With Kuka from the Harting connector to robot connectivity

- Details

- Hits: 11981

The so-called Harting Plug is a veteran of connection technology. Every electrician associates quality and reliability with it. If you add competence and trust, you get a guarantee for a good partnership. With a willingness to innovate and know-how, companies today master the challenges of the present and the future together. The technology group and Kuka have been doing this for decades. On occasion 75 years Harting this is a good reason to review what we have achieved together.

Contents

- Electrical connection technology for power signal data

- Connectors for automation communication systems

- Abdullah Cevik, Chief Compliance Officer at Kuka

- Alexander Rottmair, team leader for electrical construction at Kuka

- Three quarters of a century of family history

Our world today is through Digitalization and is increasingly relying on cooperation and partnerships. It takes specialists for the most varied of competencies in order to find suitable holistic solutions. The multitude of platforms and exchange formats for IoT or IIoT systems alone testifies to this.

Programming Robots | software and controls

Programming Robots | software and controls

The understanding of the bundling of competencies and requirements shaped the cooperation between Kuka and Harting very early on. Harting-Kuka cooperation examples show the way from the jointly developed specific solution to the standard:

Electrical connection technology for power signal data

Since Wilhelm Harting founded Wilhelm Harting Mechanic Werkstätten 75 years ago, it has developed into a global technology group. Today the company is celebrating its 75th anniversary. The technology group is one of the world's leading suppliers of industrial connection technology for the three Lifelines Power, signal and data. Checkout zones for retail, electromagnetic actuators for series use in automotive and Harting industry, charging equipment for electric vehicles as well as hardware and software for automation, mechanical and plant engineering, Robotic and Transportation also manufactures the technology group.

Harting's recipe for success

Harting has always adapted to the respective market requirements and reinvented itself over and over again over the decades. The originally established division for the development of Music and cigarette machines in the 1950s, for example, developed into today's business area for food retailing with whole installation Shop and cash register systems.

Measuring torque with sensors inside the transmission

Measuring torque with sensors inside the transmission

The further development of the Actuators plays a role: Magnets developed by Harting were originally used in textile machines, but later they also found their way into cars. With the advent of electromobility, the technology group bundled its connectivity and automotive fields of expertise in order to develop infrastructure solutions for the e-mobility industry.

High innovative strength, uncompromising quality, pronounced customer orientation, international orientation and social responsibility were decisive for the company's success story. As the driver and engine of Harting Industry 4.0, the jubilee is helping to shape the world of tomorrow.

Kuka's success story

The international Kuka group offers intelligent automation solutions from a single source worldwide: from Robot through the production cell to the fully automated production system and its networking. Kuka is present with its solutions especially in markets such as electronics, automotive, general industry, consumer goods, e-commerce / retail and medical technology.

The international Kuka group offers intelligent automation solutions from a single source worldwide: from Robot through the production cell to the fully automated production system and its networking. Kuka is present with its solutions especially in markets such as electronics, automotive, general industry, consumer goods, e-commerce / retail and medical technology.

The mechanical engineering specialist is firmly rooted in its home location in Augsburg. The company's success story began here in 1898 when Johann Josef Keller and Jakob Knappich joined Acetylene plant for lighting founded. The telegram abbreviation from the first letters of the company name Kor und Ksnap me AOver the years, ugsburg has become the brand name Kuka. Tradition meets innovation here.

More than two decades of partnership

Since the beginning of the cooperation more than 20 years ago Harting and Kuka have always created new solutions for plugs with cables, housings, etc., in short connection technology, with a view to the requirements of the market. An example of this is the ever-increasing EMC requirements, which led to special EMC housings for Harting connectors and have now become the standard.

Also in the area Robotic The aim is to reduce the number of parts in order to keep complexity low and to minimize production steps. Here the partners looked at the processes together. With the so-called multifunctional housing, they have created a specific component that optimally combines the plug function with the IP67 sealed electronics housing.

Also in the area Robotic The aim is to reduce the number of parts in order to keep complexity low and to minimize production steps. Here the partners looked at the processes together. With the so-called multifunctional housing, they have created a specific component that optimally combines the plug function with the IP67 sealed electronics housing.

Harting now offers such system solutions for various applications such as data cabling for the controller, the cable system to the robot or solutions that take mechanical requirements into account. Specific transition elements for a Profinet infrastructure on the third axis are exemplary.

Also the trend towards miniaturization has kept both partners busy in recent years. With the KR Agilus robot you have a new one Small robotics established, which is used optimally in increasingly flexible manufacturing environments. The requirement for the connector was to find a fast and intuitive handling, in which the design also plays an important role. The Han Yellock The connector system with its completely new locking technology was exactly the right product for this new robot series.

Connectors for automation communication systems

The intensification of the cooperation was ultimately evident in the expansion of the technologies and solutions to all of the "lifelines" of an application: In addition to normal connectivity such as industrial connectors on the robot base or data interfaces at the transfer points, upward integrations such as system solutions and products such as switches were used.

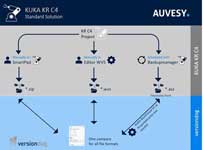

Integration of Kuka projects in data management

Integration of Kuka projects in data management

The requirement was flexibility and adaptability to the communication technology used by the customer in automation. The Switches of the Harting Technology Group became the central communication element because they can process various automation systems very openly. With this consistency of the power-data-signal infrastructure on the Kuka robot, Espelkamper was able to offer a holistic approach to these three infrastructure elements - namely customer-oriented, application-neutral and flexible.

Industry 4.0 and small robots

Kuka and Harting developed Industry 4.0 solutions together very early on. This is how Kuka equipped the I4.0 demonstrator Haii4you Factory of its partner with new sensory robots of the type LBR Iiwa. The system became the ideal stage for a holistic approach for individual and cooperative production systems from a quantity of 1.

Kuka and Harting developed Industry 4.0 solutions together very early on. This is how Kuka equipped the I4.0 demonstrator Haii4you Factory of its partner with new sensory robots of the type LBR Iiwa. The system became the ideal stage for a holistic approach for individual and cooperative production systems from a quantity of 1.

Three major trends in Harting connectors are flexibility, miniaturization and modularity. They are driving the joint developments today. In the mid-2000s, the robot control cabinet was still as big as a switch cabinet, current solutions are only as big as a desktop PC.

Applications for small robots in particular require resource-adapted solutions. In addition to the small robot, the controller will also have to be compact in the future because there is hardly any space for it. As a result, Kuka has the KR C5 micro brought on the market. It is tailored precisely to these applications.

Connectivity must also adapt to this development. Harting is contributing to this new control Har motion connectors, a solution specially designed for use in small robotics. Adapted to the power requirement and space, the Harting connector can be used flexibly for the transfer of the robot's lifelines.

Miniaturization even with large robots

But the larger robots are also subject to the trend towards miniaturization. This is particularly evident in the new one Control system KR C5. With it, up to three machines can be operated on one control cabinet in the same installation space as a previous controller.

But the larger robots are also subject to the trend towards miniaturization. This is particularly evident in the new one Control system KR C5. With it, up to three machines can be operated on one control cabinet in the same installation space as a previous controller.

The performance can also be easily and flexibly adjusted by selecting different controllers. This is made possible by a completely new, modular and scalable structure of the cabinet system. The developed for this Docking solution allows easy adaptation to customer requirements:

The control systems slide into the cabinet like drawers. In order to enable the transfer of the lifelines for a flexible coupling, a special docking connector has been developed in close cooperation.

The degree of protection applicable in the cabinet and the reduced space available with the new Hanboard Connectors taken into account. It allows a machine connection necessary for this case. Special mechanical guides and the constructive structure of the connector ensure the necessary tolerance compensation.

Robot drives for the rapidly growing market

Robot drives for the rapidly growing market

Long-term partnerships with a common view of holistic customer benefits create derivations of new technologies and products from mega trends. The connectivity and infrastructure incorporated into the KR C5 demonstrate this in particular.

Abdullah Cevik, Chief Compliance Officer at Kuka

Abdullah Cevik has been with Kuka for 31 years. After holding various positions at the robot and automation specialist in Augsburg, he was appointed purchasing manager in 2011. In this role he is the first point of contact for the Harting Technology Group.

However, he had his first encounter with Harting in the 1980s - long before he started his career at Kuka. “I was around 20 years old and at the time I was still employed in control cabinet construction,” recalls Mr. Cevik. “Back then always came with us the Harting connector for use. It was practically the epitome of a plug. "

For Abdullah Cevik, the name has since stood for the product industrial connectors. Many years later, Cevik had the opportunity to get to know the name bearers behind the product personally.

“As purchasing manager, I was at the Harting booth Hannover Messe as a guest to find out about the latest trends in the technology group. Here I got to know the managing director Philip and Dietmar Harting know. From then on I could not only associate the name with the product itself, but also the founding family. That was a great experience for me. "

The connection between the two companies has always been based on partnership with mutual respect, honesty and trust. This thought extends from an operational level to the management level. “We don't see Harting as a supplier, but as a Partner on a global level, with which we have promoted joint developments openly and fairly and will continue to do so in the future, "emphasizes Abdullah Cevik.

Alexander Rottmair, team leader for electrical construction at Kuka

In his now 22 years in which Alexander Rottmair Kuka is at home with his job, and he had contacts with the Harting name early on: "Back then, during our training, we were still assembling and installing the various Harting plugs on the robot ourselves," recalls the team leader for electrical construction in the Kuka development department.

Scara robots for beginners in digital transformation

Scara robots for beginners in digital transformation

Even then, he appreciated the product properties of Harting connectors such as the Han modular, because these have always been “very high-quality, robust and well thought-out products”. In particular, the system logic behind the portfolio continues to impress him: "The Harting connectors are based on a type modularso that they can be expanded. "

The resulting added value brings significant advantages for Kuka itself and its customers. The developers and designers need fewer processing tools because, for example Crimp contacts are identical in many product groups and can be processed with the same tools. In addition, this offers the user an advantage at the interfaces that he still has to work on himself: he benefits from little change, the same approaches and identical handling.

Three quarters of a century of family history

Harting exhibits at the FMB Bad Salzuflen, Hall 20, Stand C21.

You might also be interested in...

industrial housing | Indoor and outdoor control boxes

Electrical Wires | From cable to assembly

RFID and Barcodes | Industrial identification

Ethernet switches | The data driver in the network

Reduce carbon footprint | That's how it's done!

Charging plug, charging cable | For the electric car

Guido Selhorst is Head of Corporate Market Communication at

Harting Technology Group, Espelkamp.