Green hydrogen on the advance in Germany

- Details

- Hits: 12251

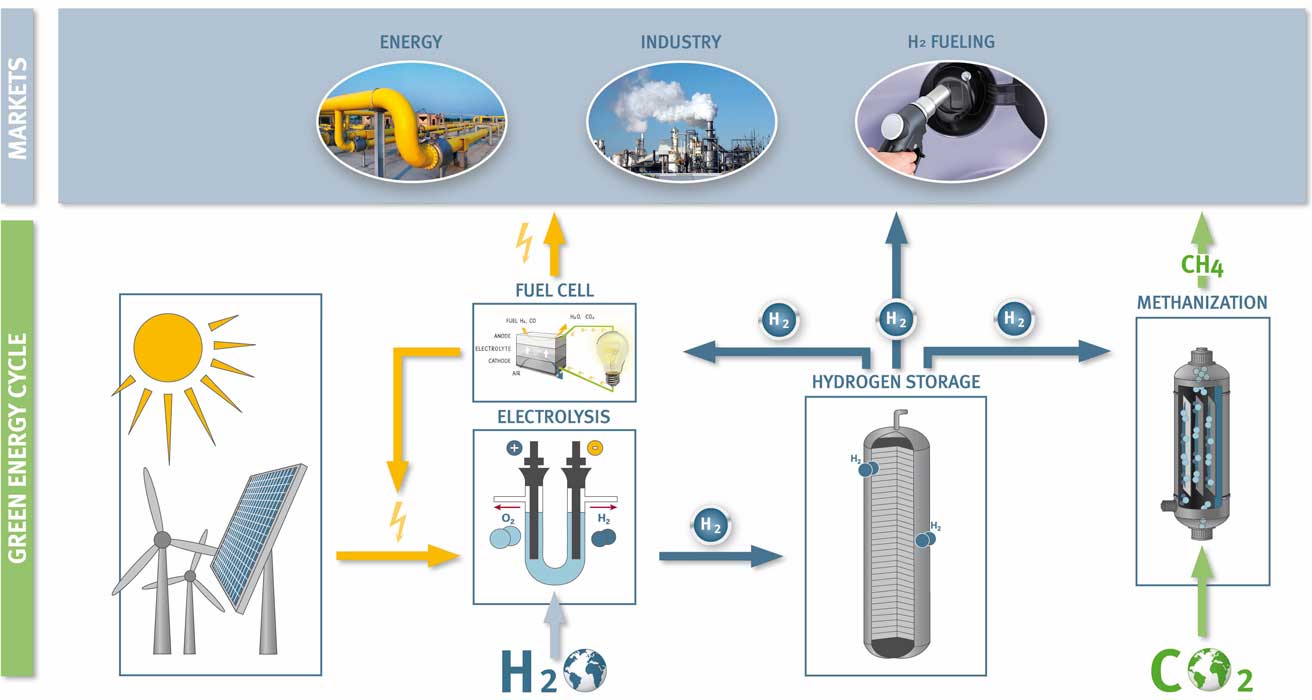

There is movement in the German hydrogen strategy. Only from Renewable energies manufactured, so-called green hydrogen is climate neutral. Pepperl + Fuchs covers the entire value chain Sensor technology and explosion protection components off, there is a new one Cooperation for the development of 5 to 15 MW hydrogen plants. You can find out more about this and other news below:

Contents

- Material testing for hydrogen applications

- Fill up with hydrogen at the right pressure

- Green hydrogen - opportunity or risk for factory automation?

- Sensor technology for the hydrogen value chain

- Cooperation to build a green hydrogen economy

- Tube forming system and high-pressure valves for hydrogen technology

- Pilot project produces green hydrogen from seawater

- Green hydrogen from Power-to-X plant

- GKN and McPhy advance use of solid-state storage

- FAQ

Material testing for hydrogen applications

18.01.2024/XNUMX/XNUMX | In the wake of the increasing importance of hydrogen as an environmentally friendly energy source, the Austrian Scioflex Hydrogen GmbH attaches great importance to the precise testing and certification of hydrogen products. The use of advanced Zwick Roell Testing machines in the testing laboratory enable realistic and reliable material tests.

18.01.2024/XNUMX/XNUMX | In the wake of the increasing importance of hydrogen as an environmentally friendly energy source, the Austrian Scioflex Hydrogen GmbH attaches great importance to the precise testing and certification of hydrogen products. The use of advanced Zwick Roell Testing machines in the testing laboratory enable realistic and reliable material tests.

Fill up with hydrogen at the right pressure

09.04.2023/XNUMX/XNUMX | To dem Hydrogen (H2) as an alternative fuel to achieve a breakthrough, we need attractive hydrogen cars and high-performance commercial vehicles that can be refueled in a nationwide filling station infrastructure. The structure of the corresponding hydrogen gas stations requires a lot Measurement Technology, so that safety when refueling with hydrogen is guaranteed.

09.04.2023/XNUMX/XNUMX | To dem Hydrogen (H2) as an alternative fuel to achieve a breakthrough, we need attractive hydrogen cars and high-performance commercial vehicles that can be refueled in a nationwide filling station infrastructure. The structure of the corresponding hydrogen gas stations requires a lot Measurement Technology, so that safety when refueling with hydrogen is guaranteed.

Green hydrogen - opportunity or risk for factory automation?

02.03.2023/XNUMX/XNUMX | The fundamental change in the entire energy supply that is shaping our society affects all fossil-based materials and CO2 emitting energy source. Because not all areas can be electrified, we need substitutes for oil, gas and coal. There is now agreement on the Use of hydrogen. What contribution Pepperl + Fuchs you can find out here.

02.03.2023/XNUMX/XNUMX | The fundamental change in the entire energy supply that is shaping our society affects all fossil-based materials and CO2 emitting energy source. Because not all areas can be electrified, we need substitutes for oil, gas and coal. There is now agreement on the Use of hydrogen. What contribution Pepperl + Fuchs you can find out here.

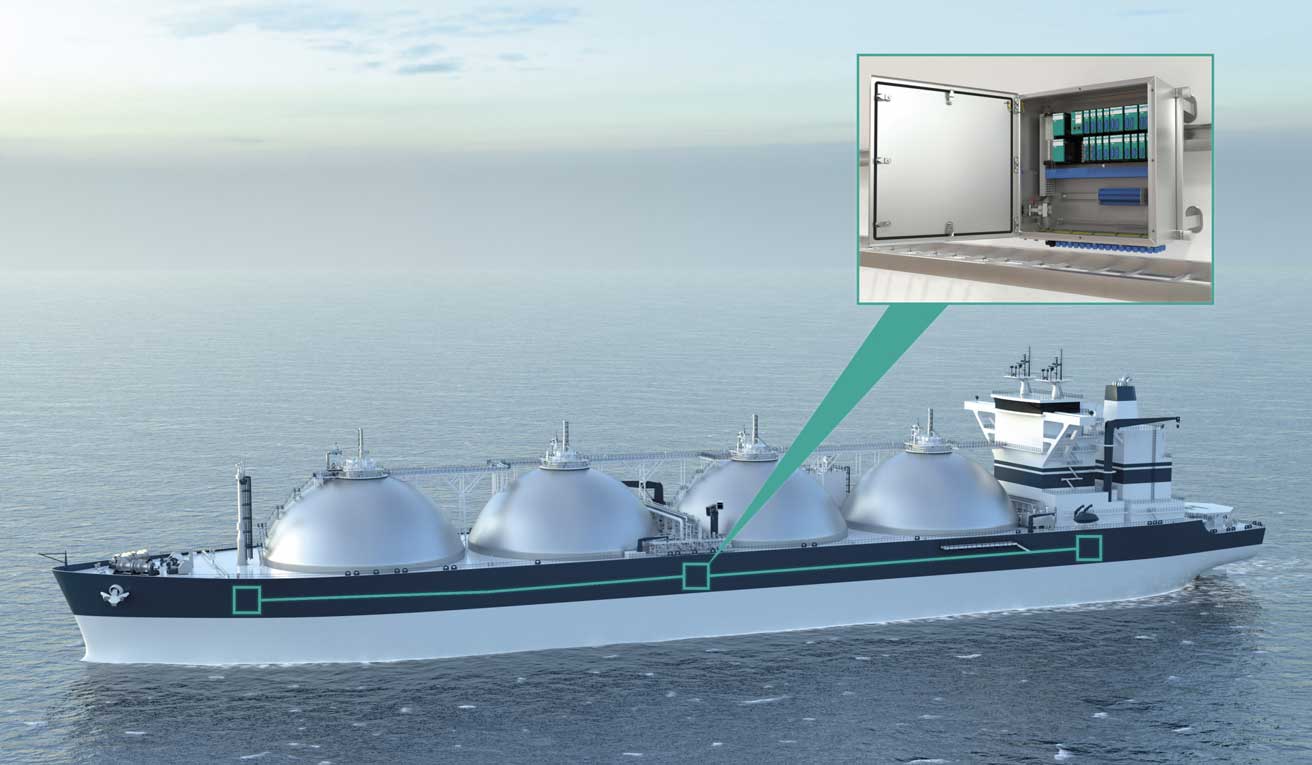

Sensor technology for the hydrogen value chain

15.09.2022/XNUMX/XNUMX | Pepperl+Fuchs has many years of experience in the field of explosion protection and the industrial sensors. With this know-how, the company is the right partner and a connecting element in the hydrogen chain - from regenerative energy production, high-pressure compression after electrolysis, transport, storage to large-scale industrial use and hydrogen filling stations.

15.09.2022/XNUMX/XNUMX | Pepperl+Fuchs has many years of experience in the field of explosion protection and the industrial sensors. With this know-how, the company is the right partner and a connecting element in the hydrogen chain - from regenerative energy production, high-pressure compression after electrolysis, transport, storage to large-scale industrial use and hydrogen filling stations.

Cooperation to build a green hydrogen economy

01.09.2022 | Siemens Smart Infrastructure, the North German State Bank and the investment company Senco Hydrogen Capital have entered into a cooperation in the field of hydrogen economy. The aim is to advance projects for the production of green hydrogen by electrolysis in Germany, in particular close to consumption.

The cooperation partners are currently working on examining business concepts that can be financed and identifying suitable locations. There will be locations for wind and photovoltaics Systems analyzed that have an H2 generation plant can receive a further revenue and marketing option. Locations that are suitable for promoting the commercial use of green hydrogen in Germany are also being scrutinized. The focus is primarily on systems with an average generating capacity of 5 to 15 MW, which can be implemented relatively quickly. The implementation of concrete projects should start in 2023.

solar storage | Products, technologies, innovations and trends

solar storage | Products, technologies, innovations and trends

The extraction, storage and use of green hydrogen on an industrial scale plays a key role in the decarbonization of the economy a. It makes an active contribution to the diversification of the energy supply in Germany and Europe. At the same time, a system-friendly mode of operation is created, which is necessary for the fundamental transformation of energy generation and which supports the stability of the power grid.

Siemens, Nord/LB and Senco have the open platform as initiative partners H2.Now! for companies and investors in the hydrogen economy. Other companies with an economic connection to the subject of hydrogen can join here. At the same time, the initiative is intended to make an entrepreneurial contribution to the creation of future-proof industrial jobs in Germany as a technology location.

Tube forming system and high-pressure valves for hydrogen technology

23.05.2022/XNUMX/XNUMX | The high-density Voss Lok tube forming system40 from Voss fluid was recently certified for highly sensitive hydrogen applications. In addition, the manufacturer has expanded its portfolio of efficient high-pressure valve components through the partnership with Hyptec GmbH. It is used in electrolysis, transport and storage of hydrogen and fuel cells. Through the use of ready-to-install lines combined with Voss Lok40 and the high-pressure valves, the company can now map complete systems for the transport and storage of hydrogen.

23.05.2022/XNUMX/XNUMX | The high-density Voss Lok tube forming system40 from Voss fluid was recently certified for highly sensitive hydrogen applications. In addition, the manufacturer has expanded its portfolio of efficient high-pressure valve components through the partnership with Hyptec GmbH. It is used in electrolysis, transport and storage of hydrogen and fuel cells. Through the use of ready-to-install lines combined with Voss Lok40 and the high-pressure valves, the company can now map complete systems for the transport and storage of hydrogen.

Hyptec develops and sells hydrogen technologies with a focus on particularly sophisticated high-pressure valves. These are up to four times smaller and six times lighter than comparable models. In combination with Voss Loco40 they create a high-density connection in hydrogen and gas-based drive systems.

Voss Fluid optimizes its product range specifically for use in hydrogen applications. The new developments are already being used in many different applications such as ready-to-install gas handling modules for the electrolysis, transport and storage of hydrogen in mobile and stationary applications. The components are also used in fuel cells, where they ensure the supply of gaseous hydrogen.

Voss Fluid will be exhibiting at the Hannover Messe 2022.

Pilot project produces green hydrogen from seawater

20.12.2021/XNUMX/XNUMX | Schaeffler is expanding its competencies, technologies and products in the field of green hydrogen production and now has an innovative solution for Desalination and purification of sea water developed. This permits the operation of Schaeffler's own PEM stack. The effectiveness of the technology was proven by the test operation in the port of Texel.

Together with Wageningen Food & Biobased Research (WFBR) from the University of Wageningen and with funding from the Dutch funding agency RVO, the Dutch start-up, which has belonged to Schaeffler since summer 2021, implemented the project Hydron Energy B.V a feasibility study. As part of the SEA2H2 project, the consortium has demonstrated that climate-neutral hydrogen can be obtained from seawater.

Seven good reasons for hydrogen propulsion and fuel cells

Seven good reasons for hydrogen propulsion and fuel cells

The challenge for the application described lies in the treatment of seawater for the membrane electrolysis. Because electrolysers require ultrapure water. To do this, seawater must first be desalinated and cleaned and filtered in a complex manner. The solution developed for this with the WFBR uses the waste heat from the electrolysis process to treat the seawater. With this technology, green hydrogen can be generated with renewable energies from offshore wind farms and transported to land via pipelines.

Hydron has already demonstrated the functionality of its water treatment in a test facility operated on the Dutch North Sea island of Texel. As part of Schaeffler, the Hydron team is now working on scaling the filter, desalination and membrane electrolysis components for industrial scale deployments. At the same time, costs should be reduced and operational efficiency and durability increased.

Hydrogen as a strategic business area at Schaeffler

“Hydrogen produced from the green energy of offshore wind turbines will play a crucial role in achieving European climate targets. We are very proud that with our development and the experience we have already gained, we can contribute to the further expansion of Schaeffler's value chain and to the competitive production of green hydrogen," says Sander ten Hoopen, one of the founders of Hydron Energy BV and Head of Schaeffler System Engineering.

Stacked bipolar plates for the core of the fuel cell

Stacked bipolar plates for the core of the fuel cell

“Wind2Hydrogen, i.e. green hydrogen is produced from wind energy, is an important growth area for Schaeffler. In cooperation with our partners in the Wind power In the industry, we want to become one of the leading suppliers of system components in this area," adds Bernd Hetterscheidt, Head of Strategic Business Area Hydrogen at Schaeffler. "To do this, we combine Hydron's innovative development with Schaeffler's strengths, such as our system understanding and our know-how in the rapid scaling of products and projects, in order to bring them to the market as quickly as possible and at the same time in accordance with the highest quality standards."

Production of new electrolysis stacks

As a key factor in the areas of mobility and sustainability, hydrogen is an important strategic business area for Schaeffler and part of the Road map 2025. The company is also involved in the H2Giga hydrogen lead project of the German Federal Ministry of Education and Research. As consortium leader of the sub-project “Stack Scale up – Industrialization of PEM electrolysis”, Schaeffler is working together with nine partners from industry and research to realize the series production of the latest electrolysis stacks as quickly as possible.

Schaeffler is exhibiting at the Hannover Messe 2022.

Green hydrogen from Power-to-X plant

13.01.2021 | The world's largest when it was commissioned Power-to-X system for the production and liquefaction of green hydrogen is currently being built in Leuna at the important chemical and refinery site in Saxony-Anhalt. The planned electrolysis system will initially run on certified green electricity. Later, from mid-2022, it will produce up to 3200 t of green hydrogen per year using renewable energies that are generated in the vicinity.

Reading tip: Measurement technology for hydrogen production

Reading tip: Measurement technology for hydrogen production

The Proton Exchange membrane (PEM) electrolysis technology comes from ITM Power, a joint venture partner of Linde. Thanks to complementary technologies such as liquefaction, gas stationsConstruction and logistics, Linde covers the entire hydrogen value chain.

Leuna location perfect for green hydrogen

“Leuna is ideally suited as a location for such a plant, because we have been supplying our local customers and the surrounding network with a complete product portfolio of industrial gases for many decades - as part of one of the largest industrial clusters in Germany”, comments Jens Waldeck, responsible for the gases business in Western Europe at Linde.

“This portfolio is perfectly complemented by the electrolysis plant on an industrial scale, especially in connection with the currently expanded liquefaction. The well-developed pipeline network and the excellent infrastructure connection also speak in favor of Leuna."

At Linde, the electrolysis process is an important component in the entire hydrogen value chain. "Thanks to the combination of first-class EPC (engineering, procurement, construction) competence and technology expertise on the part of ITM Linde Electrolysis GmbH, we can offer individual systems for the production of electrolysis-based hydrogen and oxygen", says Michael Schaeffler, Head of Hydrogen and Synthesis Gas Plants at Linde Engineering.

The use of the future-oriented, based on industrial gases Environmental technologies from Linde, like the production of green hydrogen, it allows companies around the world to increase their productivity and improve their ecological footprint. Linde will supply its industrial customers with the green electrolysis hydrogen via the existing pipeline network or by truck. It should also be used to supply hydrogen filling stations in the region.

Self-driving cars from the perspective of an automotive supplier

Self-driving cars from the perspective of an automotive supplier

In addition to the electrolysis, the construction project includes a new one Hydrogen liquefier. It is scheduled to go into operation in early 2021. Infrastructural measures are carried out in cooperation with the site operator Infraleuna GmbH. The project is supported by funds within the framework of the joint task of improving the regional economic structure (GRW). The state of Saxony-Anhalt and the federal government are involved in financing the approved subsidy.

BMBF starts hydrogen lead projects

The Federal Minister of Research (BMBF) has launched three key projects that it has around 700 million euros promotes. This is the largest funding initiative of the BMBF to date on the subject of the energy transition. Federal Research Minister Anja Karliczek sees green hydrogen as a chance of the century for Germany.

The Federal Minister of Research (BMBF) has launched three key projects that it has around 700 million euros promotes. This is the largest funding initiative of the BMBF to date on the subject of the energy transition. Federal Research Minister Anja Karliczek sees green hydrogen as a chance of the century for Germany.

“Our lead projects show that Germany is consistently entering the hydrogen economy. Because green hydrogen is a key raw material for a climate-friendly Germany and long-term growth, ”said Federal Research Minister Anja Karliczek when announcing the projects.

An ideas competition under the title Hydrogen Republic of Germany was the fuse for the three lead hydrogen projects that were launched. An independent panel of experts assessed the sketches of the lead projects at the end of 2020 and deemed them eligible. From spring 2021, over 200 partners are expected to develop the hydrogen technologies of the future for four years.

The Projects were designed so that green hydrogen can be used across the board as quickly as possible. They should be used to remove hurdles that still stand in the way of a successful, efficient hydrogen economy. Green hydrogen has so far been significantly more expensive than fossil fuels. With the lead projects, the BMBF is driving technology development forward.

Hydrogen lead projects at a glance

Hydrogen lead projects at a glance

- Lead project H2Jig develops possibilities for the series production of water electrolysers so that the production of green hydrogen is competitive and production errors are minimized.

- Lead project H2Seaside develops possibilities for the production of hydrogen and secondary products such as methane, methanol, ammonia, fuel. The production is to take place directly at sea using wind turbines without a grid connection. The costs of hydrogen production are minimized.

- Lead project transhyde develops and tests transport options for hydrogen over short, medium and long distances. It is intended to show what an efficient hydrogen economy could look like, from production and transport to use.

GKN and McPhy advance use of solid-state storage

23.07.2014/XNUMX/XNUMX | GKN Powder Metallurgy and McPhy Energy SA today announced an agreement for a technology partnership known, which will accelerate the use of cost-effective solid storage for hydrogen. Large quantities of hydrogen are already being used in industry today, and the energy source is said to play an important role in integration and storage in the future renewable energies and the development of CO2-free mobility with hydrogen fuel cells ahead.

solid storage represent a safe way to store large amounts of high-density hydrogen at low pressure.

McPhy Energy offers solid-state storage for hydrogen on an industrial scale and has been developing and industrializing this storage since 2008. With installations in five countries, most recently in the multi-energy tank station at Berlin's Schönefeld Airport, the company was able to demonstrate the performance of solid-state storage.

GKN Powder Metallurgy is a global manufacturer of powder metallurgy products. With sintered components for automotive construction and industry as well as powder metallurgy applications, the company achieved sales of more than one billion euros in 2013.

FAQ

What is green hydrogen?

Green hydrogen is a term for the production of hydrogen, which is obtained from renewable energies. The renewable energy required for electrolysis or water splitting is obtained from wind or solar energy sources. Hydrogen is considered an environmentally friendly fuel and is intended to reduce CO2 contribute reduction. The hydrogen strategy can make a significant contribution to Climate protection and achieve the energy transition. Hydrogen can be used in many ways, for example as an energy carrier or fuel for fuel cell cars or as a raw material for the chemical and steel industries.

Source: This article is based on information from the following companies: BMBF, Linde, Pepperl+Fuchs, Schaeffler, Siemens, Voss-Fluid, Wika, Zwick Roell.

You might also be interested in...

Artificial Intelligence | trends and developments

battery production | Facts and Technologies

3D printer metal | Amazing Possibilities

Transducer | Transmitters for pressure, temperature and more

Control Fair 2024 | The industry is already looking forward to Stuttgart

Industrial radar sensor with CAN interface

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.

Hydrogen lead projects at a glance

Hydrogen lead projects at a glance