for the drive train

Planetary gears, spur gears or heavy-duty gears, low backlash and networkable for mechanical engineering

Image: Schaeffler

for the drive train

Planetary gears, spur gears or heavy-duty gears, low backlash and networkable for mechanical engineering

Image: Schaeffler

Table of Contents

This is a construction site. We optimize for you!

Find the latest here Transmission for mechanical engineering and special industries, including planetary gear, spur gears or heavy duty gears, low backlash and networkable for the smart Powertrain in future-proof machines - with many features.

coming soon...

With a gear you can Translations or change movement sizes. The transmission is driven by a motor. There are mechanical gears and fluid drives. You can find the latter in our section Hydraulic System. A gear sits between the Motor and the one to be driven machine element. The drive elements are often connected via Couplings. There are the following types of gears: gear gears, cam gears, crank gears, roller gears, screw gears. The translation can take place in stages or continuously. Then there are electric transmissions, which we will not go into here.

coming soon

The compact design, the low-noise operation, the possibility of high torquee to transfer, energy efficiency with high efficiencies and much more planetary gear out. Due to their high torsional rigidity, the arrangement of the Gears also for very good stability. Here we present new developments for industrial applications such as the smooth-running rotary gearboxes from Reccon or the industry 4.0 capable transmission von Wittenstein and various applications.

An worm gear is characterized by its ability to achieve high torque transmission in a compact design. It finds Application in elevators, conveyor systems or in automation technology where low-noise operation and self-locking are required. Modern worm gears are efficient, durable and optimized for precise control tasks. In this article you will discover some of these gearboxes from various manufacturers.

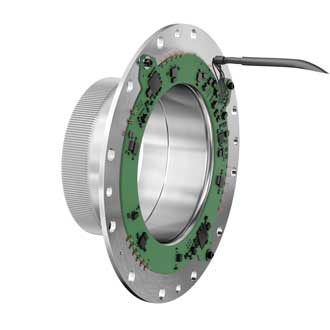

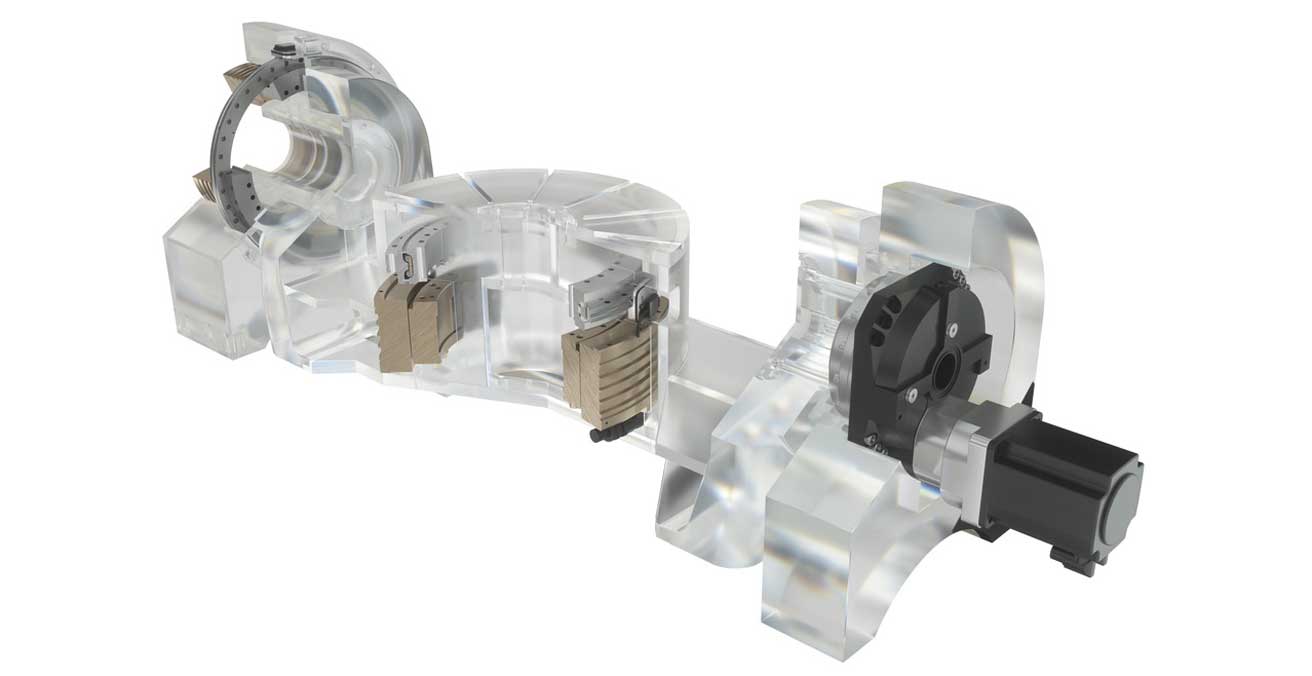

Wave gears are suitable for applications that require precise positioning and high repeatability. The Schaeffler Group puts on the Hannover Messe equal three new precision wave gears before: for Cobots, Industrial robots and torque applications. The kit for fully integrated Tribo strain wave gear from Igus has everything a Cobot needed to accelerate low-cost automation.

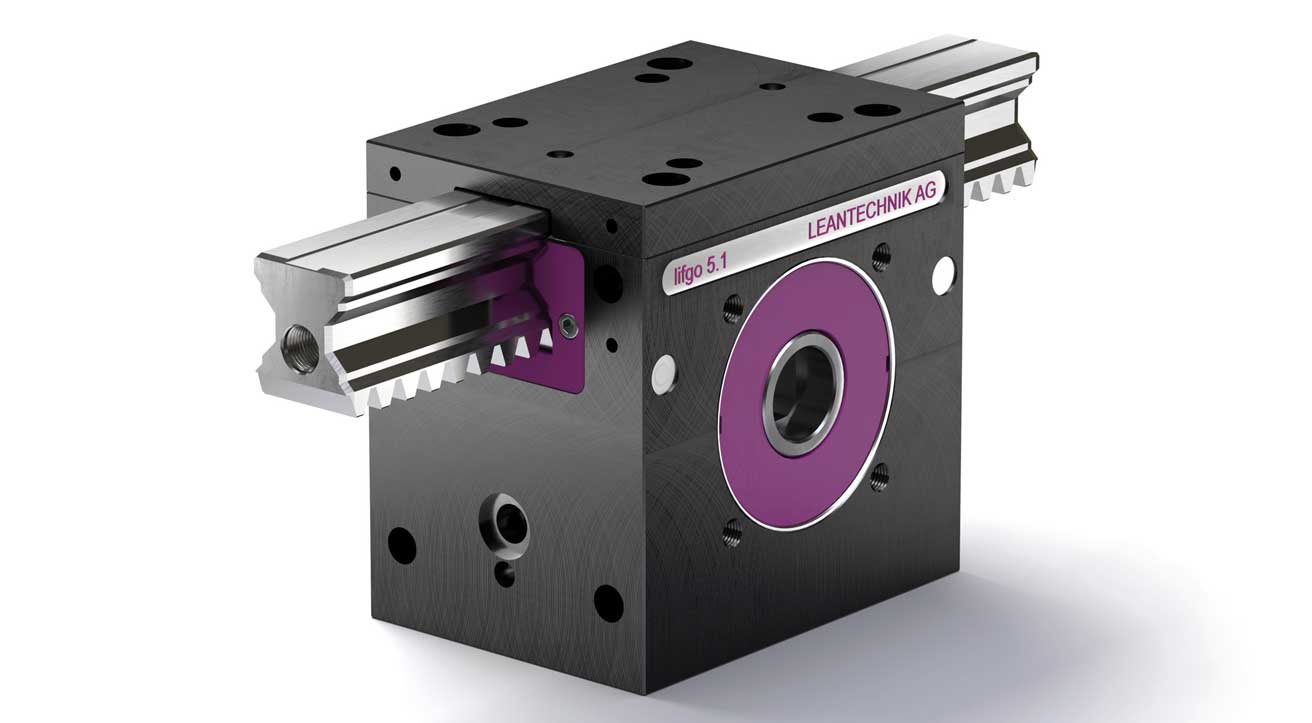

Systems for positioning tasks in mechanical engineering and in the Food industry defy harsh environmental conditions. Such extremely high loads hold the Rack gear from Leantechnik stood easily. Such a rack and pinion drive is available in numerous lifting systems, handling components and positioning systems in use worldwide. The following product information is dedicated to the new developments.

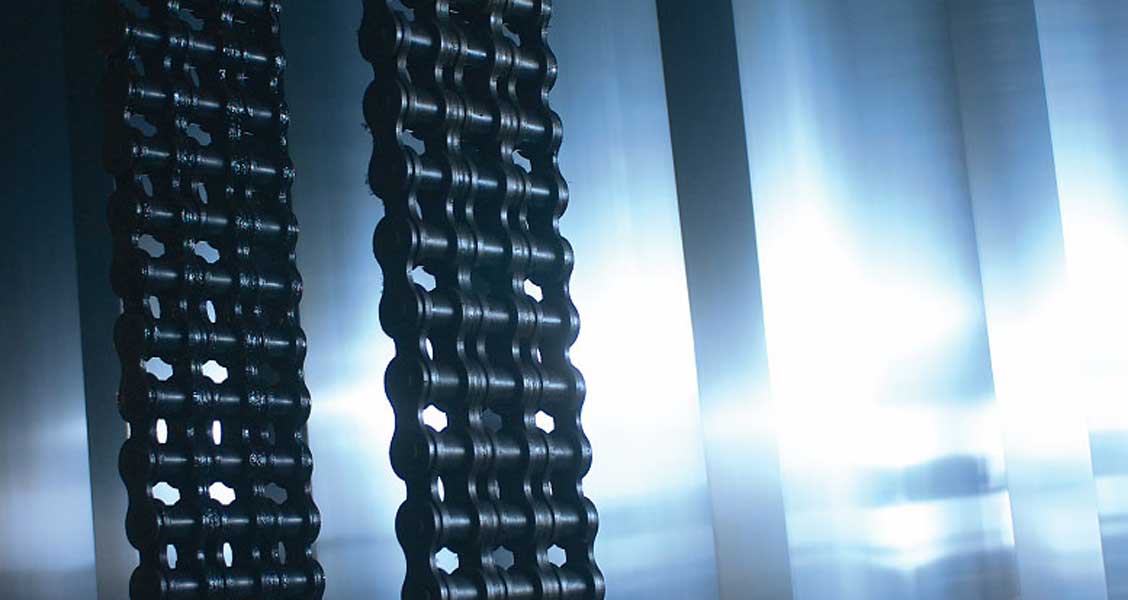

A manufacturer of insulating glass fiber wool found out that premature wear of the chain installed in a conveyor system was responsible for the deteriorating product quality. He replaced the chain with a premium chain from the leading manufacturer of drive technology products, Tsubaki. This not only solved the quality problems, but also tripled the service life of the system.

A manufacturer of insulating glass fiber wool found out that premature wear of the chain installed in a conveyor system was responsible for the deteriorating product quality. He replaced the chain with a premium chain from the leading manufacturer of drive technology products, Tsubaki. This not only solved the quality problems, but also tripled the service life of the system.

When it comes to a lack of service life, excessive wear and tear and unreliability of drive chains, it is advisable to think outside the box and ask an alternative supplier. In the present case, a Dutch steel mill was able to increase the productivity of its heat treatment in the long term. How? Because Tsubkaki has replaced his failure-prone lifting chains with high-tech chains with a service life of up to 15 years.

An worm gear is characterized by its ability to achieve high torque transmission in a compact design. It finds Application in elevators, conveyor systems or in automation technology where low-noise operation and self-locking are required. Modern worm gears are efficient, durable and optimized for precise control tasks. In this article you will discover some of these gearboxes from various manufacturers.

Discover the latest developments from Tsubaki in the world of Drive and conveyor chains. This article introduces you to innovative new products, shows their efficiency using user examples from the wood industry and automotive engineering, and introduces you to exclusive service offers. Learn how to be eco-friendly roller chains Optimize your production processes in every industry and so on Reduce TCO costs.

roller chains are in their function as Drive chain or conveyor chain in industry often as machine element perceived as a means to an end, while the more complex components surrounding them receive greater attention. And so designers often use cost-effective standard solutions and don't even question them custom Development. Find out about Tsubaki, as Find the optimal chain for your specific requirements.

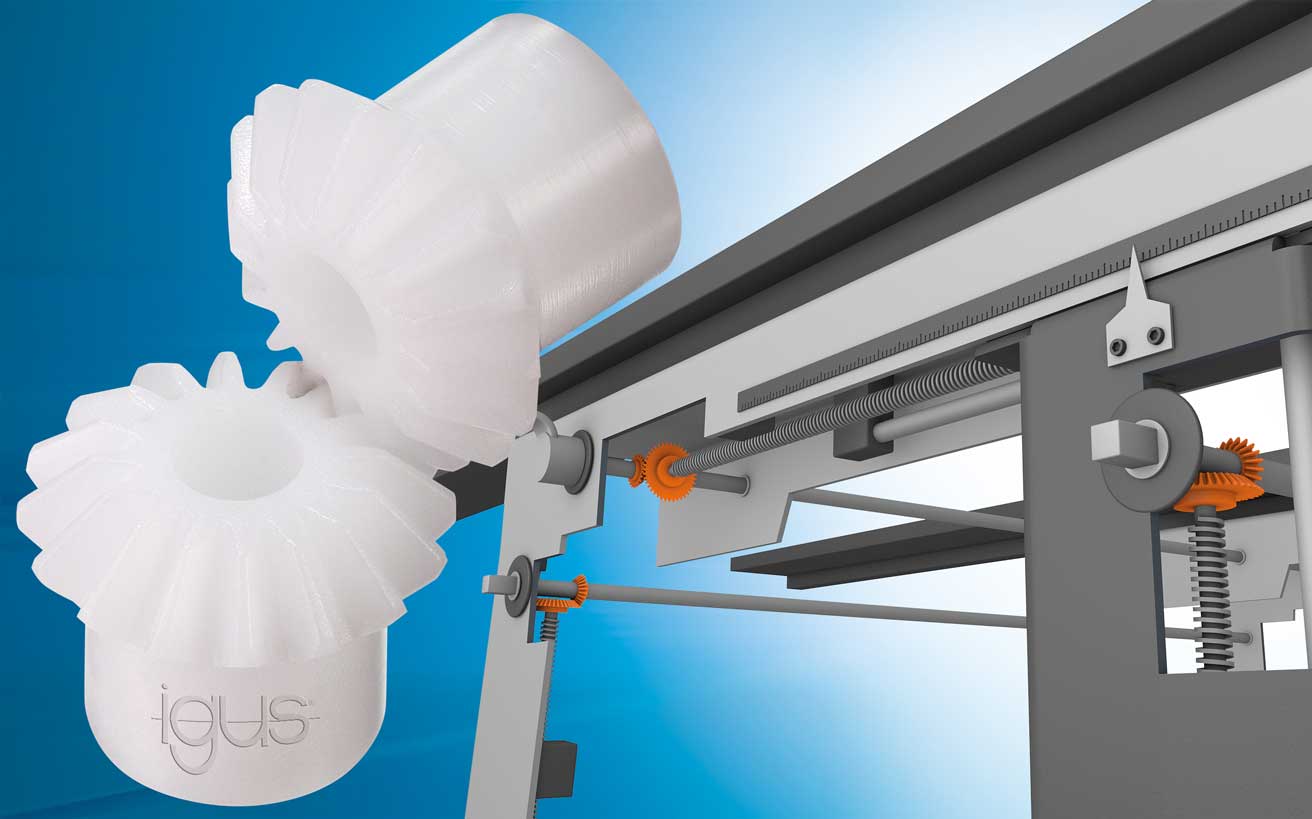

Plastic Gears from Igus ensure lubricant-free power transmission in countless applications. Because of its special material Composition of base polymers, fibers, fillers and solid lubricants is a Gear Made of Iglidur high-performance polymers, highly wear-resistant. Below we present the New developments before:

Systems for positioning tasks in mechanical engineering and in the Food industry defy harsh environmental conditions. Such extremely high loads hold the Rack gear from Leantechnik stood easily. Such a rack and pinion drive is available in numerous lifting systems, handling components and positioning systems in use worldwide. The following product information is dedicated to the new developments.

An rack walks in Rack drive rotating movements into linear ones. It is suitable for applications in automation technology, vehicle steering or is used in CNC machines. Modern racks are very precise and robust against environmental influences. We have a few for you below New Products for your convenience.

The compact design, the low-noise operation, the possibility of high torquee transferred to, the energy efficiency with high efficiencies and much more characterize the planetary gear out. Due to their high torsional rigidity, the arrangement of the Gears also for very good stability. Here we present new developments for industrial applications such as the smooth-running rotary gearboxes from Reccon or the industry 4.0 capable transmission von Wittenstein and various applications.

Precision gears have a significant influence on the dynamics, positioning and repeat accuracy or the service life of a construction. Schaeffler effect in the young company Ultra Precision Drives Two types of transmission have been developed that exceed the current state of the art: the Strain wave gear Series RT and the planetary gear of the PSC series. Learn how to use your Robotic-Take application to a new level.

Gears play a central role in Industrial driven, which are used in a variety of machines and systems. Such a Gear must withstand extreme stress, is typically corrosion resistant, and is often designed to be self-lubricating for longer life and reduced maintenance. Find out about new developments and basic knowledge in this article.

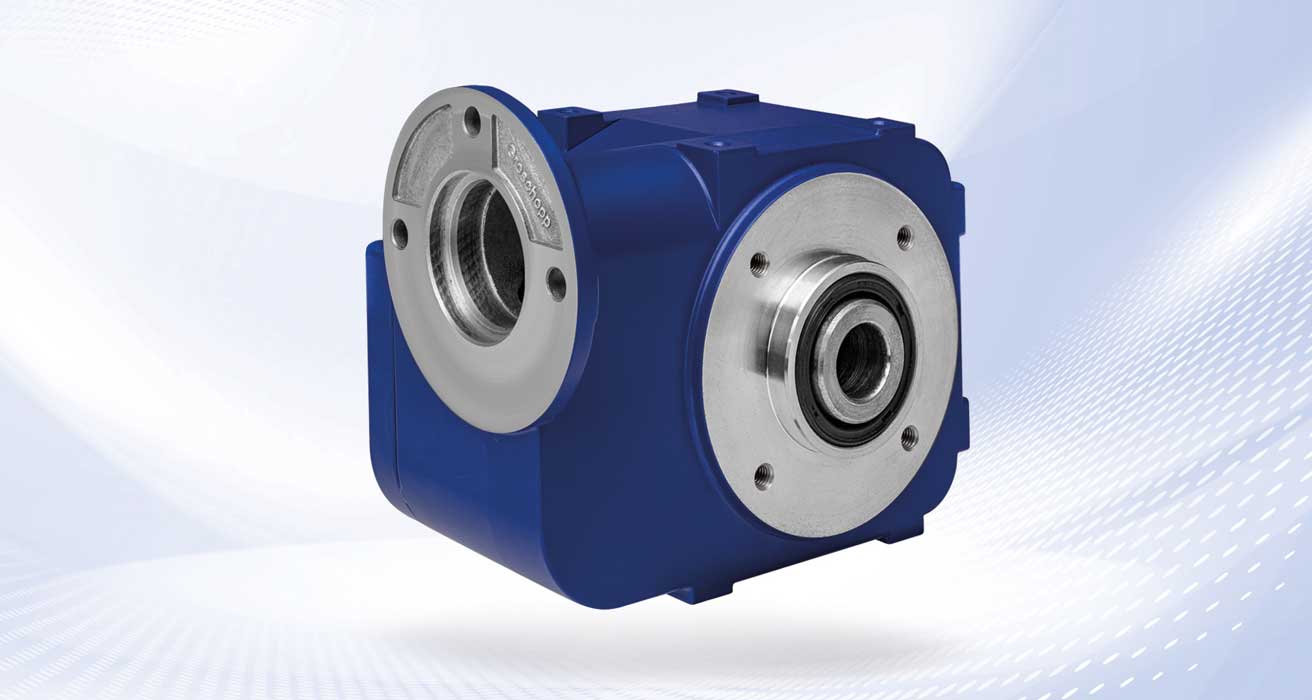

ABM Greiffenberger presents ABM angular gearboxes suitable for intralogistics, which are available in 2- and 3-stage versions. They offer a high efficiency of over 90% and are therefore significantly more efficient than worm gear with an efficiency of only 40 to 70%.

ABM Greiffenberger presents ABM angular gearboxes suitable for intralogistics, which are available in 2- and 3-stage versions. They offer a high efficiency of over 90% and are therefore significantly more efficient than worm gear with an efficiency of only 40 to 70%.