Rack | Corrosion-resistant and up to 2 m long

- Details

- Hits: 7141

An rack walks in Rack drive rotating movements into linear ones. It is suitable for applications in automation technology, vehicle steering or is used in CNC machines. Modern racks are very precise and robust against environmental influences. We have a few for you below New Products for your convenience.

Contents

- Racks 2023 – The most important things in brief

- Rack and pinion innovations

- Frequently asked questions

Racks 2024 – The most important things in brief

The rack is a classic machine element in the Drive Technology. Advances in manufacturing, such as high-speed milling and precise control grinding, have led to significant increases in the quality and precision guided by racks. Material such as hardened steel or more advanced Plastic expand the possible uses of racks in a wide variety of applications, from Robotic to aerospace.

rack gear | Highly accurate for precise movements

rack gear | Highly accurate for precise movements

A trend in the development of racks is intelligent rack gears, equipped with Sensors and IoT connectivity. They enable ongoing monitoring and Condition analysis, which supports preventive maintenance measures and optimization of operating conditions in real time. These smart systems make a significant contribution to increasing efficiency and reducing costs by reducing downtime and extending the service life of the drive systems.

The focus on sustainability and energy efficiency is also leading to innovations in racks. Lightweightand the improvement of the tribological properties, i.e. the friction and wear characteristics, are the focus of development.

Rack and pinion innovations

Modern racks are more precise, more powerful and more versatile than ever before. Below we present to you New Products .

Racks now also up to 2 m long

Sep 05.09.2023, 1 | The tried and tested racks with a length of XNUMX m Wittenstein now also available with a length of 2 m for linear systems. Especially in short ones linear axes simplify assembly. If you combine it with the simple, quick, ergonomic and precise “Inira” assembly concept, there are further advantages with the new 2-meter version.

The 2 meter rack has high gearing quality, which was requested by the market in this length. Typical applications are lifting axes of gantry robots, plasma and water jet cutting machines, Y-axes in laser cutting machines, telescopic axes of Cartesian robots, Tool changer and 7-axis in the Robotic.

The ones that have already proven themselves 1 meter racks are easy to transport, standardized in storage, easy to assemble and offer the highest feed forces. Inira clamping, adjusting and pinning also makes assembly faster and more efficient. The 1 m racks are suitable for use in machining centers for wood, Plastic and composite material, for metal-cutting machine tools, laser cutting machines or traversing axes of gantry robots.

Helical gear with rack calculation for steering in the car

November 27.11.2019, XNUMX | In vehicles, the transmission is from the steering wheel to the steering the wheels are often carried out by a rack and pinion drive. KISSsoft has the option of using the ZE2019 module in the 7 release Helical gear with rack calculation integrated.

November 27.11.2019, XNUMX | In vehicles, the transmission is from the steering wheel to the steering the wheels are often carried out by a rack and pinion drive. KISSsoft has the option of using the ZE2019 module in the 7 release Helical gear with rack calculation integrated.

Corrosion-resistant thermoplastic rack for positioning systems

April 06.04.2016, XNUMX | The latest generation of rack and pinion systems from nexen offers new application possibilities for positioning systems. The Versa Rack thermoplastic rack is corrosion resistant, durable and low maintenance. It has medium accuracy and load capacity and is a cost-effective alternative to conventional metal racks.

April 06.04.2016, XNUMX | The latest generation of rack and pinion systems from nexen offers new application possibilities for positioning systems. The Versa Rack thermoplastic rack is corrosion resistant, durable and low maintenance. It has medium accuracy and load capacity and is a cost-effective alternative to conventional metal racks.

Rack and pinion systems are: linear actuatore, which are essential in many linear positioning systems. The products of the series Versa rack are suitable for goods removal, marking and portal systems, conveyor systems and CNC routers for wood, plastic and composite materials. Large amounts of chips are produced here, which can impair the lubrication of steel racks.

Versa Rack is made of a self-lubricating Polymer manufactured. The rack can be operated at full speed without additional lubrication, making it a cost-effective alternative for clean rooms, the food technology and pharmaceutical industry. It tolerates splash water, is suitable for outdoor applications and can even be used in saline coastal climates and other harsh or dirty environmental conditions.

The Tooth play The Versa Rack rack is less than 3,2 µm, the positioning accuracy is ±580 µm depending on the selected pinion. Depending on the pinion size selected, the thermoplastic racks can withstand loads of 500 to 1200 N. The combination of value pinion with thermoplastic rack can be achieved at 480 to 750 min-1 or operate at 2 m / s.

Racks for high performance linear systems

04.02.2011 | Dr. Anna Katharina Wittenstein, Managing Director, Wittenstein AG Switzerland, Grüsch, will provide information about the International Trade Press Day the abandonment of the Grüsch location of Wittenstein AG. She also explains the innovation of the new ones Rack and pinion systems, whose high performance racks are manufactured here.

Rack class for cost-optimized linear drive systems

07.09.2010 | Atlanta Drive systems closes a gap in the portfolio of quality racks with ground racks of quality 7 and 8. These are the world's first bridge between the Ulta-High Precision Class with quality 4 and 5 and the Basic Class with quality 9 and 10. The new quality classes, with their ground teeth, enable the realization of energy-efficient rack drives by reducing friction losses even in precision classes in which this has not been possible since then.

07.09.2010 | Atlanta Drive systems closes a gap in the portfolio of quality racks with ground racks of quality 7 and 8. These are the world's first bridge between the Ulta-High Precision Class with quality 4 and 5 and the Basic Class with quality 9 and 10. The new quality classes, with their ground teeth, enable the realization of energy-efficient rack drives by reducing friction losses even in precision classes in which this has not been possible since then.

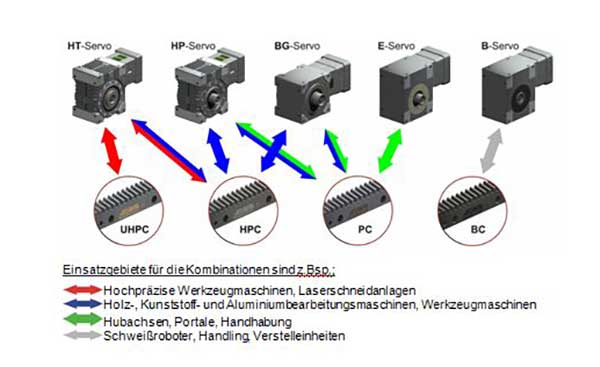

Suitable for the complete Servo gearboxfamily, the manufacturer now also offers the complete rack family. This makes it possible to offer individual rack and pinion drive systems tailored precisely to the respective requirements, from gear drives to pinions/pinion shafts to racks, from a single source at an affordable price.

The following rack types are offered:

- UHPC = Ultra-High Precision Class: Quality 4, Quality 5

- HPC = High Precision Class: Quality 6, Quality 7

- PC = Precision Class: Quality 8

- BC = Basic Class: Quality 9, quality 10

- and the matching servo transmission family:

- HT = high-torque servo worm gearbox: highest torque, <1 arcmin

- HP = high-performance servo worm gear: very high torque, <2 arcmin

- E = economy servo worm gear: very high torque, <6 arcmin

- B = basic servo worm gear: high torque, <12 arcmin

- BG = bevel gear servo gearbox: highest torque, < 6 arcmin

Frequently asked questions

What tasks do racks have in conjunction with gears?

Racks in combination with gears play a crucial role in the Transformation of forms of movement within mechanical systems. This configuration allows rotating movements to be converted into linear movements and vice versa. The gear, or pinion, engages with the rack, whereby the rotational movement of the gear is converted into a rectilinear movement of the rack. This type of power transmission is particularly important in applications where precise and reliable linear movement is required, such as in automation technology, CNC machines, vehicle steering or stage technology. The specific design of rack and pinion Gear enables high transmission efficiency, precision and the ability to transmit large forces.

What is the module in racks?

The module in racks is a measurement that determines the size of the teeth by dividing the pitch diameter of a gear by the number of its teeth. This unit of measurement, usually given in millimeters, is crucial for compatibility between gear and rack as it indicates the tooth size and therefore ensures that both parts mesh correctly. The modulus is a relative quantity that is not directly measured. The results result from calculations using the geometric data of the gearing.

Source: This article is based on information from the following companies: Atlanta, Nexen, Wittenstein.

You might also be interested in...

Servo controller | Servo amplifiers and servo converters

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.