Gear | Types, manufacturer, configurator

- Details

- Hits: 6446

Gears play a central role in Industrial driven, which are used in a variety of machines and systems. Such a Gear must withstand extreme stress, is typically corrosion resistant, and is often designed to be self-lubricating for longer life and reduced maintenance. Find out about new developments and basic knowledge in this article.

Contents

- Gears 2024 – The most important things in brief

- Gears – The new products

- New manufacturing technologies improve crown gear production

- Gear calculation online – super easy!

- Configurator for ultra-robust plastic gears

- Plastic bevel gear as a maintenance-free alternative to metal gearwheels

- Polymer gear: printed, milled or injected

- Webinar on gear life calculation

- The easy alternative: toothed parts made of plastic

Gears 2024 – The most important things in brief

The development in gear technology is continuously striving for higher levels Efficiency and lower emissions by using advanced materials such as titanium alloys and composites as well as more precise manufacturing processes. These trends ensure the reliability and cost-effectiveness of industrial transmissions in an increasingly automated future.

Types of gears

Depending on the type of gearbox, there are different types of gears. Here are the most important ones:

- Elipse wheels have a special shape and are typically spur gears. They have involute-shaped teeth and are used to achieve an uneven translation.

- Internally toothed wheels engage an external gear with the teeth facing inward, which is often in planetary gears occurs.

- Bevel gears transmit force between intersecting axes and have a conical shape.

- Face gears is a special type of bevel gear that has a cylindrical shape with radially aligned teeth and is often used in differential gears.

- worm gears consist of a worm and a worm wheel that transmit torque between non-parallel, crossing axes.

- spur gears have parallel axes with straight or oblique teeth and are the most common shape for simple power transmission.

- Racks are linear "gears" that interact with a pinion to convert rotating motion into linear.

Classification of gear transmissions

Gear transmissions can be classified according to various criteria:

- After Axis position of the gears:

- Parallel axis gearbox (helical gearbox)

- Cross-axis gearbox (bevel gearbox)

- Screw axis gear (worm gear)

- After Type of gearing:

- Straight gearing

- Helical gearing

- herringbone teeth

- Circular toothing

- After Shape:

- Single-stage and multi-stage gearboxes

- planetary gear

- Compact transmission

Gears – The new products

Below we will introduce you to the new developments from various manufacturers relating to gears:

New manufacturing technologies improve crown gear production

April 14.04.2024, XNUMX | In the past, bevel gears had the edge due to their manufacturing advantages. Has now Welter has further developed its production processes for crown gears and can now replicate them DIN 3967 in quality 5 produce. Through the use of modern technologies and optimization of manufacturing processes, crown gears are now available for a wider range of applications. These gears are very flexible with axis angles from 0 to 150 degrees. They enable the pinion to be moved axially, which ensures easy assembly and a consistent contact pattern under load.

The advantages of this innovation include one high efficiency, comparable to spur gears, temperature insensitivity and minimal axial forces with straight-toothed pinions. Separate manufacturing of the crown gear and pinion eliminates the need for mating. A longer service life and wear-free use, gear ratios up to i = 20, easily adjustable triple sets and an arrangement with axis offset are also possible.

All Areas of application These include drives for passenger transport systems, roller adjustment in construction machinery, rear axle drives in vehicles, swivel devices on operating tables, angle milling heads and driven tool systems.

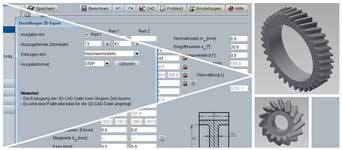

Gear calculation online – super easy!

11.01.2022 | GWJ Technology offers software for the Gearcalculation in Transmission and mechanical engineering. The calculation professional from Braunschweig supports design and development engineers in their daily work. Here you will find further developments of the web-based calculation software eAssistant and the transmission software TBK.

11.01.2022 | GWJ Technology offers software for the Gearcalculation in Transmission and mechanical engineering. The calculation professional from Braunschweig supports design and development engineers in their daily work. Here you will find further developments of the web-based calculation software eAssistant and the transmission software TBK.

Configurator for ultra-robust plastic gears

Oct 17.10.2021, XNUMX | With the new Igus configurator Gears can now be configured online in just 1 minute and ordered directly from the online shop. The gears are printed in the 3D printing service from Iglidur I6 using the SLS process. The high-performance plastic specially developed for gears beats milled gears made of common materials such as POM and PBT in the test.

Oct 17.10.2021, XNUMX | With the new Igus configurator Gears can now be configured online in just 1 minute and ordered directly from the online shop. The gears are printed in the 3D printing service from Iglidur I6 using the SLS process. The high-performance plastic specially developed for gears beats milled gears made of common materials such as POM and PBT in the test.

Plastic bevel gear as a maintenance-free alternative to metal gearwheels

05.10.2021 | For the lubricant-free Power Type presented around the corner Igus its bevel gear portfolio made from two abrasion-resistant and durable high-performance plastics. This gives users a cost-effective and maintenance-free alternative to metal gears for transmitting forces at an angle of 90 degrees.

05.10.2021 | For the lubricant-free Power Type presented around the corner Igus its bevel gear portfolio made from two abrasion-resistant and durable high-performance plastics. This gives users a cost-effective and maintenance-free alternative to metal gears for transmitting forces at an angle of 90 degrees.

Polymer gear: printed, milled or injected

March 04.03.2021, XNUMX | A plastic gear ensures the power transmission in countless devices, from the fully automatic coffee machine to the actuator. So far has Igus such a gear portfolio is mechanically machined from a semi-finished product or in the 3D pressure manufactured. The Motion Plastics specialist now also offers injection molding especially for the production of wear-resistant and long-lasting gears in large series.

March 04.03.2021, XNUMX | A plastic gear ensures the power transmission in countless devices, from the fully automatic coffee machine to the actuator. So far has Igus such a gear portfolio is mechanically machined from a semi-finished product or in the 3D pressure manufactured. The Motion Plastics specialist now also offers injection molding especially for the production of wear-resistant and long-lasting gears in large series.

Webinar on gear life calculation

31.08.2020/XNUMX/XNUMX | A gear wheel made of tribo plastics offers numerous advantages: In contrast to Metal Gear is light, quiet, self-lubricating and low-maintenance. But the question that arises here is what loads a plastic gear can withstand over what period of time? The answers to that are there Tom Krause, Head of Additive Manufacturing at Igus.

31.08.2020/XNUMX/XNUMX | A gear wheel made of tribo plastics offers numerous advantages: In contrast to Metal Gear is light, quiet, self-lubricating and low-maintenance. But the question that arises here is what loads a plastic gear can withstand over what period of time? The answers to that are there Tom Krause, Head of Additive Manufacturing at Igus.

The easy alternative: toothed parts made of plastic

February 14.02.2019, XNUMX | Low weight, corrosion resistance, smooth running, minimal maintenance thanks to self-lubrication and, last but not least, a good price-performance ratio: plastic gears offer numerous advantages compared to steel models. Norelem has now added numerous versions to its range, which can be used in various industrial areas thanks to the high-performance materials used.

February 14.02.2019, XNUMX | Low weight, corrosion resistance, smooth running, minimal maintenance thanks to self-lubrication and, last but not least, a good price-performance ratio: plastic gears offer numerous advantages compared to steel models. Norelem has now added numerous versions to its range, which can be used in various industrial areas thanks to the high-performance materials used.

The drive elements can reliably take on power transmission and positioning tasks in mechanical engineering and automation technology. This ensures spur gears a positive and slip-free transmission of forces with changing directions of rotation, for example for raising and lowering machine elements or loads. Straight-cut plastic spur gears with 12 to 150 teeth are available in modules 0,5 to 3.

The combination of rack and spur gear converts rotary movements into linear movements or vice versa. The range includes plastic models in modules 0,5 to 3 with a standard length of 250 mm.

Plastic-Bevel gears in modules 1 to 3,5 are available with ratios from 1:1 to 1:5 as a standard version. The gear size is given in module m (tooth center to tooth center / π). They are primarily required for the construction of angular gears, which in turn are in demand in applications with high reductions and torques as well as fast movements.

All gear parts are available in versions made from the standard material polyacetal and the premium material Polyketone available. While polyacetal guarantees high hardness and a low coefficient of friction, polyketone offers a significantly longer service life and optimal power transmission. The susceptibility to tooth fracture is also significantly reduced. This is ensured by the exceptionally high abrasion resistance and the very good tribological properties of this material.

Under normal conditions both plastics can be used in a temperature range from -40 ° to + 140 ° C.

Source: This article is based on information from the following companies: GWJ, Igus, Norelem, Welter.

You might also be interested in...

Sustainability plastics – CO2 neutral with recycling

Igus linear guide quiet, resistant, maintenance-free

Electrical Wires | From cable to assembly

Cobot | Discover collaborative robots as a new employee

Igus energy chain: stable, recyclable, plastic.

linear guide | Precise, light, durable

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.