Mitsubishi Electric | Automating the World

- Details

- Hits: 29902

Mitsubishi Electric News: A girl in a red dress shows the way to the automation sustainable production. A new innovation and technology center in Ratingen is opened in the form of a competence center for Mechatronics CNC. The GB Factory Automation Systems receives one new slogan, which the Service for CNC controls and Robot bundles. You can find this and other reports in our new ticker below.

Contents

- Factory automation for a sustainable future

- Fabrik Automation gets new factory in India

- Innovation center for Mechatronics CNC opened

- Automation the World – new slogan Factory Automation

- Joint service for CNC controls and robots

- Geva – 30 years of Mitsubishi Electric in Austria

- Virtual factory tours through production sites

- Partnership with for battery large-scale production

- Manufacturing of lithium-ion batteries in Europe

- Archive for Mitsubishi Electric company news

- Who is Mitsubishi Electric?

Factory automation for a sustainable future

06.12.2023/XNUMX/XNUMX | Mitsubishi Electric wants to with its new global campaign highlight the importance of sustainable and future-oriented production methods. The aim is also to raise awareness among people who are not directly involved with factory automation, because many products in our daily lives are produced industrially.

06.12.2023/XNUMX/XNUMX | Mitsubishi Electric wants to with its new global campaign highlight the importance of sustainable and future-oriented production methods. The aim is also to raise awareness among people who are not directly involved with factory automation, because many products in our daily lives are produced industrially.

Three different motifs illustrate the importance of one sustainable productionin order to ensure a future worth living for future generations. The recurring motifs of the girl in the red dress and the robot arm emphasize that automation serves to support and help people achieve their goals. v

1. Customer focus

Under the motif Let's manufacture what matters to you The example of a rocket illustrates how the development, production and logistics of products should be tailored to individual needs in the future.

2. Digitization

The second motif Digitally multiplying the potential of manufacturing. focuses on the ways digital technologies will drive modern manufacturing in the future. Meaning “The digital maximization of manufacturing potential,” it explains how digital technologies and the use of data free manufacturing from previous limitations. Higher productivity and quality while reducing rejects should reduce waste and defects.

3. Sustainability

In the motif sustainable production it is about sustainable production that can contribute to a sustainable world. Efficiency not only makes economic sense, but also reduces the burden on the environment.

All three topics aim to make the topic of factory automation more tangible for society.

Fabrik Automation gets new factory in India

29.08.2023/21,8/XNUMX | Mitsubishi Electric Corporation has announced that it is investing around EUR XNUMX million in its subsidiary Mitsubishi Electric India Pvt. ltd will invest. A new production site in India is planned. It is expected to be commissioned in December 2023 and will include propulsion and Control Technology produce for factory automation.

29.08.2023/21,8/XNUMX | Mitsubishi Electric Corporation has announced that it is investing around EUR XNUMX million in its subsidiary Mitsubishi Electric India Pvt. ltd will invest. A new production site in India is planned. It is expected to be commissioned in December 2023 and will include propulsion and Control Technology produce for factory automation.

The demand on the Indian market is growing annually about 8%. With the new factory, the company will be able to react flexibly and locally to the increasing demand, especially in the Automotive industry, Food, beverage and pharmaceutical industries as well as data centers and the textile industry react. Forecasts continue to predict consistently strong market expansions in the future.

Active in India since the 90s

Mitsubishi Electric has been active in the Factory Automation (FA) sector in India since the mid-1990s. With the acquisition of an Indian FA component manufacturer in 2012, the automation company has further expanded its local business presence. This included developing a regional engineering team and expanding service and support capabilities. Local production started in .

The new construction of the planned production facility will cover an area of 15.400 m2 on a 40.000 m2 large area nearby Pune, Maharashtra, occupy and extend over two floors. This investment is in line with the "Make in India" initiative promoted by the Indian government.

It should be environmentally friendly and sustainable

Mitsubishi Electric attaches great importance to environmentally friendly and sustainable constructionin order to meet its goals for sustainability and environmental protection. Among other things, it is planned to use the CO2-Reduce emissions through the use of energy-efficient air conditioning systems and LED lamps. In addition, measures for waste water treatment and greening are planned, which are in line with the Sustainable Development Goals (SDGs).

Innovation center for Mechatronics CNC opened

03.07.2023 | Artificial intelligence and the digital transformation are two exemplary instruments that can provide valuable solutions to reduce production costs and increase automation, but are still in the starting blocks. In order to advance the development here, Mitsubishi Electric has a new European innovation and technology center in Ratingen (ITC) opened. This forward-looking initiative aims to advance technological progress on the basis of interdisciplinary and global cooperation.

Mitsubishi Electric has long been one of the big players in the ranks CNC manufacturer worldwide. As one of the major CNC manufacturers, the company sees itself primarily as a system partner that develops tailor-made customer solutions and supports customers right from the start. So far, these services have mostly been provided by the parent company in Japan and adapted worldwide. With the ITC, the automation specialist is building a new European competence center. It brings together experienced specialists from several European countries. The needs of European customers should be the focus of their work in order to develop innovative solutions for the European market.

Jan Gesthuysen, Project Manager Engineering CNC Europe, is confident that the ITC will be a catalyst for innovation. With his colleagues, he wants to create a platform that encourages creativity, collaboration and a quick response to customer needs.

Automation the World – new slogan Factory Automation

09.12.2022 | Mitsubishi Electric Corporation introduces a new global slogan for its Factory Systems division. With Automating the World aims to reflect the company's contribution to a better world through automation. It expresses the automation company's goal of leveraging automation to improve global society with the combination of advanced technology, know-how and experience, and supporting customers as trusted partners.

09.12.2022 | Mitsubishi Electric Corporation introduces a new global slogan for its Factory Systems division. With Automating the World aims to reflect the company's contribution to a better world through automation. It expresses the automation company's goal of leveraging automation to improve global society with the combination of advanced technology, know-how and experience, and supporting customers as trusted partners.

Automating the World was formulated on the basis of many different stakeholders of the global player from all over the world. This includes industrial automation customers and employees who identify with Factory Automation Systems. For China, the global slogan is added zizai linghuo follow. That means "free and flexible". It is intended to support the local understanding of the global slogan.

Joint service for CNC controls and robots

25.11.2022 | Mitsubishi Electric Germany expands the European service center in Ratingen with the integration of the robot service into the CNC service organization. Customer proximity and high service quality are two pillars of the business strategy CNC area. That is why the company created a service organization early on that is probably exceptional in the industry.

25.11.2022 | Mitsubishi Electric Germany expands the European service center in Ratingen with the integration of the robot service into the CNC service organization. Customer proximity and high service quality are two pillars of the business strategy CNC area. That is why the company created a service organization early on that is probably exceptional in the industry.

Also for areas such as controls, Drives and the peripherals, which have been on the market for over 30 years, the manufacturer offers spare parts and service. For this purpose, a modern one was built in Ratingen 3D printer installed, with which new covers and housings can be made. This extends the life cycle of these products.

Repair in terms of sustainability

For service and sales, the responsiveness in focus to ensure high availability of the machines. The supply of spare parts for products for Europe is coordinated in a large warehouse. Qualified service technicians immediately replace defective drives or control components with a functioning spare part and send the defective part back to the service workshop for error analysis and repair.

For service and sales, the responsiveness in focus to ensure high availability of the machines. The supply of spare parts for products for Europe is coordinated in a large warehouse. Qualified service technicians immediately replace defective drives or control components with a functioning spare part and send the defective part back to the service workshop for error analysis and repair.

In the sense of the Sustainability and resource conservation Mitsubishi Electric has been repairing defective returns since the 90s and putting them through their paces. The overhauled parts are then returned to the cycle with a two-year guarantee. This strategy offers an effective tool against global delivery bottlenecks and ensures the production capability of customers.

In the course of the 2017 started digitization project the two divisions Factory Automation and Mechatronics CNC have moved ever closer together in Europe. As a logical consequence, the manufacturer has now included the service for Mitsubishi Electric robots in the service organization CNC controls integrated.

Geva – 30 years of Mitsubishi Electric in Austria

18.11.2022 | For 30 years the Geva Elektronik- und Handelsgesellschaft GmbH the partner for Mitsubishi Electric automation technology in Austria. The traditional company has been family-owned since 1984, initially managed by the founders and namesakes Gerhard Schich and Eva Löffler. Since 2009, Martin Schich has been successfully leading the company in the next generation.

18.11.2022 | For 30 years the Geva Elektronik- und Handelsgesellschaft GmbH the partner for Mitsubishi Electric automation technology in Austria. The traditional company has been family-owned since 1984, initially managed by the founders and namesakes Gerhard Schich and Eva Löffler. Since 2009, Martin Schich has been successfully leading the company in the next generation.

Mitsubishi Electric won for the year 1992 Geva as a reliable partner for automation and the corresponding services. Both pursue the common goal of offering modern and future-oriented technologies and solutions from the world's leading automation company for Austria. They also want to identify and implement innovations for tomorrow's needs. To date, this has been successful across the entire range of automation options.

"Market and customer orientation not only serve the business relationship and partnership, they are the foundation of a friendship for an unlimited period of time," says Geva Managing Director Martin Schich. "To keep you is a high priority for us". Division Manager Stefan Knauf, Mitsubishi Electric is pleased about: "Such a long and successful cooperation cannot be taken for granted and we are very proud and grateful for it."

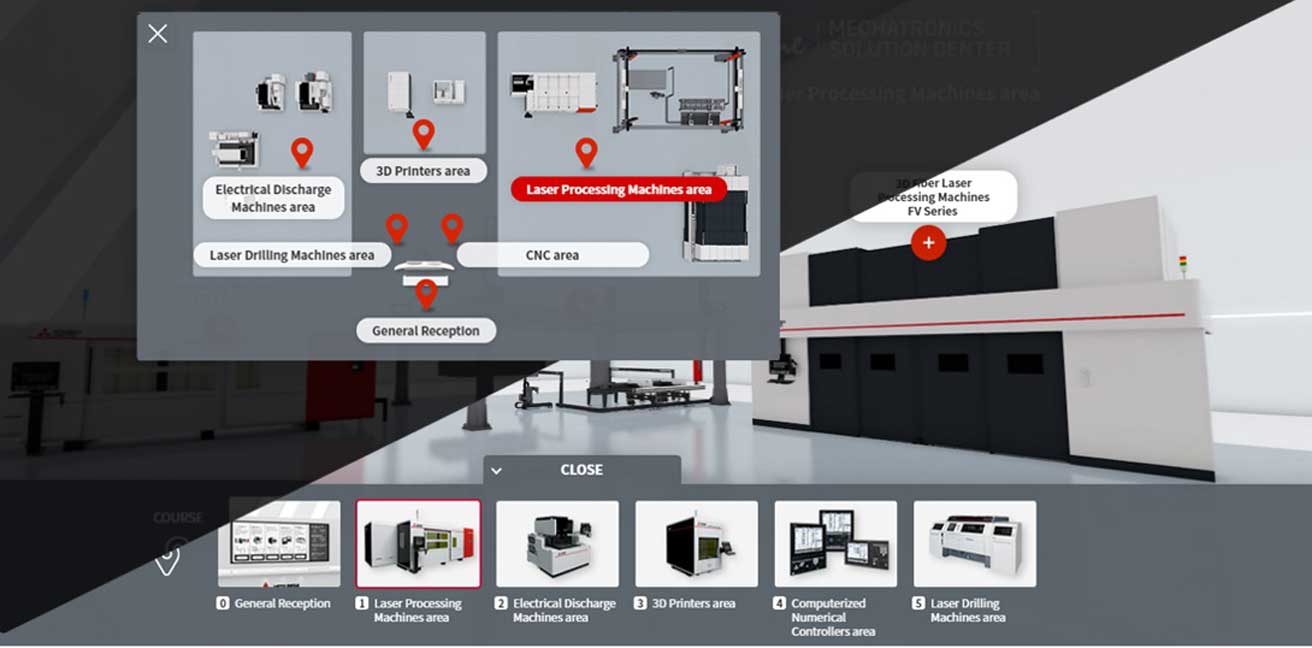

Virtual factory tours through production sites

24.08.2022/XNUMX/XNUMX | Not everyone can take a guided tour of the site Manufacturing plants of Mitsubishi Electric participate, Japan is too far away for that. That's why the automation company now offers virtual tours through Nagoya and Fukuyama. Interested parties can take a look at parts of these factories and showrooms. They also receive information about the current production methods.

Industry 4.0 and digital transformation are popular terms today. On their journey to digital manufacturing, it is important for companies to be up front about Best practices and applications for your own production.

Reading tip: Ctrlx automation platform

Reading tip: Ctrlx automation platform

Before the Covid 19 pandemic, thousands of people from all over the world visited Mitsubishi Electric's manufacturing sites in Fukuyama and Nagoya, Japan. Her focus was on learning how Mitsubishi uses its digital manufacturing and that eF@ctory concept to manufacture its own products. With the Virtual Factory Tour you can now find out about new technologies and production methods around the clock. The following onlinefactory tours are available on the website:

Nagoya: Production of programmable logic controllers

The first video tour shows how the products for factory automation in the Nagoya plant getting produced. The visitor also gets insights into work processes, manufacturing technologies and the production of programmable logic controllers (PLC).

Fukuyama: Production of power monitoring and distribution components

The second video tour presents the production lines in the Fukuyama Works before. They use the integrated FA IT solution "eF@ctory" to implement digital production. The tour of the Fukuyama plant takes you through the production of circuit breakers and circuit boards and the office building. On top of that, there is a presentation of how processes have been improved with artificial intelligence (AI) and other cutting-edge technologies in digital manufacturing.

Online Mechatronics Solution Center

The Mechatronics Solution Center informs visitors about processing machines, Computerized Numerical Controllers (CNCs) and other machine tools.

Partnership with Novali for large-scale battery production

18.07.2022 | Mitsubishi Electric Europe and the Belgian start-up Novali have joined forces to advance large-scale production of battery cells in Europe. "This strategic partnership aims to reduce Europe's dependence on external battery sources and strengthen manufacturing capabilities within the EU trading bloc.

18.07.2022 | Mitsubishi Electric Europe and the Belgian start-up Novali have joined forces to advance large-scale production of battery cells in Europe. "This strategic partnership aims to reduce Europe's dependence on external battery sources and strengthen manufacturing capabilities within the EU trading bloc.

Manufacturing of lithium-ion batteries in Europe

12.05.2022/XNUMX/XNUMX | The manufacturing of lithium-ion batteries in Europe was hardly worth mentioning until now, but a turnaround is now needed. Michael Grondowski, Business Development Manager – Central Europe at Mitsubishi Electric Europe BV: “Production plants have been announced for a total annual output of approx 750GWh."

12.05.2022/XNUMX/XNUMX | The manufacturing of lithium-ion batteries in Europe was hardly worth mentioning until now, but a turnaround is now needed. Michael Grondowski, Business Development Manager – Central Europe at Mitsubishi Electric Europe BV: “Production plants have been announced for a total annual output of approx 750GWh."

Mitsubishi Electric is a globally recognized market leader in the manufacture, marketing and sales of electrical and electronic devices for industrial technology, energy, information processing and communication, space development and satellite communication, entertainment electronics, mobility and building technology as well as technology for heating, cooling and air conditioning devices. The automation company will celebrate its 2021th anniversary in 100. With around 146.500 employees, the company achieved consolidated sales of 31.03.2020 billion US dollars * at the end of the fiscal year on March 40,9, 30. Mitsubishi Electric has manufacturing facilities, sales offices, research companies and development centers in 1978 countries. Mitsubishi Electric has been a subsidiary of Ratingen, Germany, since XNUMX Mitsubishi Electric Europe represent. Mitsubishi Electric Europe is a wholly owned subsidiary of Mitsubishi Electric Corporation of Tokyo. E-mail address: mitsubishi-automation@meg.mee.com, Website: https://de.mitsubishielectric.com/fa/

You might also be interested in...

Artificial Intelligence | trends and developments

Predictive maintenance for robotics, machines and systems

Cobot | Discover collaborative robots as a new employee

Intelligent CNC control for machine tools

battery production | Facts and Technologies

Programming Robots | software and controls

Silvia von Dahlen is

Marketing Communications Officer at Mitsubishi Electric Europe BV in Ratingen.