Different measurement principles are used to record limit levels or measure fill levels. Turck offers a comprehensive portfolio for various media and environmental conditions. These include the one presented below Ultrasonic level sensor and the radar sensor for level measurement. IO-Link interfaces do that Sensors IIoT suitable.

Contents

which Measuring principle used to measure the level depends on whether liquids or a granular medium such as bulk solids are to be measured. The extensive sensor product range from Turck is designed for various media in liquids and bulk solids and can measure in contact with the media or without contact. It contains capacitive, ultrasonic, magnetostrictive, fiber optic level switches and also devices with guided microwave. Below we introduce you to two new level sensors before:

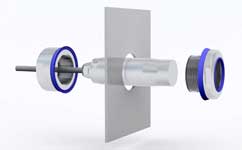

February 18.02.2021, XNUMX | The ultrasonic level sensor LUS211 von Turck is designed for level measurement in the range of up to 40 or 130 cm. The ultrasonic sensor based on Turck's Fluid 2.0 platform can be operated at pressures of 0,5 to 5 bar at the process connection. The new LUS211 level sensor is therefore after the pressure sensor PS+, the flow sensor FS+ and the temperature sensor TS+ is the fourth sensor category of this robust Turck platform. All sensors offer a uniform design.

Each level switch has in common the consistent operating concept for simplified commissioning, flexible installation options with a rotatable sensor head and the touch display under a translucent front cap that does not protrude controls requires. Like all sensors of the Fluid 2.0 program The LUS211 devices also offer protection class IP67 / 69K.

Pressure sensor innovations for digitization in measurement technology

Pressure sensor innovations for digitization in measurement technology

This means that they function reliably even under adverse conditions. The continuous evaluation of the signal strength as well as the reset and thus protected sound transducer of the level sensor ensure increased system availability. In the event of overfilling, an air cushion prevents the medium from contacting the sound transducer.

The LUS211 series has process connections G ¾ and NPT ¾. The Reach is 40 and 130 cm respectively. Either two switching outputs or one switching and one analog output are available. With the additional IO-Link interface and intelligent, decentralized signal preprocessing, all ultrasonic level sensors are also suitable as smart data providers for the Industrial Internet of Things (IIoT). The ultrasonic sensor can be parameterized with existing container geometry data via IO-Link. This directly outputs the values for distance, level or volume in absolute terms or in percent.

Temperature Sensor | humidity sensor | vibration sensor

Temperature Sensor | humidity sensor | vibration sensor

The following video presents the Smart Sensor Solutions Solutions from Turck. It includes sensors for distance measurement, object recognition and the detection of fluids:

Turck's new radar sensor family LRS510 offers extensive analysis functions for challenging level measurement in tanks and silos. The IO-Link capable level sensor from the newly developed LRS series complements the portfolio for level measurement in the range from 0,35 to 10 m. The new level sensors with protection class IP67/69K are particularly recommended for continuous level measurement in factory automation, for which optical or ultrasonic sensors are not suitable because of their limited range or due to disruptive factors such as dust, wind or light.

IoT sensor monitors level and position remotely

IoT sensor monitors level and position remotely

The free-radiating LRS radar sensor offers detailed analysis functions of the measurement, which so far have mostly been in the process industry used high-end radar sensors were reserved. A metallic lead rod was dispensed with in the construction. This favors the use in hygienic areas. This also simplifies commissioning.

The operating unit from the LRS level sensor is equipped with capacitive buttons and a translucent front cap. The design follows the concept of the Fluid 2.0 sensor platform from Turck. It allows the values of distance, level and volume to be output. The radar sensors are also available with two switching outputs or with one switching and one analog output. The additional IO-Link interface and the intelligent, decentralized signal preprocessing enable numerous additional information for processing in condition monitoring applications in the IIoT. In addition to the signal strength, these are values for temperature and the number of operating hours or switching cycles.

Ultrasonic sensors for distance, distance and level

Ultrasonic sensors for distance, distance and level

Without additional software, users of the IO-Link master can use the IODD configurator go to the radar monitor. The browser-based configuration tool offers access to the plain text of all relevant parameters and shows the measurement curve of the sensor graphically. B. can easily hide the interference signal from a grid or agitator or align the sensor perfectly using real-time feedback. This guarantees the reliability of continuous level measurement even in demanding applications.

Turck is exhibiting at the Hannover Messe 2022.