Level sensor for every level measurement

- Details

- Hits: 7572

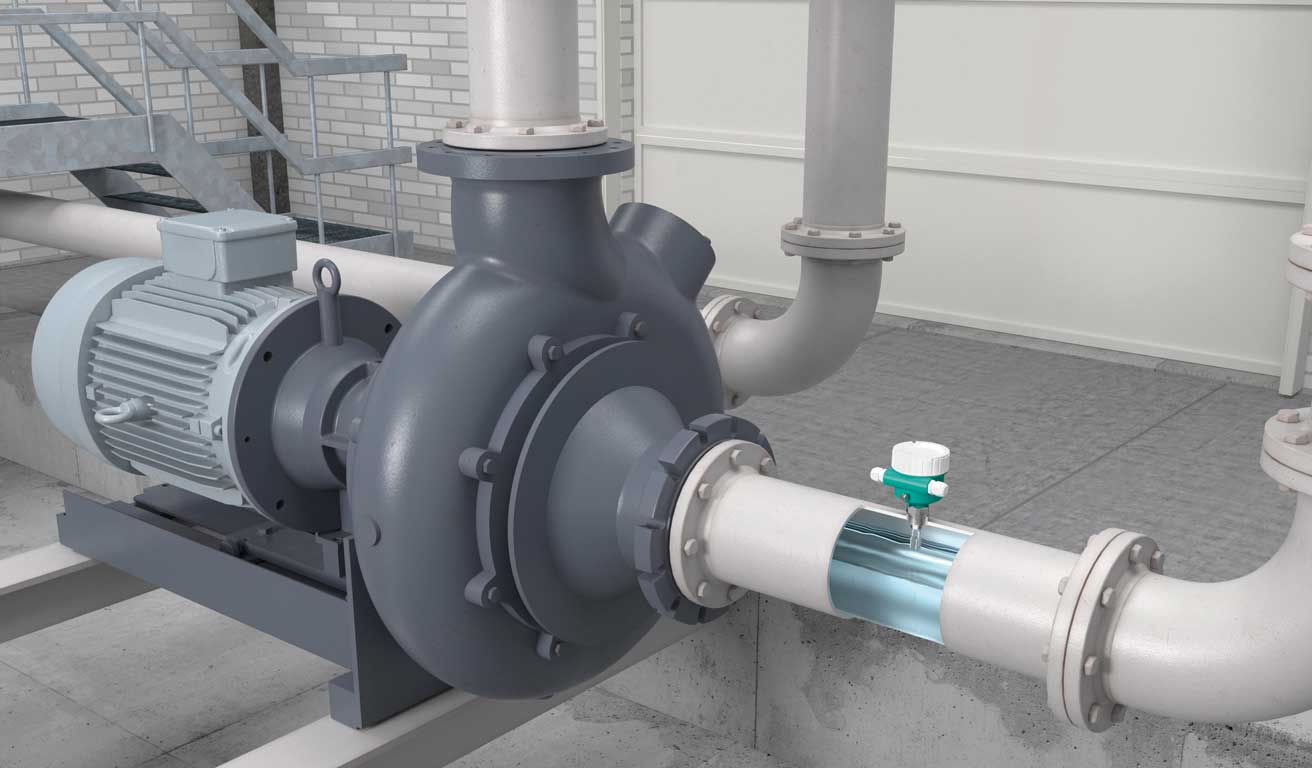

level sensors, also referred to as fill level gauges or level sensors, are devices that are used to measure the fill level or the quantity of a medium within a container or tank or are used for limit level detection. They are required in many applications for level measurement, such as in the process industry, Food industry, chemical industry, water and waste water treatment and many more. Pepperl + Fuchs has a solution for every application.

Contents

All-rounder for level measurement

27.07.2023/XNUMX/XNUMX | In chemical plants as well as in the oil and gas industry, vibrating level switches reliably detect the level or the filling level of liquids. With the level switch Vibracon LVL-M3 and -M4, Pepperl+Fuchs offers two new series of vibrating level switches. With their Atex and IECEx approvals, they are suitable for use in potentially explosive areas worldwide.

27.07.2023/XNUMX/XNUMX | In chemical plants as well as in the oil and gas industry, vibrating level switches reliably detect the level or the filling level of liquids. With the level switch Vibracon LVL-M3 and -M4, Pepperl+Fuchs offers two new series of vibrating level switches. With their Atex and IECEx approvals, they are suitable for use in potentially explosive areas worldwide.

The level meter LVL-M3 is suitable for universal use in all pumpable liquids. The vibrating level switch withstands process temperatures from -40° to +150 °C and process pressures of up to 40 bar.

The LVL-M4 variant is ideal for security applications up to SIL 3. The sensor withstands process temperatures from -50° to +150 °C and process pressures of up to 100 bar. As a particular highlight, the LVL-M4 variant has a Bluetooth interface for the level sensor, which can be used to connect the level limit switch to the Level App from Pepperl+Fuchs. This mobile application offers a variety of options - from status and error display to performing repeat tests.

Terahertz receiver for 6G network with the highest data rate

Terahertz receiver for 6G network with the highest data rate

The vibrating level switches of the Vibracon series do not have any mechanically moving parts and therefore offer a special long service life. Thanks to the plug-and-play principle, there is no need to calibrate to different media. A large selection of process connections and electronic inserts allows flexible adaptation to different environments.

IoT level sensors monitor level and position

16.01.2020/XNUMX/XNUMX | With the Level sensor concept "Wilsen.sonic.level" from Pepperl + Fuchs With the help of the Internet, the levels of liquids and bulk materials in containers, tanks or silos can be monitored remotely. The IoT sensor has an integrated ultrasonic level measurement for measuring filling heights, levels and water levels. These measured values are recorded at regular intervals and transmitted to the Internet together with the current geo-position. The autonomously working radio sensor is battery operated and thus enables measurements in mobile containers.

16.01.2020/XNUMX/XNUMX | With the Level sensor concept "Wilsen.sonic.level" from Pepperl + Fuchs With the help of the Internet, the levels of liquids and bulk materials in containers, tanks or silos can be monitored remotely. The IoT sensor has an integrated ultrasonic level measurement for measuring filling heights, levels and water levels. These measured values are recorded at regular intervals and transmitted to the Internet together with the current geo-position. The autonomously working radio sensor is battery operated and thus enables measurements in mobile containers.

The Wilsen.sonic.level is suitable for level applications in different radio networks. One version is with GSM (2G) interface for public cellular networks fitted. Another has a Lora WAN interface for the use of privately operated low power radio networks. The respective radio interface is used to transmit the sensor data to the Internet.

Depending on the radio standard selected, a corresponding remote station waits for the incoming sensor data from the level measurement. So send the Lorawan devices your telemetry data to the network and application server of any Lora network operator. For applications with the public cellular standard GSM, the middleware Wilsen.service is available as a secure counterpart for the telemetry data from the sensor.

System concept of the Wilsen.service

The system concept of the Wilsen.service guarantees the decryption and targeted forwarding of the sensor data. It also offers convenient and secure device management. This is particularly advantageous if there are many in later practice IoT sensors are used. They are to be registered in the wireless network as automatically as possible and assigned to their legitimate users.

2D lidar sensor for more flexible transport shuttle from Montratec

2D lidar sensor for more flexible transport shuttle from Montratec

In addition, the Wilsen.service device management allows an automatable Application parameterization the IoT Sensors and a structured roll-out for software updates. In this way, a large number of IoT sensors can be kept up to date in the field for level measurement.

The Wilsen concept provides for a modular IoT system in which the individual components such as radio nodes, sensor modules, data processing and middleware can be added to.

You might also be interested in...

Industrial radar sensor with CAN interface

Artificial Intelligence | trends and developments

RFID and Barcodes | Industrial identification

RFID reader and barcode scanner for identification

battery production | Facts and Technologies