Hydrogen + fuel cell: components for energy generation

- Details

- Hits: 5890

The future of energy supply lies in Renewable energies. The Technologies Hydrogen fuel cells or electrolysers are promising candidates for the energy carriers of the future, if they are "green". The automation expert Pepperl + Fuchs offers products for the entire hydrogen value chain on the basis of its extensive and many years of know-how. Find out below where we stand with green hydrogen and which products are driving development forward.

Contents

- Housing for measurement technology in hydrogen production

- Hydrogen as a crisis rescuer

- Energy supply in transition

- Green hydrogen is the joker

- Sensor technology for the hydrogen value chain

- FAQ

Housing for measurement technology in hydrogen production

Oct 11.10.2013, XNUMX | The comprehensive one energetic transformation places increased demands on everyone involved in the production chain - from green electricity to hydrogen production to the production of various derivatives, including all transport steps between the stations.

Oct 11.10.2013, XNUMX | The comprehensive one energetic transformation places increased demands on everyone involved in the production chain - from green electricity to hydrogen production to the production of various derivatives, including all transport steps between the stations.

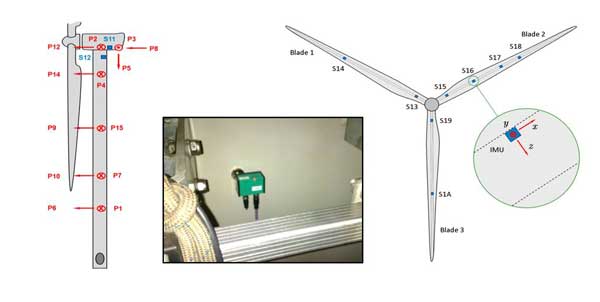

Wind turbines and wind farms are expected to have better functions that serve the grid. To do this, the controls require data, which in turn is provided by sensors from Pepperl+Fuchs. The sensors can detect the positions of Leaf and gondola as well as precisely detect speeds and vibrations.

If hydrogen is produced from renewable electricity using electrolysers, the pressure must be adapted to the various further transport and processing steps. This also raises questions about the explosion protection .

Pepperl+Fuchs offers a special one for this explosion protection Housing technology for corresponding Ex zones and switch cabinet-Modules for signal separation and further processing.

These are used in pressure measuring and pressure control systems. Special solutions in the “Purge” area are also offered. These allow the use of non-explosion-proof measuring devices. Last but not least, explosion-proof ones make it easier Tablets and smartphones can communication technology in potentially explosive areas.

Hydrogen as a crisis rescuer

More than a year ago, hydrogen (H 2) was still considered a crucial component in the Decarbonization of industry and transport. But now we are not only struggling with the climate crisis, but also with an energy crisis that could drive the expansion of green hydrogen as an energy source for electrical energy to ensure electricity and heat requirements. The problem here lies less in the concepts and the technical know-how, but above all in the timely implementation.

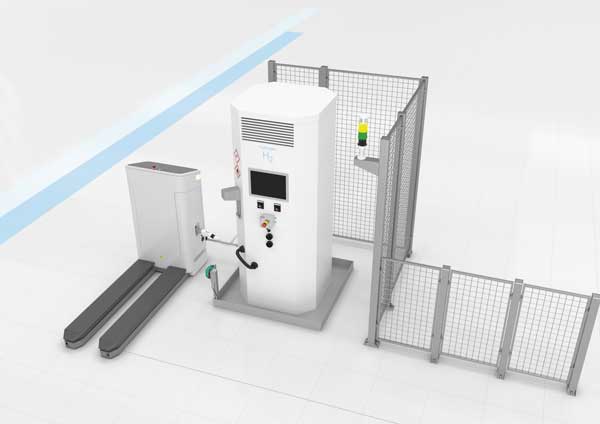

IO module secures Resato hydrogen filling stations

IO module secures Resato hydrogen filling stations

Major hydrogen projects have already been announced around the world, from Canada to Germany to Japan. But um Green hydrogen To generate electricity, we must first expand renewable energy generation. Offshore wind turbines play a crucial role here by supplying the required green electricity.

Green Hydrogen - Opportunity or Risk for Factory Automation Engineers?

09.02.2023 | With the clearly predicted strong growth in the field of wind power over the next 20 years, there are excellent opportunities for sensor manufacturers and factory automation companies. These are exponentiated by the fact that the same applies to storage, transport and the manufacture of all these systems. Wolfgang Weber, Global Industry Manager at Pepperl+Fuchs, speaks on the subject in the following video at the trade press days of the RBS Stutensee in Karlsruhe.

Energy supply in transition

The supply of electrical energy is facing a fundamental upheaval, in which all known processes are being put to the test. The Atomic Energy, which promised unrestricted availability in the 60s and 70s, fell into disrepute for various reasons and is now only being considered in a few countries.

The way food is Hydropower can only be expanded to a limited extent, as it has an immense impact on the landscape and has consequences for flora and fauna. Biomass, on the other hand, is highly controversial because it competes with food production and also has its limitations.

Basic considerations on the energy transition

so far were fossil substances such as oil, natural gas and coal are the preferred energy sources. Contrary to earlier forecasts, however, they are still available in almost unlimited quantities, are inexpensive and there are many possible uses for fossil fuels. They not only serve to generate energy, but also as basic materials for chemistry, pharmacy and many other areas.

so far were fossil substances such as oil, natural gas and coal are the preferred energy sources. Contrary to earlier forecasts, however, they are still available in almost unlimited quantities, are inexpensive and there are many possible uses for fossil fuels. They not only serve to generate energy, but also as basic materials for chemistry, pharmacy and many other areas.

In the last two decades, two representatives of renewable energies have particularly distinguished themselves in the field of power generation. This is what you think of first wind and Sun, since these sources of energy are apparently available free of charge.

In Germany we assume that the Powerrequirements will double in the next 20 years. At the moment, however, we only cover just under half of our current electricity requirements from regenerative sources. So we need to quadruple the generation of electricity. Indeed, amazing developments have taken place during this period – both in terms of scale and cost. Wind turbines with a capacity of up to 18 MW per unit are installed offshore today, which was unthinkable in the 1980s. The idea that photovoltaic systems in sunny areas would generate electricity at a cost of less than 1 cent per kWh was considered utopian at best.

Problem solved? Not at all!

Does this mean that all problems are solved? Not at all, because fundamental challenges were unfortunately negligently underestimated for a long time. Germany is one of the countries that can have reliable power supply at all times. This is by no means a matter of course, not even in highly developed countries.

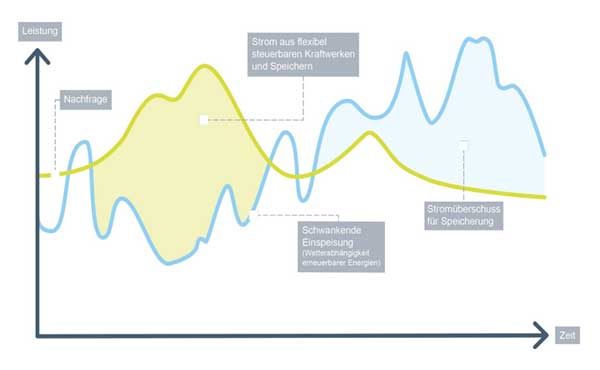

When planning the power supply system, it was always about being able to cover the absolute peak demand in any case, even if it only occurs for one hour a year. The stylized graphic (right) illustrates the problem. Wind and sun provide either too much or too little energy. Both cause problems because either power has to be curtailed or reserve power plants have to provide energy. However, both scenarios are uneconomical. The goal must therefore be to minimize the two situations as much as possible.

When planning the power supply system, it was always about being able to cover the absolute peak demand in any case, even if it only occurs for one hour a year. The stylized graphic (right) illustrates the problem. Wind and sun provide either too much or too little energy. Both cause problems because either power has to be curtailed or reserve power plants have to provide energy. However, both scenarios are uneconomical. The goal must therefore be to minimize the two situations as much as possible.

The Power generation depends not only on the temporal, but also on the spatial requirements. It therefore made sense to build large power plants near large consumers such as populous metropolises or industrial sites.

With the energy sources sun and wind, however, these requirements are no longer met. The positioning of wind turbines depends on the available space and the wind supply. The installation of PV modules on the other hand, is heavily dependent on the individual investment willingness of private individuals. The power generation of these plants is in turn subject to weather conditions.

For many years, Germany afforded itself the luxury of a double energy supply in order to compensate for the problems described. Even if it is claimed that we already 46% of our electricity generated regeneratively, on certain days of the year this share is hardly more than 20%. The more we reduce conventional power plants, the more we get into a situation that can no longer be controlled.

Saving energy as a challenge

In order to balance the relationship between supply and demand, it is necessary to take measures both in the short term and seasonally. It is obvious that more energy is needed in winter than in summer. Therefore, a solution must be found that can store energy for any length of time, transport it easily and use it in a variety of ways, including the ability to reconversion. As a supplier of electronic components and Sensors Pepperl+Fuchs is initially interested in controlling such processes. The point is that wind turbines increasingly have to take over grid-related functions and be able to react to grid requirements.

Reading tip: Measurement technology for hydrogen production

Reading tip: Measurement technology for hydrogen production

Let's consider Germany as a reference, where around 20% of the country's total energy needs are met by electricity, while the vast majority is mainly supplied by oil, gas and coal. These include the transport sector, the heating market and industry, especially in the steel, chemical, cement, glass and other sectors. While there are certainly ways to "electrify" some portion of it, time will tell to what extent this is possible. Because it ultimately depends on the cost and availability.

Green hydrogen is the joker

Hydrogen is the wild card in this game, that rules these days worldwide consensus. As a storage medium, hydrogen can compensate for the irregular fluctuations in wind and solar energy and, as a basic material with its well-known derivatives, can replace fossil fuels in all applications.

The hydrogen used today is made from gas with the release of CO2 won. If you think of the procedure of Carbon capture and storage (CCS) as an alternative, then so-called green hydrogen is the method of choice.

The hydrogen used today is made from gas with the release of CO2 won. If you think of the procedure of Carbon capture and storage (CCS) as an alternative, then so-called green hydrogen is the method of choice.

In order for hydrogen to replace fossil fuels in practice in the future, further detailed steps are required and enormous amounts of green hydrogen are required. Hydrogen is through a electrolytic fission generated from water using electricity, whereby water is split into hydrogen and oxygen. This process takes place in an electrolyser, while the reversal occurs in the fuel cell. There, hydrogen is used as a fuel and, in combination with oxygen, electricity is generated. The "waste product" is water.

The raw material water is practically unlimited available on our planet in the form of the seas. However, electricity must be generated to produce the hydrogen. If this succeeds in a climate-neutral manner, the transformation of our energy supply can help to balance between CO2-Restore generation and absorption and halt further warming of the atmosphere.

Sensor technology for the hydrogen value chain

The first element of the periodic table is a key factor in the Decarbonization of economy and transport, but only with green hydrogen, for which the gas without CO2 output was obtained. The value chain from the wind turbine to the hydrogen filling station is full of technical challenges.

Above all, the desired decarbonization will change the way in which we generate, store, distribute and consume energy. The Green Hydrogen becomes one key role in future power generation and decarbonization of industry and heavy-duty transport. Many Sensors various functions as well as explosion-proof components are required to secure the automated processes.

Pepperl+Fuchs has many years of experience in the field of explosion protection and industrial sensors. As an expert in functional safety that supplies compatible components along the hydrogen value chain, the company is the right partner and a connecting element in the hydrogen chain - from regenerative energy production, high-pressure compression after electrolysis, transport, storage to large-scale industrial use and hydrogen gas station. Below we present a few products and applications:

Ultrasonic sensors for the production of bipolar plates

04.07.2023 | In the near future, the operational capability and the price of hydrogen and its derivatives are largely dependent on availability. The price of electricity during production and the acquisition costs of the systems play a decisive role in this.

04.07.2023 | In the near future, the operational capability and the price of hydrogen and its derivatives are largely dependent on availability. The price of electricity during production and the acquisition costs of the systems play a decisive role in this.

Although electrolysers and fuel cells are technologically similar, they have different areas of application. Electrolysers are unique in producing green hydrogen, while fuel cells compete with other processes. In particular, hydrogen cars score points in heavy-duty transport compared to car's battery performancepowered electric motors, but also the alternative to e-mobility is still being discussed.

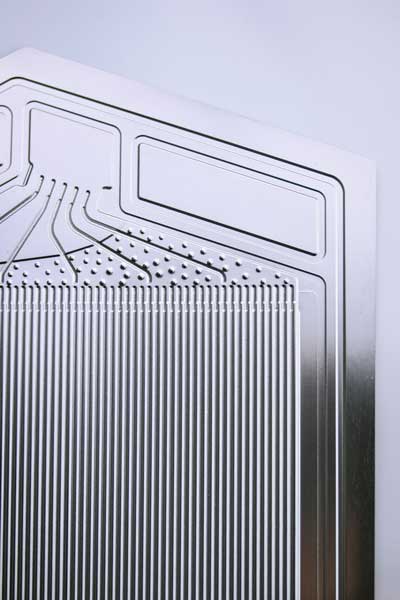

In both cases, however, the production quantities to increase significantly in order to cover the growing demand and to reduce costs in the long term. The industrialization and Automation production plays a central role. Key components are the bipolar plates (BPP) and the membrane electrode assembly (MEA). The MEA can be fabricated in 3-, 5- and 7-layer configurations and requires the application of catalytic layers for electrolytic processes.

Research project reference factory H2

The Fraunhofer-Institute for machine tools and forming technology IWU The reference factory H2 project has started in Chemnitz, which focuses on optimizing the production of these components. They examine, test and optimize processes from the production of the bipolar plates and the function of seals to the assembly of the entire stack.

The Fraunhofer-Institute for machine tools and forming technology IWU The reference factory H2 project has started in Chemnitz, which focuses on optimizing the production of these components. They examine, test and optimize processes from the production of the bipolar plates and the function of seals to the assembly of the entire stack.

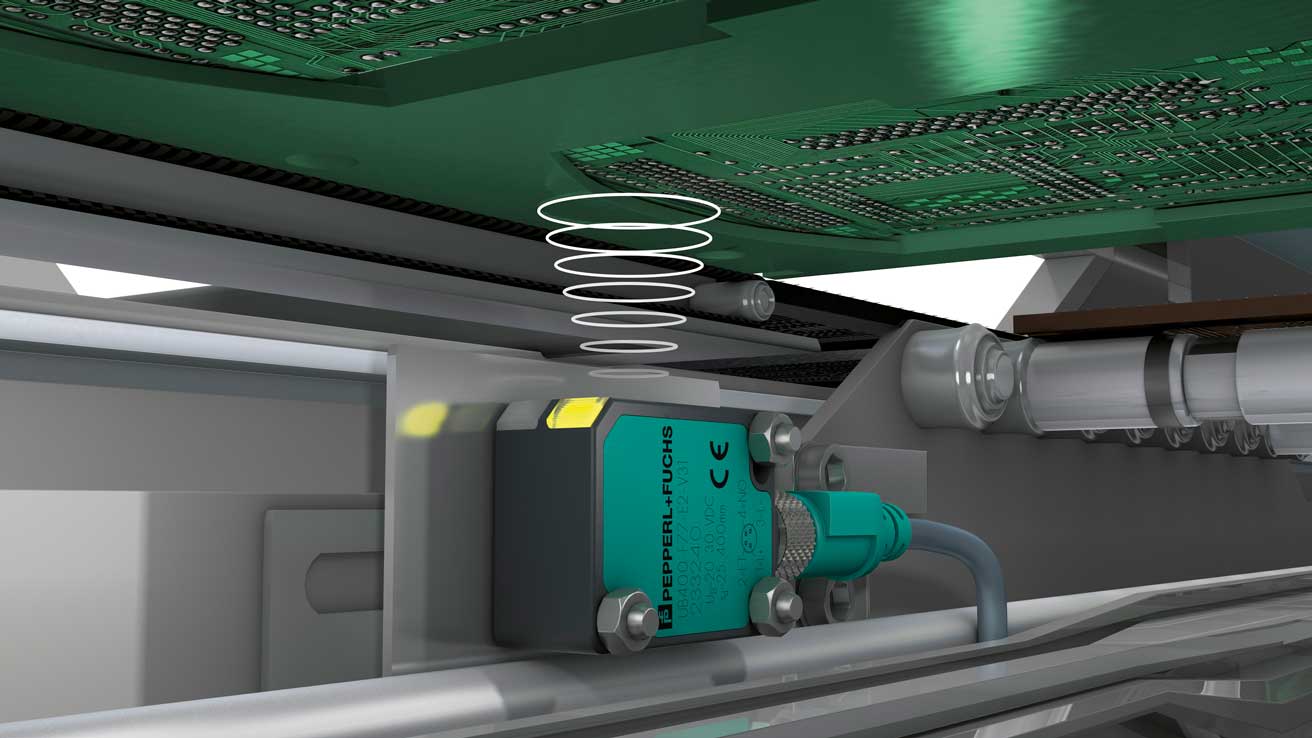

The first practical applications have shown that checking for possible double layers can be an important criterion. Ultrasonic sensors have proven to be reliable sensor technology. Ultrasonic sensors can measure precise distances in the tenths of a millimeter range and detect multiple layers and cracks.

A major advantage of ultrasound lies in its independence from material properties such as colour, surface gloss or transparency. This offers in particular metallical and translucent materials considerable advantages.

The F77sensor series from Pepperl+Fuchs enables precise height measurements in the range of 0,2 mm. With the help of the UDC double sheet controls, multiple layers can be detected by detecting boundary layers and the transition to an air gap. Furthermore, the supplied components can be easily checked for presence or position.

These advanced Ultrasonic sensors have a standardized IO-Link interface via which settings can be made and status data can be queried. With the available interface modules (master), the data can be OPC UA transferred to other units of the IT infrastructure. This means that all the requirements for an Industry 4.0-compliant architecture are met.

Components for safe green energy generation

12.09.2022/XNUMX/XNUMX | The production of green hydrogen renewable energies is therefore crucial for its industrial use.

12.09.2022/XNUMX/XNUMX | The production of green hydrogen renewable energies is therefore crucial for its industrial use.

For example, in order to use wind energy optimally, the Rotor blades have the correct angle of inclination. In strong winds, the systems must be placed in a sheltered position to avoid possible overloading. Pepperl+Fuchs supplies the required values by using encoders as well as vibration and acceleration sensors. Surge protection modules are required to Control Technology and secure signal transmission from lightning strikes.

With these measures, we can efficiently use energy generation from wind power and thus promote the production of green hydrogen. This is a crucial step in making our energy supply more sustainable and environmentally friendly.

Green electricity is converted into hydrogen, transported and temporarily stored to reach its destination. Hydrogen is transported either by gas tanker, by truck or by pipeline. Der Transport poses technical challenges due to its explosive properties. Pepperl+Fuchs offers a wide range of connection components for explosion protection. Various interface modules and terminal boxes from the SR series ensure reliable signal transmission in the gas pressure control measuring system. Series 6000 pressurized enclosure systems are used for hydrogen analysis.

Valves regulate the gas flow in the pipes and pipelines. The F31K2 inductive dual sensors, among other things, ensure safe valve position feedback in hazardous outdoor areas. The intrinsically safe mobile devices and Smart Glasses from Pepperl+Fuchs Ecom brand provide real-time information to mobile workers and plant operators during valve maintenance work.

Vibration sensor and acceleration sensor in wind turbine

02.03.2023 | Imagine that a modern Wind power plant a tower height of 130 m and the mass to be supported by the machine house and nacelle is 400 to 600 t. The different wind loads put enormous mechanical strain on the construction. Vibration sensors are installed in the tower, nacelle, rotor hub and the rotor blades deployed. Inertial measurement systems record this loads in real time.

02.03.2023 | Imagine that a modern Wind power plant a tower height of 130 m and the mass to be supported by the machine house and nacelle is 400 to 600 t. The different wind loads put enormous mechanical strain on the construction. Vibration sensors are installed in the tower, nacelle, rotor hub and the rotor blades deployed. Inertial measurement systems record this loads in real time.

FAQ

How does the fuel cell work?

A fuel cell is an energy converter that converts chemical energy directly into electrical energy. It works similarly to a battery, but is continuously supplied with fuel (e.g. hydrogen) and an oxidizer (e.g. oxygen from the air). A fuel cell uses the reaction of hydrogen and oxygen to produce electrical energy, with water being the only waste product. In short: hydrogen+oxygen=fuel cell.

How does a fuel cell make electricity?

A fuel cell generates electricity through a electrochemical reaction: At the anode (the negative pole), hydrogen is split into protons and electrons by a catalyst. The electrons flow through an external circuit to the cathode (the positive terminal), producing electric current. At the cathode, the electrons react with oxygen and the protons coming from the anode to form water. The result is the conversion of chemical energy into electrical energy.

Are hydrogen and fuel cells the same?

No, hydrogen and fuel cells are not the same thing. Hydrogen is a chemical element and a possible fuel. A fuel cell is a device that uses a fuel and an oxidizer such as oxygen to produce electrical energy. Hydrogen can be used as fuel in a fuel cell.

What are the advantages and disadvantages of a fuel cell?

Fuel cells offer efficient and low-emission energy production, but with challenges in terms of cost, infrastructure and durability.

Advantages of a fuel cell:

- low emission: When using hydrogen, a fuel cell only produces water as a waste product.

- Height Efficiency: Fuel cells can be more efficient than conventional combustion engines.

- Continuous Energy production: As long as fuel and oxidizer are supplied, the cell continuously generates electricity.

- Quieter Operation: Fuel cells operate quietly compared to combustion engines.

Disadvantages of a fuel cell:

- Costs: Current technologies are often expensive, especially when using precious metal catalysts.

- Hydrogeninfrastructure: The availability and distribution of hydrogen may be limited.

- Storage and Transport: Hydrogen requires special storage and transport conditions due to its low density and reactivity.

- Lifespan: The lifespan and longevity of some types of fuel cells may be limited.

You might also be interested in...

Industrial radar sensor with CAN interface

Artificial Intelligence | trends and developments

RFID and Barcodes | Industrial identification

RFID reader and barcode scanner for identification

battery production | Facts and Technologies

Level sensor for every level measurement

Wolfgang Weber is Global Industry Manager for Renewable Energies at Pepperl+Fuchs.