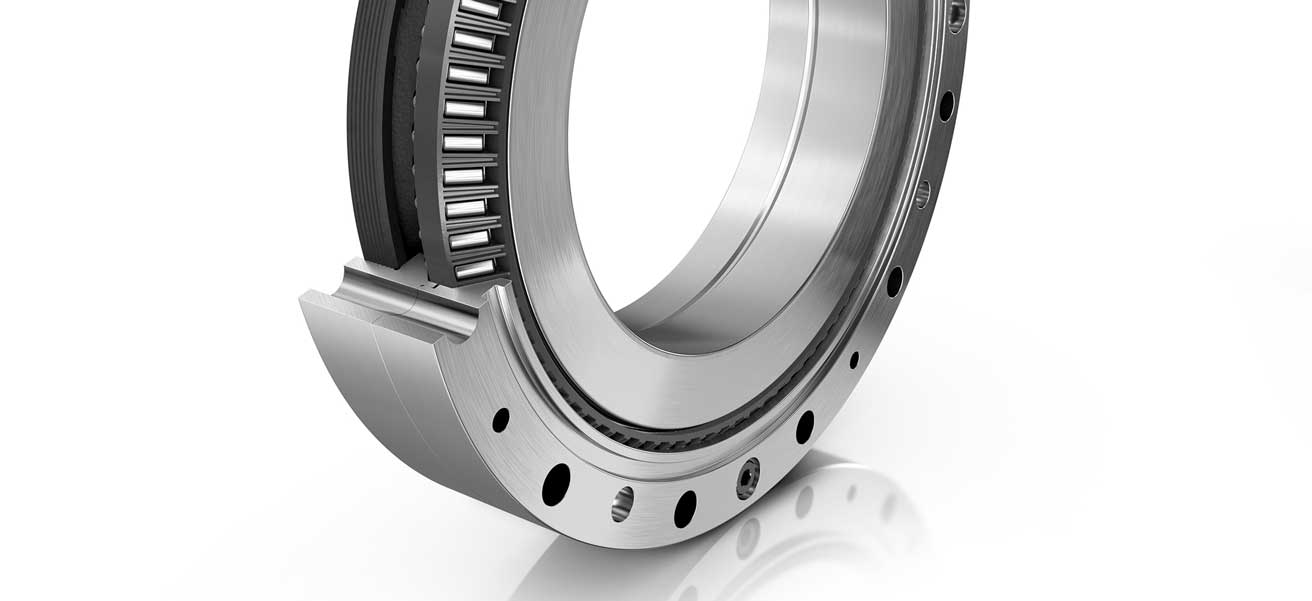

Plain and roller bearings for your construction

Ball bearings, roller bearings, air bearings, linear bearings, ceramic bearings, RTB bearings and much more. made of metal or plastic for many applications

Image: Igus

Plain and roller bearings for your construction

Ball bearings, roller bearings, air bearings, linear bearings, ceramic bearings, RTB bearings and much more. made of metal or plastic for many applications

Image: Igus

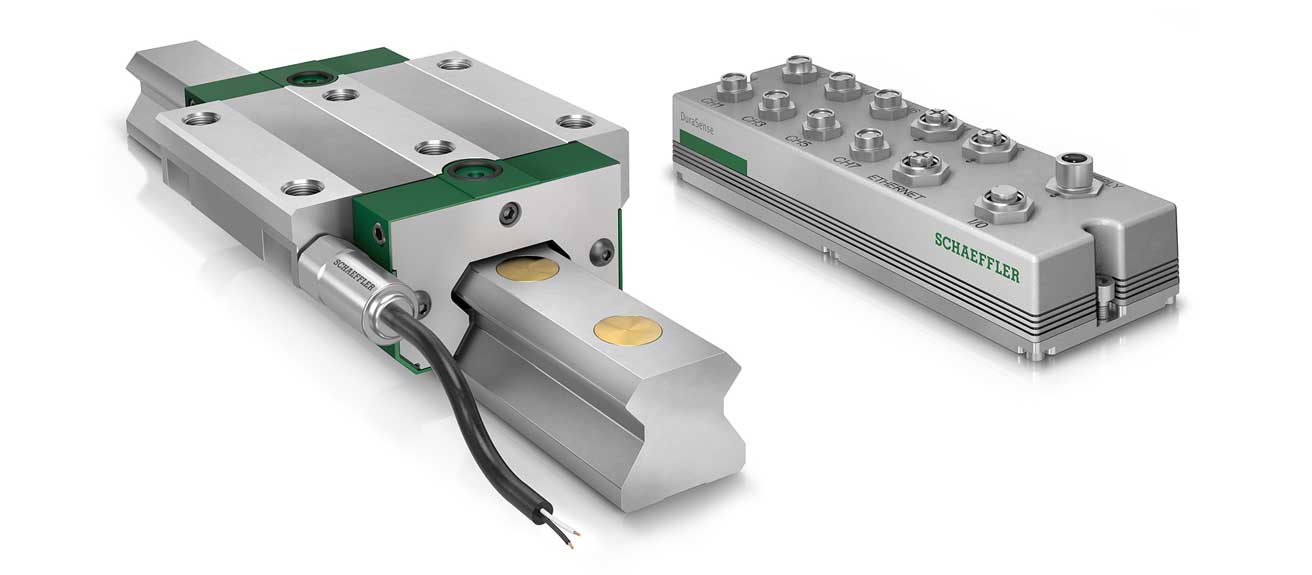

Linear technology for movement

Profile rail guides, heavy-duty guides, telescopic guides, ball screws, threaded spindles for mechanical engineering

Image: Schaeffler

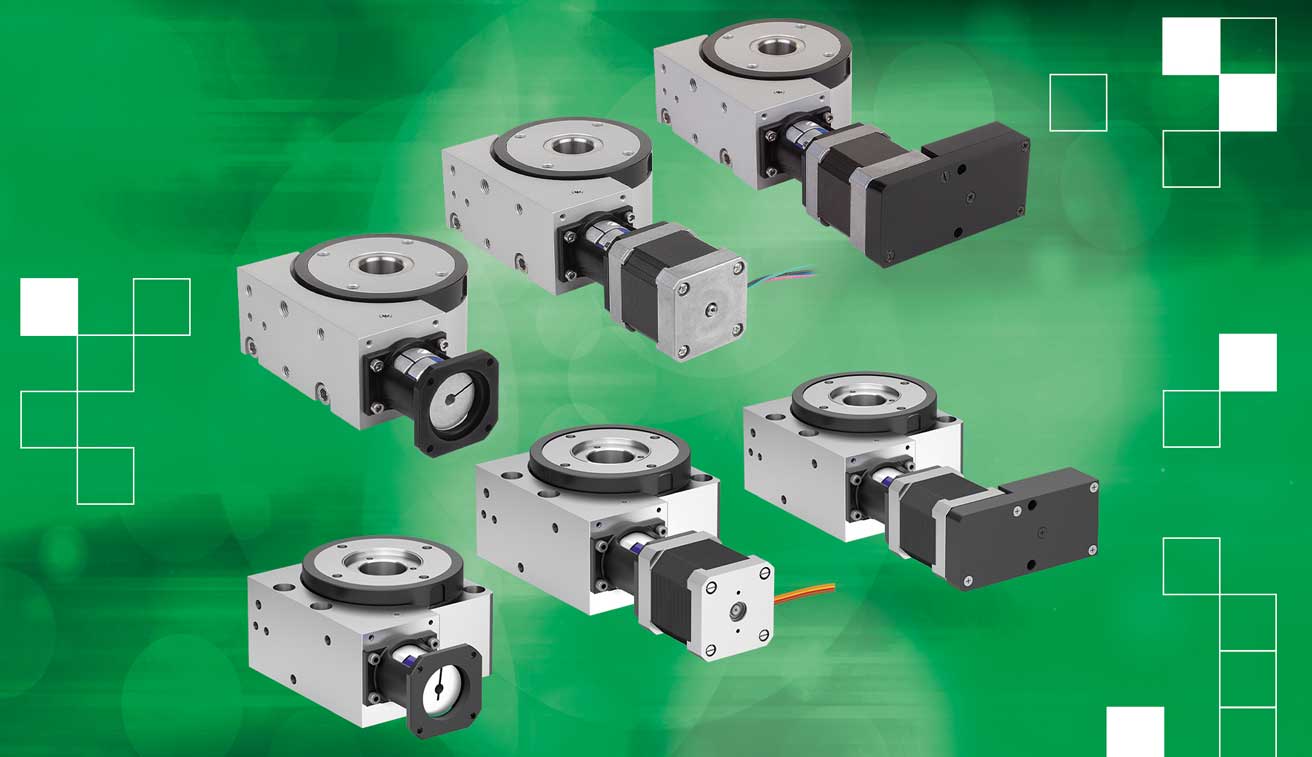

Construction components for research & development

Rotary table, spring, machine frame, standard part, brush, shock absorber, seal, handle, CNC component, standard part, etc

Image: ACE

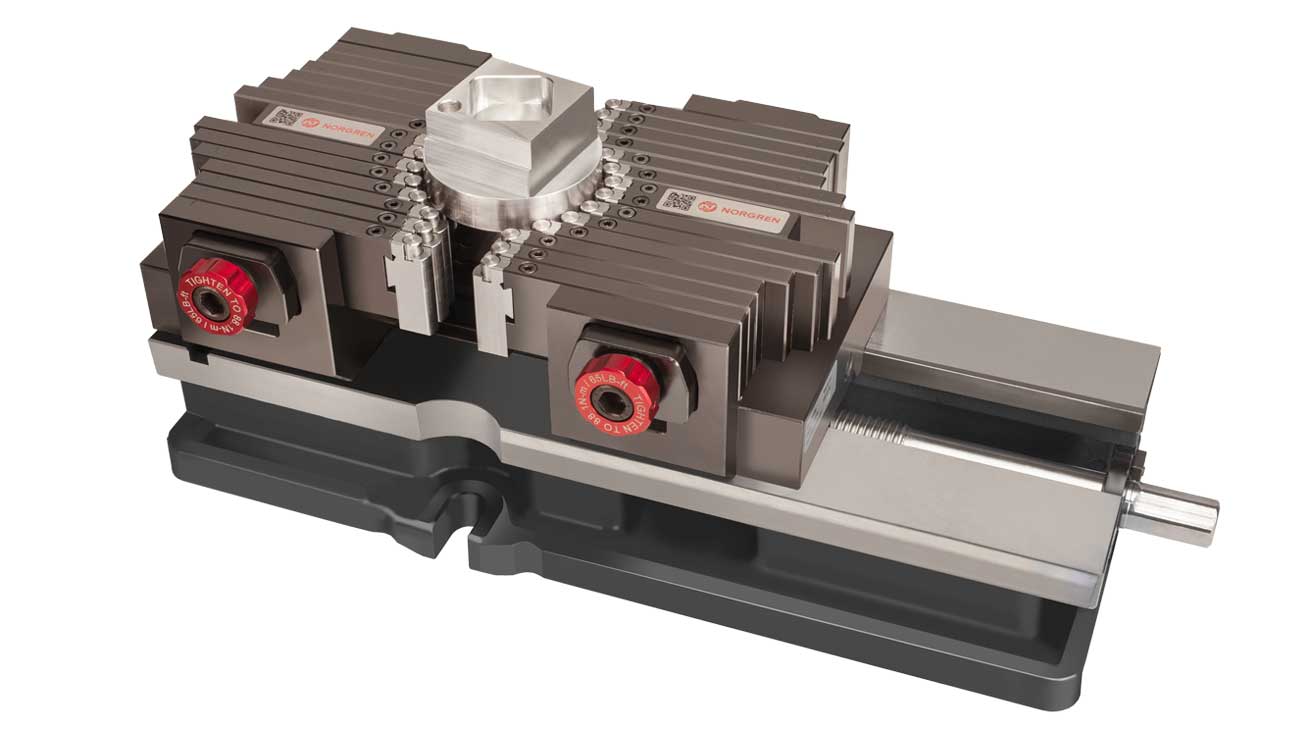

Tools, clamping technology, device

High-precision cutting tools and non-cutting tools for machines as well as clamping technology for jig and mold construction

Image: Dormer Pramet

Are machine elements Construction componentsthat are not only contained in machines, but rather can be found in every technical construction. Often they are as inconspicuous as they are important at the same time. If, for example, a seal fails, it can have a major impact on the entire machine or system. We'll bring you the latest Machine Elements before how Rolling and plain bearings, Linear Technology, Shock absorbers, shafts, Tools, Springs, seals, Controls and much more.

Contents

The calculation of the machine elements is increasingly done online today. In our section Configuration you will find numerous innovations of such tools. Or go straight to our service area. There you will find apps and tools for machine elements, which often make your design or shopping easier for you online, much like Amazon. exceptions like Fasteners with z. B. Screws can be found in the department Connection Technology, Couplings, Brakes and Drive Elements in the field of drive technology.

Special industries like Automotive industry, Renewable energies, Technical Building Services, Medical Technology, Microsystems Technology require specially designed developments and knowledge. Here we introduce you to the latest machine elements for these applications.

In the past, machine elements were exclusively mechanical components which, when put together in a construction, resulted in assemblies. Today, the individual components in mechanical engineering do not stop at Industry 4.0. In the mechanical elements more and more electronics or Measurement Technology a. The smart rolling bearing or the profile rail guide with path measurement lead to more intelligence in the machine elements. These are the new features:

From the tiny mini Rolling from a huge rolling bearing measuring several meters to a system solution: the portfolio Schaeffler Ball and roller bearings has solutions for every application - from machine tools, robotics and industrial automation to the food and packaging industry Wind Turbine or mobile work machines, just to name a few. These are getting stronger too digitized. Here we present the innovations:

High precision, short cycle times, dynamic and modular should be a roundtable be the z. B. transported the workpiece to its destination as a positioning system. In machine tools, handling systems, Measuring devices and other applications, it should also function quickly with high repeat accuracy. Below we give you an overview of the developments of various Manufacturers of rotary tables:

In classic mechanical engineering, users are increasingly confronted with the requirements of clean production. IEF-Werner shows sophisticated solutions with which companies can design handling processes economically and safely - also for production under clean-technical conditions.

In classic mechanical engineering, users are increasingly confronted with the requirements of clean production. IEF-Werner shows sophisticated solutions with which companies can design handling processes economically and safely - also for production under clean-technical conditions.

The controls, switches and buttons portfolio from Schmersal for the machine or system in industry focuses on intelligent sensor technology and decentralized automation solutions. The products support modular systems, reduce commissioning times and even cover hygienic design requirements. Below we present them to you New Products and their use.

The compactness and light weight of the Kaydon Thin section bearings not only meet the requirements of the robot age often better than conventional ones Bearing. With the slim all-rounders, which from Rodriguez are offered, space and weight of more than 80% can be saved in many applications - with high performance and precision. Here you will find new developments, information and applications for thin section bearings.

In the area of precision bearings, the Rodriguez GmbH with their Kaydon “Realislim” Thin section bearingsn a key technology for the Aerospace available. These specialized rolling bearings contributed to the success of the Mars mission in 2021 by allowing NASA's Perseverance rover to carry out its tasks efficiently and reliably. The Precision ball bearings but are also suitable for other applications in the demanding industry.

A linear guide linear or rectilinear movements in machines and systems, robots or devices. Rollers, balls, sliding surfaces, air, oil films or electromagnets are used for this purpose. Below you will find information different manufacturers zu Roller guide, Ball bearing guide, Rail guide, miniature tour.

If you ever fall into memory mode, you can remember previous developments of all types of machine elements here 2011 – 2018. Plug-and-play, service life and ease of maintenance were just some of the requirements that shaped the development. Exciting déjà vu and have fun remembering!

The linear guides from Schaeffler not only enable low-friction movements to offer the highest possible efficiency when moving masses. Products are also becoming increasingly intelligent as a result of Industry 4.0. Equipped with the Durasense lubrication system, the linear guide is suitable, for example. B. for condition monitoring use. Applications can be found in automation, Robotic, Medical Technology, food technology as in mobile machines. We present you new products and applications here:

The one presented here Workholding is used to fix and hold a workpiece in devices, machine tools or machining centers. clamping jaw, collet, Quick release, chipboard, Mandrel & Co. must work safely, precisely and reliably when milling, turning, grinding and other processing of workpieces. Below you will find New developments different manufacturers:

Weforma damping technology has developed damping cylinders that can be used flexibly for a large number of applications. With their WM-Z and WM-ZG series, an extensive range of hydraulic damping cylinders is available, which are suitable, for example, for the vibration decoupling of motors or in commercial washing machines and as rope tensioners.

Weforma damping technology has developed damping cylinders that can be used flexibly for a large number of applications. With their WM-Z and WM-ZG series, an extensive range of hydraulic damping cylinders is available, which are suitable, for example, for the vibration decoupling of motors or in commercial washing machines and as rope tensioners.

The Icaros GmbH brings a new type of sports equipment onto the market. With the device, the company managed to combine fitness equipment and Virtual reality flight simulator. Anyone who climbs in can experience the dream of flying like Icarus from ancient times. But in contrast to the namesake and Greek myth, the developers made no compromises when choosing the right components and chose the Linear Technology the robust ones Bow guides the “Curviline” from Rollon .