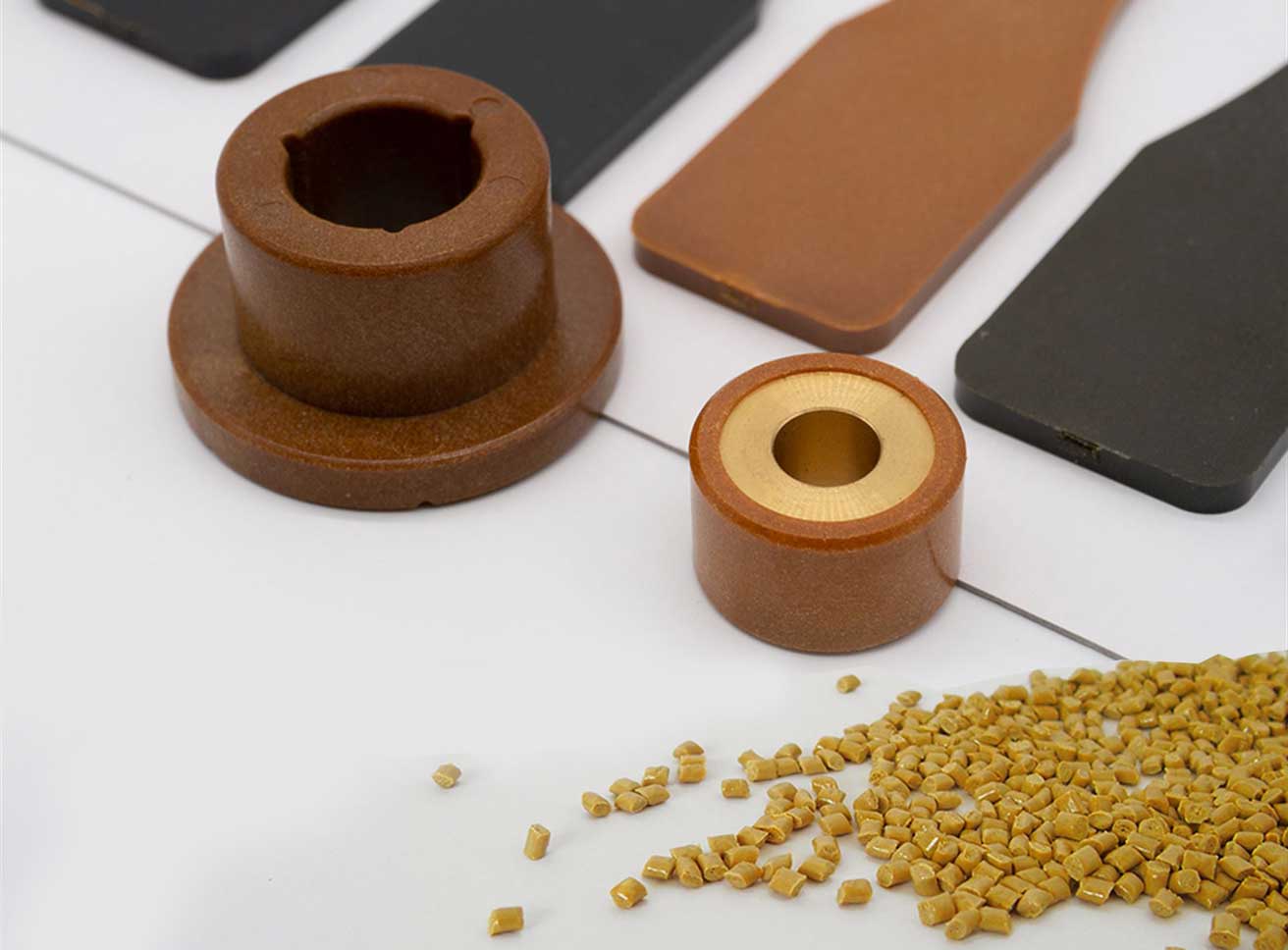

as alternative industrial materials

Polymers, elastomers, duroplastics, thermoplastics, polystyrene, etc. extend the service life of your newly developed products.

Image: BASF

as alternative industrial materials

Polymers, elastomers, duroplastics, thermoplastics, polystyrene, etc. extend the service life of your newly developed products.

Image: BASF

Even if Plastic has a rather bad reputation today, so rejoice plastics increasing popularity in industry. Plastics are light, low-maintenance, durable, environmentally friendly and inexpensive. In addition, plastics offer further positive properties compared to other materials, which can also be explicitly generated in their composition. They can be made particularly break-proof, elastic or temperature-resistant. Parts made of plastic are manufactured using the plastic injection molding process.

The Plastics industry is booming and is developing more and more new compositions such as polymers, elastomers, thermosets, thermoplastics, polystyrene and many others - you too can extend the life of your new development with products made of plastic.

Here you will find new developments in plastics technology. Find out about the alternatives material Plastic for your efficient construction!

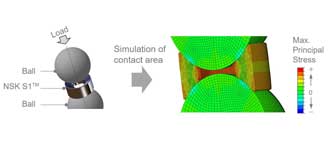

NSK presents a world first with the spacer element for ball screws made of 100% bio-based Plastic. Compared to a spacer element made of fossil plastic, the CO2-Footprint by 90% reduced over the entire life cycle. The developers have the bio-based high-performance for thispolyamide Ecopaxx selected by DSM.

NSK presents a world first with the spacer element for ball screws made of 100% bio-based Plastic. Compared to a spacer element made of fossil plastic, the CO2-Footprint by 90% reduced over the entire life cycle. The developers have the bio-based high-performance for thispolyamide Ecopaxx selected by DSM.

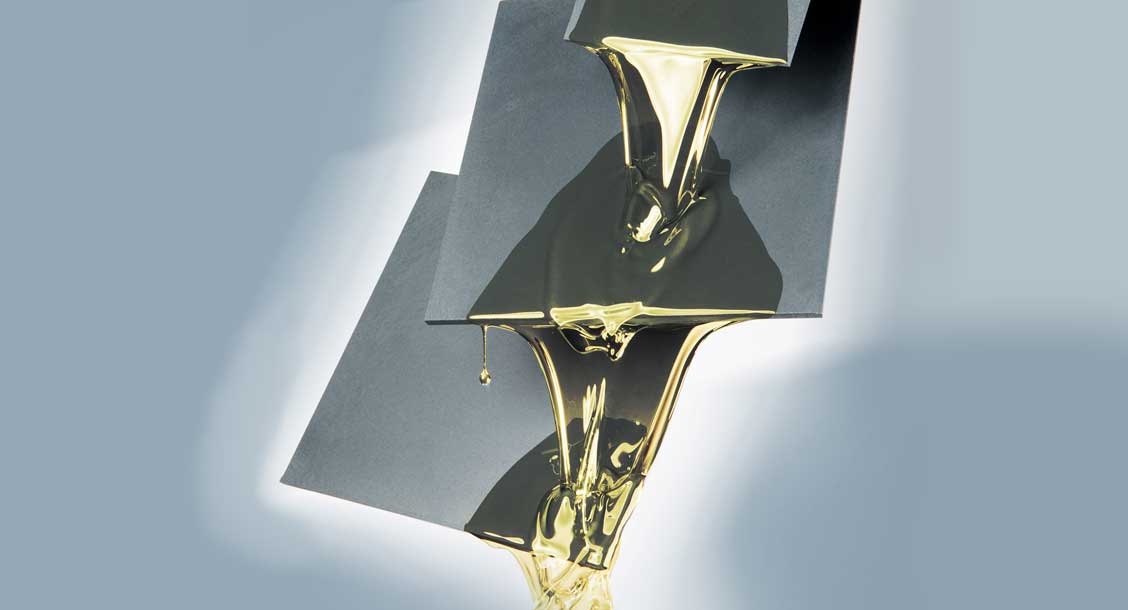

Heat is not just heat. Infrared emitters make the difference. This shows an example of the British company Hepworth drainage: The use of infrared emitters here improved a process in plastics processing, in which parts of an inspectiontoolss for ducts made of polypropylene. Various tubes are to be connected to a base unit. Hot glue was used for this in the past. Hepworth was looking for more efficient solutions to save money and protect the environment.

Heat is not just heat. Infrared emitters make the difference. This shows an example of the British company Hepworth drainage: The use of infrared emitters here improved a process in plastics processing, in which parts of an inspectiontoolss for ducts made of polypropylene. Various tubes are to be connected to a base unit. Hot glue was used for this in the past. Hepworth was looking for more efficient solutions to save money and protect the environment.

The division Molding Solutions of the Barnes Group expanded the Foboha technology center for injection molding in Haslach in 2021. The technical center imparts injection molding expertise all year round and is available to customers for tests. In addition, small series can be produced here if necessary and customer events can be held. Included are the grippers and Vacuum Technology from Gimatic.

The division Molding Solutions of the Barnes Group expanded the Foboha technology center for injection molding in Haslach in 2021. The technical center imparts injection molding expertise all year round and is available to customers for tests. In addition, small series can be produced here if necessary and customer events can be held. Included are the grippers and Vacuum Technology from Gimatic.

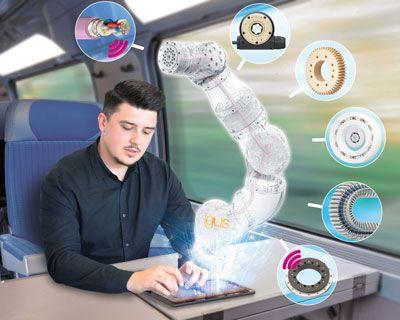

When it comes to wear-resistant tribo-polymers, users have Igus the agony of choice. For small series or series production in injection molding, a prototype from the 3D printer or semi-finished products, the plastics specialist has now developed an offline configurator for its 39 Iglidur standard materials: The user can determine the appropriate material using templates. An Iglidur expert system is also available for the selection and calculation of the service life.

When it comes to wear-resistant tribo-polymers, users have Igus the agony of choice. For small series or series production in injection molding, a prototype from the 3D printer or semi-finished products, the plastics specialist has now developed an offline configurator for its 39 Iglidur standard materials: The user can determine the appropriate material using templates. An Iglidur expert system is also available for the selection and calculation of the service life.

Maintenance-free, lubricant-free, sustainably produced and rustproof sets the new urban bike from Igus new standards in sustainable mobility. The bike off recycled plastic will transport generations of people. On the Hannover Messe The plastic visionary had the new one in 2022 Igus: bike Platform presents the groundbreaking concept. Here you can follow the development to date.

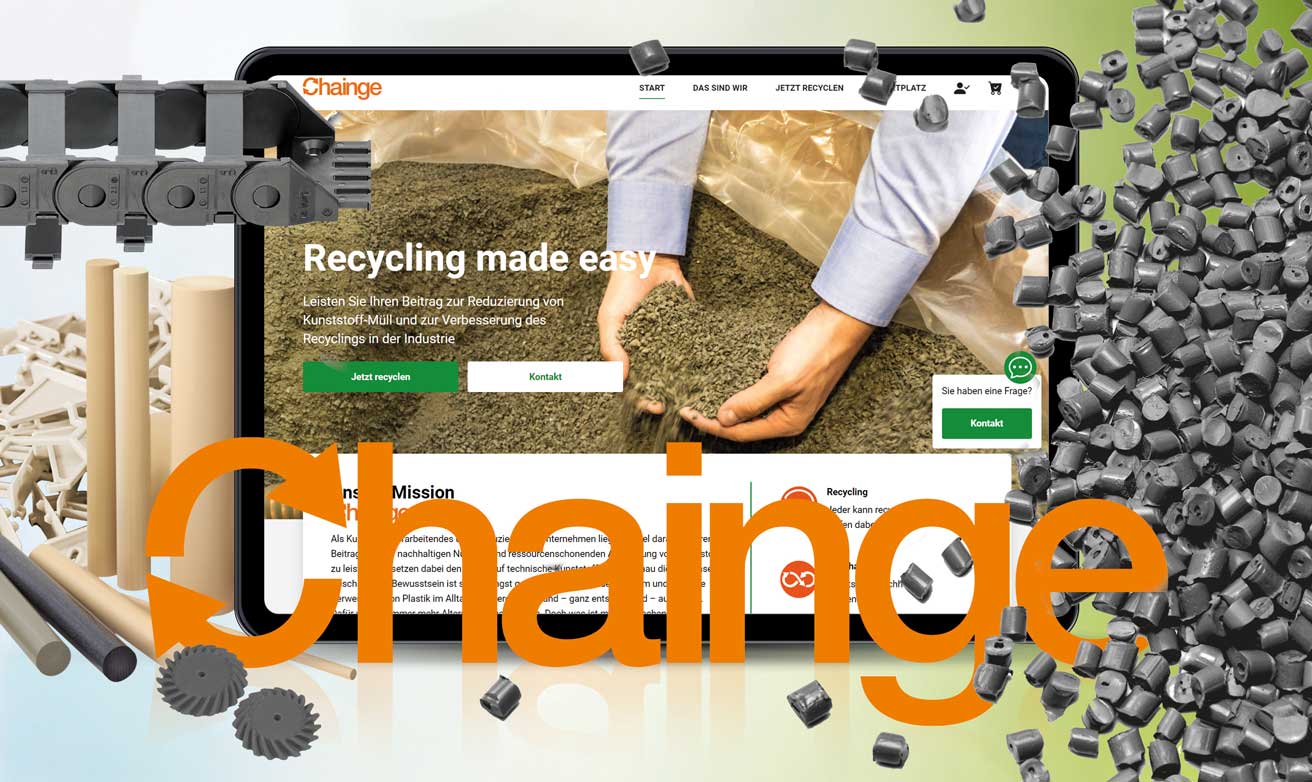

For several years there has been a clear trend towards more Plastic recycling due to the worldwide increasing demands on a Recycling for plastic. Some industrial companies are already responding to this trend – and the trend is increasing. We report on their investments, strategies and innovations here.

For the resource-efficient use of Plastics develops that Fraunhofer Institute for environmental, safety and energy technology "prudence" new materials. The focus is on bioplastics, a circular plastics economy and strategies to reduce macro- and microplastics in the environment.

The importance of sustainability in the plastics industry is growing. Recycling is becoming more and more important. Companies like Igus are increasingly focusing on environmentally friendly solutions and contributing to changing the plastics industry. The motion plastics specialist shows how the use of high-performance plastics can have a positive impact on the circular economy. Read how sustainable plastics and their production CO2-neutral can be.

The demand for new sustainable plastics that are also recyclable is increasing. This also applies to thermoplastics, which is common in the Automotive industry be used. In addition to a material modeling technology that measures the proportion of carbon in Plastic Reduced by 60%, you will find further thermoplastic innovations here, with which, among other things, weight can be saved and other advantages opened up.

The engineering plastic polyamide Above all, it offers high strength, good oil resistance and is very durable. the BASF has recently expanded its portfolio with a flame-retardant PA66 polyamide type. In strong orange one comes to the strong dye demand in the Automotive sector to. You can find these and other polyamide innovations below:

The BASF presents a new one Engineering plasticwho is particularly good Automotive components protects against contact with hot oil. The polyethersulfone (PESU) Ultrasound E0510 C2TR offers very good tribological properties, dimensional stability even under large temperature fluctuations as well high resistance to oil.

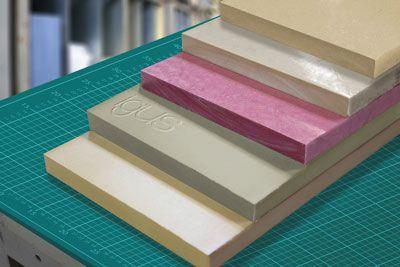

So that the user can use even more tribologically optimized special solutions, Igus now has five wear and abrasion-resistant high-performance plastics in its range as semi-finished panel strips. These allow the designer new geometric design freedom.

So that the user can use even more tribologically optimized special solutions, Igus now has five wear and abrasion-resistant high-performance plastics in its range as semi-finished panel strips. These allow the designer new geometric design freedom.

The thermoplastic Polyimide Aurum is a highly heat-resistant super-engineering Plastic with high production efficiency in injection molding. The thermal plastic challenges the conventional wisdom that polyimide performs very well but is difficult to process. As a distributor for PI Meldin from Saint-Gobain, Bieglo presents the PI portfolio, which is also suitable for the 3D pressure suitable.

Because the expected demand quantities are falling in most industries, KVH Hartung presents plastic vacuum deep-drawn parts produced using the negative process as a real alternative to injection molding. The result is housings that cannot be distinguished from the injection molded part when closed.

Because the expected demand quantities are falling in most industries, KVH Hartung presents plastic vacuum deep-drawn parts produced using the negative process as a real alternative to injection molding. The result is housings that cannot be distinguished from the injection molded part when closed.

Configurable online on the tablet, as a long-lasting special edition 3D-printed or equipped with smart intelligence: Motion plastics are developing more and more into high-tech components. This development shows Igus at this year's Hannover Messe with 120 innovations - from intelligent slide bearings to the world's first online platform that brings together providers and users of cost-effective robotics.

Configurable online on the tablet, as a long-lasting special edition 3D-printed or equipped with smart intelligence: Motion plastics are developing more and more into high-tech components. This development shows Igus at this year's Hannover Messe with 120 innovations - from intelligent slide bearings to the world's first online platform that brings together providers and users of cost-effective robotics.

Jihed Marzouki, Junior Key Technology Manager Electro Casting Resins, Rampf Polymer Solutions GmbH & Co. KG, Grafenberg, on the trade fair highlight for tailor-made electro casting resins.