Components for excavators & Co.

Modern technologies such as satellite-controlled navigation, communication technology and sensors are making inroads

Image: Turck

Components for excavators & Co.

Modern technologies such as satellite-controlled navigation, communication technology and sensors are making inroads

Image: Turck

Mobile machines such as excavators, cranes or combine harvesters are becoming increasingly intelligent and equipped with more and more electrical drive technology. The previously quite unergonomic work machines are also becoming more comfortable. Against the background of the Precision farming the customer focuses on yield, service life and maintenance. Targeted seed application is an example of this.

Discover the latest developments in the fields of mechanics and automation for mobile machines below Drive Technology, Fluid Technology, communication technology, sensors, Machine elements and much more for your efficient mobile Working machine.

16.04.2024 | Schaeffler presents its new ones Cylindrical roller bearings NJ23-ILR series for construction machinery and heavy industrial gearboxes. The rolling bearings are compact and equipped with the high-performance Mpax cage. With regard to the base bearing type NJ23, the load capacity could be increased by an average of 24%. The service life doubles.

IFM Electronic represents the isobus Gateway which is designed for agricultural equipment. By implementing the provided library, which is compatible with Codesys V2.3 or V3.5, the user interface can be efficiently adapted to specific needs.

Wittenstein is presenting the safety-certified servo controller "Cyber Simco drive 2" with Profisafe interface and integrated safety card at Logimat. In the performance variants SIM2050 and SIM2100 and combined with the drive actuator The servo controllers are suitable for use in the compact servo drives "Cyber Itas System 2" for applications such as driverless transport systems.

Lenord + Bauer presents an innovative solution for mobile machines with the robust speed sensor GEL SEI10 (picture above). This sensor was designed for challenging environmental conditions. The Rev counter Guarantees a high level of mechanical stability thanks to its robust stainless steel housing and the robust cable gland.

Lenord + Bauer presents an innovative solution for mobile machines with the robust speed sensor GEL SEI10 (picture above). This sensor was designed for challenging environmental conditions. The Rev counter Guarantees a high level of mechanical stability thanks to its robust stainless steel housing and the robust cable gland.

A manufacturer of vibrating screens has on NSK turned because he keeps having problems with the Warehousefastening in the sieve units. He also wanted to reduce manufacturing costs and increase the overall performance of the screening plants. The vibrating screens are used in mining and quarries.

A manufacturer of vibrating screens has on NSK turned because he keeps having problems with the Warehousefastening in the sieve units. He also wanted to reduce manufacturing costs and increase the overall performance of the screening plants. The vibrating screens are used in mining and quarries.

If you try to hang a picture horizontally or determine the inclination using a spirit level, this is quite easy because the air bubble in the level shows when the picture is hanging straight. The bucket of a wheel loader cannot be steered horizontally while the machine is accelerating or braking. The IMU F99 inclination sensor from Pepperl + Fuchs provides a remedy.

If you try to hang a picture horizontally or determine the inclination using a spirit level, this is quite easy because the air bubble in the level shows when the picture is hanging straight. The bucket of a wheel loader cannot be steered horizontally while the machine is accelerating or braking. The IMU F99 inclination sensor from Pepperl + Fuchs provides a remedy.

![]() Systems of the first generation of robots are often packed with a wide variety of components and cables. This often leads to a blatant lack of space and a chaos of components and Cable inside the automation system. Synapticon creates these problems with its servo drive for Robot and Cobots out of the way. Of the Somanet Circulo based on the specially developed Integrated Motion Technology.

Systems of the first generation of robots are often packed with a wide variety of components and cables. This often leads to a blatant lack of space and a chaos of components and Cable inside the automation system. Synapticon creates these problems with its servo drive for Robot and Cobots out of the way. Of the Somanet Circulo based on the specially developed Integrated Motion Technology.

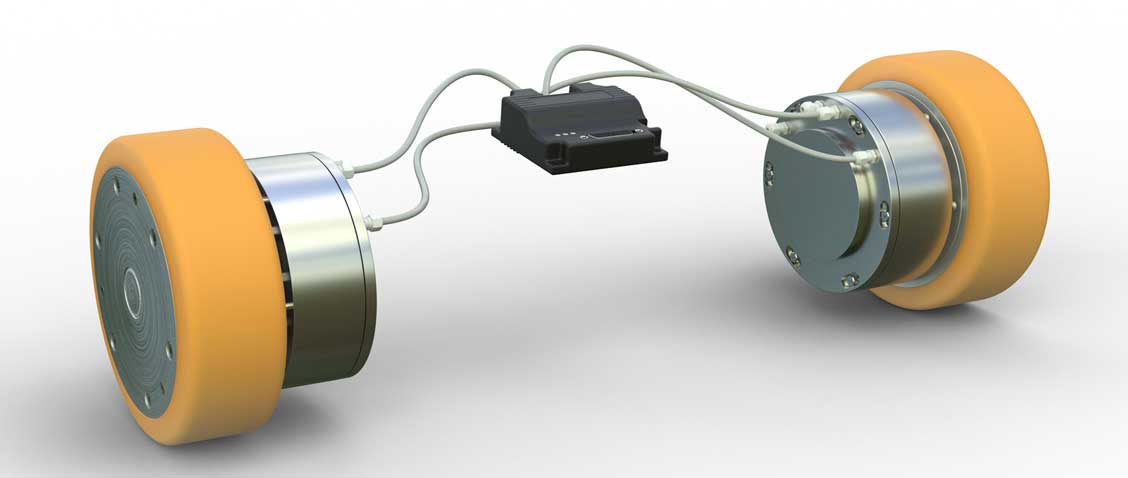

Framo Morat and Minebea Mitsumi Technology Center Europe now present their innovative hub motor before, which they have optimized for driverless transport vehicles. The hub motor is predestined for applications that require high performance in the tightest of spaces. The all-inclusive power packs combine all functional elements.

Framo Morat and Minebea Mitsumi Technology Center Europe now present their innovative hub motor before, which they have optimized for driverless transport vehicles. The hub motor is predestined for applications that require high performance in the tightest of spaces. The all-inclusive power packs combine all functional elements.

Two tunnel boring machines are the largest machines on the construction site Semmering Base Tunnels. The safety clutch EAS-HT from Mayr Antriebstechnik, These Couplings trigger reliably and comprehensibly and protect the drive components sustainably. They cannot be manipulated and the factory-set torque is available again even after disengagement. Recommissioning is also quick and easy, without any additional tools.

The next stage of development of Agricultural industry is data-driven and demands robust sensor technology in the field. With its products enabled Turck the operation of intelligent driver assistance systems, the harbinger of fully autonomous work processes. QR20 encoders use the steer-by-wire method to measure the steering angle of axles or accompany the unfolding of the spray arms of a field sprayer. For positional alignment of the spray boom, however, are ultrasound and Inclinometerswhile Banner Engineering's compact TM18 photoelectric sensors can monitor the material flow in the grain lift of a combine harvester.

The next stage of development of Agricultural industry is data-driven and demands robust sensor technology in the field. With its products enabled Turck the operation of intelligent driver assistance systems, the harbinger of fully autonomous work processes. QR20 encoders use the steer-by-wire method to measure the steering angle of axles or accompany the unfolding of the spray arms of a field sprayer. For positional alignment of the spray boom, however, are ultrasound and Inclinometerswhile Banner Engineering's compact TM18 photoelectric sensors can monitor the material flow in the grain lift of a combine harvester.

The Schmersal Group In collaboration with Aconno, has developed the prototype of an Industry 4.0 switch for the bulk industry developed. With the switchgear Heavy Duty Switch (HDS) series can wirelessly transmit data over distances of several kilometers in extensive conveyor systems in heavy industry.

Inspecting gas pipelines with helicopters is expensive and time-consuming. As an alternative, the German company offers Exabotix a drone team that automatically carries out inspection flights. After the bets, everyone lands Professional drone in a remote drone hangar, also by Exabotix. These droneports are thanks linear guide, housing bearings and bearings from Igus maintenance free.

As a general contractor, SSI Schaefer largely relies on standardized assemblies in order to optimize procurement processes, streamline internal logistics and reduce assembly and maintenance times. The intralogistics specialist relies on suppliers such as Harting and Igus, not only because both companies take the system thought into account.

As a general contractor, SSI Schaefer largely relies on standardized assemblies in order to optimize procurement processes, streamline internal logistics and reduce assembly and maintenance times. The intralogistics specialist relies on suppliers such as Harting and Igus, not only because both companies take the system thought into account.

During the mining and subsequent storage of bauxite, a sedimentary rock used to produce aluminum oxide, a lot of dust is formed, which poses a major challenge, especially for the moving machine parts of the conveyor units. The aluminum oxide producer AOS uses energy chains from in its plants Igus on. For several years now, they have reliably supplied power units and stockpiles with energy, data and media.

During the mining and subsequent storage of bauxite, a sedimentary rock used to produce aluminum oxide, a lot of dust is formed, which poses a major challenge, especially for the moving machine parts of the conveyor units. The aluminum oxide producer AOS uses energy chains from in its plants Igus on. For several years now, they have reliably supplied power units and stockpiles with energy, data and media.

Energy chains in construction machinery, crane systems, lifting platforms, lifters, etc. require more unsupported length. Sahl chains are often used here because they are stiffer than plastic chains. Igus offers hybrid chains made of steel and plastic. They are lighter than pure steel chains, but stiffer than plastic chains. Below we present two types:

Thyssen Krupp is presenting a world first: the largest KB 63-130 rotary crusher weighs 490 t and is significantly lighter than its predecessor - despite the 14% increase in cone diameter of 130 inches (around 3,3 m). With a throughput of up to 14.000 t / h, the rotary crusher achieves an increase in performance of more than 30% compared to its predecessor.

Thyssen Krupp is presenting a world first: the largest KB 63-130 rotary crusher weighs 490 t and is significantly lighter than its predecessor - despite the 14% increase in cone diameter of 130 inches (around 3,3 m). With a throughput of up to 14.000 t / h, the rotary crusher achieves an increase in performance of more than 30% compared to its predecessor.

The Schmersal Group presents its new HDS switchgear series for heavy industry. The modular series is the first to combine various functions on one platform, making it suitable for a wide variety of applications. The basis of the new platform is the uniform housing concept, which consists of two variants: plastic (thermoset) and cast iron.

The Schmersal Group presents its new HDS switchgear series for heavy industry. The modular series is the first to combine various functions on one platform, making it suitable for a wide variety of applications. The basis of the new platform is the uniform housing concept, which consists of two variants: plastic (thermoset) and cast iron.

Equipment for stubble cultivation in agriculture, so-called cultivators, used to be used primarily for weed control. Today the main benefit is to loosen the arable land, mix in organic matter and prepare it for the next sowing. The "Karat 9" from Lemken is an intensive cultivator that can be used for shallow, medium and deep work. Lubrication-free plastic plain bearings perform at the bearing points Igus their reliable service.

Equipment for stubble cultivation in agriculture, so-called cultivators, used to be used primarily for weed control. Today the main benefit is to loosen the arable land, mix in organic matter and prepare it for the next sowing. The "Karat 9" from Lemken is an intensive cultivator that can be used for shallow, medium and deep work. Lubrication-free plastic plain bearings perform at the bearing points Igus their reliable service.

With the new E2 hoop chain from Igus, there is now an energy and media supply in one system even for tight installation spaces on support legs. Stable, space-saving and easy to assemble, the e-chain not only carries power and control lines but also two hydraulic hoses. The E2 shackle chain saves maintenance in special machine construction and significantly reduces downtimes.

With the new E2 hoop chain from Igus, there is now an energy and media supply in one system even for tight installation spaces on support legs. Stable, space-saving and easy to assemble, the e-chain not only carries power and control lines but also two hydraulic hoses. The E2 shackle chain saves maintenance in special machine construction and significantly reduces downtimes.

Rigid, stationary transport devices such as conveyor belts are used in the today Intralogistik increasingly through autonomous transport units or Automated Guided Vehicles (AGV) replaced. For economic operation you need powerful, compact drives with a long service life. Heinzman and Framo Morat have a new one for this hub motor Developed with integrated gear.