Safety switches and sensors for machine safety

- Details

- Hits: 14812

The Schmersal group offers Safety switch with -tumbler and Safety sensors for machine safety. The extensive portfolio for monitoring machine protective doors allows the protective device to be precisely adapted to the application. It also contains products for special requirements such as explosion protection or hygienically sensitive use. In the following we present the new developments:

Contents

- With Cloud Solution and AZM40 innovations at the Hannover Messe

- Sensor box for position detection of electric monorails

- Security packages for the retrofit

- Small, versatile cable pull switch for automation

- Door handle for door locking of heavy swing doors

- Smallest electronic solenoid interlock with UL certification

- Efficient safety switch with integrated software logic

- Electromechanical solenoid interlock with high coding

- Safety switches and sensors archive

With Cloud Solution and AZM40 innovations at the Hannover Messe

20.02.2024/XNUMX/XNUMX | In keeping with the main theme of Hannover Messe 2024 "Energizing a sustainable industry", the Schmersal Group presents new products and systems for the safe, efficient and sustainable design of machines and systems. The automation company supports companies with innovative safety and automation solutions digital transformation and compliance with high environmental and energy standards.

20.02.2024/XNUMX/XNUMX | In keeping with the main theme of Hannover Messe 2024 "Energizing a sustainable industry", the Schmersal Group presents new products and systems for the safe, efficient and sustainable design of machines and systems. The automation company supports companies with innovative safety and automation solutions digital transformation and compliance with high environmental and energy standards.

Further focus topics are future-proof solutions for security Food production and intralogistics.

Cloud Solution – Apps for energy management

IIoT solution Data and information from production can be collected, made available centrally in the back office and analyzed in real time. The field level as the basis of the IIoT solution includes networked ones Sensors and actuators also safety switching devices.

The Schmersal Cloud Solution connects them Field and back office-Level with the aim of increasing the efficiency of machines and systems through condition monitoring, predictive maintenance and the calculation of key performance indicators (KPIs). In the future, energy management apps will be used to monitor power peaks and identify potential energy savings.

Safety locking with reduced energy consumption

For the interlock AZM40 The manufacturer presents new variants with escape release and emergency release. Both give the user added security. Extended to include protection class IP69, additional application options arise.

The tumbler also uses less energy: Thanks to the bistable operating principle of the locking device, more than monostable tumblers can be used 50% of electricity consumption can be saved.

Sensor box for position detection of electric monorails

14.02.2023/XNUMX/XNUMX | The Schmersal Group presents a new Magnetic track sensor box for the position detection of electric monorail systems in intralogistics and the automotive industry. Wear-free magnetic switches have been used in the automotive industry for many years, where they monitor the speed and position of moving machine parts. Such electric monorails transport car bodies, doors, motors, etc. to the various assembly workstations. The new sensor box SSB-R can now do this too, but much more precisely.

The magnetic track sensor box records the field of suitable actuator magnets four independent lanes. When driving past, it changes the signal state. This level change, which is generated even when driving past quickly, is retained until the next activation - also non-volatile and therefore suitable as a zero-voltage switch. A connected controller determines the position and route section of the sensor box from the signals and regulates, for example, the stopping position or the speed of the drive.

Intelligent CNC control for new + old machine tools

Intelligent CNC control for new + old machine tools

In the sensor box, two allow it angle sensorsthat e.g. B. stopping a monorail at the desired stop position with an accuracy of ± 1,5 mm. Robotworkstations need the function because components have to be positioned very precisely here. This fine positioning does not require any additional magnets.

Four integrated shielded tracks in latching reed technology can be connected with just one M12 Plug much easier to install than the previously used magnetic switches. Another signal evaluation can be connected via a second plug that can be integrated without major wiring effort.

The sensor box is up to the maximum speed of 300 m / min usable. It is designed in protection class IP 65 and withstands temperatures from -25° to +70 °C. The box has already proven itself in initial applications such as e-mobility production. The SSB-R is also prepared for the increasing demand for this type of drive thanks to its UL approval for the US market.

Security packages for the retrofit

20.09.2022 | Small, digital and networked is what the Schmersal Group is supposed to be doing at the SPS 2022 in Nuremberg. In addition to the innovations, intelligent package solutions for machine safety will also be shown. These can be optimally adapted to the applications and meet the normative requirements.

Tumblers like these are presented AZM161, AZM300, Type control panels BDF200 as well as new versions of evaluation logics such as the safety relay module SRB-E-402FWS. In combination, these components result in a perfect 'out of the box' solution for old machines. One example is protection against dangerous overrun movements on lathes.

RFID and Barcodes | Industrial identification

RFID and Barcodes | Industrial identification

The Safety relay SRB-E-402FWS combines the functions of safe two-channel time monitoring with safe two-channel protective door monitoring in one device. The protective door monitoring is implemented by a safety interlock. The electromechanical safety locking device AZM161 or the electronic locking device AZM300 with a safety-technically upgraded RFID sensor come into question here. The BDF200 operator panel is used as the third component of the retrofit package solution. Thanks to its slim design, it can be mounted directly on the door.

Small, versatile cable pull switch for automation

28.03.2022/XNUMX/XNUMX | the Schmersal group introduces a new one with the PS216 Cable switch in front. It is suitable as a signal transmitter for starting machines and systems, for opening electrically driven gates and doors and as a light switch in the elevator shaft. The pull-rope switch has a small design and can be used in a variety of ways. Not least because he has high Degrees of protection according to EN 60529 and can withstand a wide temperature range.

28.03.2022/XNUMX/XNUMX | the Schmersal group introduces a new one with the PS216 Cable switch in front. It is suitable as a signal transmitter for starting machines and systems, for opening electrically driven gates and doors and as a light switch in the elevator shaft. The pull-rope switch has a small design and can be used in a variety of ways. Not least because he has high Degrees of protection according to EN 60529 and can withstand a wide temperature range.

Thanks to the protection class IP66 the PS216 rope pull switch is protected against dust and heavy water jets. Through IP67 it also withstands repeated immersion in water. The ambient temperatures can be -30° to +80 °C.

The Ballpoint pen principle in the pull-rope switches is quite practical: thanks to the stepping function, the switch remains switched on after it has been pressed for the first time and then released. The latching of the switching elements is only triggered and the switch switched off when the button is pressed a second time and then released.

Whisper-quiet elevator brake secures elevators and escalators

Whisper-quiet elevator brake secures elevators and escalators

The cable pull switch PS216 is available in two versions: The Q200 variant offers a pulling force of 45 N. It is suitable for rope lengths of up to 50 m. The Q210 variant has a pulling force of 70 N with a possible rope length of up to 100 m. When the pulling rope is pulled, the switching function of the rope pull switch is triggered. The Cables The cable pull switch is introduced via M20 or M12 connectors. There are six different NC/NO contacts.

Door handle for door locking of heavy swing doors

13.07.2022/XNUMX/XNUMX | The new practical door handle system DHS-150 now makes the slim AZM150 door locking device from Schmersal even more user-friendly. The ergonomic handle saves a separate door handle. It is suitable for machine enclosures or machine fencing and all 40 mm wide standard aluminum profiles with a width of 40 mm. The robust door bolt was designed for heavy swing doors and is suitable for harsh environmental conditions.

13.07.2022/XNUMX/XNUMX | The new practical door handle system DHS-150 now makes the slim AZM150 door locking device from Schmersal even more user-friendly. The ergonomic handle saves a separate door handle. It is suitable for machine enclosures or machine fencing and all 40 mm wide standard aluminum profiles with a width of 40 mm. The robust door bolt was designed for heavy swing doors and is suitable for harsh environmental conditions.

The actuator is pre-positioned by the bolt in the door handle and thus moves optimally into the device. That's what the door lock does stable against lateral forces. Because if insurmountable transverse forces occur with guard locking, the protective door will not open. This delays the production process. In this respect, the DHS-150 door handle system in conjunction with the AZM150 safety locking device increases system availability.

The integrated Locking device Loto protects the operating personnel of larger, walk-in machines and systems from being accidentally locked in during maintenance and repair work. The locking pliers function ensures that the door of the protective device cannot be closed and unintentional machine start-up is prevented.

Relays or switches for safety, semiconductors, time, protection, etc.

Relays or switches for safety, semiconductors, time, protection, etc.

The AZM150 safety locking device in a slim, space-saving design offers a Locking force of 1500 N. It can be combined with three different actuators for different mounting situations. The rotatable actuator head can be locked by simply putting on the cover instead of by screwing it. With its two insertion slots, it enables various mounting positions and approach options. The tumbler can therefore be used in a variety of ways.

The safety switches AZM150 are electromechanical versionsthat can be combined with a high security standard: The locking device is available with a low coding level as standard and optionally with a high coding level in accordance with ISO14119. The door handle system can be used for standard version and individually coded version with actuator B1 (straight). The B1 is included with the variant with a high coding level and must be ordered separately for the standard version.

Schmersal is exhibiting at the SPS 2022.

Smallest electronic solenoid interlock with UL certification

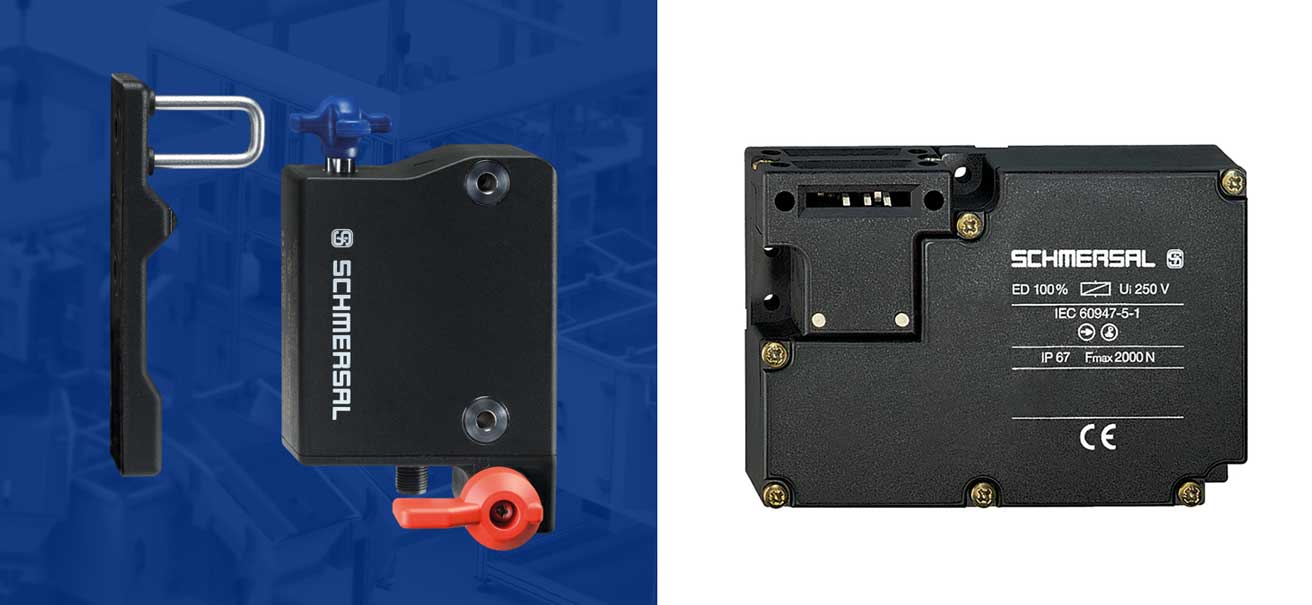

11.10.2021/XNUMX/XNUMX | The Schmersal Group presents its compact at the Smart Production Solutions trade fair in Nuremberg interlock AZM40 based on RFID. It is the smallest electronic safety interlock in the world with a high locking force of 2 kN. Thanks to the angular flexibility, the safety switch can also be easily installed in narrow areas that are not easily accessible. With the dimensions 119,5 x 40 x 20 mm, it is particularly suitable for smaller doors and flaps in the machine. She was born in May 2021 UL certified and can be ordered in the webshop.

The safety switch can also be used in machines and systems for the North American market can be used. The solenoid interlock is generating great interest in the market because it follows the trend towards miniaturization. Machine builders who want to optimize their design in terms of size, complexity and material expenditure will find the ideal safety solution in the AZM40.

Safety interlock with angular flexibility

thanks to the 180 ° angle flexibility of the actuator, it can be approached steplessly to the AZM40 so that the guard locking can also be used with flaps that do not close at a 90 ° angle or with flaps that open upwards at a 45 ° angle. The angular flexibility thus contributes to the fact that the guard locking can also be installed without problems in confined and not easily accessible areas. In addition, the AZM40 can be easily mounted on standard 40 mm profiles without a protrusion. The solenoid interlocks can be used universally on revolving and sliding doors with just one design.

Light barrier, light grid and light curtain for safety

Light barrier, light grid and light curtain for safety

The AZM 40 solenoid interlock and the actuator are available in two housing variants. For typical mechanical engineering applications, there are housings with a flat screw surface for cylinder head screws. Another variant with countersink for countersunk head screws was designed for optically better installation and lack of space.

Despite its small size, the AZM 40 safety switch has a high Locking force of 2000 N. A guard lock must be selected so that it withstands the forces to be expected. With the locking force of 2 kN, the user is on the safe side with regard to the normative recommendations. Thanks to integrated RFID technology, the “high” coding level is achieved. The guard locking thus offers increased protection against manipulation in accordance with the requirements of DIN ISO 14119.

Bistable operating principle for safe operation

The AZM40 works according to the bistable operating principle: It keeps in the event of a power failure the current position. This ensures safe operation in every operating state of the machine. Even in the event of a power failure, protective devices remain securely locked in position in the event of dangerous overtravel movements. Another advantage of the bistable operating principle is the permanently lower energy consumption, because the safety locking device only needs to be energized when the protective device is to be locked or unlocked.

For applications with Personal protection (guard locking monitored) the safety outputs are switched on when the protective door is closed and the guard locking is locked. The AZM40B version (actuator monitored) can be used for applications with process protection. With the actuator-monitored variant, the safety outputs are already switched on when the door is closed. Locking the guard locking is not absolutely necessary with this device.

Safety switches available in the webshop

The AZM40 safety switch can be controlled via the Schmersal webshop be ordered. Here prices and delivery times are displayed and various forms of payment are offered. A live chat helps with questions that arise.

Efficient safety switch with integrated software logic

11.10.2021 | The Schmersal Group has its compact Safety switches RSS260 has been further developed and is also exhibiting it at the SPS trade fair in Nuremberg. The safety sensor has been equipped with new software and thus offers the four additional, optionally selectable functions of feedback loop monitoring (EDM), automatic / manual restart, reset and emergency stop monitoring.

In the F0 / F1 variant, the safety switch takes over RSS260 the duties of a Safety relaybrick. This means that the logic integrated in the safety switch monitors the movable safety guard and the contactors that are directly controlled by the sensor outputs. A separate evaluation device is no longer required.

With the F0 series of safety switches, the Automatic restart of the machineas soon as the protective door or all doors are closed. However, an actuator enable can also be switched into the feedback circuit without edge monitoring. The F0 version is suitable for small machines without a protective space that can be stepped behind.

Safe access to smaller systems

Schmersal recommends the F1 safety switch variant for smaller systems. Because the danger area can be entered by the operator, the safety switch has a Reset function. The edge-monitored reset button must be actuated before the machine is restarted if it is guaranteed that the system is in a safe state and that no person is in the danger area. This function corresponds to the manual reset function according to EN ISO 13849-1.

In machines that require an emergency stop safety switch, the RSS260 comes with the Q function for use. Emergency stop safety switches integrated in a series connection can be monitored using the Q function in the last safety sensor in the chain. This means that the separate safety circuit for the emergency stop safety switch is no longer necessary. The emergency stop safety switches monitored with the Q function meet the requirements up to PL e. A reset button is also required, because an automatic restart of the machine is not permitted after an emergency stop command has been withdrawn.

Safety switch with less installation effort

“The additional functions of the RSS260 not only make it possible to save one safety relay module, they also reduce it wirings and installation effort. In addition, with the Q variant, there is no need for a separate safety circuit for the emergency stop,” summarizes Your Richter, Product Manager Safety Technology, summarized the advantages of the new software.

Code meter for monetizing embedded software

Code meter for monetizing embedded software

In addition, the contactless RFID security switch The standard version also has many plus points: with the very small dimensions of 40 x 18 x 30 mm, the non-contact actuator with the right sensor-target combination is suitable for mounting on aluminum profiles and many other door formats. These include e.g. B. the frequently used plexiglass doors and panes.

The Sensor has one AS-i Safety at Work interface and an interface for the Schmersal SD bus. Up to 31 safety sensors and safety interlocks can be connected in series via the serial diagnostic function (SD). It can also be used to transmit non-secure diagnostic and status data from the connected devices.

Electromechanical solenoid interlock with high coding

November 22.11.2020, XNUMX | The Schmersal Group is bringing a new electromechanical safety locking device onto the market: The AZM150 The slim design offers a locking force of 1400 N. It can be combined with three different actuators for different mounting situations: a straight actuator for sliding doors, an angled actuator for large revolving doors and a movable actuator for smaller revolving doors.

November 22.11.2020, XNUMX | The Schmersal Group is bringing a new electromechanical safety locking device onto the market: The AZM150 The slim design offers a locking force of 1400 N. It can be combined with three different actuators for different mounting situations: a straight actuator for sliding doors, an angled actuator for large revolving doors and a movable actuator for smaller revolving doors.

Instead of one Gland gets involved rotatable actuator head lock by simply putting on the cover. With its two insertion slots, it enables different mounting positions and approach options. This means that the guard locking can be used in a variety of ways.

The AZM150 solenoid interlock is a electromechanical designwhich can be combined with a high safety standard: The guard locking is available as standard with a low coding level and optionally with a high coding level. The advantage for the user:

In the case of a high coding, according to ISO 14119. fewer additional measures are required to prevent locking devices from being bypassed, such as mounting them out of reach or in a concealed position. Incidentally, Schmersal is the only manufacturer that electromechanical safety switches and locking devices with high coding can offer.

Safety interlock for small machines

The AZM150 is suitable due to its slim, space-saving design especially for smaller machines as well as for packaging and machine tools. The solenoid interlock is available in both the open-circuit and closed-circuit versions. Guard locks that work according to the closed-circuit principle are preferred when it comes to protecting people from dangerous overtravel movements. Guard locks with the open-circuit principle are particularly suitable for process protection, as they can be used in the event of a fault, e.g. B. grant access to the danger area in the event of a power failure.

The guard locking can be controlled with the help of a mounting plate easy to install on 40 mm groove profiles. In addition, it can optionally be equipped with an escape release or emergency release. If required, the AZM150 can optionally be supplied with locking pliers, which protect the operating personnel from being accidentally locked in when using larger, accessible machines and systems.

You might also be interested in...

This is how you build a collaborative robot cell

RFID and Barcodes | Industrial identification

3D Camera | Industrial image processing

Relays & Switches | Discover the possibilities!

Machine safety from the Schmersal tec.nicum

Gateways | The bridge to the Industry 4.0 factory

Sylvia Blömker is PR Manager at the Schmersal Group, Wuppertal.