RFID and Barcodes | Industrial identification

- Details

- Hits: 7838

Efficient and transparent processes are essential in modern production. Identification systems such as RFID and barcodes offer optimization possibilities here. In combination with the proven Kanban-Method, they develop their full potential, for example. In this article, we use industrial Applicationshow RFID-supported systems and barcode technology make production more efficient, present new products and convey a little basic knowledge.

Contents

- RFID 2024 – The most important things in brief

- Innovations in RFID technology

- Multi-tag capable RFID devices with unique range

- IIoT functions for RFID interfaces with OPC UA Server

- RFID read / write head for Ex zone 1/21

- Fast RFID I / O module for Ethercat

- Consistent identification of the process chain

- First RFID safety sensor in Ex version

- HF-RFID/sensor data carrier to be read contact-free

- RFID sensor and position switch for maintenance

- RFID for Integrated Industry - lecture

- Applications RFID systems and barcode scanners

- Safe positioning for working platforms

- Kanban box models with RFID automatically reorder C-parts

- Tracking system for child seats based on RFID and TBEN-S

- Barcode scanner for reliable identification in deep-freeze storage

- Intelligent PCB 4.0 by UHF RFID technology

- RFID read/write heads in tire production

- FAQ

RFID 2024 – The most important things in brief

In the last few decades, the RFID technology has developed from a niche technology to an integral part of modern manufacturing, logistics and retail processes. Modern RFID tags are extremely small and can be integrated into products or materials. The chips can store more data and can be read faster. The ranges have been significantly increased. In addition, RFID chips are merging with sensors, IoT platforms and cloud technologies. This expands the possible applications.

RFID is becoming more and more common as a key technology in the Internet of Things (IoT) by connecting physical objects to the Internet. Real-time tracking systems expand the ability to track the precise location of objects in real-time. This has revolutionized applications in logistics, healthcare and manufacturing. With growing privacy concerns, advanced encryption and authentication mechanisms are being built into RFID systems. However, RFID also generates benefits in the circular economy: the ability to track products throughout their life cycle enables better recycling and reuse processes.

Innovations in RFID technology

These trends and the ones that follow New Products illustrate the potential of identification technology. Overall, the continuous development and diversification of RFID technology shows that it can meet the requirements of various industries.

Multi-tag capable RFID devices with unique range

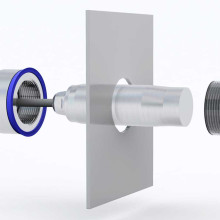

08.01.2024 | Pepperl + Fuchs introduces two new ones RFID writing/reading devices before. The high-performance IQH3-FP-V1 and IQT3-FP-IO-V1 are suitable for identification tasks. They offer the advantages of high-frequency RFID with a unique detection range and are housed in a modern, compact housing to save space.

08.01.2024 | Pepperl + Fuchs introduces two new ones RFID writing/reading devices before. The high-performance IQH3-FP-V1 and IQT3-FP-IO-V1 are suitable for identification tasks. They offer the advantages of high-frequency RFID with a unique detection range and are housed in a modern, compact housing to save space.

IIoT functions for RFID interfaces with OPC UA Server

30.06.2022 | Turck presents new IIOT functions for its RFID interfaces with OPC UA Server. The IP67 RFID interfaces are equipped with a free firmware update for barrier-free communication in the Industrial Internet of Things (IIoT).

30.06.2022 | Turck presents new IIOT functions for its RFID interfaces with OPC UA Server. The IP67 RFID interfaces are equipped with a free firmware update for barrier-free communication in the Industrial Internet of Things (IIoT).

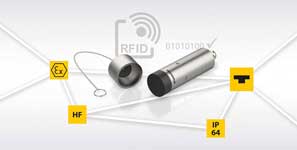

RFID read / write head for Ex zone 1/21

11.05.2021 | Turck presented with a new one HF RFID read / write head in type of protection Ex-m the world's only RFID reader for contactless identification applications using an RFID transponder in explosion-protected areas - approved for Atex Zone 1/21.

11.05.2021 | Turck presented with a new one HF RFID read / write head in type of protection Ex-m the world's only RFID reader for contactless identification applications using an RFID transponder in explosion-protected areas - approved for Atex Zone 1/21.

Fast RFID I / O module for Ethercat

11.03.2021/XNUMX/XNUMX | That TBEC interface from Turck supports RFID applications with data carriers that follow each other very quickly and up to 128 read/write heads. With the TBEC family, the range of compact, robust RFID systems has been expanded to include fast interfaces for EtherCAT networks.

11.03.2021/XNUMX/XNUMX | That TBEC interface from Turck supports RFID applications with data carriers that follow each other very quickly and up to 128 read/write heads. With the TBEC family, the range of compact, robust RFID systems has been expanded to include fast interfaces for EtherCAT networks.

Consistent identification of the process chain

28.02.2020/XNUMX/XNUMX | The video provides an overview of how RFID technology from Turck a continuous identification by scanning the RFID tag of the goods in the Goods Receipt through production to the issue of goods. All processes can be implemented with an RFID system from Turck.

28.02.2020/XNUMX/XNUMX | The video provides an overview of how RFID technology from Turck a continuous identification by scanning the RFID tag of the goods in the Goods Receipt through production to the issue of goods. All processes can be implemented with an RFID system from Turck.

First RFID safety sensor in Ex version

31.10.2019/XNUMX/XNUMX | the Schmersal Group has the first RFID-based Safety sensor presented, which is designed according to the Atex directive 2014/34/EU and can be used in Ex zones 2 (gas Ex, category 3G) and 22 (dust Ex, category 3D). This one unites functional safety and explosion protection.

31.10.2019/XNUMX/XNUMX | the Schmersal Group has the first RFID-based Safety sensor presented, which is designed according to the Atex directive 2014/34/EU and can be used in Ex zones 2 (gas Ex, category 3G) and 22 (dust Ex, category 3D). This one unites functional safety and explosion protection.

HF-RFID/sensor data carrier to be read contact-free

20.04.2017 | Turck offers the development and production of application-specific RFID data carriers integrated sensor function at. The sensor data carriers record and store process variables such as temperature or pressure in moving components. The sensor element is replaceable.

20.04.2017 | Turck offers the development and production of application-specific RFID data carriers integrated sensor function at. The sensor data carriers record and store process variables such as temperature or pressure in moving components. The sensor element is replaceable.

RFID sensor and position switch for maintenance

01.09.2015/XNUMX/XNUMX | the Schmersal Group indicates their new generation safety switches. With the RSS 16 safety sensor, the target is identified contact-free instead of using a mechanical actuator. The RFID technology forms the basis for Industry 4.0 concepts.

01.09.2015/XNUMX/XNUMX | the Schmersal Group indicates their new generation safety switches. With the RSS 16 safety sensor, the target is identified contact-free instead of using a mechanical actuator. The RFID technology forms the basis for Industry 4.0 concepts.

RFID for Integrated Industry - lecture

26.02.2015/XNUMX/XNUMX | At the Harting press workshop in Espelkamp in the run-up to the Hannover Messe explains dr. Jan Regtmeier, Team Manager Oroduct Management at Harting IT Software Development GmbH & Co. KG, Espelkamp, about the importance of RFID for Integrated Industry.

Applications RFID systems and barcode scanners

Safe positioning for working platforms

07.08.2023 | Working on lifts near danger areas, such as near railway overhead lines, require special safety measures. A sophisticated security system Pepperl + Fuchs continuously compares the voltage state of the catenary with the position of the platform.

07.08.2023 | Working on lifts near danger areas, such as near railway overhead lines, require special safety measures. A sophisticated security system Pepperl + Fuchs continuously compares the voltage state of the catenary with the position of the platform.

Kanban box models with RFID automatically reorder C-parts

03.03.2020 | Otto Roth will present its extensive expertise in the efficient and customized procurement of C-Parts. The highlight is a new Kanban method with RFID technology. Users can use it to automate their C-parts supply and thereby automatically reduce the ordering effort and delivery time.

03.03.2020 | Otto Roth will present its extensive expertise in the efficient and customized procurement of C-Parts. The highlight is a new Kanban method with RFID technology. Users can use it to automate their C-parts supply and thereby automatically reduce the ordering effort and delivery time.

With a product portfolio of more than 100.000 different items, Otto Roth has been supplying screws, fittings, flanges and dowels through to high-quality drawing parts for trade and industry since 1914. The strengths also include extensive C-parts management, which simplifies procurement processes and fulfills individual requirements.

Smart box orders itself

At the Logimat, the company is presenting a clever box that automatically reorders. The new Kanban concept works with RFID technology. Each container is equipped with an RFID transponder in the form of a label. All important information about the respective article is stored on it. On the top rows of the Kanban shelves there is an electronic RFID mat that reads the tags on the empty Kanban boxes and transmits the data wirelessly to a central computer. This calculator is the Master Kanban Box.

Select Gutekunst compression spring, tension spring and leg spring

Select Gutekunst compression spring, tension spring and leg spring

The Master Kanban Box forwards the order to the in-house IT system at predefined intervals via W-Lan, LAN or the mobile network. The employees place the empty Kanban containers on the RFID mat and thus automatically trigger the ordering process. The RFID tags on the containers can then be blocked for a defined period of time. This prevents items from being ordered multiple times. However, if necessary, users can manually increase the order quantity.

The master kanban box is multifunctional and is also suitable as an RFID mailbox for RFID tags. Employees can therefore simply throw individual transponders into the box to order. The Master Kanban Box can also read barcode labels. Users can thus optimally adapt the Kanban system to their individual needs. The automated ordering of the RFID transponder saves time because manual barcode label scanning is no longer necessary. It also avoids errors and ensures that required C-parts are delivered as quickly as possible.

Tracking system for child seats based on RFID and TBEN-S

24.04.2019/XNUMX/XNUMX | the Kirschenhofer Maschinen GmbH developed for Britax Romans a system for production control and quality assurance in the manufacture of child seats. Both companies have it all without SPS implemented using RFID tags and TBEN-S Ethernet multi-protocol modules from Turck in connection with Labview.

24.04.2019/XNUMX/XNUMX | the Kirschenhofer Maschinen GmbH developed for Britax Romans a system for production control and quality assurance in the manufacture of child seats. Both companies have it all without SPS implemented using RFID tags and TBEN-S Ethernet multi-protocol modules from Turck in connection with Labview.

Barcode scanner for reliable identification in deep-freeze storage

05.08.2019 | In the Freezer zones other laws prevail than in environments below normal temperatures. The barcode scanner VB14N-T from Pepperl+Fuchs ensures optical identification here at temperatures down to -35 °C. It offers very good reading performance even with low barcode contrast.

05.08.2019 | In the Freezer zones other laws prevail than in environments below normal temperatures. The barcode scanner VB14N-T from Pepperl+Fuchs ensures optical identification here at temperatures down to -35 °C. It offers very good reading performance even with low barcode contrast.

Intelligent PCB 4.0 by UHF RFID technology

30.07.2018/XNUMX/XNUMX | Printed circuit boards are a basic component of electronic devices, cars, robots, Smartphone, Tablets and Co. They must therefore be reliable and meet the increasing quality requirements. Thanks to Hartings Thanks to UHF RFID technology, the electronic component can now speak and think for itself.

30.07.2018/XNUMX/XNUMX | Printed circuit boards are a basic component of electronic devices, cars, robots, Smartphone, Tablets and Co. They must therefore be reliable and meet the increasing quality requirements. Thanks to Hartings Thanks to UHF RFID technology, the electronic component can now speak and think for itself.

RFID technology in tire manufacturing

23.01.2018/XNUMX/XNUMX | In order to achieve as much as possible a XNUMX% read probability, it is necessary to select the optimum read/write head and select transponders for an application. At a tire manufacturer it is Pepperl + Fuchs succeeded in ensuring the traceability of semi-finished products.

23.01.2018/XNUMX/XNUMX | In order to achieve as much as possible a XNUMX% read probability, it is necessary to select the optimum read/write head and select transponders for an application. At a tire manufacturer it is Pepperl + Fuchs succeeded in ensuring the traceability of semi-finished products.

FAQ

What is Radio Frequency Identification, or RFID for short?

RFID, translates identification using electromagnetic waves, is an identification technology with which objects and living beings can be clearly identified without contact. Data is read or written using electromagnetic waves. RFID transmitter receiver systems consist mainly of an RFID tag, consisting of a chip and antenna, and an RFID reader, the device that emits the radio waves that activates the tag.

What does a barcode scanner do?

A barcode scanner, often also called barcode reader is an electronic device specially designed to capture the data encoded in a barcode and translate it into a form that computers can understand. A barcode itself is a machine-readable representation of information that is printed or affixed to a surface. The reader works as follows:

The scanner uses a light source, usually a laser or LED to illuminate the barcode. An optical sensor or camera registers the light reflected from the barcode. For decoding, the information contained in the barcode is converted into a digital form. The pattern of dark and light stripes is translated into alphanumeric characters. The decoded data is sent to a computer system.

RFID versus barcodes

Overall, both RFID and barcodes each offer specific advantages that can make the difference depending on the application and environment. When choosing between the two technologies, companies should consider their specific requirements and the cost-benefit ratio account.

RFID advantages over barcodes:

- contactlesse Query possible from a distance and without visual contact

- Multiple tags readable at the same time

- Some are RFID tags rewritable

- Robustness for demanding environments

- Usually higher data capacity

RFID disadvantages compared to barcodes

- RFID tags are usually expensive as barcodes

- vulnerability by metal and liquid in the environment

- Privacy concerns about unnoticed readability without security measures

Barcode advantages over RFID

- Manufacturing and printing relative favorable

- Established, widespread and widely accepted

- Simple technology

- Tried and Reliable

Barcode disadvantages compared to RFID

- visual contact necessary

- Once printed, not alterable or rewritable

- Limited data capacity

- susceptibility for damage

You might also be interested in...

Control Fair 2024 | The industry is already looking forward to Stuttgart

Edge Computing | Devices, applications and lots of tips

Level sensor | Level switch for simple to IIoT use

encoders | Industrial Ethernet and Industry 4.0 encoders

Ultrasonic sensor | For distance, distance and level