rack gear | Highly accurate for precise movements

- Details

- Hits: 31801

Systems for positioning tasks in mechanical engineering and in the Food industry defy harsh environmental conditions. Such extremely high loads hold the Rack gear from Leantechnik stood easily. Such a rack and pinion drive is available in numerous lifting systems, handling components and positioning systems in use worldwide. The following product information is dedicated to the new developments.

Contents

- Customized rack and pinion gears from the modular system

- Rack and pinion gears for positioning in mechanical engineering

- Smooth rack gear and stepless holding brake

- Frequently asked questions

Customized rack and pinion gears from the modular system

15.06.2022/XNUMX/XNUMX | Leantechnik manufactures special gears for applications with special requirements leanunique with individual specifications. Depending on the specification, these rack and pinion gears can withstand extreme loads. You will be made special Materials in individual dimensions with special Coatings manufactured. The gears are blued, galvanized, anodized or provided with a Duralloy coating.

Stainless steel linear guides from Rollon are indestructible

Stainless steel linear guides from Rollon are indestructible

Some of these special gears will later be included in the standard portfolio. An example is the Lean SL 5.5 gearbox with lifting forces of up to 25 kN. It was originally developed for a nuclear power plant application. Now this rack and pinion gear can also be found in other industrial ones heavy duty applications. The particularly small Lean SL 5.m rack and pinion gear with its maximum lifting force of 300 N was originally designed for the Food industry designed and is now also available in a standard version.

The Leanunique rack and pinion gears are available moderate quantities with customer-specific connection bores.

Rack and pinion gears for positioning in mechanical engineering

02.12.2020/XNUMX/XNUMX | Leantechnik is a manufacturer of rack and pinion gears for mechanical engineering and installs them in customer-specific systems for the food industry. There are many applications for this rack drive. Such a partially and functionally ready system is known under the name lean transport offered.

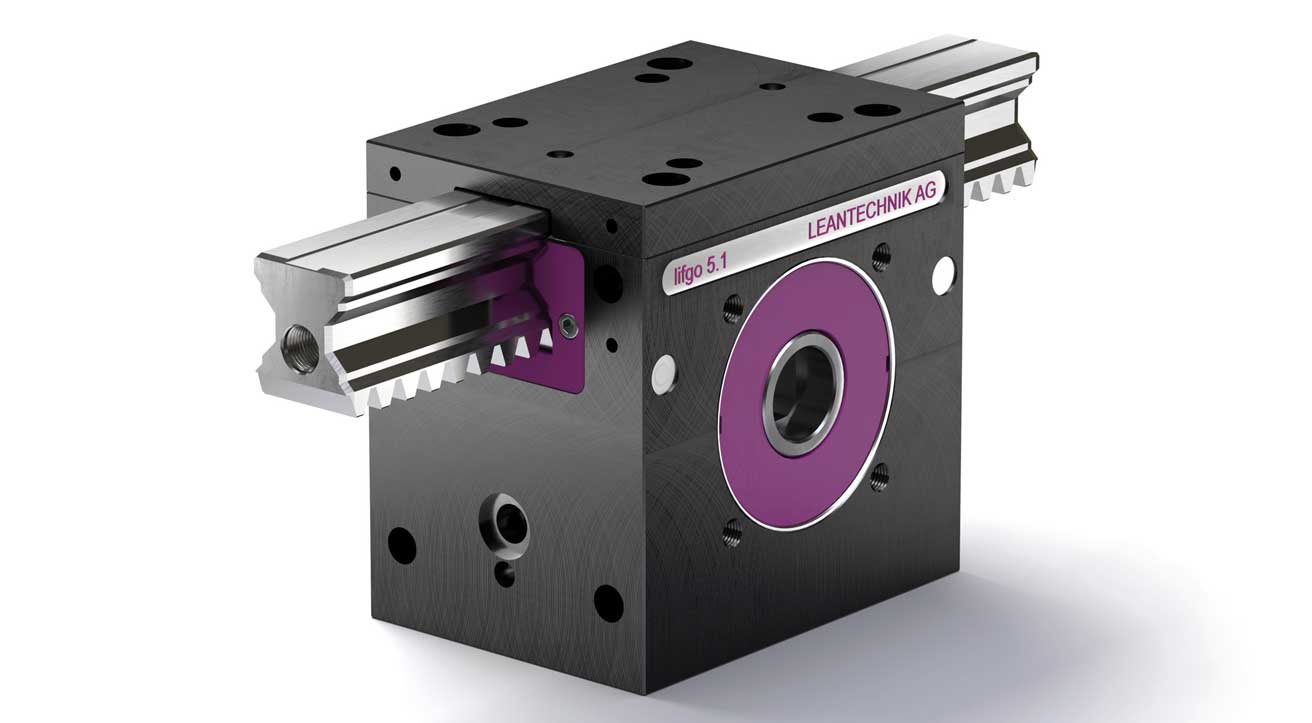

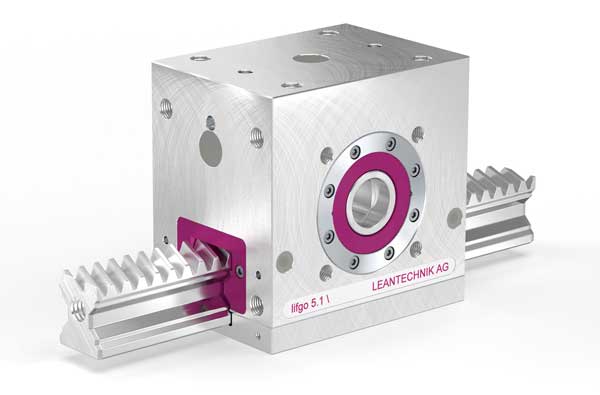

A rack and pinion gear Ligo 5.1 A manufacturer of packaging machines from Leantechnik installs in its wrap around or tray packers. The packers wrap the packaging of soft products such as margarine and butter in a cardboard box that protects it from damage.

Gear calculation for gears with background graphic

Gear calculation for gears with background graphic

The Lifgo racks take over in the machines Transmission with 3800 N lifting loads the precise guidance of the vacuumunit that feeds the cardboard blanks. The gearbox, which is based on the rack, must deliver maximum performance. The packers produce up to 25 wrap around boxes and more than 30 layers per minute. This corresponds to a cycle time of less than 2 s.

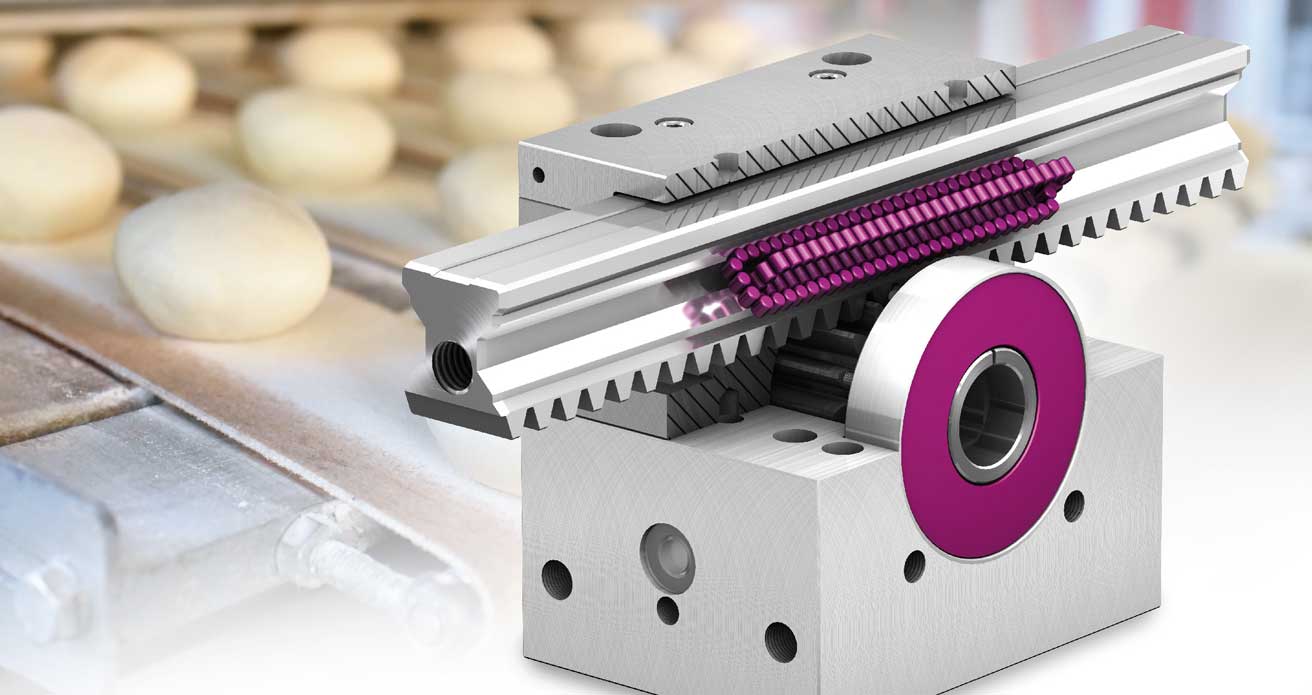

Rack and pinion gearboxes for bakery technology

Such a gear with a rack is also used in the baked goods industry. A Lifgo of the special size 5.4, for example, takes over the synchronous lifting movement of a piston that feeds soft and sticky raw dough for further processing. The rack and pinion drive leads with one per minute Stroke force of 25.000 N a total of 65 double strokes of 200 mm each. Temperatures of up to 40 °C prevail here. In addition, the Drive Technology with rack resist flour dust, cooking oil splashes and deposits.

Leantechnik also manufactures on the basis of its high-precision Lifgo and Lean SL rack and pinion drives customized positioning systems. These include lifting columns and lifting tables, transfer, handling or pick-and-place systems. The Lifgo rack and pinion gearbox offers high positioning accuracy and lateral force absorption. In contrast, the Lean SL gearbox is ideally suited for applications with simple, synchronous lifting tasks. Both rack and pinion series can be combined with one another as required.

Rack and pinion gear Lifgo in detail

The gearboxes of the series Ligo 5 are extremely precise, resilient and durable. The design combines drive and separate guide in one component. It thus meets the highest requirements in terms of lifting force, synchronicity, precision and speed.

Calculate crown gearbox geometrically and in strength

Calculate crown gearbox geometrically and in strength

The compact housing is closed all around and insensitive to external influences. An internal pinion with 4-fold roller guide moves the rack in the axial direction. This is able to absorb strong transverse forces. High load capacities can be achieved with low running noise. At the ends of the racks you can also grab, clamps, vacuum devices or other additional devices can be installed.

Lifgo 5 rack and pinion drives are available in standard sizes 5.0, 5.1 and 5.3. Even with a lifting force of up to 3800 N they can lift Speeds of 3 m / s. Just as fast, but even more powerful, is the special size Lifgo 5.4, developed for particularly heavy loads, with which a lifting force of up to 25.000 N can be achieved at a lifting speed of 3 m / s.

Smooth rack gear and stepless holding brake

02.05.2018/XNUMX/XNUMX | Leantechnik presents the extremely smooth-running rack and pinion gear Lifgo SVZ for particularly noise-sensitive applications and the stepless SHB holding brake with fail-safe function. The helical toothed rack and pinion gears run very quietly, since the power transmission does not start suddenly and over the entire tooth width as with straight teeth, but increases slowly.

02.05.2018/XNUMX/XNUMX | Leantechnik presents the extremely smooth-running rack and pinion gear Lifgo SVZ for particularly noise-sensitive applications and the stepless SHB holding brake with fail-safe function. The helical toothed rack and pinion gears run very quietly, since the power transmission does not start suddenly and over the entire tooth width as with straight teeth, but increases slowly.

These running characteristics lower the noise of the transmission clearly. Lifgo SVZ gears are just as robust as the standard Lifgo gears and achieve the same values in terms of precision and lifting speed. The three sizes SVZ 5.1, 5.3 and 5.4 offer lifting forces of 3400, 14.400 and 22.600 N. Four different versions are available:

The SVZ is an extremely resilient gear and achieves high synchronicity even at high speeds, the linear SVZ is particularly suitable for long stroke and travel distances, the double SVZ was designed for gripping and centering movements and the linear double SVZ for gripping and centering movements in applications with long travel distances.

Continuously variable holding brake for safety

stepless Holding brake SHB users can significantly reduce the risk of danger for system operators, especially on vertical, gravity-loaded axes. The brake module is opened with compressed air at 6 to 20 bar and jams automatically if the pneumatics fail. In the available versions it achieves nominal holding forces of 7500 to 30.000 N.

Since the pressure available in the compressed air system is sometimes not sufficient to operate the SHB, the manufacturer supplies a so-called pressure booster With. This increases the pressure purely mechanically and is therefore significantly cheaper than a general increase in system pressure, which would entail high energy costs. With the booster, the SHB can be operated with a pressure of 20 bar, so that nominal holding forces of up to 30 kN can be achieved.

Frequently asked questions

How does a rack and pinion gear work?

A rack and pinion gear consists of two main components: one Gear and an rack. The rack is an elongated element with straight teeth along one side. As the gear rotates with its teeth along its circumference, its teeth on the gears mesh with those on the rack. This interaction transforms the rotational motion of the gear into linear motion of the rack. The efficiency of converting torque into linear force is directly dependent on the number of teeth and the precision with which the teeth of the gear and rack mesh. Through this principle, a rack and pinion gear can effectively convert rotating to linear motion.

Source: This article is based on information from the following companies: Leantechnik.

You might also be interested in...

Roller chain for the high demands of food technology

Flexible solar modules, rotating solar panels and other photovoltaics

Gear calculation online – super easy!

Potato harvester reliable again after conversion from freewheel

Heavy duty rails | High loads welcome