Flexible solar modules, rotating solar panels and other photovoltaics

- Details

- Hits: 7640

Solar Panels and photovoltaic systems fed around 8,8 billion kWh of electricity from solar energy into the grid in the first quarter, according to the Federal Statistical Office. Compared to 2021, the capacity has increased by 34,7%. The technology is becoming more and more mature: Rotating solar panel with durable drive chains optimize the yield. That flexible solar module Fraunhofer has its sights set on the roll, and the towers of wind turbines can also be used with flexible photovoltaic cells.

Contents

- Corrosion resistant chains for large format solar panels in Spain

- Flexible solar modules for new photovoltaic applications

- Hybrid regenerative energy generation from sun and wind

Corrosion resistant chains for large format solar panels in Spain

18.08.2022/XNUMX/XNUMX | While the rotating solar panels from a Spanish manufacturer follow the sunlight, they are moved by a drive. This was previously equipped with a low-performance drive chain. Replacing the standard chain with a Tsubaki corrosion-resistant, long-life chain eliminated frequent chain changes and reduced costly maintenance.

Spain has proven to be a leader in the development and use of photovoltaic technology as a renewable energy source. As a pioneer in this field, however, the country lost some momentum in the years after the millennium because the global financial crisis in 2008 led to a high solar tax on existing and new systems.

Reading tip: Measurement technology for hydrogen production

Reading tip: Measurement technology for hydrogen production

After that, the contribution of renewable energies to the national energy mix in Spain rose sharply again. According to the International Energy Agency, with 38% in 2019 and with 44% in 2020 its total contribution Renewable energies increased. Much of Spain's renewable energy mix comes from solar energy with solar panels and photovoltaic panels.

Rotating solar module ensures maximum yield

A leading solar module manufacturer in Spain produces large-scale photovoltaic modules for commercial solar parks. The solar panels are installed in rows on fields and slopes that are unsuitable for building or agricultural cultivation. Each solar module panel is mounted on a pedestal for optimal solar energy generation capacity. The plinths are equipped with a drive system that rotates slowly throughout the day, aiming the photovoltaic system directly at the sun.

A leading solar module manufacturer in Spain produces large-scale photovoltaic modules for commercial solar parks. The solar panels are installed in rows on fields and slopes that are unsuitable for building or agricultural cultivation. Each solar module panel is mounted on a pedestal for optimal solar energy generation capacity. The plinths are equipped with a drive system that rotates slowly throughout the day, aiming the photovoltaic system directly at the sun.

The drive motor works over one chain mechanism. Because the drive chain originally used quickly corroded due to rain, dew and humidity, this resulted in costly maintenance work. The short service life of the chain also led to frequent replacement.

The experts from Tsubaki recommended the following solution to this problem. The standard chains have been replaced by quality chains from the "Neptune" series. These are ideal for the harsh environment of the solar modules, have a high tensile strength and are provided with a corrosion-resistant special coating.

No corrosion thanks to two-stage coating

A two-stage Coating reliably protects the base chain from corrosive environments. The outer or top coat resin preserves the Neptune chain against physical influences. A second layer underneath prevents the chain from corroding. To ensure each component is fully coated, they are coated at ambient temperature prior to chain assembly. That's how it will be Metal not affected by heat. The Neptune chains are designed for outdoor use, damp environments and washdown applications. Even on a first try, they lasted much longer than the original chain. Due to the higher strength, they stretch less.

Flexible solar modules for new photovoltaic applications

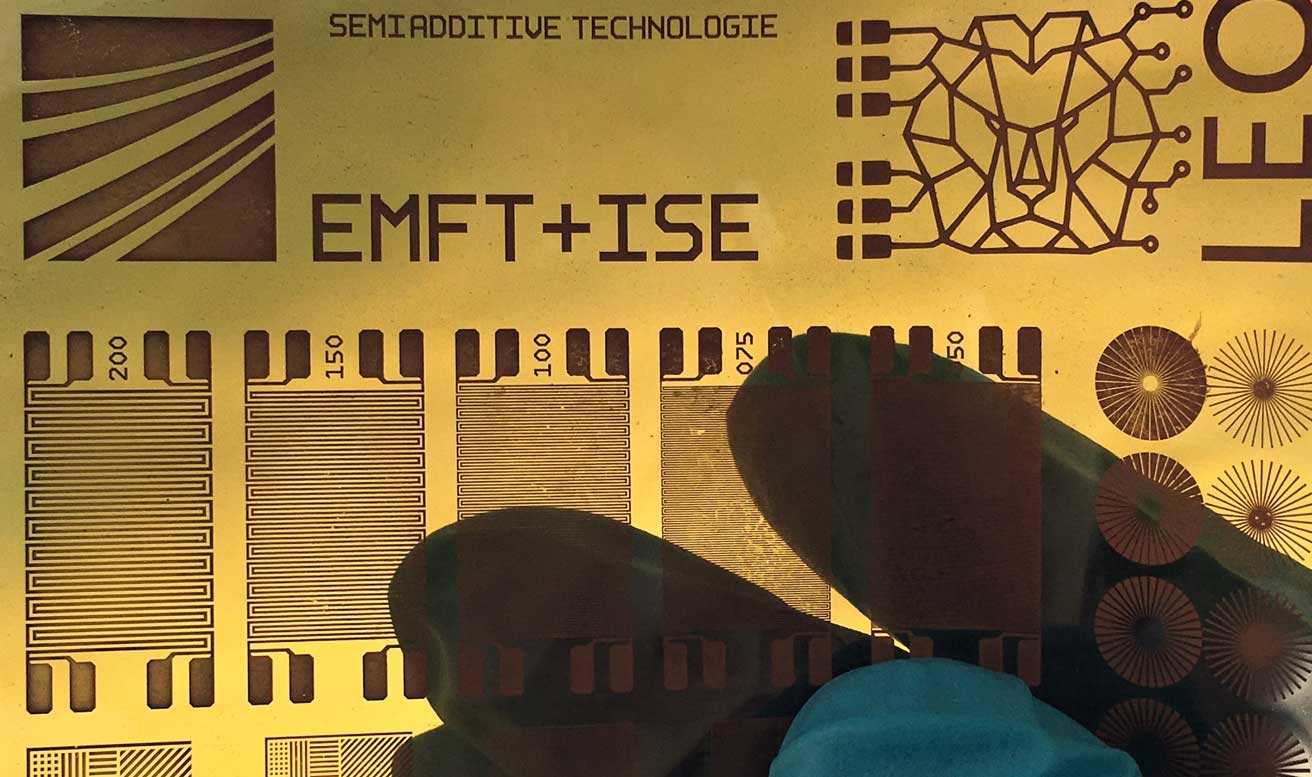

02.12.2020 | The researchers from Fraunhofer EMFT and ISE in sight. In the joint LEO project, they are developing a new manufacturing process for circuit boards that can be used to create flexible solar cells. Noisy Ixchen Elias Ilosvay photovoltaics is essential for the energy transition. "But the potential is far from being exhausted," says the scientist at the Fraunhofer Institute for Microsystems and Solid State Technologies EMFT.

Molded release film prevents galvanic corrosion in the car

Molded release film prevents galvanic corrosion in the car

In order to advance the development of more efficient solar modules with new properties such as mechanical flexibility and optical transparency, new manufacturing processes are required. Researchers at Fraunhofer EMFT and the Fraunhofer Institute for Solar Energy Systems ISE im are pursuing a very promising approach Project LEO, which aims at platform technology for the resource-saving production of conductor paths on large surfaces equipped with electronics.

Work is being carried out on a process that enables cost-effective and resource-saving production of large-area conductor track patterns enables. Such conductor track patterns are also required as electrical contacts for dissipating the photocurrent on solar cells.

Cost efficient and environmentally friendly manufacturing

The Fraunhofer researchers use a thin one laser-structured aluminum layer as a mask for the galvanic deposition of the electrical conductor tracks. "With our aluminum masking instead of the photoresist that is usually used to structure the conductor tracks, we avoid organically contaminated waste water, which can only be cleaned up in a very complex and costly manner", describes dr Markus Glatthaar from Fraunhofer ISE the process. "Aluminum is relatively easy to filter out of the wastewater and the small amount that is generated in our process can be completely recycled".

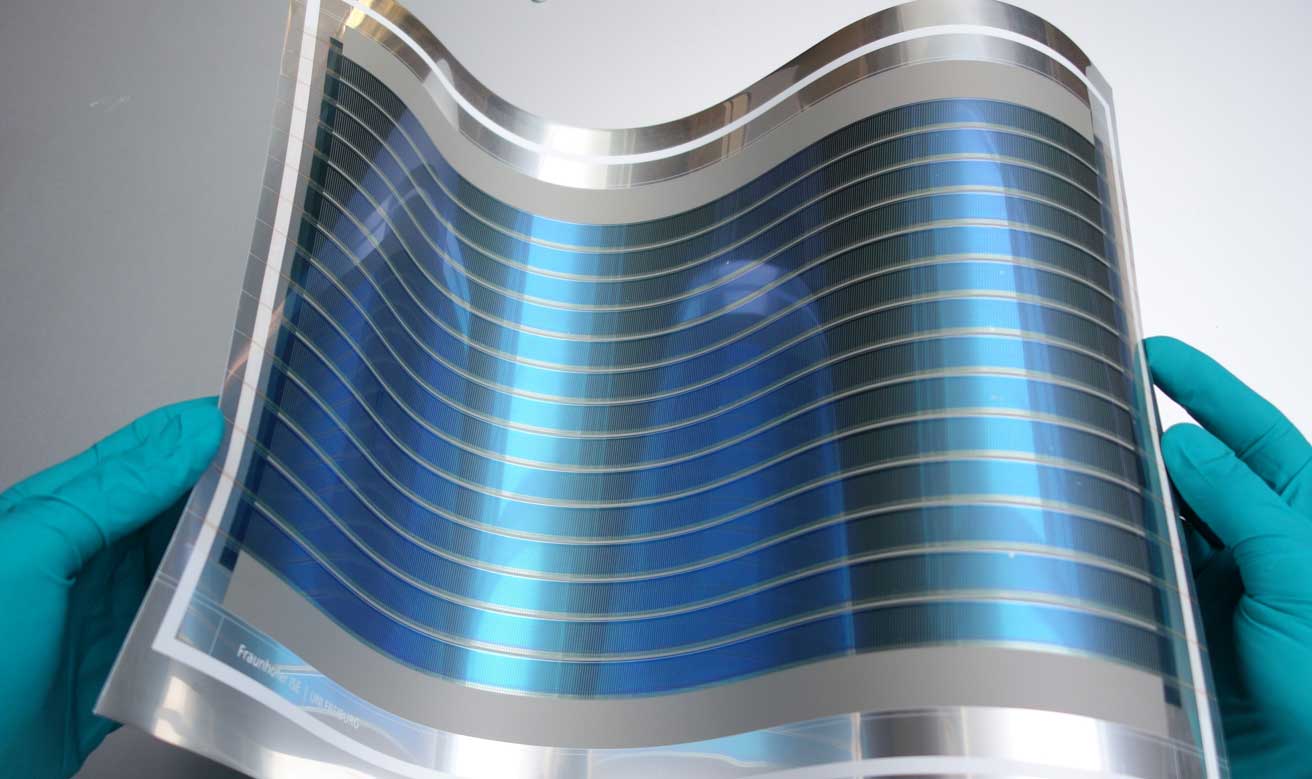

Solar cells off the roll

With the technology, flexible and transparent organic solar cells can be used in Roll-to-roll process getting produced. These flexible solar modules can then be integrated into a wide variety of applications. With the newly developed process sequence, the research team has already been able to produce 20 µm wide, galvanically reinforced conductor tracks on film substrates for organic flexible solar cells.

Comprehensive corrosion protection for steel in Kristal Solar Park

Comprehensive corrosion protection for steel in Kristal Solar Park

A second application is the production of a new, highly efficient Heterojunction solar cell. The cold metallization developed in the LEO process could make the production of solar cells significantly cheaper in the future. "Up to now, metallization has been a sticking point, as the hetero junction modules cannot withstand the high-temperature process that is used today for standard solar cells," explains Mr. Glatthaar. The scientist hopes that these high-performance solar modules can establish themselves on the market more quickly with the new manufacturing process.

Research under the sign of sustainability

The two researchers are personally very motivated and want to do more with their work Sustainability contribute. "I grew up in a tropical developing country. It shaped me to have seen things like the deforestation of the rainforests, fires, the extinction of species, outbreaks of new diseases, hurricanes and floods, but also periods of drought," says Ixchen Ilosvay.

Markus Glatthaar knows from the past how research can contribute to solving urgent environmental problems: "Through the consistent introduction of appropriate technologies, the forest dying and the disappearance of ozone layer be held back then. With my work on flexible solar modules and environmentally friendly production processes, I want to make my contribution to protecting our environment. "

Flexible photovoltaic cells on the wind turbine

20.10.2020/XNUMX/XNUMX | Many can already generate the electricity of the future. THE Energy however, has developed a worldwide unique solution. A wind turbine tower covered with flexible photovoltaic cells enables the hybrid Energy generation. It brings together the energy sources sun and wind. In cooperation with the energy carrier Energy Burgenland such a wind turbine was put into operation for the first time at the beginning of June.

20.10.2020/XNUMX/XNUMX | Many can already generate the electricity of the future. THE Energy however, has developed a worldwide unique solution. A wind turbine tower covered with flexible photovoltaic cells enables the hybrid Energy generation. It brings together the energy sources sun and wind. In cooperation with the energy carrier Energy Burgenland such a wind turbine was put into operation for the first time at the beginning of June.

You might also be interested in...

Infrared camera optimizes Laser Powder Bed Fusion 3D printing

Artificial Intelligence | trends and developments

3D printer | Additive manufacturing of plastic parts

3D printer metal | Amazing Possibilities

Programming Robots | software and controls