Level sensor | Level switch for simple to IIoT use

- Details

- Hits: 17625

Level sensors are used for continuous measurement of the levels of liquids, bulk solids, etc. Media. Discover the latest developments in capacitive level sensors Level sensor and ultrasonic level sensor. Our article highlights current ones Market innovations, discusses a variety of things Fields of application and offers insights into the current state of the art as well as the latest Trends.

Contents

- Fill level sensor – the most important things in brief

- All-rounder for level measurement

- Capacitive fill level sensor for point level indication

- Level sensor measures an unusual amount of media

- Ultrasonic and radar level sensor with IO-Link for the IIoT

- Level sensor for viscous media

- Level sensor for SIL2 and SIL3 in the Köstritzer brewery

- IoT sensor monitors level and position remotely

- Custom level sensors with guided microwave

- Coated miniature ultrasonic level sensor

- Precise level sensor for hygienic areas under foam

- Versatile level switch certified for UL listing

- FAQ

Fill level sensor – the most important things in brief

Driven by the need for more accurate, efficient and versatile monitoring across a variety of industries, level sensors are continually evolving. Current trends include integrating IoT capabilities for better connectivity and remote monitoring, which plays a key role in Industry 4.0. There are also advances in miniaturization and energy efficiency, which offer more flexible and environmentally friendly applications.

Another trend is the development of sensors expanded diagnostic capabilitiesn that not only measure the level, but also provide data for condition monitoring and predictive maintenance. This increases system availability and reduces maintenance costs.

In addition, sensors with higher accuracy and reliability are available extreme environmentconditions developed to meet the requirements of specialized applications such as petrochemical, pharmaceutical or Foodprocessing needs to be met. The increasing acceptance of non-invasive measurement methods such as ultrasonic or radar level sensors, which enable non-contact measurement, also characterizes current trends in this area.

All-rounder for level measurement

27.07.2023/XNUMX/XNUMX | In chemical plants as well as in the oil and gas industry, vibrating level switches reliably detect the level or the filling level of liquids. With the level switch Vibracon LVL-M3 and -M4 offers Pepperl + Fuchs two new series of vibration limit switches - with Atex and IECEx approval for potentially explosive areas.

27.07.2023/XNUMX/XNUMX | In chemical plants as well as in the oil and gas industry, vibrating level switches reliably detect the level or the filling level of liquids. With the level switch Vibracon LVL-M3 and -M4 offers Pepperl + Fuchs two new series of vibration limit switches - with Atex and IECEx approval for potentially explosive areas.

Capacitive fill level sensor for point level indication

29.11.2022/XNUMX/XNUMX | The capacitive level indicator Jumo Zelos C01 LS detects the level of liquids and solids. The level sensor can also be used in pressurized pipes and tanks. In industry, it meets the requirements for overflow protection, dry-running protection and media detection.

The Zelos C01 LS is suitable for use in liquids and bulk materials at temperatures between -40° and +200 °C. Based on the unique auto-calibration functionality, the sensor detects the point level measurement reliably and with long-term stability. After configuration, the two switching outputs can automatically and reliably distinguish between the measuring medium and cleaning media or foam.

The level sensor also detects buildup. The product design carries the miniaturization in the sensor calculation. Installation is easy with a standardized torque wrench. The sealing to the medium takes place via the sensor tip. Thus, no separate seal is required. A mix-up is impossible.

Industrial Ethernet encoders and other Industry 4.0 rotary encoders

Industrial Ethernet encoders and other Industry 4.0 rotary encoders

Short-circuit protection and reverse polarity protection offer additional security. An antivalent circuit recognizes line errors such as a Cablesfracture. The sensor can be updated when installed using a firmware update profile. This minimizes system downtimes. PNP, NPN, push-pull and IO-Link are available as output signals. A 360° illuminated status display shows the sensor status according to Namur and VDI/VDE.

The point level detector has protection classes IP67 / IP69. The parts that come into contact with the medium are made of peek with a homogeneous surface roughness of less than Ra 0,8 µm. The level sensor has extensive approvals for use in the Food industry, railway technology and shipbuilding. Furthermore, the requirements according to the Water Resources Act (WHG), intrinsically safe explosion protection and electrical safety according to UL are met.

The Zelos C01 LS monitors containers, controls valves, PLC inputs or warning signals and protects pumps from running dry. Typical applications are storage tanks for solid and liquid food, sand or granules as well as water and waste water. the automatic media detection can be taught in specifically with and without software.

Level sensor measures an unusual amount of media

15.08.2022/XNUMX/XNUMX | The new level sensor Combilevel PLP70 from Baumer automatically adapts to an exceptionally large number of media. With the large touch display, it is very user-friendly in process monitoring. The potentiometric level sensor handles a low minimum conductivity of the medium. Up to now, the previous model LSP could measure media with a conductivity from 50 microsiemens/cm.

15.08.2022/XNUMX/XNUMX | The new level sensor Combilevel PLP70 from Baumer automatically adapts to an exceptionally large number of media. With the large touch display, it is very user-friendly in process monitoring. The potentiometric level sensor handles a low minimum conductivity of the medium. Up to now, the previous model LSP could measure media with a conductivity from 50 microsiemens/cm.

The fill level sensor even detects fill levels of process media with very low Conductivity greater than 10 microsiemens/cm. It thus pushes forward into previously unattainable limits and is also suitable for media such as process water. «The PLP70 can be used particularly profitably with a large variety of types or frequent media changes. Due to the media-independent measuring principle, the Sensor highest accuracy and repeatability even with the most demanding applications," says product manager Julian Budde. Examples of difficult applications are processes with pasty, adhesive or foaming media with low conductivity that are difficult to measure.

The PLP70 potentiometric level sensor has a IO-Link interface. It can be used flexibly for efficient process monitoring and process control. With exact and reliable measurement results, processes can be optimized, such as the precise fill level monitoring of feed tanks and storage tanks. Thanks to its short response time of less than 100 ms, the level sensor is particularly suitable for highly dynamic processes with rapid level changes in bottling plants.

The areas of application floatless potentiometric Level sensors include industrial applications of process tanks, cleaning systems, filter systems, agricultural machines, water treatment systems through to hygienic applications in filling systems, storage and buffer tanks, reservoirs, filter systems, process tanks or cleaning systems).

The Baumer Display displays all the information you need in a clear manner – also for recording remotely. "The change in the background color, which clearly shows the current process status from afar, makes a significant contribution to simple process monitoring," explains the product manager Julian Budde. The touch display allows convenient operation directly on the sensor.

Ultrasonic and radar level sensor with IO-Link for the IIoT

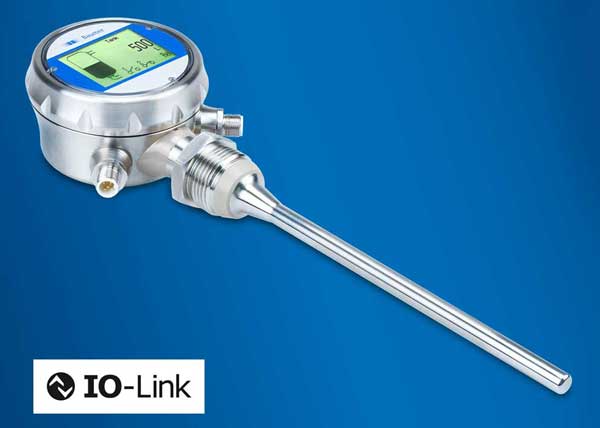

18.02.2021 | Turck offers a comprehensive portfolio for various media and environmental conditions for detecting limit levels or measuring fill levels. These include the one presented below Ultrasonic level sensor and the radar sensor for level measurement. IO-Link interfaces make the sensors IIoT suitable.

18.02.2021 | Turck offers a comprehensive portfolio for various media and environmental conditions for detecting limit levels or measuring fill levels. These include the one presented below Ultrasonic level sensor and the radar sensor for level measurement. IO-Link interfaces make the sensors IIoT suitable.

Level sensor for viscous media

25.10.2020/XNUMX/XNUMX | A Level sensor based on Cortec technology from EBE detects fill levels even with highly conductive and strongly adhesive media such as those in the Medical Technology occurrence. In contrast, the Capatec sensor is suitable for non-conductive tanks. With it the tolerances of the built-in Plastic Balance components from production and assembly.

The strengths of the Cortec Sensors can be seen in the clear distinction between volume and film as well as in the compensation of external interferers. EBE developed the Cortec level sensors to significantly improve the level measurement of viscous liquids. In the case of strongly adhering liquids, a level check with contactless sensors is often not reliable. Conventional, non-contact level switches usually reach their limits when measuring film-forming liquids. Level switches based on the Cortec platform, on the other hand, reliably detect columns of liquid in non-conductive containers and not only see through the walls of the container but also buildup.

Inductive sensor detects carbon for the first time in the world

Inductive sensor detects carbon for the first time in the world

Developed by EBE Evaluation algorithms can be designed for a wide variety of operating conditions. The Cortec technology is a multi-channel capacitive measuring process which excites the measuring electrodes in a defined spectral range. Due to the film adhering to the container walls, incorrect measurements can easily occur with classic capacitive sensors. With the Cortec it doesn't matter how strongly a medium adheres and conducts or how tough it is. The level is measured reliably.

Level measurement in medical technology

Facing the greatest challenge for level measurement Outer walls of containers that are covered with a film. Such applications often occur in medical technology when measuring blood or secretions. At the same time, contact with the medium is not possible in medical technology because safety and sterility have the highest priority. Coretec level sensors master both of these difficult conditions for conventional sensors without any problems.

Facing the greatest challenge for level measurement Outer walls of containers that are covered with a film. Such applications often occur in medical technology when measuring blood or secretions. At the same time, contact with the medium is not possible in medical technology because safety and sterility have the highest priority. Coretec level sensors master both of these difficult conditions for conventional sensors without any problems.

The level sensors see through attachments of blood, secretions or even liquid food, while they sit completely contact-free outside the container behind a protective wall or in a tight, seamless and therefore easy-to-clean housing. It cannot touch or damage anything there.

EBE designs and manufactures for OEM partner Ready-to-install level solutions, also with a housing and customer-specific interface. The sensors are suitable e.g. B. ideal for use in feeding and infusion pumps, dialysis machines, for urine monitoring or secretion and wound suction. The sensors reliably measure fill levels in suction pumps, blood samples or in laboratory diagnostics even when there is very little space. The technology is also suitable for pure detection tasks. This also offers the option of hose monitoring using capacitive sensors.

Level sensor with air gap compensation on the tank

The Level sensor A swap tank system often has to deal with fluctuating gap dimensions. EBE has developed a combined level sensor solution with air gap compensation for non-contact level measurement for non-conductive tanks. With the sensor Capatec can be the tolerances of the built Plastic Balance components from production and assembly.

The manufacturing tolerances that arise in the manufacture of plastic tanks and devices are caused by plastic frames fluctuating gap dimensions between the tank wall and the device frame of containers. However, measuring distances can also be influenced by variable wall thicknesses, thermal deformation of the plastic components or incorrectly inserted tanks. If the measured level fluctuations exceed 2 mm or more, level measurement for commercially available capacitive sensors becomes problematic. The new level sensor technology from EBE was specifically designed for such applications.

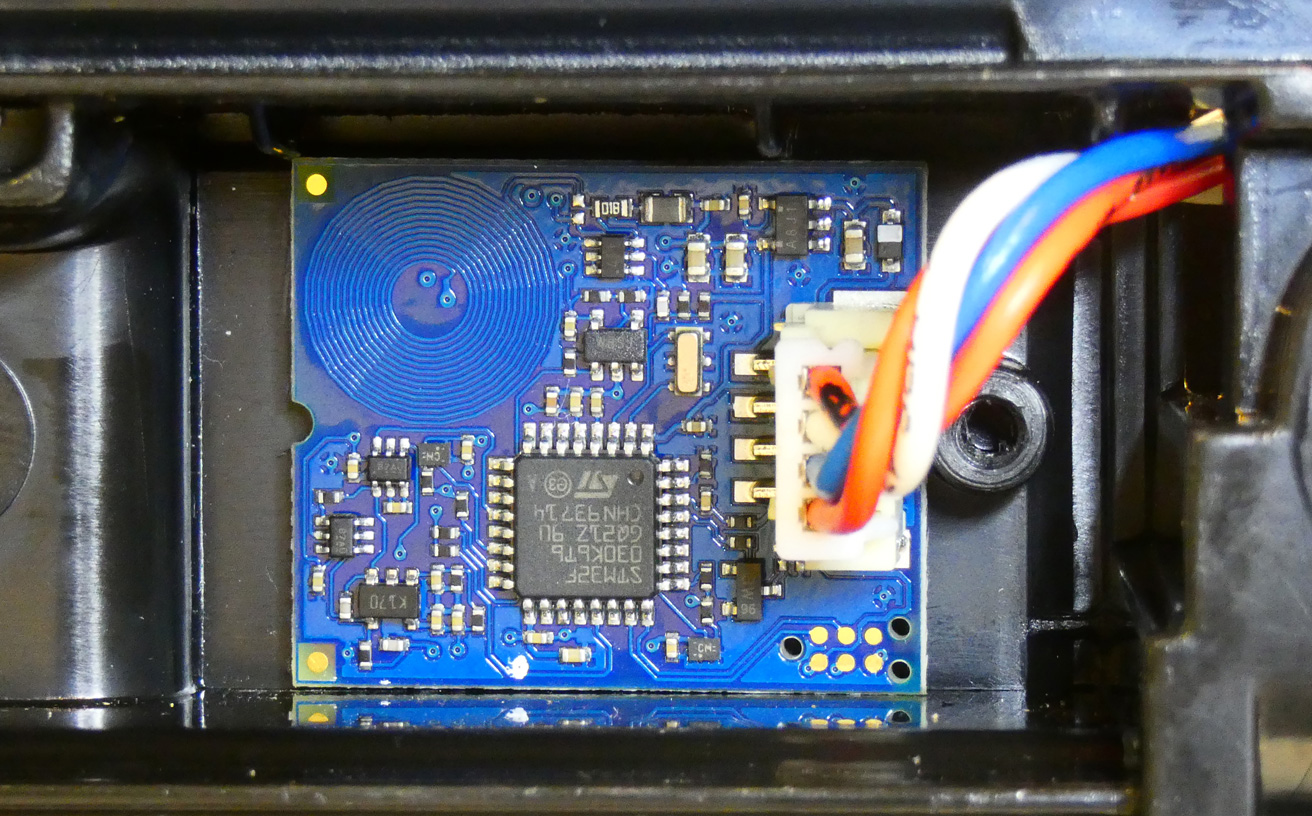

The new Combination sensor from EBE compensates for the effect of fluctuating gap dimensions. The capacitive level sensor with electrode structure and µcontroller was also equipped with an inductive proximity sensor. The fill level is capacitively measured from the outside through the tank wall, tank cavity and device frame. Thanks to the proximity sensor, the actual distance between the tank surface and the sensor surface is measured.

A small piece of aluminum is sufficient as a counterpart for the Indutec Sensor completely off. In this way, the parameters for the capacitive sensor can be updated in real time, depending on the individually existing air gap. The sensors are available as level sensors or limit value switches and as sensors with continuous measurement.

On the basis of the customer-specific development, the engineers determine the individual Parameter sets once and store them in the flash memory of the level sensors. There is therefore no need to calibrate the level sensor. There is no additional electronic effort. The coil structure required for the proximity sensor is integrated on the circuit board of the Capatec sensor. The µController takes over the electronic evaluation of the measurement and calculation.

The shape and surface of the combined level sensor can be adapted to the conditions and requirements of the tank. From a sensor area of 25 x 30 mm, you can already Air gaps and wall thicknesses a total of 7 mm or more can be overcome without any problems. Deposits and dirt in the liquid tank are irrelevant. Parasitic effects arise from the coverings. These are compensated by Capatec's algorithms.

The level sensor is suitable for use on swap tank systems in the process industry, white goods, mobile cleaning devices as well as in the sanitary and camping area.

Level sensor for SIL2 and SIL3 in the Köstritzer brewery

11.02.2020/XNUMX/XNUMX | In the field level sensor has Endress + Hauser Now the Liquiphant series, which has proven itself a million times over, has been expanded to include the new FTL51 model. The Liquiphant FTL51 was specially developed for the process industry according to IEC 61508 and is suitable for direct use in SIL2 and SIL3 applications without additional effort.

Ultrasonic sensors for distance, distance and level

Ultrasonic sensors for distance, distance and level

The video shows the use of the Liquiphant FTL51 in the CIP system Köstritz brewery. There it increases the safety of employees during maintenance work. Of the Level sensor measures reliably without being influenced by changing media properties. Regular proof tests according to SIL or WHG should now be carried out easily and mobile with the new point level switch with an intuitive assistant and the results should then be automatic.

IoT sensor monitors level and position remotely

16.01.2020/XNUMX/XNUMX | With the Level sensor concept "Wilsen.sonic.level" by Pepperl + Fuchs With the help of the Internet, the levels of liquids and bulk goods in containers, tanks or silos can be monitored remotely. The IoT sensor has an integrated ultrasonic measurement for measuring filling heights, filling levels and water levels.

16.01.2020/XNUMX/XNUMX | With the Level sensor concept "Wilsen.sonic.level" by Pepperl + Fuchs With the help of the Internet, the levels of liquids and bulk goods in containers, tanks or silos can be monitored remotely. The IoT sensor has an integrated ultrasonic measurement for measuring filling heights, filling levels and water levels.

Custom level sensors with guided microwave

Custom level sensors with guided microwave

10.01.2019 | EGE electronics also offers level sensors with guided microwaves in customer-specific versions. Based on its proven standard system, the sensor specialist is able to provide the measuring devices promptly different tank geometries, installation conditions or difficult media.

So allow z. B. angled measuring probes also the side installation in the tanks. For probes that are used in aggressive media, EGE uses special materials such as Hastelloy or titanium.

By specifically adapting to the dielectric constants and temperature ranges of the liquids to be measured, EGE's measuring systems ensure precise results even in problematic media and cramped installation conditions.

Coated miniature ultrasonic level sensor

17.04.2018/XNUMX/XNUMX | Aggressive media such as vapors or cleaning agents can damage the sensor front of ultrasonic sensors, the so-called transducer, and thus impair its function. The chemically robust ones Unar / Urar 12 Miniature sensors from Baumer are ideal for such environments thanks to a patented, wafer-thin Parylene coating on the sensor front and a full-metal stainless steel housing.

17.04.2018/XNUMX/XNUMX | Aggressive media such as vapors or cleaning agents can damage the sensor front of ultrasonic sensors, the so-called transducer, and thus impair its function. The chemically robust ones Unar / Urar 12 Miniature sensors from Baumer are ideal for such environments thanks to a patented, wafer-thin Parylene coating on the sensor front and a full-metal stainless steel housing.

The compact sensors are available as proximity switches, reflection barriers and distance sensors. Possible uses include, for example, level measurement of paints and varnishes in the graphic arts industry or in pressure tanks and compact laboratory containers pharmaceutical industry.

Thanks to very short response times of < 6 ms, a narrow sound cone and the FDA compliant material they are also suitable for fast applications such as detecting the presence of bottles in bottling plants in the food and beverage industry. In contrast to ultrasonic sensors with metal caps, the sensors with Parylene coating can be installed very easily and without any additional tools.

Precise fill level sensor for hygienic areas under foam

20.04.2015/2750/XNUMX | The new level sensor LRXNUMX from IFM Electronic withstands a wide variety of types of foam, often including reflective ones. The device was specially developed for demanding applications in the food industry, has a hygienic design and withstands aggressive cleaning processes. In addition, the sensor is equipped with an "Aseptoflex-Vario" thread for a large number of process adapters.

20.04.2015/2750/XNUMX | The new level sensor LRXNUMX from IFM Electronic withstands a wide variety of types of foam, often including reflective ones. The device was specially developed for demanding applications in the food industry, has a hygienic design and withstands aggressive cleaning processes. In addition, the sensor is equipped with an "Aseptoflex-Vario" thread for a large number of process adapters.

Through the use of high-quality and insensitive materials such as PEEK and EPDM as a sealing material and a housing made of V4A, the level sensor is very well suited for cleaning the inside and outside. It has protection class IP69K, increased pressure resistance up to 40 bar and is also designed for high media temperatures of up to 150°C. This further development is highly resistant to the most adverse environmental conditions such as cleaning with a steam jet.

An optional tank calibration makes the LR2750 extremely flexible. Even in difficult installation situations like on Tankstutzen the device works precisely and flawlessly. It is possible to shorten or replace the probe rods yourself. This means there is no need to stock multiple bar lengths when using different types of tanks, which simplifies replacement. Whether for smaller storage tanks, expansion tanks, separators or in bottling, the LR can be used almost anywhere and at will.

Versatile level switch certified for UL listing

15.01.2015/XNUMX/XNUMX | The versatile level switch "Clever Level LBFS/LFFS" from Baumer has now been listed by the American certification company Underwriters Laboratories Inc. (UL). The Clever Level test included numerous safety-related aspects according to the relevant UL standards and requirements. The renowned and globally accepted UL listing as a further quality feature makes it easier to use the level switch in important international markets, primarily in the USA.

15.01.2015/XNUMX/XNUMX | The versatile level switch "Clever Level LBFS/LFFS" from Baumer has now been listed by the American certification company Underwriters Laboratories Inc. (UL). The Clever Level test included numerous safety-related aspects according to the relevant UL standards and requirements. The renowned and globally accepted UL listing as a further quality feature makes it easier to use the level switch in important international markets, primarily in the USA.

With the Clever Level series LBFS/LFFS, this level switch offers numerous advantages as an all-rounder: It is for almost all media such as liquids, granules or electrostatic media. On the other hand, it is insensitive to buildup or foam, which can lead to faulty switching with other technologies.

Accurate and with a response time of less than 100ms the Clever Level reliably detects fill levels in tanks or pipes and protects pumps from running dry, for example. In addition, he is also able to distinguish different media, such as the differentiation of e.g. e.g. water and oil.

FAQ

How does a level sensor work?

A level sensor measures the level or height of a liquid, powder or other bulk material within a container. There are different types of level sensors that use different technologies to measure level. The most common technologies in level measurement include float sensors, ultrasonic sensors, capacitive sensors, radar sensors, Optical Sensors.

How does ultrasonic level measurement work?

Send ultrasonic sensors sound waves which are reflected from the liquid surface. The time it takes for the sound to travel there and back is measured and converted into a level signal.

How does hydrostatic level measurement work?

The hydrostatic level measurement is based on the principle that the pressure exerted by a column of liquid on the bottom of a container is directly proportional to the height of the liquid column above the measuring point. In this method, a pressure sensor is placed at the bottom of the container or at a certain depth below the surface of the liquid. The sensor measures the pressure created by the weight of the liquid above it. Since this pressure depends on the height of the liquid column, the filling level can be calculated from the measured pressure.

Source: This article is based on information from the following companies: Ege-Elektronik, Endress+Hauser, IFM Electronic, Jumo, Pepperl+Fuchs, Turck.

You might also be interested in...

Gateways | The bridge to the Industry 4.0 factory

Control Fair 2024 | The industry is already looking forward to Stuttgart

RFID and Barcodes | Industrial identification

Ethernet APL | The game changer

PLC | The programmable logic controller

Thermocouple | Temperature sensor for measuring temperature

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.