3D Camera | Industrial image processing

- Details

- Hits: 8789

The industrial image processing is an increasingly important part of modern production processes. With a 3D camera high-precision images of objects can be spatially captured and further processed. 3D camera systems thus enable the precise measurement and analysis of components and products. In our article you will learn how 3D camera technology supports you in optimizing your production processes.

Contents

- ToF 3D camera with time-of-flight technology

- High-performance 3D cameras for industrial image processing

- High-precision 3D time-of-flight GigE camera in real time

- 3D GigE camera based on Realsense technology

ToF 3D camera with time-of-flight method

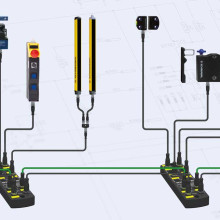

07.11.2023 | the Schmersal Group presented at the PLC 2023how the Industrial Internet of Things (IIoT) on the Field level can be implemented in an exemplary manner. A number of new innovative components and systems enable the comprehensive machineseffective communication as well as holistic networking from the field level to the cloud.

This will be illustrated using an IIoT demonstrator at the Schmersal stand in Hall 9, Stand 460: The demonstrator consists of a conveyor belt over which two 3DToF cameras are installed. He demonstrates how the cameras work Safety control Protect-PSC1 as well as data and information collected by a PLC OPC UA to an edge Gateway or forwarded to a cloud infrastructure if necessary. This happens e.g. B. as a starting point for determining production-related KPIs (Key Performance Indicators).

On Hannover Messe Schmersal introduced 3D cameras for the automated capture of digital process data in real time for the first time. The AM-T100 is a time-of-flight (ToF) camera that comes with a Sony Depthsense Sensor millimeter-precise 3D depth images are created. The image processing system uses ToF technology. This means that the transit time measurement of emitted light pulses is carried out in the infrared range (850 Nm). The light pulses are reflected on the objects to be detected. This type of image processing very quickly creates a millimeter-precise 3D image of the scene, which is available as a point cloud.

Image processing up to 60 fps

The high frame rate of the ToF cameras of up to 60 fps allows applications in industrial image processing for quality control in manufacturing processes as well as applications in robotics, logistics and Automation services. In sectors such as logistics and packaging technology, the 3D recordings can support the processes efficiently and precisely, for example to support tasks in packaging, carton filling, volume recording, stacking or labelling.

Robust GigE camera reliably detects the finest details

Robust GigE camera reliably detects the finest details

However, the image processing systems also look into containers or large load carriers and detect their filling levels. The monitoring of staging areas in production, assembly, storage and picking from a bird's eye view or the determination of the volume of general cargo are other conceivable applications. Other tasks for the image processing systems are the acquisition of images of dimensions and surface properties. With powerful IR lighting and an image resolution of 640 x 480 pixels, the AM-T100 achieves a viewing area of 67° x 51° with a range of up to 6 m.

Standardized data interface

The image data is transmitted via the standardized data interface Genicam provided. The image data can then be processed with standard image processing software. Extensive data can also be quickly transmitted via the Ethernet interface and, if necessary, the 24V power supply can be implemented (Power over Ethernet).

Software for configuring the camera systems

The configuration software is on the AM-T100 Consam T preinstalled. With the help of this software, the camera models can be configured in such a way that they monitor complex and individually defined 3D zones. If an object is detected within the zones, digital outputs are switched. In addition, it is possible to switch back and forth between different 3D zones via digital inputs. An integrated software development kit supports software developers and system integrators in configuring the camera systems and creating the software application.

High-performance 3D cameras for industrial image processing

08.12.2022 | The further developed systems of the 3D cameras from the Ensenso N series from IDS have twice the resolution and accuracy at the same cost. The new stereo vision image processing systems N31, N36, N41, N46 have a compact housing made of aluminum or Plasticnetwork and an integrated pattern projector. In industrial image processing, the systems are equally suitable for recording static and moving objects.

08.12.2022 | The further developed systems of the 3D cameras from the Ensenso N series from IDS have twice the resolution and accuracy at the same cost. The new stereo vision image processing systems N31, N36, N41, N46 have a compact housing made of aluminum or Plasticnetwork and an integrated pattern projector. In industrial image processing, the systems are equally suitable for recording static and moving objects.

The integrated projector projects a high-contrast texture onto the objects to be captured. A pattern mask with a random dot pattern does not complement existing surface structures or only weakly. This allows you to prepare detailed images in difficult lighting conditions 3D point clouds no problems with these image processing systems.

Image processing system in the same optics

With the Ensenso models N31, N36, N41 and N46, IDS brings the Next Generation of the previously available N30, N35, N40 and N45 3D cameras on the market. Visually, the cameras do not differ from their predecessor models. With the IMX392, however, a new sensor from Sony with a higher resolution of 2,3 MP instead of 1,3 MP in the previous model is used. All cameras are pre-calibrated and are so easy to set up. The Ensenso selector on the IDS website helps to choose the right model.

Whether permanently installed or mobile Robotic arm the Ensenso N is suitable for a reliable 3D quality check, quality assurance or inspection – whatever the application. The camera models support remote control Industrial robots, take on tasks in individual part picking or are deployed in logistics. They even help automate large laundries and ensure quality here.

High-precision 3D time-of-flight GigE camera in real time

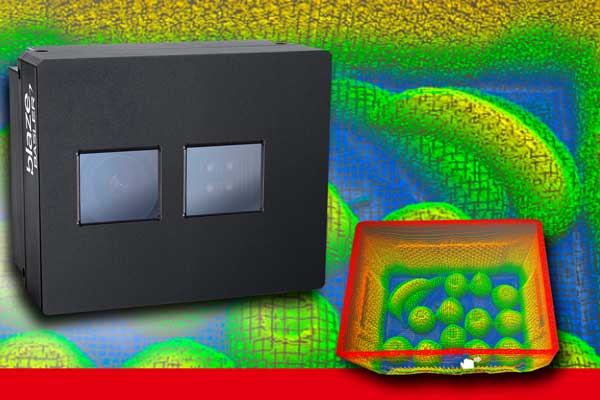

31.10.2019/XNUMX/XNUMX | the Basler Blaze 3D camera with GigE interface and VGA resolution (sales: Rauscher) is suitable for image processing of position, location and volume determination of objects and for detecting obstacles thanks to Sony Depthsense ToF technology. The industrial 3D camera works on the basis of the time-of-flight principle.

31.10.2019/XNUMX/XNUMX | the Basler Blaze 3D camera with GigE interface and VGA resolution (sales: Rauscher) is suitable for image processing of position, location and volume determination of objects and for detecting obstacles thanks to Sony Depthsense ToF technology. The industrial 3D camera works on the basis of the time-of-flight principle.

Equipped with the latest laser diodestechnology (VCSEL), the camera works in the near-infrared spectrum, i.e. in the wavelength range around 940 nm, and is therefore also uncompromisingly suitable for industrial image processing under daylight conditions. With a multipart image consisting of a distance, intensity and confidence map and a frame rate of 30 fps, it generates 3D point clouds and 2D images in real time within the camera, thus relieving the processor of the host system.

The measuring principle ToF camera is based on the time it takes for light to travel from the light source to the subject and back to the camera. The further the distance, the longer the time required. The light source and the image acquisition are synchronized in such a way that the distances can be calculated from the image data.

Clearly more precise scanning of the reflected light

The integrated Sony Depthsense IMX556PLR-C sensor With CAPD (Current Assisted Photonic Demodulator) pixel structure, in combination with the back-illuminated CMOS sensor architecture, enables significantly more precise and sensitive scanning of the reflected light. This enables the Blaze 3D camera, independent of light and contrast and with a resolution of 640 pixels x 480 pixels, 3D images for optical measurement with almost millimeter precision over a measurement range of up to 10 m, in which e.g. B. fit two Euro pallets or a small car.

Fastest 3D stereo camera and image processing in one device

Fastest 3D stereo camera and image processing in one device

With an integrated lens and invisible infrared lighting, the Basler Blaze is a compact, IP67 protectede Unit with no moving components, which, due to its low overall weight, can be used e.g. B. suitable for mounting on robot arms. The camera for industrial image processing is particularly easy to integrate and can be operated in multi-camera systems without mutual interference thanks to an intelligent process.

Typical areas of application are industrial image processing in automation, robotics, logistics, Medical Technology and in many areas of the smart factory, as well as in applications of freight sizing, palletizing, object counting and autonomous vehicles.

3D GigE camera based on Realsense technology

10.09.2019/3/435 | The new DXNUMXe plug-and-play XNUMXD digital camera Framos was specially designed for industrial image processing and requirements and harsh environments such as robotics, logistics or retail. The precise and easy-to-implement 3D technology with GigE Vision enables advanced automation applications here. The 3D cameras have the intels Realsense technology.

You might also be interested in...

This is how you build a collaborative robot cell

Safe field box with reduced wiring effort

RFID and Barcodes | Industrial identification

Light barrier, light grid, light curtain for safety

Relays & Switches | Discover the possibilities!

Safety switches and sensors for machine safety

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.