Reduce carbon footprint | That's how it's done!

- Details

- Hits: 5506

Your carbon footprint More and more companies want to reduce in order to counteract climate change with various climate protection measures. In this way, tons and tons of dangerous greenhouse gases can be saved. We present you here product and process solutions, with which CO2-Let emissions be reduced for a sustainable, climate-neutral industry.

Contents

CO2 Calculate footprint – who, how, what?

The CO2-Footprint advances under the CSR policy increasingly in the focus of medium-sized companies. In 2024, companies with more than 500 employees must include environmental indicators in the calculation of their 2023 annual reports and also request the indicators from their suppliers. From January 2025, this regulation will already apply to companies with more than 250 employees. But how is the CO2-Footprint actually calculated?

World's first urban bike made from recycled plastic

World's first urban bike made from recycled plastic

International standards like that Greenhouse Gas Protocol and the ISO 14064 standard are applicable here. Key figures such as the purchased energy consumed in the form of electricity, heat or cold, the company's own vehicle fleet, and the CO produced on business trips are included as factors2 emissions or purchased products and services. In the following, we present ways of expanding your “climate protection horizon”:

CO2 Gasket footprint down to the gram

07.02.2023 | As a manufacturer of low-friction seals Freudenberg Sealing Technologies live up to their responsibility for climate protection. To this end, the company has developed a method that can be used to determine the CO2 footprint from the manufacture of seals and other components.

How many grams of CO2 are in a seal? And how can already in the construction phase of a component Greenhouse gas balance from production minimize? To answer these questions seriously, Dr. Meike Rinnbauer and Volker Schroiff at Freudenberg Sealing Technologies. For two years they have been working on a way to precisely determine the carbon footprint of their products. Two factors significantly influence the emission balance of a component: the material and the manufacturing process of the seal. The influence of transport, on the other hand, is smaller by orders of magnitude and can therefore initially be ignored.

Reading tip: Measurement technology for hydrogen production

Reading tip: Measurement technology for hydrogen production

For determining the greenhouse gas balance of Materials Freudenberg has its own GreenIndex developed. In addition to the climate-relevant emissions, other environmental properties of chemical substances should also be taken into account in order to be able to compare and evaluate materials and processes internally. "We try to avoid toxic precursors as far as possible in order to ensure the occupational safety of our employees and also to take other environmental influences into account," says dr Rinnbauer. Since modern seals often consist of material mixtures, all individual components are taken into account in order not to set any false incentives for the selection of certain materials.

Determination of greenhouse gas potential

To determine the greenhouse gas potential, eng. Global warming potential (GWP), individual material components, Freudenberg Sealing Technologies uses an expert database. This meets the ISO standard 14044 for life cycle assessments. Mean and location-independent GWP values are used for each individual material, regardless of its specific origin. In the future, the experts expect that manufacturer and location-specific parameters will be available along the entire supply chain. "This would also allow us to select material suppliers not only on the basis of costs, quality and availability, but also on the basis of sustainability criteria," says Dr. Rinnbauer. The sum of all GWPs weighted according to material proportions ultimately results in the overall GWP of a seal.

At the same time, the harmfulness of individual material components is checked using the company's own occupational health and safety guidelines and the European Reach chemicals regulation. Depending on the harmfulness class, a penalty factor assigned, ranging from 1 (harmless) to 2 (persistent). The worst individual value determines the factor by which the overall GWP is multiplied. The resulting dimensionless value can then be assigned to a certain sustainability class of the Green Index for the sealing material. The determined index values are then available to the developers in a company-wide materials database.

Example fluororubber materials

Based on two fluororubber materials (FKM) for industrial seals, the effect resulting from the weighting process is to be presented: The first mixture does not contain any harmful material components and has a greenhouse gas potential of 9,4 kilos of CO2 / kilo of material. The second mixture generates 8,0 kilos of CO2 / kilo of material. However, the mixture contains a hazardous substance that leads to the classification "unsustainable" in the Green Index. Because the lower sustainability is taken into account with a penalty of 1,66, the first mixture performs better in the overall balance.

An example of a polyolefin based seal for fuel cells also shows that a material can also be very sustainable if it contains a persistent catalyst with a low content of 0,08%. How and to what extent sustainability factors should be taken into account beyond the GWP has not yet been finally decided at Freudenberg Sealing Technologies either. "It is important that we do not optimize one-dimensionally," explains Dr. Rinnbauer. "When selecting the material, we also take service life and wear resistance into account, which influence the ecological balance of our customers."

Die for the manufacture of seals expended energy naturally also leads to CO2 emissions if the production plants are not completely supplied by greenhouse gas-neutral sources. The big challenge is to correctly allocate the CO2 emissions that are incurred for this. It is therefore important to know how much energy is actually consumed in individual process steps in relation to weight, volume or surface area.

Based on the company's core processes, a team at the headquarters in Weinheim examined the specific energy consumption and other environmentally relevant parameters such as the amount of technical waste (engineered waste) consisting of processed material. The four core processes examined include material mixing, shaping, coating and post-heating. In terms of material weight, mixing turned out to be about as energy-intensive as shaping and vulcanization. "But we were particularly surprised that reheating consumes almost as much energy as shaping and vulcanization," says Volker Schroiff.

Simmerring and housing part as sample products

To launch the team, the results were transferred to two sample products: a Simmerring FK extension and a housing part polyamide 6.6 with a functional coating for electromagnetic shielding. There were clear differences: in the case of the Simmerring, shaping and vulcanization account for around half of the entire production-related energy consumption. CO 2 emissions could be reduced by a third with an optimized molding process without post-processing. In the case of the housing part, the plastic production requires a significantly higher proportion of around 40% energy, around a tenth is caused by the coating. In the production of polyamide components, too, a significant proportion of the total emissions are attributable to the material and possibly the technical waste.

Overall it shows a clear trend: "The avoidance of waste during production is the greatest lever for manufacturing components in a more climate-friendly manner, as long as we at least still use fossil energy," explains Mr. Schroiff. "Freudenberg Sealing Technologies is already consistently using waste-avoiding production technology. Just by using cold runner injection molding with valve gate, the company already saves around 70 t of waste and emits 600 t less carbon dioxide every year.

Great interest in CO2-Footprint tracking

10.01.2023/XNUMX/XNUMX | the Ecospeed AG can look back on a very good financial year and is planning further growth for 2023. This development is fueled by the industrial business. Very many, especially medium-sized companies are looking for solutions to reduce the CO2-Determine the footprint of your products and processes.

10.01.2023/XNUMX/XNUMX | the Ecospeed AG can look back on a very good financial year and is planning further growth for 2023. This development is fueled by the industrial business. Very many, especially medium-sized companies are looking for solutions to reduce the CO2-Determine the footprint of your products and processes.

Ecospeed is owner-managed, has been in business for twenty years and has now reached a critical mass with over 2000 customers that is responsible for Future security stands. The sudden increase in demand here did not come as a complete surprise.

“On January 1, 2024, the scope of the will be extended in the EU CSR policy to companies with more than 500 employees," comments Christoph Hartmann, founder and managing director of Ecospeed AG. "Companies must include environmental indicators in their annual reports for the year 2023 and also request these indicators from their suppliers. A year later, from January 2025, this also applies to companies with 250 or more employees. This means that the industry must deal with this topic. For this task, we offer proven and easy-to-use software for determining the key figures for the CO2-Footprint."

For this reason, the view of the new financial year is consistently positive: “We plan with you at least a hundred new customers from the industry and primarily have in mind medium-sized companies with around 200 to 2000 employees who precisely and easily measure their CO2-Footprint or want to determine the product carbon footprint.”

Ecospeed already has 20 years experience in the field of CO2-Emissions related to climate protection. The company started with applications for buildings and municipalities, before later adding industry. This applies to the product-related calculation of CO2-Footprint and for the emissions of the whole company (Corporate Carbon Footprint / CCF), ie for the CO2Footprint.

The software is according to the standard eco scout certified, which leading German companies such as VW, SAP and TÜV Rheinland have developed in cooperation with the German Federal Ministry for the Environment (BMU), the Federal Environment Agency (UBA) and the Federal Office for the Environment (BAFU) of Switzerland. The software for determining the CO2 footprint is up to date and is constantly being updated. "Of course we also feel the shortage of skilled workers in the IT industry, but we have committed developers in-house and a dense network of certified specialist consultants," reports Mr. Hartmann.

Workshops to develop a climate strategy

09.01.2023 | First Climate offer workshops on climate-related topics to support companies in developing efficient climate strategies. The “Plan climate commitment” service offers the opportunity to book fee-based introductory workshops related to climate and to take part in the workshops digitally in an uncomplicated way and from any location.

09.01.2023 | First Climate offer workshops on climate-related topics to support companies in developing efficient climate strategies. The “Plan climate commitment” service offers the opportunity to book fee-based introductory workshops related to climate and to take part in the workshops digitally in an uncomplicated way and from any location.

The offer is aimed at companies that are committed to climate protection Climate strategy want to develop and those who do not yet have the necessary prior knowledge.

"As part of the interactive, needs-based training, the necessary basics are taught that are important for preparing for the requirements of corporate climate protection management," explains Barbara Mettler, Head of Climate Engagement Programs at First Climate. A company with any number of employees can take part in the individual training courses. The introductory workshops can be tailored to the individual needs of small and medium-sized companies.

The following two topics are available:

- Workshop 1: Climate change and entrepreneurship Climate protection commitment

- Workshop 2: Entrepreneurial Define climate targets – Introduction to the world of Science-Based Targets (SBTs)

CO2 footprint proof for Tribo plain bearings

26.10.2022/XNUMX/XNUMX | How much CO2 gets into the atmosphere through the production of a plastic plain bearing? Igus publishes for the first time the exact CO2 footprint for many lubrication-free and maintenance-free iglidur polymer bearings. Users can enter the values as Scope 3 emissions in the CO2-Include the balancing of climate-neutral products.

26.10.2022/XNUMX/XNUMX | How much CO2 gets into the atmosphere through the production of a plastic plain bearing? Igus publishes for the first time the exact CO2 footprint for many lubrication-free and maintenance-free iglidur polymer bearings. Users can enter the values as Scope 3 emissions in the CO2-Include the balancing of climate-neutral products.

Dassault Systèmes is a founding member of the EGDC

07.04.2021 | Dassault Systemes is a founding member of European Green Digital Coalition (EGDC). The association of leading technology companies pursues the common mission of supporting the green and digital transformation of the economy in and outside of Europe.

07.04.2021 | Dassault Systemes is a founding member of European Green Digital Coalition (EGDC). The association of leading technology companies pursues the common mission of supporting the green and digital transformation of the economy in and outside of Europe.

Calculate servo hydraulic CO2 savings online

26.01.2022/XNUMX/XNUMX | With a change from Hydraulic System on servo-hydraulic drives, more than 50% energy (kWh) per cycle can be saved with a hydraulic machine, depending on the application. Baumüller presents an energy calculator. The energy consumption of a classic fixed displacement pump is similar to that of one servohydraulic pump faced.

26.01.2022/XNUMX/XNUMX | With a change from Hydraulic System on servo-hydraulic drives, more than 50% energy (kWh) per cycle can be saved with a hydraulic machine, depending on the application. Baumüller presents an energy calculator. The energy consumption of a classic fixed displacement pump is similar to that of one servohydraulic pump faced.

Products and processes that reduce CO2 emissions

Many companies record their New developments already the ecological footprint. The CO2 footprint or product carbon footprint of a product shows which CO 2 emissions or which CO2 -Emissions occur in the various phases of the life cycle of products - from raw material extraction to transport, production, use and end-of-life scenario. The following products and solutions will bring you one step closer to your climate protection goals:

- Cylindrical roller bearings for heavy industrial gears

- Brake energy manager in automobile assembly

- Curve slide made from recycled high-performance plastic

- Plain bearing made of plastic regranulate

- With stock processing CO2-Reduce emissions

- Cooperation for green steel saves 80% CO2

- Spacer reduces CO2-Footprint by 90%

- With Ultrasonic Welding CO2 reduce footprint

- CO2 poor steel for the Hyperloop

- Domino connector saves 50% space and weight

- Climate-neutral fuel cell versus electric drive

- 50% less CO2-Emissions with mineral casting

Cylindrical roller bearings for heavy industrial gearboxes and construction machinery

16.04.2024 | Schaeffler presents its new ones Cylindrical roller bearings NJ23-ILR series for construction machinery and heavy industrial gearboxes. The rolling bearings are compact and equipped with the high-performance Mpax cage. With regard to the base bearing type NJ23, the load capacity could be increased by an average of 24%. The service life doubles.

16.04.2024 | Schaeffler presents its new ones Cylindrical roller bearings NJ23-ILR series for construction machinery and heavy industrial gearboxes. The rolling bearings are compact and equipped with the high-performance Mpax cage. With regard to the base bearing type NJ23, the load capacity could be increased by an average of 24%. The service life doubles.

Brake energy manager in automobile assembly

21.02.2024/XNUMX/XNUMX | A car manufacturer wanted to make its vehicle production more energy efficient and therefore more environmentally friendly - not least because the previous assembly process did not produce COXNUMX2-Specifications met. In the new direction, the CO2-Footprint should be as small as possible. With the energy management devices from Michael Koch let themselves 3,5 t CO2 save.

21.02.2024/XNUMX/XNUMX | A car manufacturer wanted to make its vehicle production more energy efficient and therefore more environmentally friendly - not least because the previous assembly process did not produce COXNUMX2-Specifications met. In the new direction, the CO2-Footprint should be as small as possible. With the energy management devices from Michael Koch let themselves 3,5 t CO2 save.

Mineral casting instead of gray cast iron for machine beds

29.11.2023 | Rampf Machine Systems has had the CO2 footprint of its epument mineral casting determined. The result is an around that 4,5 times lowerhe emission value than that of gray cast iron. For example, with a machine frame weighing 10 t, 12.940 kg of CO can be produced using Epument mineral casting2 save compared to gray cast iron.

29.11.2023 | Rampf Machine Systems has had the CO2 footprint of its epument mineral casting determined. The result is an around that 4,5 times lowerhe emission value than that of gray cast iron. For example, with a machine frame weighing 10 t, 12.940 kg of CO can be produced using Epument mineral casting2 save compared to gray cast iron.

Curve slide made from recycled high-performance plastic

19.10.2023/XNUMX/XNUMX | The new Slide Drylin Econ from Igus are particularly sustainable. Iglidur ECO P regranulate is used for injection molding, which consists of 100% waste such as sprues and missing parts from injection molding production. You can realize movements in a quarter, half or full circle as well as convex and concave arch guides.

19.10.2023/XNUMX/XNUMX | The new Slide Drylin Econ from Igus are particularly sustainable. Iglidur ECO P regranulate is used for injection molding, which consists of 100% waste such as sprues and missing parts from injection molding production. You can realize movements in a quarter, half or full circle as well as convex and concave arch guides.

Plain bearing made of plastic regranulate

Oct 19.10.2023, XNUMX | Because plastic is a valuable resource and as little as a gram should be lost, Igus produces regranulate for the plain bearing series from sprues and missing parts from injection molding production Iglidur ECO. New to the range is the chemical-resistant version Iglidur ECO P210.

Oct 19.10.2023, XNUMX | Because plastic is a valuable resource and as little as a gram should be lost, Igus produces regranulate for the plain bearing series from sprues and missing parts from injection molding production Iglidur ECO. New to the range is the chemical-resistant version Iglidur ECO P210.

Reduce CO2 emissions with warehouse processing

01.08.2023/XNUMX/XNUMX | With the Remanufacturing or the systematic reconditioning of roller bearings Schaeffler has been providing its customers with an important service in the field of sustainable circular economy for many years. This service is provided for the regional market by Schaeffler Industrial Remanufacturing Services AG & Co. KG, based in Wuppertal.

01.08.2023/XNUMX/XNUMX | With the Remanufacturing or the systematic reconditioning of roller bearings Schaeffler has been providing its customers with an important service in the field of sustainable circular economy for many years. This service is provided for the regional market by Schaeffler Industrial Remanufacturing Services AG & Co. KG, based in Wuppertal.

Cooperation for green steel saves 80% CO2

13.06.2023/XNUMX/XNUMX | The collaboration between ArcelorMittal, Finkernagel and Ejot is a premiere in the form of a cooperation between manufacturers, processors and end product manufacturers to reduce environmental impact.

13.06.2023/XNUMX/XNUMX | The collaboration between ArcelorMittal, Finkernagel and Ejot is a premiere in the form of a cooperation between manufacturers, processors and end product manufacturers to reduce environmental impact.

Arcelor Mittal Hamburg produces high levels of CO2-reduced XCarb steel made from recycled and renewable material with significantly lower CO2-Footprint than conventionally produced steel. The wire factory Finkernagel processes the steel. Ejot makes from the drawn wire in cold forming screws here for them Batteries in electric cars or for mounting solar modules.

By using XCarb steel, the CO2-Savings totaling 80% compared to producing conventional steel. In addition, the CO2-reduced steel in the solar panels and Electric Cars a second time benefiting the energy transition.

Arcelor Mittal green steel

Arcelor Mittal has been bundling with the umbrella brand since 2021 XCarb the efforts towards climate-neutral steel production. The company invests in technologies and start-ups, issues certificates for CO2- Savings in steel production and is dedicated to particularly low-carbon production variants.

The XCarb steel is made from recycled and renewable material in one electric arc furnace Manufactured using 100% renewable electricity and up to 100% scrap depending on steel grade.

The emissions from these steel products are sometimes up to 333 kg CO₂ equivalents per tonne of the end product. The green steel used by Finkernagel and Ejot significantly reduces the Scope 3 emissions of both companies.

CO2 Goals of the cooperation partners

The Ejot Group wants its CO 2-Emissions from currently approx. 190.000 t/year to 2035 lower to zero.

In addition to various own measures to reduce CO 2 emissions (Scope 1 and Scope 2), Finkernagel primarily relies on the use of a CO2-poor steel-primary material.

Arcelor Mittal intends to up its decarbonization strategy 2050 achieve net-zero emissions worldwide.

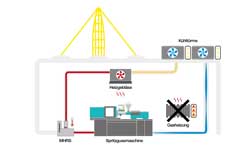

Hall heating concept uses waste heat from machines

May 15.05.2023, XNUMX | Igus engineers have a simple method heat recovery for the hall heating developed. They heat with waste heat from machines and thus reduce gas costs and CO2-emissions. The Cologne-based company also offers the concept of innovative technology to other companies – free of charge!

May 15.05.2023, XNUMX | Igus engineers have a simple method heat recovery for the hall heating developed. They heat with waste heat from machines and thus reduce gas costs and CO2-emissions. The Cologne-based company also offers the concept of innovative technology to other companies – free of charge!

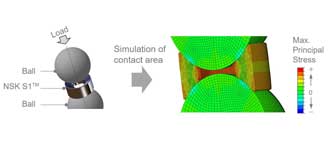

Spacer reduces carbon footprint by 2%

21.06.2023 | NSK presents a world first with the spacer element for ball screws 100% bio-based Plastic. Compared to plastic made from fossil fuels, the CO2-Footprint reduced by 90% over the entire life cycle. The bio-based high-performance is usedpolyamide Ecopaxx.

21.06.2023 | NSK presents a world first with the spacer element for ball screws 100% bio-based Plastic. Compared to plastic made from fossil fuels, the CO2-Footprint reduced by 90% over the entire life cycle. The bio-based high-performance is usedpolyamide Ecopaxx.

Reduce carbon footprint with ultrasonic welding

11.10.2022 | At the Ultrasonic welding Heat and pressure are generated and used differently. The vibration with precise frequency and amplitude generates heat between the surfaces of the thermoplastic layers. Taken together, ultrasonic welding on an assembly line results in: Emerson a 25% reduced CO2 Footprint.

11.10.2022 | At the Ultrasonic welding Heat and pressure are generated and used differently. The vibration with precise frequency and amplitude generates heat between the surfaces of the thermoplastic layers. Taken together, ultrasonic welding on an assembly line results in: Emerson a 25% reduced CO2 Footprint.

Low-CO2 steel for the Hyperloop

04.10.2022 | Harden Hyperloop and Tata Steel have signed a contract for the supply of Zeremis Carbon Lite. the green steel has a CO reduced by up to 100%2 Footprint verified by DNV (Det Norske Veritas). The steel is indispensable in the production of the light but stable Hyperloop tubes.

04.10.2022 | Harden Hyperloop and Tata Steel have signed a contract for the supply of Zeremis Carbon Lite. the green steel has a CO reduced by up to 100%2 Footprint verified by DNV (Det Norske Veritas). The steel is indispensable in the production of the light but stable Hyperloop tubes.

Domino connector saves 50% space and weight

30.05.2022/XNUMX/XNUMX | Presented against the background of industrial transformation Harting a new Han-Modular series with the Domino modules. With that, the industry Connectors raised to a new module level. One Domino connector saves space and weight up to 50%, which reduces CO2-Footprint reduced.

30.05.2022/XNUMX/XNUMX | Presented against the background of industrial transformation Harting a new Han-Modular series with the Domino modules. With that, the industry Connectors raised to a new module level. One Domino connector saves space and weight up to 50%, which reduces CO2-Footprint reduced.

World's first 100 percent recycled e-chain

May 11.05.2022, XNUMX | From cradle to cradle: with the new one Cradle chain E2.1.CG Energy chain Igus once again conserves resources and extends the product life cycle. The world's first energy chain made from recycled material was developed based on Chainge's own energy chain recycling program.

May 11.05.2022, XNUMX | From cradle to cradle: with the new one Cradle chain E2.1.CG Energy chain Igus once again conserves resources and extends the product life cycle. The world's first energy chain made from recycled material was developed based on Chainge's own energy chain recycling program.

Climate-neutral fuel cell versus electric drive

17.11.2021 | If you use regenerative electricity, the Fuel cell lt Bosch completely climate neutral. If you calculate the CO2 Output for production, operation and disposal together is the CO2 The balance for large or heavy vehicles is better than for electric drives. The CO2-Footprint is significantly smaller.

50% less CO2 emissions with mineral casting

21.02.2019/XNUMX/XNUMX | In the manufacture of Mineral casting waived for machine frames Rampf now on the addition of rock cave fly ash. Because Epudur high-performance concrete saves on processing, around 50% less CO is produced compared to milling2 emissions. Users can use this to optimize their ecological footprint.

21.02.2019/XNUMX/XNUMX | In the manufacture of Mineral casting waived for machine frames Rampf now on the addition of rock cave fly ash. Because Epudur high-performance concrete saves on processing, around 50% less CO is produced compared to milling2 emissions. Users can use this to optimize their ecological footprint.

FAQ

What is meant by a CO?2 Footprint?

The CO2-Footprint is an important tool for sustainable companies to assess their impact on climate change. As a central component of the eco or CO2 balance and reporting on sustainability, the CO2-Footprint, in which areas the most greenhouse gases are released and where the greatest potential for reducing the carbon footprint lies. The CO2 footprint is the result of the calculated emissions that arise through entrepreneurial activity in the business and production processes as well as through the manufactured products themselves.

How can I get my CO2 Calculate footprint?

For your carbon footprint to calculate, you can use various online tools, often referred to as "CO 2 calculator" or "CO calculator". These carbon calculators assess your carbon footprint or carbon footprint based on various aspects of life including energy use, dietary habits, modes of transport and more.

They usually give the result as CO 2 equivalent aus, a measure that takes all different types of greenhouse gas emissions into account and relates them to the effect of CO2. This helps to quantify CO 2 emissions and CO emissions. Some of these tools also offer tips on how to reduce your footprint. The statement that can be drawn from these calculations is a quantified value that represents your personal commitment to climate protection.