for component handling

Innovations and further developments in vacuum technology for industrial applications such as vacuum pumps, grippers, compressors

Image: Gimatic

for component handling

Innovations and further developments in vacuum technology for industrial applications such as vacuum pumps, grippers, compressors

Image: Gimatic

for component handling

Innovations and further developments in vacuum technology for industrial applications such as vacuum pumps, grippers, compressors

Image: Gimatic

Here you will find new developments in this area Vacuum Technology for mechanical and plant engineering as well as for special sectors such as gripper technology, vacuum pumps, vacuum ejectors and applications such as for the clean room Food industry or battery production for example.

Content:

Vacuum Technology is used today in many industrial sectors such as Handling of components in production and manufacturing technology, Measurement Technology, Food Processing or in medical equipment deployed. During development, it is increasingly necessary to pay attention to energy efficiency and sustainability. Leybold GmbH is a pioneer of industrial vacuum technology. It celebrates its 2020th company anniversary in 170.

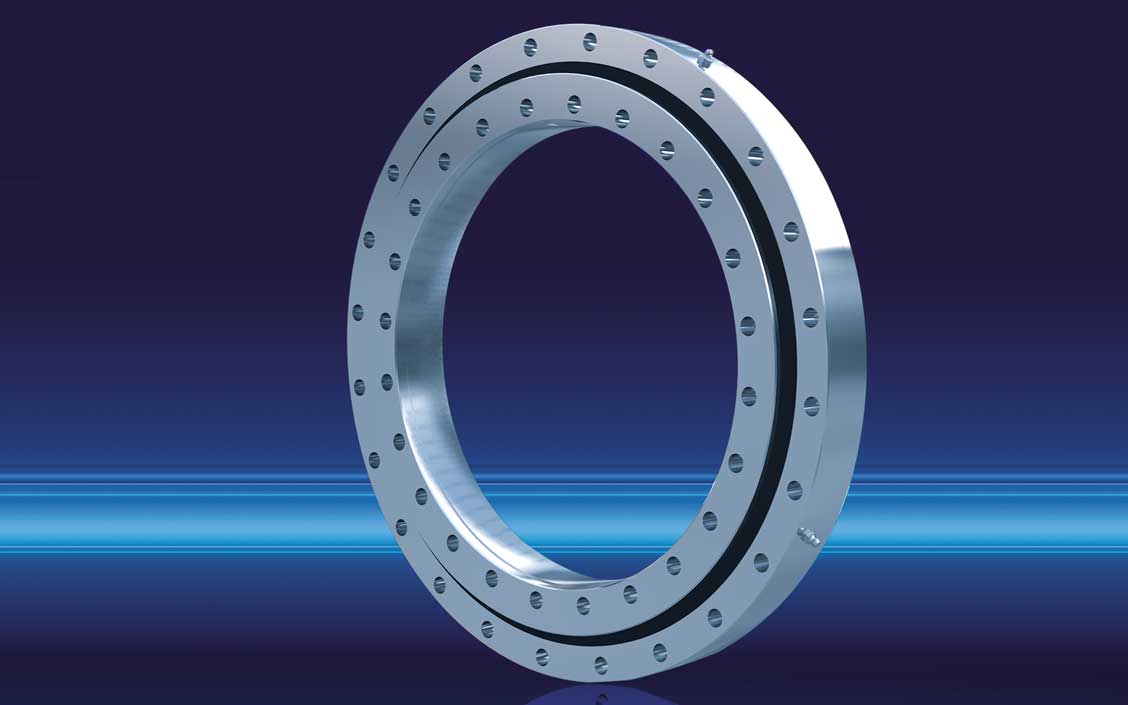

Here you will find components and systems for vacuum technology from specialists such as Heraeus, Witte, Pfeiffer Vacuum, SMC, with which the processes in the modern factory have it optimized - including Vacuum ejectors or vacuum generators or vacuum pumps with rotary vane pumps, scroll pumps, diaphragm pumps, Roots pumps, screw vacuum pumps, diffusion pumps and turbo pumps as well Vacuum gripper or vacuum clamping devices.

food technology

Microsystems Technology

Robotic

Traditional companies are only sustainable if they are innovative. The specialist for Vauum technology Leybold this combination of tradition and innovation has been impressively successful over the course of its company history. Today the company is proud of its 170. Birthday to celebrate a very special milestone in 2020.

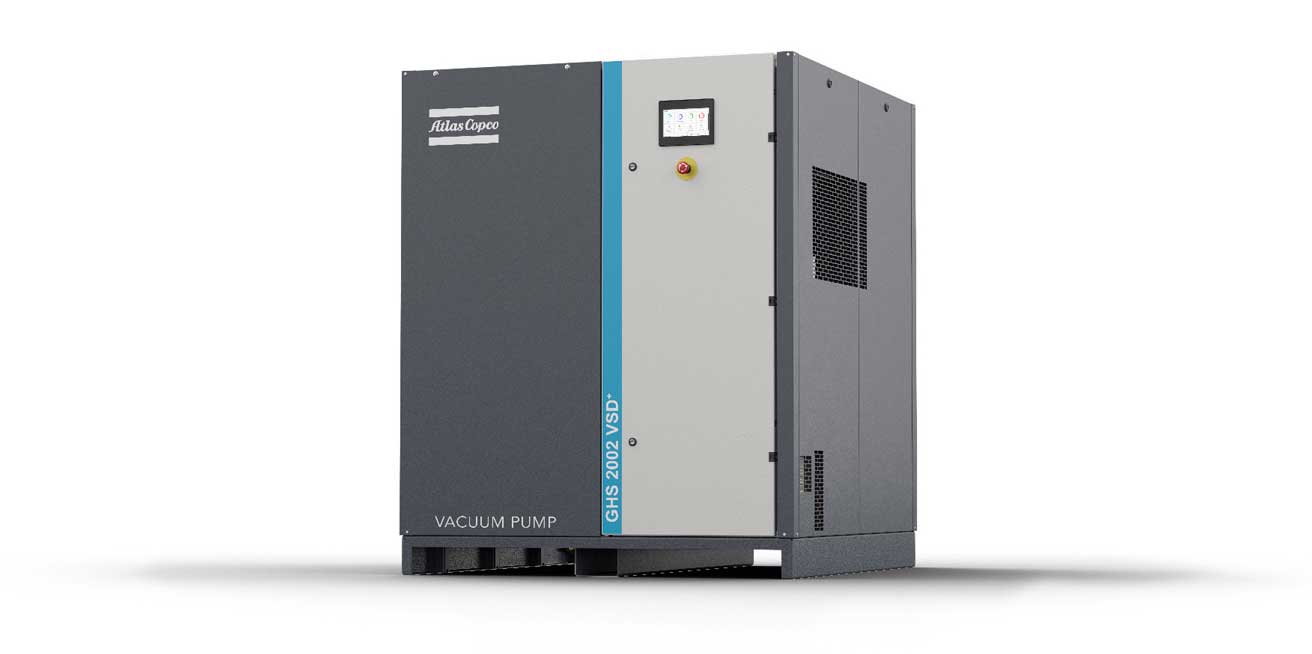

High-quality, energy-efficient, quiet and much more must be Vacuum pump for industrial applications today. Intelligently controlled, it is also ideally suited for use in Industry 4.0. We present you here New developments before, including a new speed-controlled screw vacuum pump from Atlas Copco, which can be intelligently networked.

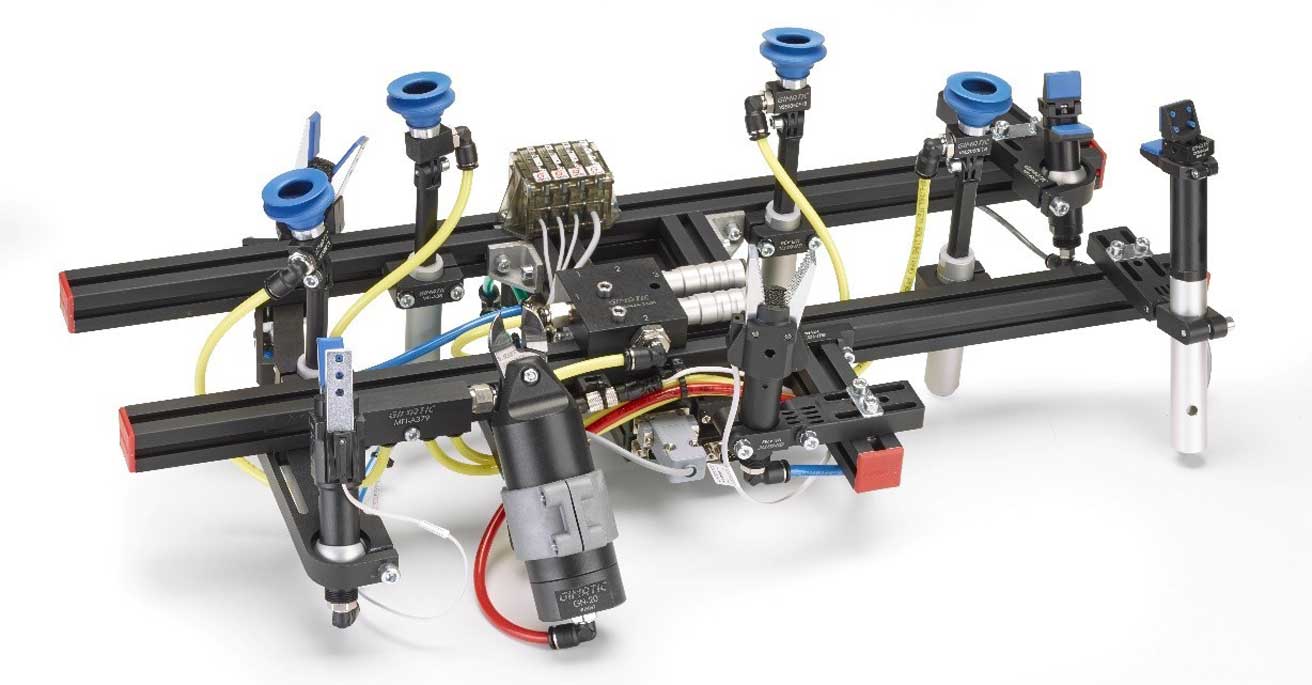

Gimatic, a member of the Barnes Group, has expanded its mechatronics product range to include a range of Vacuum Technology like Vacuum pump, suckers, Sensors and accessories expanded. The newcomers are energy efficient, high quality and food safe. There are many applications for them in a wide variety of industries.

Pfeiffer Vacuum and Glimo have jointly developed the "Vacu²" multi-stage vacuum process for die casting, in which the casting chambers and mold cavities are evacuated in two stages. The vacuum created in this way leads to very good part quality.

Pfeiffer Vacuum and Glimo have jointly developed the "Vacu²" multi-stage vacuum process for die casting, in which the casting chambers and mold cavities are evacuated in two stages. The vacuum created in this way leads to very good part quality.

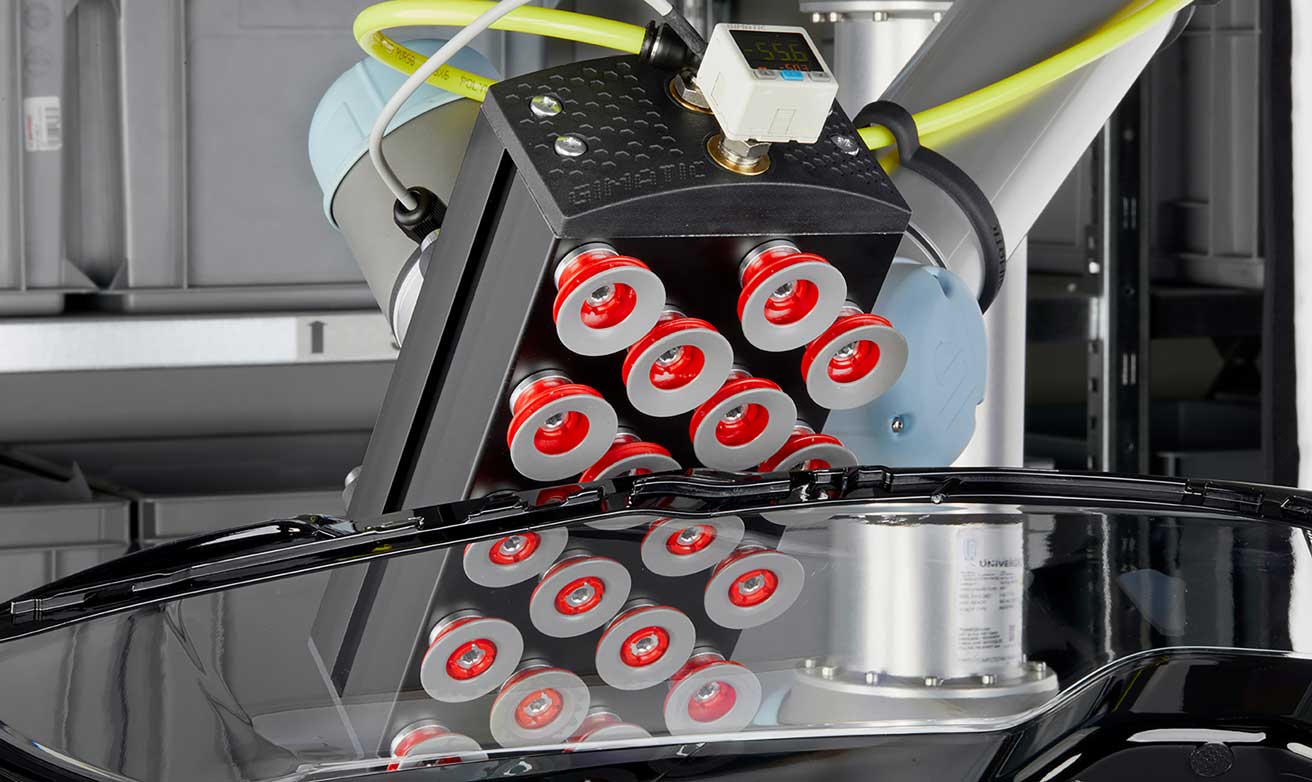

The new Vacuum gripper Series FGS-120 from Gimatic is modular, very flexible and energy efficient. With the modular vacuum grippers, differently shaped components in various sizes and different porosities can be handled very easily. A integrated vacuum generator provides the vacuum and makes the grab suitable for use in various industries. In packaging technology or intralogistics, the vacuum cups or vacuum plates reliably grip sheet metal, Plastic, Glass, wood, cardboard or cans.

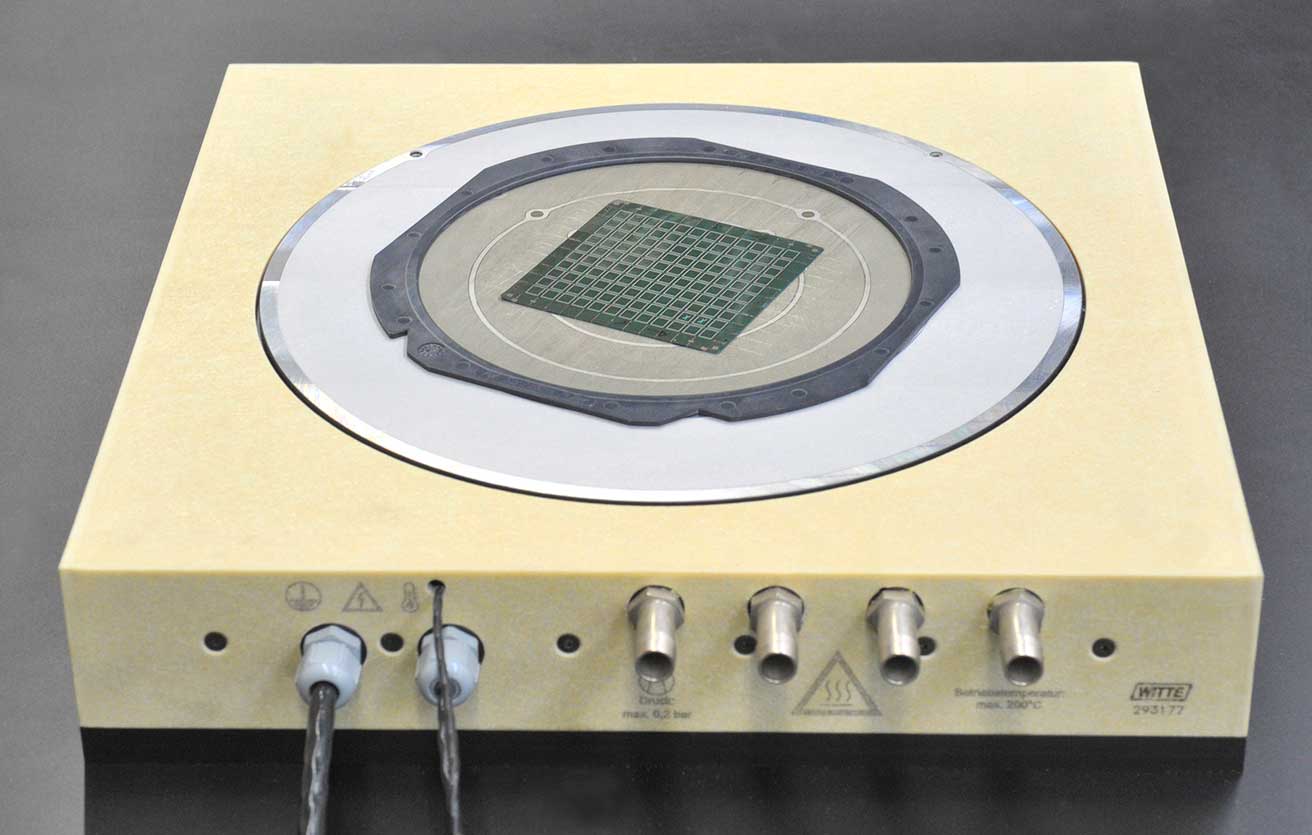

Bis 200 ° C lets the new microporous vacuum chuck from Witte Warm up. This makes the clamping plate particularly suitable for complex high-tech tasks. With the Quadrovac vacuum clamping technology workpieces with complex contours can also be clamped. You can find these and other innovations below:

Owis offers a large portfolio Vacuum Technology from High vacuum (HV), about Ultra high vacuum (UHV) up to extremely high vacuum (XHV). It starts with positioners and optical components in pressure ranges up to 10-6 mbar. In 2017 the company expanded the UHV to 10-9 mbar with new ultra-high vacuum products for a considerable expansion of the possible applications. Last but not least, in the last few years the know-how for XHV products has increased to 10-11 mbar worked out.

The multi-stage vacuum generators of the ZL250A series from SMC bring about 112% higher suction volume flow compared to a single-stage model. On the basis of the highly efficient 3-stage diffuser construction, they are very powerful. The lightweight powerhouses are also 8% narrower and 60% lighter.

The multi-stage vacuum generators of the ZL250A series from SMC bring about 112% higher suction volume flow compared to a single-stage model. On the basis of the highly efficient 3-stage diffuser construction, they are very powerful. The lightweight powerhouses are also 8% narrower and 60% lighter.

The new Scroll pump of vacuum pumps Hiscroll series from Pfeiffer Vacuum offer a high nominal pumping speed of 6 to 20 m³ / h. The compact design of the oil-free, hermetically sealed vacuum pumps and you low-vibration, quiet operation are particularly beneficial.

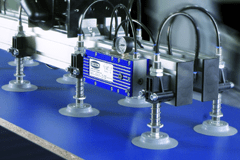

For the gentle transfer of workpieces from or to the machines vacuum cups used, be it in paper production, packaging technology, food technology or beverage industry. The suction cups not only have to grip securely, they should also be able to be installed and maintained as quickly and easily as possible. The new vacuum cup ZP3C from SMC is ideal for this. You can find these and other innovations below:

The integrated IO-Link functionality in the compact ejectors SCPi / SMPi from Schmalz is the prerequisite for standardized and therefore cost-effective networking of system components and for preventive system monitoring. In addition, up to 65% compressed air can be saved with these vacuum generators. The power blow-off function ensures more process speed, with which even sensitive workpieces can be removed without damage.

The integrated IO-Link functionality in the compact ejectors SCPi / SMPi from Schmalz is the prerequisite for standardized and therefore cost-effective networking of system components and for preventive system monitoring. In addition, up to 65% compressed air can be saved with these vacuum generators. The power blow-off function ensures more process speed, with which even sensitive workpieces can be removed without damage.

Efficient vacuum generation with compressed air is possible. If the vacuum generator is optimally designed for the application, all parameters such as workpiece properties, cycle times and transport routes have been taken into account and if a suitable, performance-based ejector with functionalities relevant to the requirements is selected, compressed air is not expensive, but a highly efficient energy carrier. Vacuum technology specialist J. Schmalz shows how it's done.

Efficient vacuum generation with compressed air is possible. If the vacuum generator is optimally designed for the application, all parameters such as workpiece properties, cycle times and transport routes have been taken into account and if a suitable, performance-based ejector with functionalities relevant to the requirements is selected, compressed air is not expensive, but a highly efficient energy carrier. Vacuum technology specialist J. Schmalz shows how it's done.