Energy-efficient vacuum pump, suction cups, sensors & Co.

- Details

- Hits: 8093

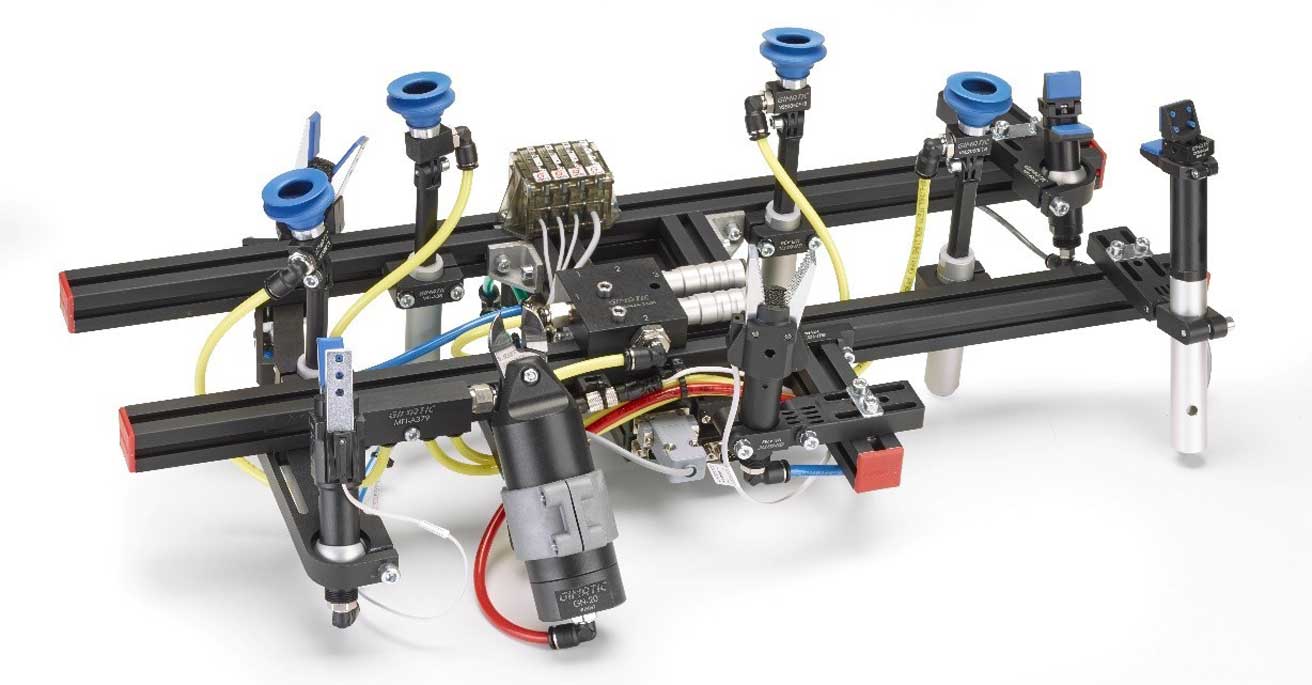

Gimatic, a member of the Barnes Group, has expanded its mechatronics product range to include a range of Vacuum Technology like Vacuum pump, suckers, Sensors and accessories expanded. The newcomers are energy efficient, high quality and food safe. There are many applications for them in a wide variety of industries.

Vacuum pump, cartridge, release system, vacuum switch, vacuum filter, suction cups, suspensions with and without Brake as well as angle joints move into the Gimatic product portfolio. The VG range includes an estimated 900 products.

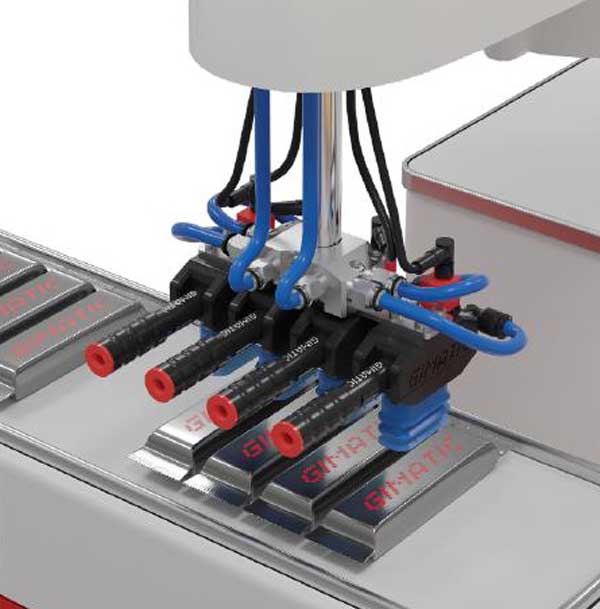

Robot grippers and EOAT solutions

Robot grippers and EOAT solutions

Vacuum technology made from high quality material

The new components offer Energy Efficiency and are made of high quality Materials manufactured like polyurethane in two degrees of hardness, hydrogenated nitrile butadiene rubber (HNBR), nitrile butadiene rubber (NBR) and silicone. FDA-compliant silicone versions are available for the direct processing of unpackaged food. The synthetic cartridges do not contain paint-wetting impairment substances (PWIS). Therefore, they can be used in applications where contamination of the material can be ruled out.

The new components offer Energy Efficiency and are made of high quality Materials manufactured like polyurethane in two degrees of hardness, hydrogenated nitrile butadiene rubber (HNBR), nitrile butadiene rubber (NBR) and silicone. FDA-compliant silicone versions are available for the direct processing of unpackaged food. The synthetic cartridges do not contain paint-wetting impairment substances (PWIS). Therefore, they can be used in applications where contamination of the material can be ruled out.

Suction cups also for uneven surfaces

The suction cups ensure one secure hold even on uneven surfaces. They are used, for example, on the packaging of snacks or welded bars. There are 18 product families available for even the most demanding applications such as those in packaging technology, Food industry, Pharmaceutical sector, Plastic manufacturing or the processing industry such as sheet metal, wood, Glass and Automotive can be found.

Cartridge and pump - compact and light

The EJ series from cartridge and vacuum pump comprises around 150 different items from eight product families. The cartridges are available in three sizes, three versions each. Thanks to their extremely efficient, compact and lightweight design, they can be integrated into the machine where the vacuum is needed.

These vacuum grippers handle everything

These vacuum grippers handle everything

The operators benefit from the higher performance of the Vacuum gripper with lower energy consumption. The vacuum pump area includes distributors made of aluminum or POM, with which further functions can be embedded in the operational process. The object being processed can e.g. B. are automatically released without solenoid valves. Suspension, ball joint and actuator, release system, switch or filter complete the new product range.

Vacuum technology for the packaging line

You might also be interested in...

Robot Gripper | Automated little hands

Gimatic | The smart gripper specialist

Robot grippers and EOAT solutions

gripper | pneumatic, electrical, magnetic

Medical technology Grippers for the mega trend