Drive elements for power transmission

Save total cost of ownership with efficient gear wheels, drive chains, conveyor chains, toothed racks and toothed belts

Image: Tsubaki

Drive elements for power transmission

Save total cost of ownership with efficient gear wheels, drive chains, conveyor chains, toothed racks and toothed belts

Image: Tsubaki

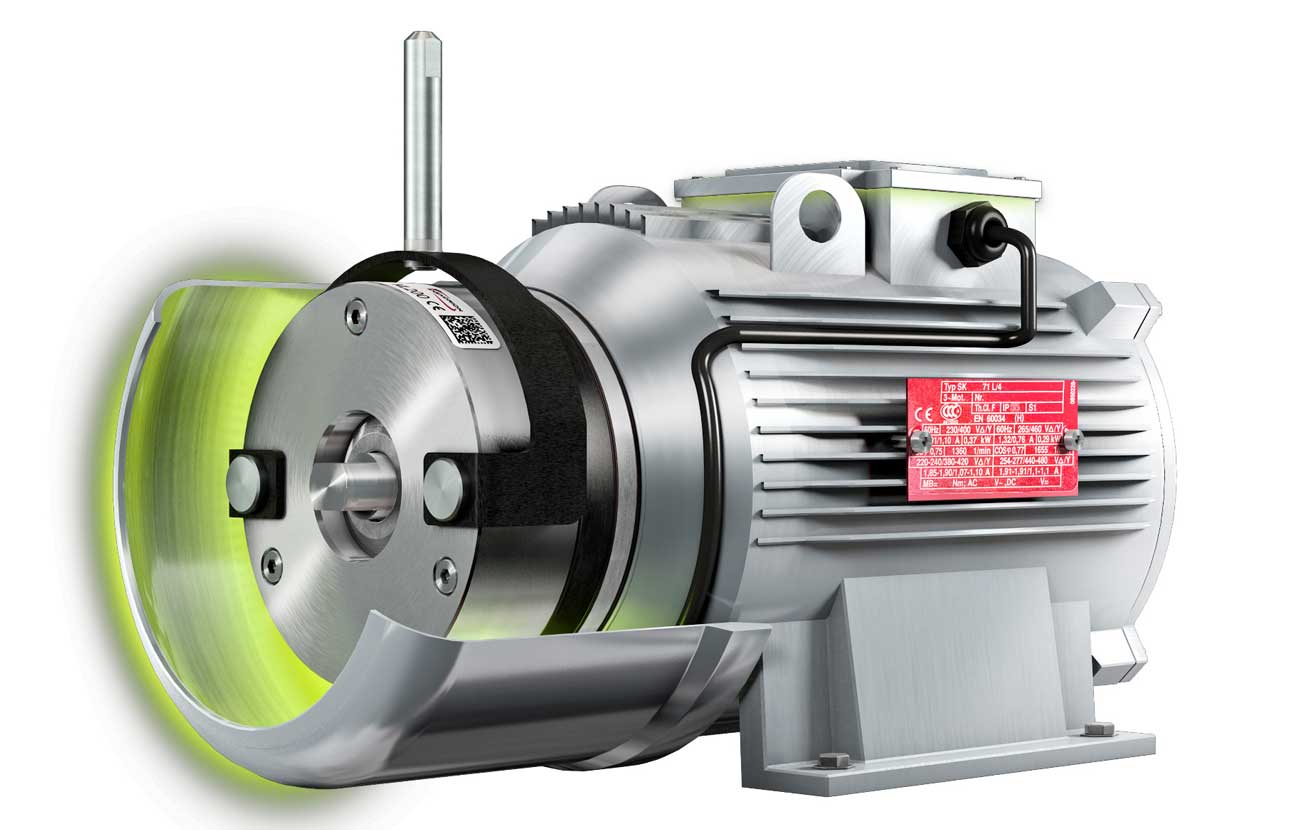

Brakes for machine safety

with safety brakes, hydraulic, electromagnetic or spring-actuated brakes and clamping elements

Image: Mayr drive technology

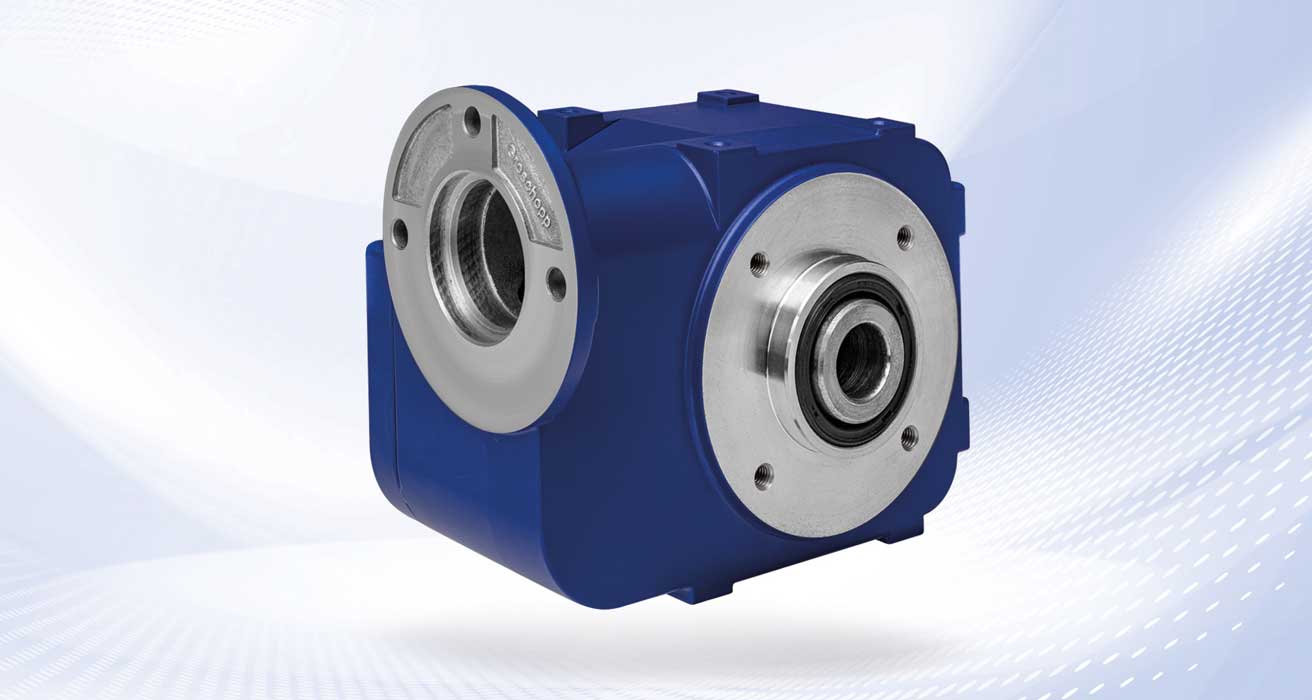

Transmission for the drive train

Planetary gears, spur gears or heavy-duty gears, low backlash and networkable for mechanical engineering

Image: Schaeffler

Drive transmission clutches

Disk coupling, safety coupling, shaft coupling, clamping element, shaft-hub connection for machines and systems

Image: Orbit drive technology

Linear drives for precise movement

Electric linear motor innovations such as ball screws, trapezoidal screws, rack and pinion drives, linear modules and actuators for positioning and strokes

Image: Rodriguez

Engines with future potential

Synchronous motor, asynchronous motor, geared motor, DC motor, DC and BLDC, stepper motor for your cost-conscious design

Image: Koco Motion

Converters for drives in mechanical engineering

Electrical drive technology such as frequency converters, DC converters, stepper motor drivers for efficient drive technology in Industry 4.0

Image: Mitsubishi Electric

Here you will find the mechanical, electrical and mechatronic Drive Technology for the modern Engineering. We inform about individual Drive Elements or components like Transmission, Couplings, Brakes, Linear Drives, Engines, Inverter etc. as well as complete drive solutions for power transmission in the drive train of a machine or system.

Contents

Drive technology today no longer only includes individual components such as gearbox, motor, clutch. Rather, they merge here in the sign of Drive technology 4.0 or Industrial 4.0 increasingly the technical disciplines. Due to the growing integration, networking and autonomy of modern drive technology and its machines, developers focus on their reliability and efficiency.

The following new products are for special industries like the Automotive industry, Renewable energies, Technical Building Services, Medical Technology, food technology, Microsystems Technology, Mobile Machinery has been developed. You will also find new drive technology from the applied research.

Drive technology plays an important role in machine and plant engineering in the context of factory automation in the context of Industry 4.0. Preventive Maintenance (preventive maintenance), Predictive Maintenance (predictive maintenance) or Condition monitoring (Machine condition monitoring) is integrated into countless mechanical and electrical applications. Sensors, encoder and communication technology have found their way into engines, transmissions, Rolling and even clutch or brake.

Discover the latest developments from Tsubaki in the world of Drive and conveyor chains. This article provides information about innovative new products, shows their efficiency using user examples from the wood industry and automotive engineering, and presents you with exclusive service offers. Learn how to be eco-friendly roller chains Optimize your production processes in every industry and so on Reduce TCO costs.

A manufacturer of insulating fiberglass wool found out that premature wear of the components installed in a conveyor system conveyor chain was responsible for the declining product quality. He replaced the chain with a premium chain from the leading manufacturer of drive technology products Tsubaki. This not only solved the quality problems, but also tripled the service life of the system.

When it comes to the lack of service life, excessive wear and unreliability of drive chains, it is advisable to think outside the box and ask an alternative provider. In the present case, a Dutch one could Steel mill thereby increasing the productivity of its heat treatment in the long term. How? By him Tsukaki its failure-prone drive chains High-tech lifting chain with a service life of up to 15 years.

The Timing belts is a universally applicable drive element for many industrial sectors such as automotive, packaging technology, mechanical engineering, tool making, printing technology, textile engineering. The latest new development is the Breco timing belt from Mulco, which comes with a new coating material can handle extremely hot temperatures. Details about this and other innovations can be found below in this article:

An rack walks in Rack drive rotating movements into linear ones. It is suitable for applications in automation technology, vehicle steering or is used in CNC machines. Modern racks are very precise and robust against environmental influences. We have a few for you below New Products for your convenience.

While machine parts must be protected against contamination and the influence of aggressive media, care must be taken that e.g. B. the worker is not injured on rotating parts such as shafts or spindles. This is done through appropriate protective measures such as bellows. For special applications, Steinbock is now presenting a bellows with Velcro or zip.

While machine parts must be protected against contamination and the influence of aggressive media, care must be taken that e.g. B. the worker is not injured on rotating parts such as shafts or spindles. This is done through appropriate protective measures such as bellows. For special applications, Steinbock is now presenting a bellows with Velcro or zip.

A pair of worm gear is characterized by its ability to achieve high torque transmission in a compact design. It finds Application in elevators, conveyor systems or in automation technology where low-noise operation and self-locking are required. Modern worm gears are efficient, durable and optimized for precise control tasks. In this article you will discover some of these gearboxes from various manufacturers.

roller chains are in their function as Drive chain or conveyor chain in industry often as machine element perceived as a means to an end, while the more complex components surrounding them receive greater attention. And so designers often use cost-effective standard solutions and don't even question them custom Development. Find out about Tsubaki, as Find the optimal chain for your specific requirements.

Discover the Electromagnetic brake, their functionality and areas of application. As precise Spring pressure brake or efficient Permanent magnet brake They are essential for control and safety in automated and manual drive systems. Learn how these innovative braking systems improve performance and ensure reliable operation.

The key points of tomorrow's machine maintenance are permanent inspection, needs-based maintenance - planned and appropriate to the workload, automated remote maintenance or error analysis across machines and plants. Mayr Antriebstechnik offers solution concepts in the area based on permanent inspection clutches and brakes for Condition monitoring and predictive maintenance. We present the new developments to you in this article:

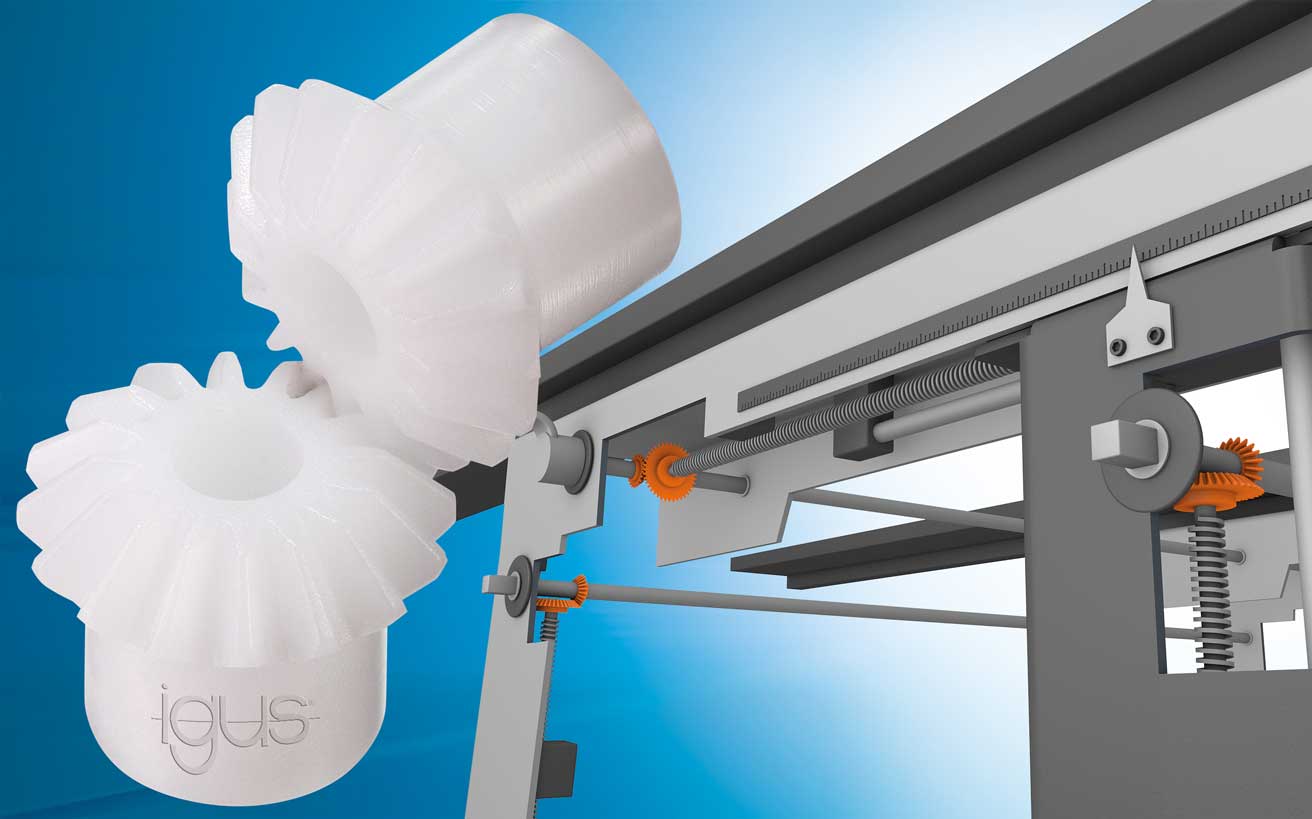

Plastic Gears from Igus ensure lubricant-free power transmission in countless applications. Because of its special material Composition of base polymers, fibers, fillers and solid lubricants is a Gear Made of Iglidur high-performance polymers, highly wear-resistant. Below we present the New developments before: