Programming Robots | software and controls

- Details

- Hits: 7700

If it is about Industrial robots or Cobots acts: Without suitable Software and an interactive one Programming robots nothing or nothing works easily. With new trends such as cloud-based programs or the use of artificial intelligence robot programming is becoming easier and more efficient. Read how this can be done and what software is already available for this.

Contents

- Smart robot software for processes with tolerances

- Partner for sensor-adaptive robotics

- User interface simplifies interaction with robots

- CNC + robot programming on one platform

- Robot programming for automated THT assembly

- Artiminds webinars to get you started with robot automation

- ABB robots for 3D printing made software ready

- Intelligent robot software for assembly automation

- Camera-based sensor software lets robot grippers see

- Frequently asked questions

Smart robot software for processes with tolerances

29.02.2024/XNUMX/XNUMX | If you try the traditional approach, processes subject to tolerance This is often a big challenge to automate. With the smart robot software from Artimind's Robotics Reliable solutions can be created very easily. Various implemented examples illustrate the wide range of applications.

29.02.2024/XNUMX/XNUMX | If you try the traditional approach, processes subject to tolerance This is often a big challenge to automate. With the smart robot software from Artimind's Robotics Reliable solutions can be created very easily. Various implemented examples illustrate the wide range of applications.

Partner for sensor-adaptive robotics

22.06.2023 | Artimind's Robotics presents to Automatica 2023 with the in-house software solutions programmed applications. The Robot Programming Suite (RPS) and Artiminds Learning & Analytics for Robots (LAR) tools simplify the programming of sensor-based robot applications thanks to the low-code approach. This makes it possible to automate production tasks that were previously only solved manually.

22.06.2023 | Artimind's Robotics presents to Automatica 2023 with the in-house software solutions programmed applications. The Robot Programming Suite (RPS) and Artiminds Learning & Analytics for Robots (LAR) tools simplify the programming of sensor-based robot applications thanks to the low-code approach. This makes it possible to automate production tasks that were previously only solved manually.

User interface simplifies interaction with robots

30.05.2023/XNUMX/XNUMX | With the user interface Kuka.Usertech Kuka has simplified the configuration of its robot controllers. The user-friendly interface makes it easy to create and use application commands with the software extension. The software provides the user with simple inline forms and status keys via an editor with Graphical User Interface (GUI) via complex routines in the Kuka Robot Language (KRL). These application commands for programming the robot are created in Kuka.Workvisual, for example, as status keys for individual applications or in the form of scripts for entire operating processes.

Even if you have not used Kuka.Usertech before, you can easily set up the robot control on your operator panel with the created inline forms, status keys, buttons and messages. status key are buttons on the Smartpad that are used to quickly and easily enter frequently repeated commands. inline forms are predefined input masks in the form of templates that allow the use of KRL routines without any problems.

The whole world of igus robots

The whole world of igus robots

The robot controller can be configured in just a few steps via the user interface of the interface and the robot is quickly ready for operation.

Kuka exhibits at the EMO 2023.

Quick start-up via drag-and-drop

The new user interface scores particularly well with its User Experience (UX). An intuitive editor on the PC with a standard user interface ensures high efficiency and offers the option of creating configuration files quickly and easily using drag-and-drop. An intervention in the KRL is not necessary due to the user experience design. The commands are then transferred as option packages to the Kuka Smartpad hand-held control unit for the controller. This avoids copying errors at the user interfaces. The robot is quickly ready for use.

The preconfigured Inline forms make the computer editor safer for humans to use. Input errors are displayed directly on the graphical user interface and are not only discovered when testing the robot controller. The Kuka.Usertech interface can be combined with all of the manufacturer's technology packages.

Kuka exhibits at the Automatica 2023.

CNC and robot programming on one platform

15.02.2022/XNUMX/XNUMX | With the integration of Robot in the machine tool, the advantages of automation can be fully exploited. With the development of a unified programming environment creates Mitsubishi Electric a direct robot controller, with which the robot can be programmed via G-codes in the CNC machining center.

15.02.2022/XNUMX/XNUMX | With the integration of Robot in the machine tool, the advantages of automation can be fully exploited. With the development of a unified programming environment creates Mitsubishi Electric a direct robot controller, with which the robot can be programmed via G-codes in the CNC machining center.

Robot programming for automated THT assembly

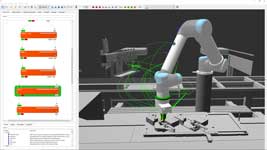

30.09.2020/XNUMX/XNUMX | The Robot Programming Suite RPS from Artimind's Robotics enables the automation of the THT assembly. The robot programming software teaches an industrial robot force-controlled processes such as scanning surfaces or controlled joining - all using drag and drop.

30.09.2020/XNUMX/XNUMX | The Robot Programming Suite RPS from Artimind's Robotics enables the automation of the THT assembly. The robot programming software teaches an industrial robot force-controlled processes such as scanning surfaces or controlled joining - all using drag and drop.

Artiminds webinars to get you started with robot automation

11.05.2020/20/2020 | Artiminds will start the webinar series on May XNUMX, XNUMX Automate with robots. This is intended to show companies how to achieve a lean entry into robotics and what requirements those responsible have to master when integrating robots. The webinar series includes nine dates and two main topics.

11.05.2020/20/2020 | Artiminds will start the webinar series on May XNUMX, XNUMX Automate with robots. This is intended to show companies how to achieve a lean entry into robotics and what requirements those responsible have to master when integrating robots. The webinar series includes nine dates and two main topics.

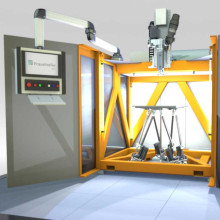

ABB robots for 3D printing made software ready

13.01.2020 | ABB robot for 3D Print can now be programmed in just 30 minutes. For this purpose, functionalities were integrated into the simulation and offline programming software "Robotstudio". The novelty will be shown for the first time on the Robotic Fair Irex presented in Japan. Thanks to the new software, which is part of the Powerpac portfolio, companies no longer have to carry out manual programming and can do so 3D printing components manufacture faster.

13.01.2020 | ABB robot for 3D Print can now be programmed in just 30 minutes. For this purpose, functionalities were integrated into the simulation and offline programming software "Robotstudio". The novelty will be shown for the first time on the Robotic Fair Irex presented in Japan. Thanks to the new software, which is part of the Powerpac portfolio, companies no longer have to carry out manual programming and can do so 3D printing components manufacture faster.

As part of Robotstudio, the 3D Printing Powerpac supports a variety of 3D printer applications. Among them are welding and printing with granules or concrete. It is suitable for the production of small volumes in a large number of variants.

Modeling in half an hour

Conventional, automated 3D printing processes are time-consuming: Millions of points and paths have to be plotted to program the print paths. With the 3D Printing Powerpack the standard slicer software design can be "translated" into the simulation environment and the ABB robot code. This enables users to implement the CAD design through to the final modeling of the product in half an hour.

Research project for AI based robot calibration

Research project for AI based robot calibration

According to market researcher Markets + Markets, the market for 3D printing is expected to open by 2024 34,8 billion Dollar to grow. This is also due to the development of new, industrial 3D printing filament.

“With our 3D printing software, we offer our customers faster 3D printing. With our high-performance ABB robots, companies can now efficiently produce high-quality objects for many industrial applications,” emphasizes Steven Wyatt, Head of Portfolio and Digital of ABB's Robots and Factory Automation business.

Intelligent robot software for assembly automation

10.09.2018/XNUMX/XNUMX | That Fraunhofer IPA presents the robot software drag+bot, which reduces the programming effort of robots to a minimum. It provides ready-to-use program modules that can be combined quickly and intuitively into complex robot applications via a graphical user interface.

10.09.2018/XNUMX/XNUMX | That Fraunhofer IPA presents the robot software drag+bot, which reduces the programming effort of robots to a minimum. It provides ready-to-use program modules that can be combined quickly and intuitively into complex robot applications via a graphical user interface.

In addition, operating and input aids simplify the parameterization of the blocks. Thus, no expert knowledge is needed to reprogram robots from different manufacturers.

The robot software pitasc for force-controlled assembly processes makes it possible to automate processes that were previously carried out manually, such as the assembly of control cabinets, in an economically sensible manner. The robot software is innovative because the task, once modeled, can be transferred to new workpiece variants, other robot types and robots from other manufacturers. In addition, it is structured similar to a modular system:

The robot software contains versatile and reusable program modules that system integrators can put together individually when setting up a robot system and that can be used directly. Pitasc is in drag+bot integrated and can therefore be used easily.

Safety brake protects Robco robot kit

Safety brake protects Robco robot kit

For example, if a company wants to more automate assembly processes, it is crucial to identify the technically and economically appropriate processes. For this purpose, the IPA offers the Automation Potential Analysis, with which companies receive sound decision-making knowledge about all their assembly workplaces and production lines and suitable automation options. In this way "quick wins" can be systematically developed and, based on this, concepts can be created and implemented.

Now, for the first time, this analysis is done using an app that contains a database that allows you to compare a newly planned solution with an existing one. This significantly simplifies the planning process.

Camera-based sensor software lets robot grippers see

June 17.06.2018, XNUMX | Based on their research, it is the startup Rovi RobotVision For the first time in the world, we have succeeded in replacing expensive traditional electronic sensors with new software and common cameras. Because of the ability to directly control the motor, the inventors used it grab from Gimatic.

June 17.06.2018, XNUMX | Based on their research, it is the startup Rovi RobotVision For the first time in the world, we have succeeded in replacing expensive traditional electronic sensors with new software and common cameras. Because of the ability to directly control the motor, the inventors used it grab from Gimatic.

Frequently asked questions

Which programming language is used for robots?

Robots are coming along different programming languages controlled, depending on the model and application. C++ and Python are often used, especially in robotics research and development. ROS (Robot Operating System) also offers a collection of tools and libraries specifically designed for robotics. The choice of language often depends on the complexity and specification of the robot.

How do you program a robot?

Programming a robot requires specific software and often an associated programming language. First you define the desired movement sequences and functions. Using environments like ROS (Robot Operating System) or special manufacturer software, you can then instruct the robot step by step. Depending on the robot model, graphical interfaces or teach-in procedures can also be used to make the process intuitive.

Which programming language does Kuka use?

The in-house programming language is used for Kuka robots KRL (KUKA Robot Language) is used. KRL combines features of traditional programming languages with specific commands for robotics. It allows users to define precise movements, logic and conditions for the robot, allowing it to be optimized for a variety of industrial applications.

How does a robot work?

A robot works through the combination of Mechanics, electronics and software. Sensors collect information from the environment, which is processed by a microcontroller or computer. Programming languages give commands on how the robot should behave. Drive systems and actuators translate these commands into physical movements, enabling targeted actions.

Source: This article is based on information from the following companies: ABB, Artiminds, Fraunhofer, Kuka, Mitsubishi Electric, Rovi.

You might also be interested in...

Artificial Intelligence | trends and developments

Infrared camera optimizes Laser Powder Bed Fusion 3D printing

Mitsubishi Electric | Automating the World

Intelligent CNC control for machine tools

battery production | Facts and Technologies

3D printer | Additive manufacturing of plastic parts

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.