Whisper-quiet elevator brake secures elevators and escalators

- Details

- Hits: 12309

Passenger safety is the top priority when transporting people in elevators. Safety-relevant components such as the elevator brake must therefore meet the highest quality requirements. On the one that ended interlift effect Mayr Antriebstechnik its entire range of tried and tested elevator brakes presented as shaft-mounted ones Safety brakes and the energetic caliper brake Roba Diskstop. This and other information about the Roba brakes can be found below:

Contents

- Elevator brake for Chinese prestige high-rise buildings

- Safety brake according to future elevator standards

- Chinese elevators to be safer with brakes Mayr

Elevator brake for Chinese prestige high-rise buildings

02.05.2022/XNUMX/XNUMX | special demands elevator brakes questions High rise elevators in skyscrapers such as the Buddha Tower in Xian, the World Financial Center in Shanghai and many other metropolises in the world. The trend towards new and ever higher Buildings especially in China doesn't leave. In the last year alone, Mayr has equipped several prestige buildings there with its Roba-diskstop caliper brake. These caliper brakes have a high energy absorption capacity during dynamic braking. This makes them ideal for use in elevators with a high mass and speed.

Innovations and tips for installing safety brakes

Innovations and tips for installing safety brakes

Incidentally, the company is well prepared for the new guidelines and requirements. For example, due to Brexit, only one will be allowed in the UK in the future Brake with UKCA label (UK Conformity Assessed) are used. In China, there will be a revision of the local GB standard for elevators from 2023.

Predictive maintenance with intelligent monitoring

With the intelligent Roba brake checker module the elevator brakes can be monitored. The module has already been market-tested for the manufacturer's brakes in many sectors. At the Interlift, the company is presenting its concept with which users can generate technical Industry 4.0 added value. Of the Roba-brake-checker makes it possible to plan the maintenance of the elevator brake, so that system operators and system manufacturers can carry out maintenance in a targeted manner and in line with the work process. The error output in the event of a problem also allows remote maintenance. In some countries, regular maintenance must be carried out by service staff. The results are documented manually. If such service work is not required, customers save a lot of money.

Safety brake according to future elevator standards

10.12.2015 | The new elevator standards EN 81-20 and EN 81-50 are intended to make European elevator systems even safer in the future. As the first brake manufacturer Mayr is already implementing the new standard. At the Interlift 2015, the company presented products for the relevant elevator brakes that have the type examination certificate from TÜV Süd, which will apply to all manufacturers from April 20, 2016, in accordance with Directive 2014/33/EU.

10.12.2015 | The new elevator standards EN 81-20 and EN 81-50 are intended to make European elevator systems even safer in the future. As the first brake manufacturer Mayr is already implementing the new standard. At the Interlift 2015, the company presented products for the relevant elevator brakes that have the type examination certificate from TÜV Süd, which will apply to all manufacturers from April 20, 2016, in accordance with Directive 2014/33/EU.

The European committee for standardization (CEN) has passed EN 81-20 and EN 81-50, two new standards for the design of elevators and the testing of elevator components. These will replace the well-known EN 1-2017 and EN 81-1 standards as of September 81, 2 and aim to further increase the already high safety standards for elevators - for passengers and service personnel. The EN 81-20 standard refers to the specifications for the construction of an elevator and the technical properties. EN 81-50 regulates how elevators and individual components must be tested. Among other things, EN 81-50 places further requirements on the type examination of the braking devices as part of the protective devices for the upward-moving car against overspeed (SAFÜ) and against unintentional movement of the car (SUBF).

In order to always guarantee the greatest possible operational safety in the elevators, all Mayr safety brakes are subject to careful testing Quality control. Before delivery, all brakes are extensively tested on calibrated test benches and functionally relevant values are documented. An electronic database in which the measured values are archived together with the associated serial numbers of a product guarantees 100 percent traceability.

Design service life and braking torque tolerances

"The many years of experience and countless tests by our development and test department at the Mauerstetten headquarters form the basis for a conscientious design of the service life, taking into account realistic and verified braking torque tolerances," explains Alexander Hutler, industry manager elevators at Mayr in Mauerstetten.

Incremental and absolute rotary encoders for elevator construction

Incremental and absolute rotary encoders for elevator construction

"All brake components are safely dimensioned and only made of high-quality, well-known and proven materials. Our brakes are designed to do that required nominal torque under all operating conditions that occur, regardless of e.g. from ambient temperature or humidity.” The elevator brakes are also equipped with a patented noise dampening system. With noise-optimized versions, switching noises are practically non-existent and are below 50 dB(A) (sound pressure level measurement) when new.

Chinese elevators to be safer with brakes Mayr

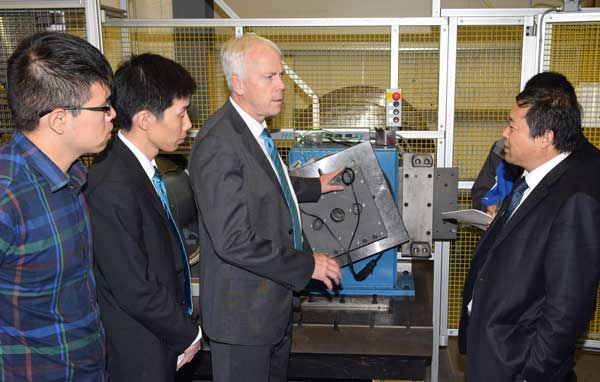

28.10.2015/2015/XNUMX | During the Interlift XNUMX, representatives of the leading Chinese elevator associations visited the German headquarters of Mayr -antriebstechnik, the world's leading manufacturer of elevator brakes. The common goal is to increase the safety of elevators in China. During the on-site factory tour, the participants saw for themselves how the brake specialist achieves the quality and reliability of its products.

28.10.2015/2015/XNUMX | During the Interlift XNUMX, representatives of the leading Chinese elevator associations visited the German headquarters of Mayr -antriebstechnik, the world's leading manufacturer of elevator brakes. The common goal is to increase the safety of elevators in China. During the on-site factory tour, the participants saw for themselves how the brake specialist achieves the quality and reliability of its products.

Every year will around 12.000 elevators in Germany newly installed. Most of them are equipped with Mayr safety brakes. The brakes in the elevators ensure the safety of passengers at all times. In China, which has been the most important international manufacturing country and the industry's largest sales market for years, far more elevators – around half a million – are installed every year. During the trade fair, around 30 representatives of the Chinese elevator associations and well-known elevator manufacturers from China took the time to visit the German parent company in Mauerstetten. During various presentations and a factory tour, the participants gained interesting insights into how quality and reliability are ensured.

XNUMX% traceability and quality control

To always be in the elevators maximum operational safety To ensure this, all safety brakes are subject to careful quality control. For each individual brake, all functionally relevant values are tested and documented on test benches before delivery. An electronic database in which the measured values are archived together with the associated serial numbers of a product guarantees 100 percent traceability. Many years of experience and countless tests by the development and test department at the Mauerstetten headquarters form the basis for a conscientious design of the service life, taking into account realistic and verified braking torque tolerances.

Devices for braking energy recuperation for electric drives

Devices for braking energy recuperation for electric drives

During the factory tour, the Chinese guests were able to see for themselves the whisper-quiet operation of the brakes in the in-house noise measurement cabin and were enthusiastic. For access to the Asian market, Mayr has had its own since 2004 Plant in Zhangjiagang near Shanghai with around 110 employees today. "The same quality standards apply to our Chinese plant as in Germany," explains the visitors jack tang, Sales Manager at Mayr China. “The operational quality management system in Zhangjiagang is also ISO 9001 certified. This confirms the quality awareness of the employees at all levels of the company.” The conclusion for the guests: Products can be copied, but the long-term security required is only possible with many years of experience and highly qualified employees.

You might also be interested in...

High-performance brake wind turbine with monitoring

Robco robot kit with safety brake from the construction kit

Safety brakes: innovations + tips for installation

Predictive maintenance for clutches and brakes

Shaft coupling without play, precise and smart