engineering, is still lagging a little behind in terms of the economy. Probably we will reach the end of 2012 the level of 2008.

25 years drive technology from Eschweiler

20.09.2010/25/XNUMX | Last year, Rodriguez GmbH, Eschweiler, celebrated its XNUMXth anniversary. However, the economic crisis did not provide an appropriate setting for an anniversary celebration. This was now at the beginning of September – in times of recovery – made up for and presented the current portfolio to business and market partners. As part of the anniversary celebration, Rodriguez organized an in-house exhibition where the guests could get an impression of the product range and visit the production facility with the machinery.

"A lot has changed for us in 25 years," emphasized Rodriguez Managing Director Gunther Schulz in his speech. "We can look back on solid growth in many respects." The company buildings have been expanded several times, and the workforce has also increased continuously.

"A lot has changed for us in 25 years," emphasized Rodriguez Managing Director Gunther Schulz in his speech. "We can look back on solid growth in many respects." The company buildings have been expanded several times, and the workforce has also increased continuously.

The same applies to the range of services, which today includes over 250 Kaydon thin section bearing types, precision roller bearings, special bearings, a complete range of machine elements in linear technology and other drive components for mechanical and plant engineering and automotive components.

In the early 90s, in-house production was implemented in the company in order to be able to modify standard products to suit the application and to be able to implement customer-specific solutions quickly and economically. This business area is particularly important to Gunther Schulz:

"Whether it's a boom in the industry or an economic crisis, whether innovation or the further development of proven technology based on the state of the art - companies have to be adaptable and able to react quickly to customer needs and market changes. Therefore we have above all invested in the expansion of in-house production, because it gives us maximum flexibility.”

Efficient linear guide with lubrication status monitoring

Efficient linear guide with lubrication status monitoring

The set course should also be maintained for the future. This was one of the reasons why Schulz founded GmbH taken over as 100% owner has. With the management buy-out, he also took over the southern branch in Marbach am Neckar, the French sales office in St. Germain En Laye near Paris and the Rodriguez Germany subsidiary ICB International Customized Bearings in Charlotte, North Carolina/USA, and thus connected jobs secured. The same applies to the Eschweiler site, which started out as an engineering office in the mid-70s.

You might also be interested in...

Slim precision ball bearings move high-tech in space

linear guide | Precise, light, durable

Ball screw drive | Rotating ball screw

Thin section bearings as a better alternative to standard ball bearings

Special flange bearing enables 360 degree scanner rotation

Miniature and other profile rail guide for various uses

The author Nicole Dahlen is Managing Director Sales, Marketing and Organization at Rodriguez GmbH in Eschweiler.