RFID technology for factory automation and logistics

- Details

- Hits: 8921

The RFID Technology makes a major contribution to industry by tracking goods, materials and means of production in industrial production through the entire process chain or by making access more secure. This contactless transmission of large amounts of data over large ranges is also effortless to higher-level systems from SPS Can be connected to ERP. The automation specialist has the necessary technology Turck a whole range of RFID solutions in their luggage.

Contents

- New IIoT functions for RFID interfaces with OPC UA Server

- RFID read / write head for Ex zone 1/21

- Fast RFID I / O module for Ethercat

- Consistent identification of the process chain

- Archive for more RFID innovations

New IIoT functions for RFID interfaces with OPC UA Server

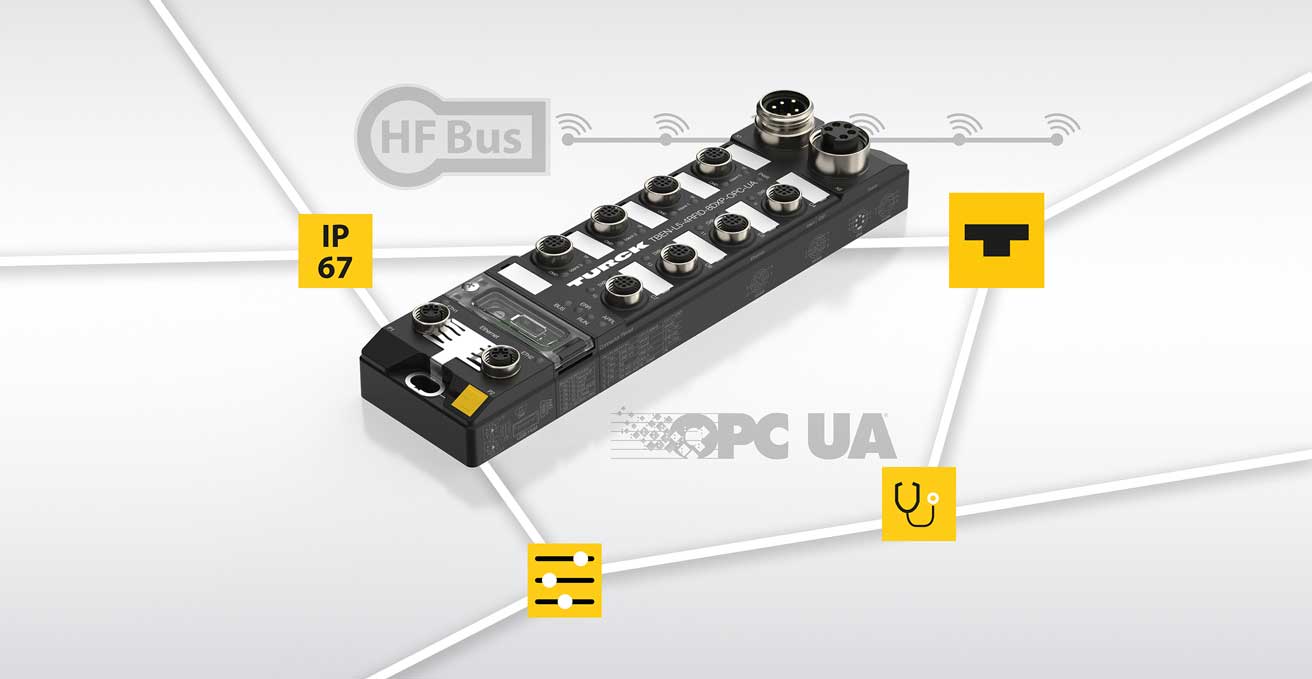

30.06.2022/XNUMX/XNUMX | Turck is presenting new IIOT functions for its RFID interfaces OPC UA Server. The IP67 RFID interface will come with a free Firmware Update equipped for barrier-free communication in the Industrial Internet of Things (IIoT). This allows you to easily identify and track products, for example. With the AutoID Companion Specification V. 1.01, the OPC UA servers ensure smooth direct communication with MES, SPS, ERP or cloud systems. Turck's HF bus mode offers cost advantages for applications with many reading points. Users also have less integration effort for HF and UHF systems.

After the update, the RFID module TBEN-L5-4RFID-8DXP-OPC-UA is the first to support the integrated OPC UA server HF bus mode. This allows the connection of up to 32 HF read/write devices to each individual RFID input. With the four RFID channels per module, up to 128 reading points can be recorded and centrally parameterized.

6G network | Bidirectional radio link and Thz receiver

6G network | Bidirectional radio link and Thz receiver

The new firmware enables a continuous reading the UID/EPC or RFID user data. An MES or SAP system can thus e.g. B. receive and process data as an event notification at any time without executing a method. It is activated by setting a variable. This is still active after a power reset, so that the RFID system continues to deliver data reliably even after a power failure.

The optimized user guidance and the intuitive design of the new web server enable a web-based configuration of the OPC UA server including the UHF parameters. The server also provides UHF tools for testing disk reading.

RFID read / write head for Ex zone 1/21

11.05.2021/XNUMX/XNUMX | Turck presents with a new HF RFID read / write head The only RFID reader in the world with ignition protection type Ex-m for applications of contactless identification by means of an RFID transponder in explosion-protected areas. The TN-R42 / TC-Ex reader is certified for immediate use in Atex Zone 1/21. The automation specialist is thus expanding its Industry 4.0 portfolio to include explosion-proof areas, thus enabling integrated Industrial Internet of Things (IIoT) solutions for the process industry.

The RFID reader is a very compact pressure-encapsulated identification solution for zone 1/21, which can also be found in cramped installation spaces. The slim TN-R42 / TC-Ex read / write head is ideally suited for the contactless identification of correct hose and flange connections in the chemical industry and pharmaceutical engineering.On the interface side, the new RFID technology behaves like a standard read/write head for safe areas. HF RFID data carriers are also available for applications with high requirements for access protection and data security Password function.

The read / write head is attached to the RFID interface series TBEN and BL20 connected. If required, these can also be installed in protective housings Zone 2/22. In addition to the hose identification, other data can be processed, such as slot, date, time or the cleaning status of the hoses. Turck's multi-protocol technology allows data to be transferred to the control system via the three Ethernet protocols Profinet, Ethernet / IP and Modbus TCP.

Fast RFID I / O module for Ethercat

11.03.2021/XNUMX/XNUMX | That TBEC interface from Turck supports RFID applications with data carriers that follow each other very quickly and with up to 128 read/write heads. With the TBEC family, the manufacturer is expanding its range of compact, robust RFID solutions about fast interfaces for Ethercat networks.

11.03.2021/XNUMX/XNUMX | That TBEC interface from Turck supports RFID applications with data carriers that follow each other very quickly and with up to 128 read/write heads. With the TBEC family, the manufacturer is expanding its range of compact, robust RFID solutions about fast interfaces for Ethercat networks.

The TBEC module was designed according to the degree of protection IP67/IP69K executed in a fully encapsulated plastic housing. It withstands temperatures from -40 ° to +70 ° C. The Ethercat RFID module allows the parallel operation of HF and UHF read / write heads. This facilitates applications with different bandwidths and reduces the variety of warehousing.

Like all Ethernet multi-protocol devices from the manufacturer, the TBEC also supports the HF continuous bus mode. Via it are up to on each of the four RFID channels 32 bus-capable HF read / write heads connectable. When used with many write or read positions, this lowers the wiringeffort, as well as costs and commissioning effort. The eight universal DXP I/Os can be Sensors, Connect lamps or other actuators. The connections are as 5-pin Plug-in connection executed in M12. The power supply is L-coded via the M12 power technology.

RFID and Barcodes | Industrial identification

RFID and Barcodes | Industrial identification

An integrated RFID data interface U with cyclic process data transmission allows a fast Access to HF and UHF functions such as B. the idle mode. This makes the Ethercat module suitable for use in RFID applications with data carriers that follow one another very quickly, such as hanging goods in conveyor technology.

Consistent identification of the process chain

28.02.2020/XNUMX/XNUMX | The video gives an overview of how to use RFID technology from Turck continuous identification can be ensured from scanning the RFID tag of the goods in goods receipt through production to goods issue. All processes can be implemented with Turck's RFID products.

Archive for more RFID innovations

Tracking system for child seats based on RFID and TBEN-S

24.04.2019/XNUMX/XNUMX | the Kirschenhofer machines GmbH developed a system for production control and quality assurance in the manufacture of child seats for Britax Römer. Both companies have that without SPS implemented using RFID tags and TBEN-S Ethernet multi-protocol modules from Turck in connection with Labview.

24.04.2019/XNUMX/XNUMX | the Kirschenhofer machines GmbH developed a system for production control and quality assurance in the manufacture of child seats for Britax Römer. Both companies have that without SPS implemented using RFID tags and TBEN-S Ethernet multi-protocol modules from Turck in connection with Labview.

RFID reader with a unique variety of interfaces

07.11.2018 | Bernd Wieseler, head of product management for RFID systems at Turck, presents the first device of his at the press conference in Mülheim an der Ruhr UHF reader family Q300 with Ethernet interface. In particular, the variety of platforms and interfaces characterize the device.

HF-RFID/sensor data carrier to be read contact-free

20.04.2017/XNUMX/XNUMX | Turck offers the development and production of application-specific RFID data carriers with integrated sensor functions. the Sensor disk record and store process variables such as temperature or pressure in moving components. The sensor element is interchangeable and can also be selected to detect moisture, magnetic fields, reed contacts or inductive sensors.

20.04.2017/XNUMX/XNUMX | Turck offers the development and production of application-specific RFID data carriers with integrated sensor functions. the Sensor disk record and store process variables such as temperature or pressure in moving components. The sensor element is interchangeable and can also be selected to detect moisture, magnetic fields, reed contacts or inductive sensors.

The sensor data carriers are connected via a HF-RFID read/write head supplied with energy and read out. Even data acquisition without contact to the read/write head is possible with the help of a self-sufficient energy source. Depending on the frequency and type of measurement as well as environmental variables, measurement cycles can be run and tracked over several hours.

The sensor data carriers are suitable for applications in which measured values or other data controlled without contact and stored and for use on moving elements that have so far been connected with high-maintenance slip ring solutions. An example is the identification of rollers including the storage of process-specific parameters. In addition, they can also be used where contactless data has to be collected from sealed interior rooms or from inaccessible places. The user can also use the classic RFID function for identifying objects as usual.

You might also be interested in...

IO module secures Resato hydrogen filling stations

Encoder: Incremental, absolute and communicative

LED signal light with and without IO-Link

Turck | Your global automation partner

Temperature sensor – humidity sensor – vibration sensor

Level sensor | Level switch for simple to IIoT use

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.