Programming robots with just low-code software

- Details

- Hits: 976

Artiminds Robotics supports this Roboticindustry with innovative software solutionswho program, operate and integrate the robot industrial robots simplify. The pioneer for sensor-based robot applications supports the implementation of advanced projects such as force control and image processing and offers comprehensive advice - from planning to optimization. Read what's new at Artiminds:

Contents

Artiminds Robotics – partner know-how

Germany is one of the top automated economies in the world. This is proven by current figures International Federation of Robotics (IFR) and also that robot density has reached a new record level. A shortage of skilled workers, reshoring and cost pressure are increasing the pressure in the industry to automate.

Germany is one of the top automated economies in the world. This is proven by current figures International Federation of Robotics (IFR) and also that robot density has reached a new record level. A shortage of skilled workers, reshoring and cost pressure are increasing the pressure in the industry to automate.

Companies that have been using robots in their production for a long time are also going one step further and automating more sophisticated, novel process steps in their production. SMBs are also increasingly deciding to move into robot-based automation so that they can reduce costs, relieve employees, increase quality and remain flexible even with small batch sizes.

It's good if you have one Partner at your side who not only offers a comprehensive range of software solutions for robot automation, but also expertise in the form of consulting, services and engineering from initial planning through implementation to ongoing support and optimization of robot applications.

Artiminds is such a partner. In this article we will introduce you to the latest developments from the Karlsruhe specialist and you will receive invaluable tips from him:

Programming robots for cable handling

March 18.03.2024, XNUMX | Artiminds Robotics is an exhibitor in the Application Park Hannover Messe 2024 an innovative cable handling application for precise Cable harness assembly before. The sensor-based robot automation demonstrates the robust detection, picking and joining of freely hanging, slack parts such as lines and cables.

March 18.03.2024, XNUMX | Artiminds Robotics is an exhibitor in the Application Park Hannover Messe 2024 an innovative cable handling application for precise Cable harness assembly before. The sensor-based robot automation demonstrates the robust detection, picking and joining of freely hanging, slack parts such as lines and cables.

The self-developed solution approach for this complex 2,5D application is based on a unique combination of laser line scanners, 2D camera technology and force-torque measurement. There are also newly developed interfaces and intelligent function modules in the Robot Programming Suite (RPS) from Artiminds.

The software processes Real time the scan result and synchronizes it with the robot movement to determine the exact pickup point. It then carries out a force-controlled joining operation, which allows the cable ends to be inserted safely and precisely into the connector housing.

The demonstration illustrates the versatile application possibilities of the manufacturer-independent programming software Artimind's RPS. It can be used to program simple, highly adaptive and sophisticated robots. Since the robot programming software generates native robot code, the programs can be executed directly on the standard controller of the industrial robot used without additional hardware.

"The application presented is an impressive example of the versatility of our software products and how we can use them to automate complex production processes using robots and enable new areas of application for robots," commented Dr.-Ing. Sven Schmidt-Rohr, Managing Director of Artiminds Robotics.

Smart robot software for processes with tolerances

29.02.2024/XNUMX/XNUMX | If you try the traditional approach, processes subject to tolerance This is often a big challenge to automate. With the smart robot software, reliable solutions can be created very easily. Various implemented examples illustrate the wide range of applications.

29.02.2024/XNUMX/XNUMX | If you try the traditional approach, processes subject to tolerance This is often a big challenge to automate. With the smart robot software, reliable solutions can be created very easily. Various implemented examples illustrate the wide range of applications.

5 most underestimated stumbling blocks in robot automation

13.02.2024/XNUMX/XNUMX | More and more companies are dealing with the topic Robot automation. However, many projects still fail during planning due to a lack of know-how, the feared high costs and the complexity of robotics projects that often cannot be calculated in advance.

13.02.2024/XNUMX/XNUMX | More and more companies are dealing with the topic Robot automation. However, many projects still fail during planning due to a lack of know-how, the feared high costs and the complexity of robotics projects that often cannot be calculated in advance.

The Robotics newbies The deployment often fails due to a lack of know-how and project experience. But even companies that have already automated processes with the help of robots and built up expertise reach their limits if they do not plan sufficiently in advance. Because no matter whether Industrial robots or Cobot: In every robotics project there are numerous aspects that must be considered, evaluated and thought through strategically in order not to fall into the time and cost trap and to implement the application in a practical manner. Structured and forward-looking planning is the key to success.

The free robotics white papers “This is how automation works” by Artiminds analyzes the five most underestimated stumbling blocks when using robots and shows which aspects users should pay attention to in order to avoid possible pitfalls. In addition, different areas of application and robot-based solution approaches are presented. In addition, the white paper provides interactive checklists that help with strategic planning and implementation of robot integration and selection of suitable hardware and software tools.

White paper free Download here: https://www.artiminds.com/de/robotik-whitepaper-stolpersteine/

Partner for sensor-adaptive robotics

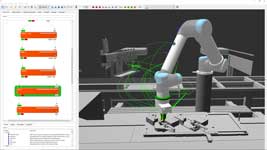

22.06.2023/XNUMX/XNUMX | The Artiminds Robotics range advanced robotics is presenting applications programmed with its in-house software solutions at Automatica 2023. The Robot Programming Suite (RPS) and Artiminds Learning & Analytics for Robots (LAR) tools simplify the programming of sensor-based robot applications thanks to the low-code approach. This makes it possible to automate tasks in production that were previously only solved manually.

22.06.2023/XNUMX/XNUMX | The Artiminds Robotics range advanced robotics is presenting applications programmed with its in-house software solutions at Automatica 2023. The Robot Programming Suite (RPS) and Artiminds Learning & Analytics for Robots (LAR) tools simplify the programming of sensor-based robot applications thanks to the low-code approach. This makes it possible to automate tasks in production that were previously only solved manually.

The sensor-based applications shown at Automatica come from the areas of cable handling, surface processing and mechanical assembly. Artiminds acts as a holistic partner for sensor-adaptive robotics in the Industry 4.0 environment.

Thanks to intelligent algorithms, new features can be used to reduce power and image-regulated processes per Drag-and-drop program easily and robustly from predefined function blocks. Various applications with robots from Kuka, Fanuc and Universal Robots demonstrate the range of possible applications.

Cable handling with Kuka robots

Presented as a highlight Cables-Handling procedure with a Kuka Robots for the robust detection, gripping and joining of freely hanging, limp parts. The software solution developed by Artiminds for this complex 2,5D application combines 2D laser scanners, force control and specially developed interfaces as well as intelligent function blocks in Artiminds RPS. First, the scan result is calculated with the robot movement in order to find the correct pick-up point. A force-controlled joining operation follows.

End of line testing with Fanuc robot

A pair of fanuc-Robot shows live teach point optimization in end-of-line testing. Here, the robot inserts a force-controlled test cable Electronicscomponents and solves this again. The components move forwards and backwards on workpiece carriers via a linear axis. The robot automatically compensates for the different tolerances of the workpiece carriers by compensating for the drift in the approach position and cycle time.

Programming complex contours with UR

A cobot from Universal robots (UR) demonstrates how to create toolpaths for parts such as shell molds with complex contours. With the CAD2 Path feature CAD-Models loaded into the software. Paths are generated from this, which are then followed under force control.

As a central data hotspot, the LAR demo aggregates all real-time sensor data from the three applications. The tolerances and forces occurring in the process are automatically analyzed and evaluated. Together with information such as runtime, cycle times or error messages, dashboards clearly visualize the results.

Quick start-up via drag-and-drop

The new user interface scores particularly well with its User Experience (UX). An intuitive editor on the PC with a standard user interface ensures high efficiency and offers the option of creating configuration files quickly and easily using drag-and-drop. An intervention in the KRL is not necessary due to the user experience design. The commands are then transferred as option packages to the Kuka Smartpad hand-held control unit for the controller. This avoids copying errors at the user interfaces. The robot is quickly ready for use.

Safety brake protects Robco robot kit

Safety brake protects Robco robot kit

The preconfigured Inline forms make the computer editor safer for humans to use. Input errors are displayed directly on the graphical user interface and are not only discovered when testing the robot controller. The Kuka.Usertech interface can be combined with all of the manufacturer's technology packages.

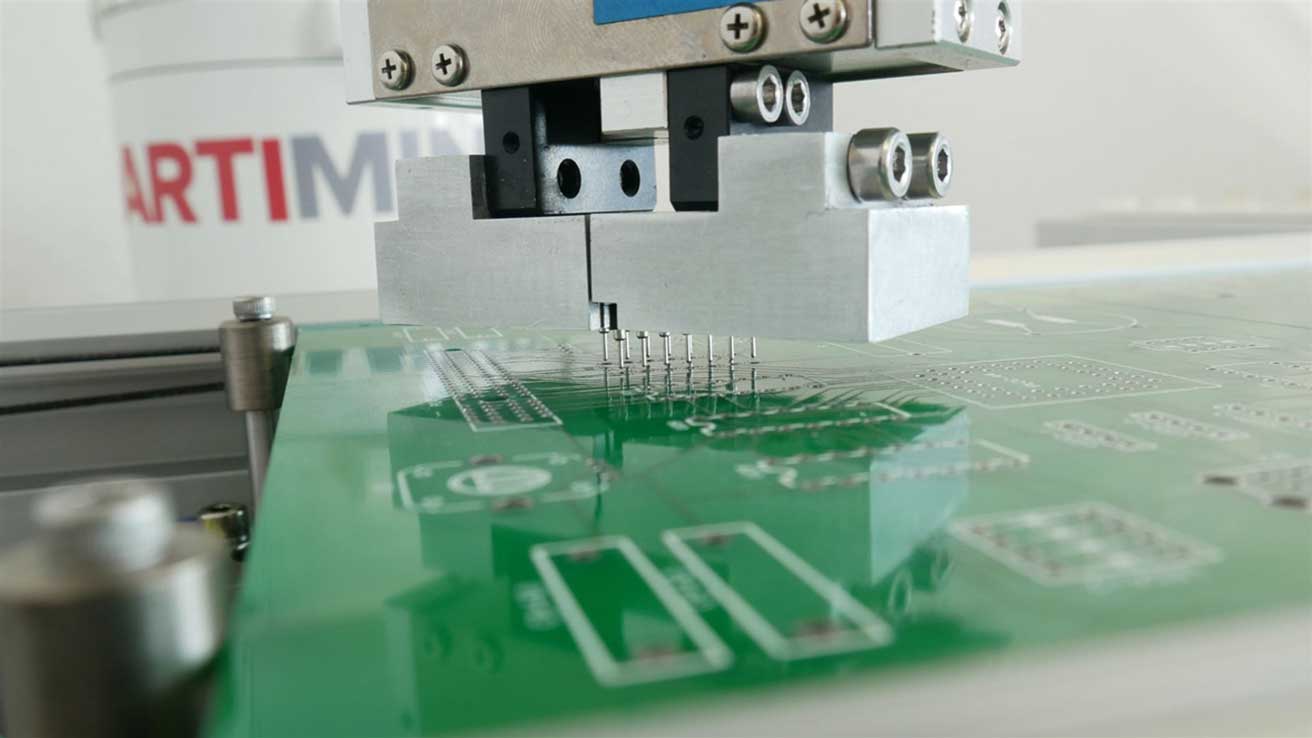

Robot programming for automated THT assembly

30.09.2020/XNUMX/XNUMX | The Robot Programming Suite RPS from Artimind's Robotics enables the automation of the THT assembly. The robot programming software teaches an industrial robot force-controlled processes such as scanning surfaces or controlled joining - all using drag and drop.

The great challenge of THT assembly lies in particular in the indulgence from Metal and Plastic. Also the tolerances of the component housings and the many variants electronic components increase the difficulty. That is why this filigree, precise work is mostly still carried out manually today. It is associated with a lot of effort.

Teaching robots via drag and drop

With the software Robot Programming Suite RPS Artiminds Robotics can automate the THT assembly with robots. The user can easily program and configure his robot application via a graphical user interface using drag and drop. A library with over 50 templates is available for programming.

The templates depict various functions and movements. Depending on the nature of the electronic component, the user selects the plugging process from two search templates. The Spiral search places the elements via a force-controlled circular movement and can also localize deviating holes.

Research project for AI based robot calibration

Research project for AI based robot calibration

Within the Spike search holes are identified by picking. Sensitive parts such as pens do not bend. The parameters are set using intuitive wizards. These query all relevant data during programming. Short instructions by video also support the user.

Combination of online and offline mode

The great advantage of the RPS lies in the combination of Online programming and offline Programming. The robot can also be taught-in offline during operation and the program can be visualized in the simulation. The automatically generated code is then entered directly into the steering transfer. The user can make changes offline in the RPS or online directly on the robot and play them back into the software. This saves time and effort in commissioning and process optimization of the robots and reduces maintenance.

Surface finishing process with RPS programmed robot

In applications at Visomax the experts use the software for robot programming. The facilities for Surface finishing have to identify faults on various components, approach them under force control and then polish them out.

Artiminds webinars to get you started with robot automation

11.05.2020/20/2020 | Artiminds will start the webinar series on May XNUMX, XNUMX Automate with robots. This is intended to show companies how a lean entry into robotics can be achieved and what requirements those responsible have to master when integrating robots. Artiminds Robotics is a software company specializing in simple and intuitive programming and the consistent use of robots. The webinar series includes nine dates and two main topics.

11.05.2020/20/2020 | Artiminds will start the webinar series on May XNUMX, XNUMX Automate with robots. This is intended to show companies how a lean entry into robotics can be achieved and what requirements those responsible have to master when integrating robots. Artiminds Robotics is a software company specializing in simple and intuitive programming and the consistent use of robots. The webinar series includes nine dates and two main topics.

Webinar on the use of robots

The webinar 5 Reviews for the fast, flexible and future-proof use of robots shows how robots can be integrated quickly and sustainably against the following background: Robots enable companies of all sizes to automate flexibly and cost-effectively. However, their technological complexity, the high costs of hardware technology and the training effort for employees often prevent companies from getting started with robotics.

Webinar on robot programming

In the webinar, simple and manufacturer-independent robot programming – this is how you get started In robotics, participants will learn specifically how to configure applications flexibly and easily using the Artiminds Robot Programming Suite software, sensors- Robustly integrate components and combine online and offline programming.

Ctrlx Automation | Third party hardware

Ctrlx Automation | Third party hardware

Moritz Rothe, webinar speaker and business development manager at Artiminds explains: “The number of industrial robots installed worldwide is increasing rapidly. Flexibility, high precision and digital manufacturing environments are drivers of this development. At the same time, the range of robots on offer is becoming more and more diverse and complex, while there is a lack of specialized robotics experts. The webinar shows how software can help here.”

Learn more about the robotics webinars

Participation in the webinars is free of charge. A webinar lasts 60 minutes and is also offered in English. These are the dates:

Webinar 5 tips for using robots

- May 20, 11:00 a.m. and 14:00 p.m.

- May 27, 11:00 a.m. and 14:00 p.m.

- May 29, 10:00 a.m.

Webinar robot programming

- May 20, 12:30 a.m.

- May 26, 11:00 a.m. and 14:00 p.m.

- May 29, 12:00 p.m.

FAQ

What language are robots programmed in?

Robots are programmed in a variety of programming languages, depending on their complexity, application area and specific robot control. The choice of language depends on the requirements of the respective project and the existing infrastructure. Some of the most common languages include:

- Robotics-specific languages: Many robot manufacturers develop their own programming languages tailored to their systems. Examples of this are Kuka KRL and ABB Rapid.

- Standard languages: Established high-level languages such as Python, C++, and Java are often used for more complex tasks or for integration into existing IT systems. Python has proven particularly useful in academic research and in the development of prototypes thanks to its simplicity and the extensive availability of libraries.

- Block-based and graphical programming languages: For training purposes or entry into robotics, intuitive, graphical programming environments such as Blockly, Scratch or specialized software such as Lego Mindstorms are often used. These make it possible to control robots even without extensive programming knowledge.

- Specialized code for machine learning and KI: Applications that require artificial intelligence or machine learning use specialized frameworks and libraries, often written in Python or C++, such as Tensorflow or Pytorch.

How is teach-in programming done?

The Teach-in programming is an intuitive and user-friendly method for programming industrial robots and other automated systems. It allows a robot to be taught specific movements or tasks through manual guidance or direct entry of positions, rather than writing complex lines of code.