for mechanical and plant engineering

Programmable logic controls, CNC controls, TNC controls or safety controls with digital twin and control technology

for mechanical and plant engineering

Programmable logic controls, CNC controls, TNC controls or safety controls with digital twin and control technology

The Control Technology and control engineering are sub-areas of Automation services. Modern production plants are controlled by Industry 4.0-compatible controllers such as programmable logic controllers (SPS) Or CNC CNC and TNC Controls among others from Mitsubishi Electric, Siemens, Heidenhain or Rockwell Automation.

Contents

Today's control technology is characterized by technologies such as digital twin or network capability, OPC UA connection and control technology. She is influenced by the digital transformation in the smart factory. We report on innovations for control technology in the field of automation technology for industrial machines and systems.

Our product reports, specialist articles and user reports include innovative SPS, CNC controls, TNC controls or safety controls. In the first block we have different ones for you industry-specific applications compiled for Control & Co. In the second block you will find control technology for mechanical and plant engineering in the Industry 4.0 factory.

The fast industrial and collaborative Melfa robots from Mitsubishi Electric are high precision, have intelligent technology and can be used in manufacturing cells. But the automation company also continually presents new developments in the area of software for robot programming, including one Teaching box and a platform that Robot programming and CNC combined.

Mitsubishi Electric has the first compact in the 1980s SPS brought on the market. Today the PLC Melsec series stands for reliability and efficiency in industrial automation in the Industry 4.0 era. As a globally recognized standard, it sets standards in control technology. With modern technology these offer programmable logic controllers Solutions for your demanding applications – especially when starting digitalization, as this article shows.

The programmable logic controller (PLC) controls and regulates machines and systems. If you are looking for a PLC, discover the new products from various manufacturers in this article. Here you will also find information about essential basics and deepen your knowledge of efficient automation systems.

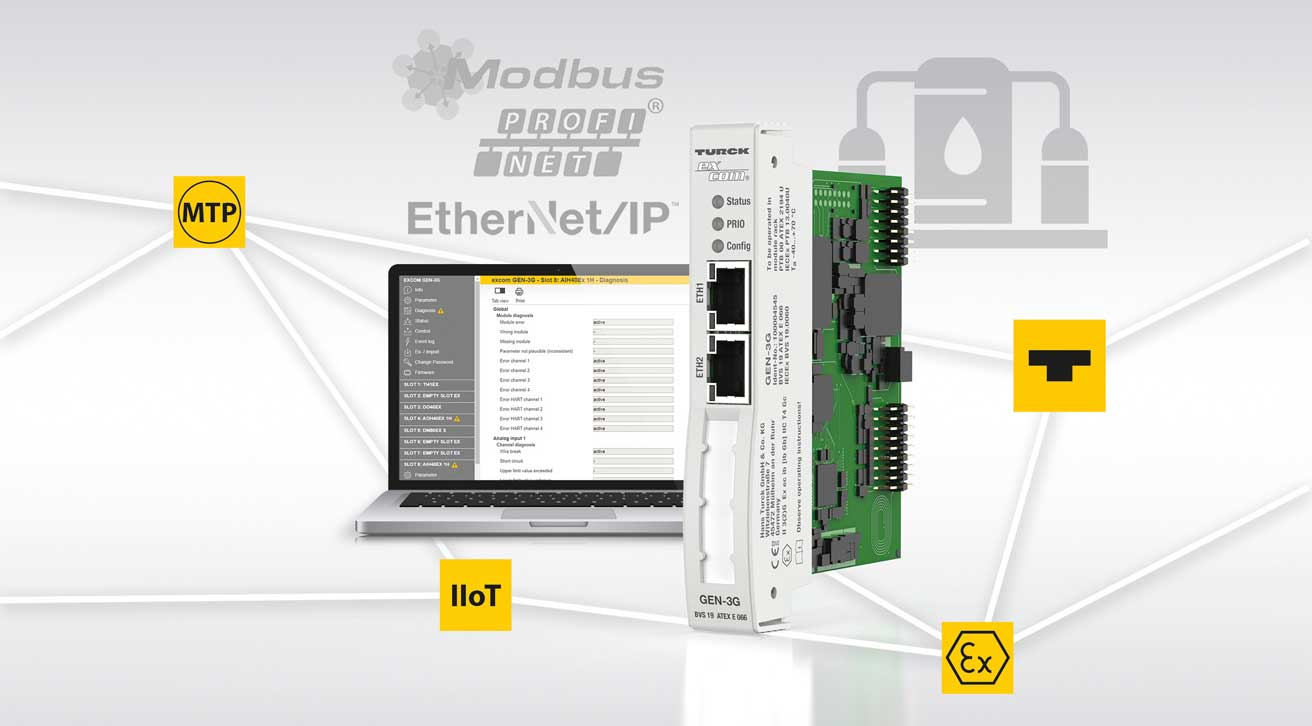

Turck offers controls for controlling and monitoring such as the IP67 PLC with cloud connection and edge gateway function, Ethernet gateways also for that hazardous area and HMI operator panels. Here we present the new developments:

The Schmersal Gruppe offers the modular, programmable safety controllers of the series for safe signal processing ProtectPSC and the multifunctional safety controls with program selection functions of the ProtectSelect Line. Both offer options for the visualization and diagnosis of signals. We present you here new developments from the field Safety control for safety applications:

Mitsubishi Electric shows how machine tools in networked production systems, with smarter CNC Control, Edge Computing and increase productivity through partner solutions. In this article you will find information about the innovations for EMO 2023, the connection of robots via a plug-and-play integration or the new one CNC Control M8V with direct WiFi connection.

With the XC300, Eaton offers a powerful and flexible control system that allows machine and system builders to implement a slim and modern automation concept in combination with the compact XN300 I / O system and the XV300 touch panel. The high-performance processor of the system enables short cycle times of less than 1 ms, so that users can achieve a high machine cycle and thus high productivity.

With the XC300, Eaton offers a powerful and flexible control system that allows machine and system builders to implement a slim and modern automation concept in combination with the compact XN300 I / O system and the XV300 touch panel. The high-performance processor of the system enables short cycle times of less than 1 ms, so that users can achieve a high machine cycle and thus high productivity.

Before a necessary Plant modernization many companies shy away. There is never the right time for this. The weekends are best suited for this. With the right preparation for implementation, downtimes and machine downtimes can be reduced to a minimum. A ensures planning security digital twin of Intralogistik Systems Uniware from Uni technology.

Before a necessary Plant modernization many companies shy away. There is never the right time for this. The weekends are best suited for this. With the right preparation for implementation, downtimes and machine downtimes can be reduced to a minimum. A ensures planning security digital twin of Intralogistik Systems Uniware from Uni technology.

With Artificial intelligence (AI) and advanced analytics (AA) can Machine control today process data, learn from it and make autonomous decisions. This increases the availability of machines and systems. These become more efficient, more reliable and more productive overall. How to embed these intelligent technologies in the steering can deliver a new paradigm of operation, knows Nils Knepper from Mitsubishi Electric.

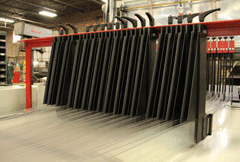

With the development of the "Jumbo assembler" Premier Paper has responded to the demand for a flexible and efficient system for the production of partition walls of corrugated fiberboard and stripes. These partitions are used during shipment and storage, the protection of sensitive products from wine bottles to cryovials. The single, integrated automation and control system from Mitsubishi Electric fulfilled all the requirements of the new Jumbo assembler.

With the development of the "Jumbo assembler" Premier Paper has responded to the demand for a flexible and efficient system for the production of partition walls of corrugated fiberboard and stripes. These partitions are used during shipment and storage, the protection of sensitive products from wine bottles to cryovials. The single, integrated automation and control system from Mitsubishi Electric fulfilled all the requirements of the new Jumbo assembler.

The first stepper motorcontrol in a 19-inch slide-in cassette from Systec's "Xemo" motion control family already contains the new ARM processor, which will soon be used in all Xemo positioning controls. Xemo Step continues the line of MCM-Step stepper motor controllers and adds new technology options to product features not previously available for Xemo controllers.

The first stepper motorcontrol in a 19-inch slide-in cassette from Systec's "Xemo" motion control family already contains the new ARM processor, which will soon be used in all Xemo positioning controls. Xemo Step continues the line of MCM-Step stepper motor controllers and adds new technology options to product features not previously available for Xemo controllers.

The HE 5684 Ethernet controller expands the "Imod Eco" product range from Hesch. The freely programmable, multitasking-capable control according to IEC 61131-3 with an ARM450 CPU clocked up to 9 MHz can control up to 16 I / O modules of the series directly and supports the manufacturer-independent development environment "Codesys V3". This means that the product can take on independent control functions as well as relieve the higher-level control technology through outsourced functions or add additional functions.