Acceleration sensor and inclination sensor for inertial measurement

- Details

- Hits: 3533

Acceleration sensors and inclination sensors of the IMU F99 series from Pepperl + Fuchs were specially developed for dynamic applications such as those in the Wind power or at Construction are to be found. Both inertial measuring systems offer a 360 degree measurement in three axes. Read how one Accelerometer in a wind turbine and a Inclinometer demonstrate their advantages in the excavator:

Contents

- Vibration sensor and acceleration sensor in wind turbine

- Dynamic inclination sensor with unique angular stability

Vibration sensor and acceleration sensor in wind turbine

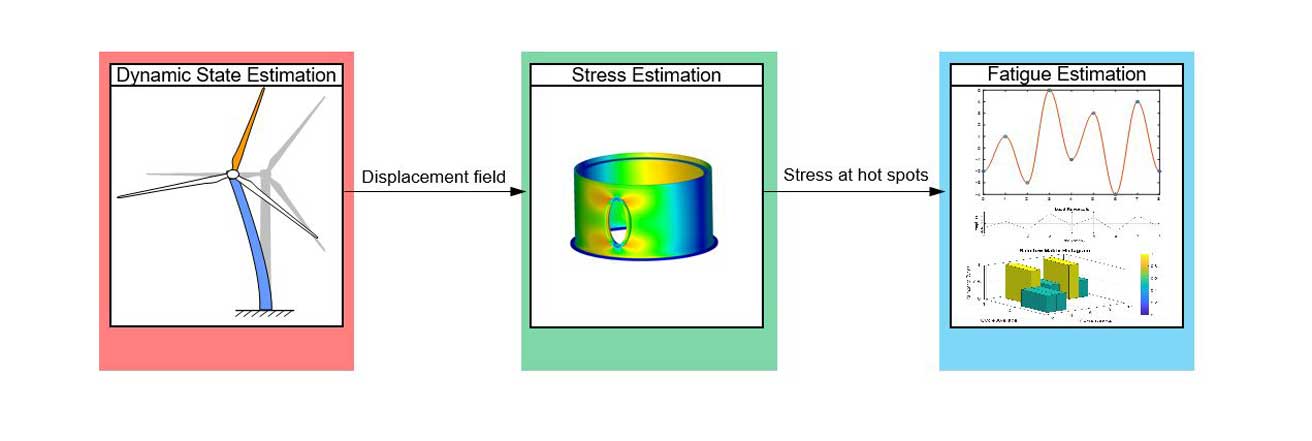

02.03.2023 | Imagine that a modern Wind power plant a tower height of 130 m and the mass to be supported by the machine house and nacelle is 400 to 600 t. The different wind loads put enormous mechanical strain on the construction. Vibration sensors are installed in the tower, nacelle, rotor hub and the rotor blades deployed. The typical frequencies range from 0 to 5 Hz. The natural vibration behavior of different system components must be separated. The forces that occur do not generally exceed 2 g.

02.03.2023 | Imagine that a modern Wind power plant a tower height of 130 m and the mass to be supported by the machine house and nacelle is 400 to 600 t. The different wind loads put enormous mechanical strain on the construction. Vibration sensors are installed in the tower, nacelle, rotor hub and the rotor blades deployed. The typical frequencies range from 0 to 5 Hz. The natural vibration behavior of different system components must be separated. The forces that occur do not generally exceed 2 g.

The required control involves braking the rotor by changing the blade angle, which results in a comparable load. This in turn has a massive effect on the service life and thus on the profitability of the plant .

State of the art sensors captures them loads in real time. The inertial measurement systems are used for evaluation in the sense of "Structural Health Monitoring" or for direct feedback from the systems steering. The sensors contain different measurement principles and deliver reliable data even at extremely low frequencies. The forces cannot only be measured in three axes. The acceleration sensors IMU360D F99 from Pepperl+Fuchs record vibrations or oscillations in the room and thus also detect torsional forces. With these acceleration sensors, the vibration behavior of the entire construction of the wind power plant can be determined.

Hydrogen + fuel cell: components for energy generation

Hydrogen + fuel cell: components for energy generation

With the aim of control systems as gently as possible, unnecessarily high loads should be excluded. In addition, the collection of data from the respective sensor over the period of operation enables the remaining service life to be determined. The forecast for the further operation of the wind turbine is decisive for its economic efficiency.

Dynamic inclination sensor with unique angular stability

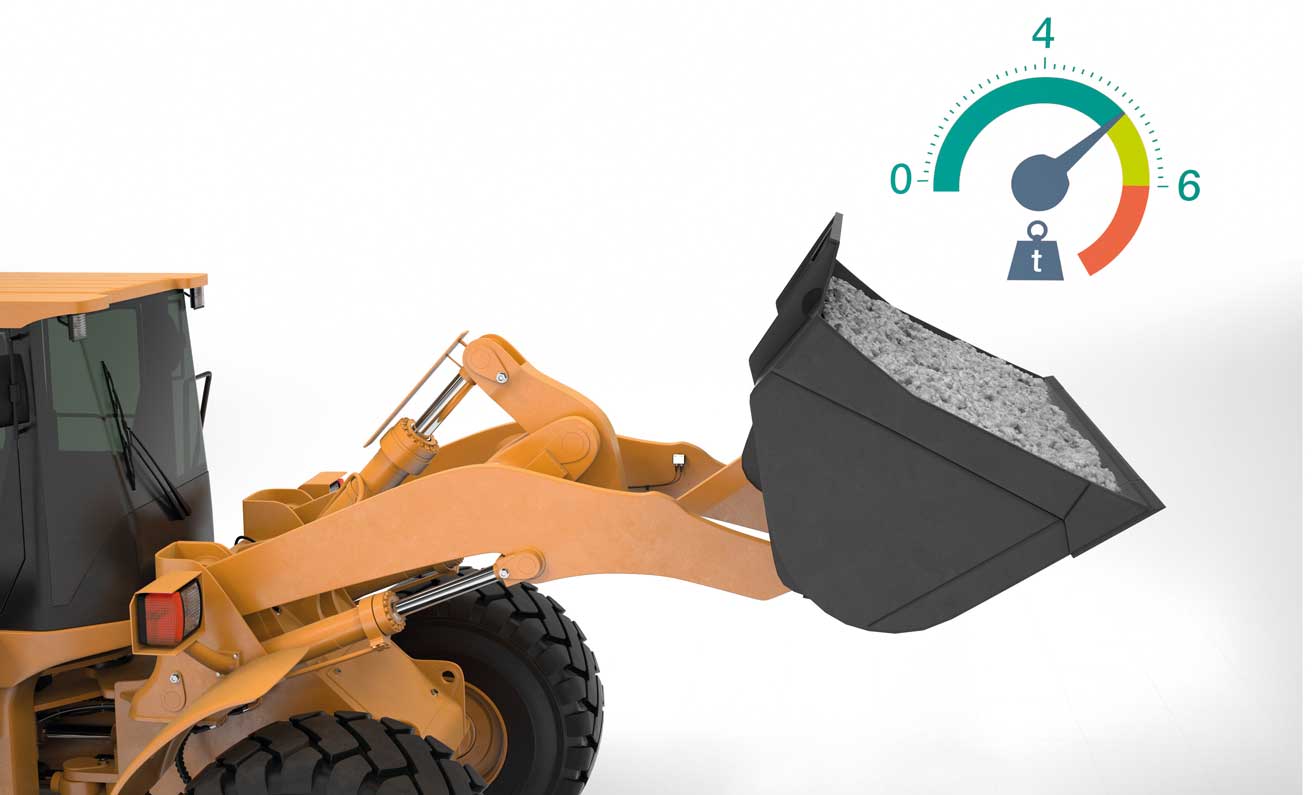

14.12.2022 | If you try to use a spirit level to hang a picture horizontally or to determine the inclination, this is quite easy to do because the air bubble of the dragonfly shows when the picture is hanging straight. With a wheel loader bucket, it is difficult to steer it so level while the machine is accelerating, braking or traveling on a gravel road. Neither the spirit level bubble nor a static one Inclinometer display a value with the required precision here. The new IMU F99 inclination sensor from Pepperl+Fuchs is different:

The sensor delivers for such dynamic applications stable inclination values, because external disturbances such as potholes are filtered out without delay. The unique software adjustment via CAN bus also enables the required angle quality, even with very different driving behavior of machines.

The sensor delivers for such dynamic applications stable inclination values, because external disturbances such as potholes are filtered out without delay. The unique software adjustment via CAN bus also enables the required angle quality, even with very different driving behavior of machines.

Static inclination sensorsn quickly reach their limits with dynamic machine movements. Such applications can be found, for example, in construction machinery, agricultural machinery, forestry vehicles, wind turbines or driverless transport systems. This is due to the fact that static inclination sensors determine the change in angle based on the always rectified gravitational acceleration. Additional accelerations, which are triggered by braking or a pothole, for example, are significant disturbance variables that make reliable angle measurement impossible.

The dynamic inclination sensor IMU F99 was designed for this use. Angular rates and accelerations are measured in all three spatial directions, which are then merged into an angle value in an intelligent algorithm. This measurement enables a stable angle output. Nevertheless, the different types of movement of machines require an individually adapted fusion of the rotation rate and acceleration. The unique user-friendly adjustability of the Pepperl+Fuchs inclinometers allows the inclination measurement of a wheel loader, a bulldozer, a crane etc. with one device.

Angular rates and acceleration in three axes

In addition, the IMU F99 inclination sensors also determine the rotation rates and acceleration in 3 axes in parallel to the angle output. So the sensors are versatile. One sensor can be used to determine the rotational speed of wind turbines or to monitor the acceleration of rotor blades. These, in turn, are subject to fluctuations as soon as unwanted ice builds up on the rotor blades. In this way, the rotational speed can be regulated and predictive maintenance of the wind turbine can be implemented.

In addition, the IMU F99 inclination sensors also determine the rotation rates and acceleration in 3 axes in parallel to the angle output. So the sensors are versatile. One sensor can be used to determine the rotational speed of wind turbines or to monitor the acceleration of rotor blades. These, in turn, are subject to fluctuations as soon as unwanted ice builds up on the rotor blades. In this way, the rotational speed can be regulated and predictive maintenance of the wind turbine can be implemented.

The accelerometers have one E1 approval and are designed with protection class IP68 / IP69K. This makes the sensors suitable for use in road traffic and in Construction. Despite dynamic acceleration, they offer a measuring range of inclination of 360 degrees in the horizontal orientation.

You might also be interested in...

Artificial Intelligence | trends and developments

RFID and Barcodes | Industrial identification

RFID reader and barcode scanner for identification

battery production | Facts and Technologies

Level sensor for every level measurement

Hydrogen + fuel cell: components for energy generation

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.