Image processing for quality assurance

Embedded vision, Gig-E and 3D cameras, frame grabbers, CMOS sensors, etc. to avoid errors and determine position

Image processing for quality assurance

Embedded vision, Gig-E and 3D cameras, frame grabbers, CMOS sensors, etc. to avoid errors and determine position

Here you will find new developments from the industrial sector Image Processing for the Quality Assurance in mechanical engineering and plant engineering as well as for special industries. We provide information about image processing systems such as embedded vision, Gig-E and 3D cameras, frame grabbers, CMOS sensors and much more. The components and methods for image processing are used, among other things, to avoid errors or to determine position and orientation in the Industry 4.0 Production.

Contents

Image processing systems are used in industrial applications such as for quality assurance in automated systems, for example when bottles to be filled in the beverage industry are monitored for their fill levels. Image processing systems can also be used in non-industrial areas like in traffic engineering or in sport.

Industries like that Automotive industry often relies on image processing due to its high level of automation. Other special applications can be found in the Technical Building Services, Medical Technology, food technology or Microsystems Technology. You will find excerpts below New developments.

From simple components such as an industrial camera to highly complex image processing systems, the quality in industrial production is guaranteed by image processing. The implementation is very versatile, for example on production lines or filling and packaging systems. We present you here the Industry 4.0 innovations image processing.

Polytec presents a complete drone solution for hyperspectral remote sensing. The ready-to-use systems from the US manufacturer Headwall Photonics are equally suitable for precision agriculture, environmental protection, forestry and surface mining.

Polytec presents a complete drone solution for hyperspectral remote sensing. The ready-to-use systems from the US manufacturer Headwall Photonics are equally suitable for precision agriculture, environmental protection, forestry and surface mining.

An telecentric lens commonly found in industrial Image Processing Mission. In three-dimensional measurements, it sometimes even surpasses the accuracy of non-contact or laser-based measurement methods. The telecentricity offers the highest accuracy and repeatability. Below we present you New Products like the telecentric lens for white LED light from Vision & Control:

Machine vision or the solutions of industrial Image Processing penetrate ever further into industrial areas, where the best image quality, highest resolution and high speeds are required. SVS-Vistek provides the new one GigE Vision industrial camera SHR461CX from the high-resolution SHR series.

Pepperl + Fuchs offers based on 2D and 3D cameratechnologies provide a wide range of options for detection, identification, positioning and measurement in factory automation. The "Smartrunner" technology combines the powerful light section process with a Vision sensor including LED lighting. The 2D vision is based on this Sensors "Matcher" and "Detector". The Smartrunner "3D Explorer" with ToF and Stereo Vision was designed for precise 3D capture. The modular one Universal vision sensor VOS closes the gap between 2D vision sensor and a complex system.

Designed for mobile use, this 3D smart camera from IFM Electronic is the first 3D sensorsystem with an additional integrated 2D camera. The overlay function can be used to graphically display obstacles and issue warnings, symbols and even complex drawings in real time. In addition, the signal processing in the sensor means that no external process unit is required.

Designed for mobile use, this 3D smart camera from IFM Electronic is the first 3D sensorsystem with an additional integrated 2D camera. The overlay function can be used to graphically display obstacles and issue warnings, symbols and even complex drawings in real time. In addition, the signal processing in the sensor means that no external process unit is required.

Get on the plane and just a few hours later get off again thousands of kilometers away: Airplanes take us to almost any place around the world. Innovative scan technologies from Pepperl + Fuchs can help ensure that an aircraft is not only comfortable, but above all safe.

Baumer extends his 10th GigE Camera LX series by four new models for industrial image processing. These support applications with very high demands on resolution and image quality. In this way, the smallest details and deviations can be reliably identified. They also offer a very high frame rate for increased throughput.

The industrial image processing is an increasingly important part of modern production processes. With a 3D camera high-precision images of objects can be spatially captured and further processed. 3D camera systems thus enable the precise measurement and analysis of components and products. In our article you will learn how 3D camera technology supports you in optimizing your production processes.

Rauscher presents eight new Basler ACE U cameras with global shutter CMOS sensors in VGA and 1,6 megapixel resolution that deliver up to 520 images / s. The Sony Pregius IMX273 sensor with a pixel size of 3,45 µm offers optimal image quality, high speeds and low noise. The IMX287 sensor has twice the pixel size with an edge length of 6,9 µm.

Rauscher presents eight new Basler ACE U cameras with global shutter CMOS sensors in VGA and 1,6 megapixel resolution that deliver up to 520 images / s. The Sony Pregius IMX273 sensor with a pixel size of 3,45 µm offers optimal image quality, high speeds and low noise. The IMX287 sensor has twice the pixel size with an edge length of 6,9 µm.

The original idea of this new development comes from the aircraft industry. There, high-resolution 3D measurement with laser scanners is used to precisely connect components, for example. Pepperl + Fuchs showed the potential of this technology for applications in the sense of Industry 4.0 and brought another dimension of measurement into play.

The original idea of this new development comes from the aircraft industry. There, high-resolution 3D measurement with laser scanners is used to precisely connect components, for example. Pepperl + Fuchs showed the potential of this technology for applications in the sense of Industry 4.0 and brought another dimension of measurement into play.

GigE Vision has long been an integral part of the world of image processing. However, the 120 MB / s transfer performance of GigE slows down current cameras. "Nbase-T" from Rauscher increases the transfer performance without compression from 1 Gbps to 5 Gbps when using the same cables and the same software.

GigE Vision has long been an integral part of the world of image processing. However, the 120 MB / s transfer performance of GigE slows down current cameras. "Nbase-T" from Rauscher increases the transfer performance without compression from 1 Gbps to 5 Gbps when using the same cables and the same software.

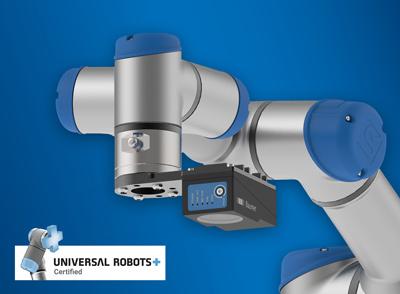

The new Verisens vision sensors XF900 and XC900 from Baumer control the collaborating robots (cobots) from Universal Robots after just a few minutes of setup. The robot-compatible vision sensors are mounted directly on the cobot or above it. The calibration with regard to image rectification, conversion to world coordinates and coordinate comparison between the vision sensor and the robot takes place automatically and very easily thanks to the patent-pending Smartgrid.

The new Verisens vision sensors XF900 and XC900 from Baumer control the collaborating robots (cobots) from Universal Robots after just a few minutes of setup. The robot-compatible vision sensors are mounted directly on the cobot or above it. The calibration with regard to image rectification, conversion to world coordinates and coordinate comparison between the vision sensor and the robot takes place automatically and very easily thanks to the patent-pending Smartgrid.