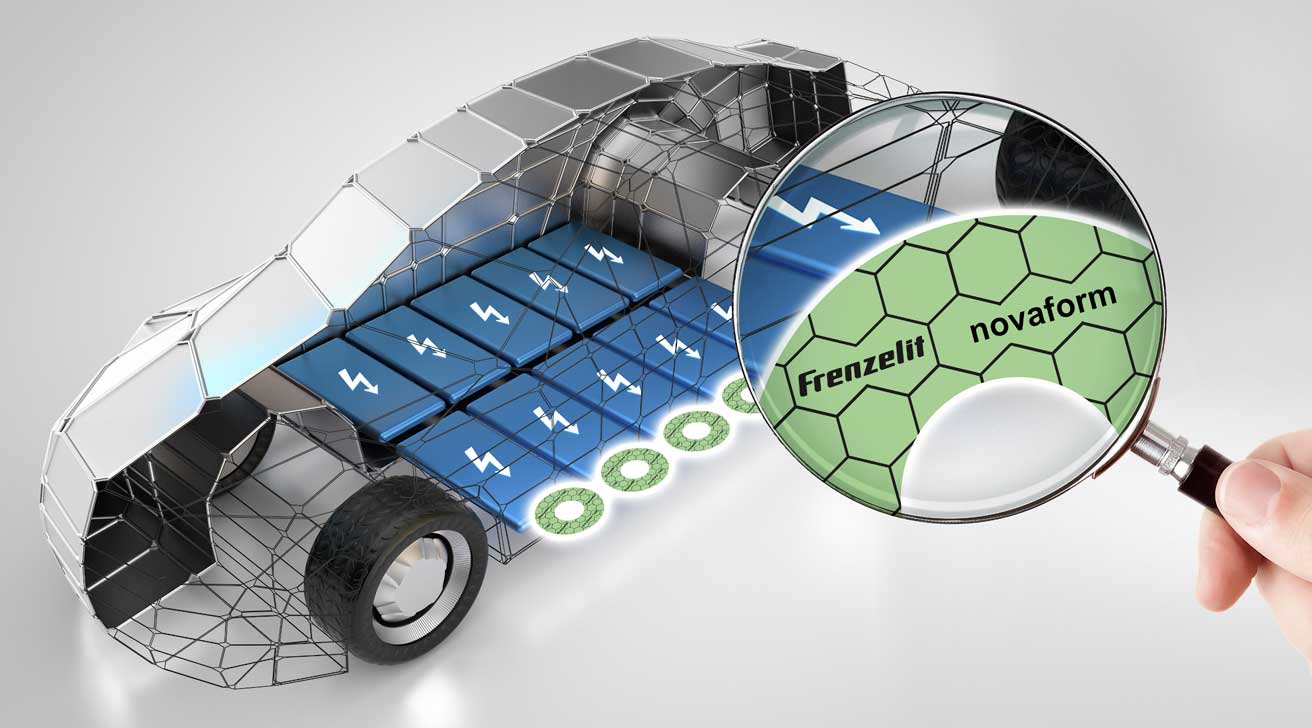

Molded release film prevents galvanic corrosion in the car

- Details

- Hits: 7489

Frenzelite offers a molded part from the fiber gasket nova formwhich galvanic corrosion avoids. It galvanically decouples surfaces from metals in vehicles. This makes the molded part a cost-effective and effective alternative to common corrosion protection such as painting.

Contents

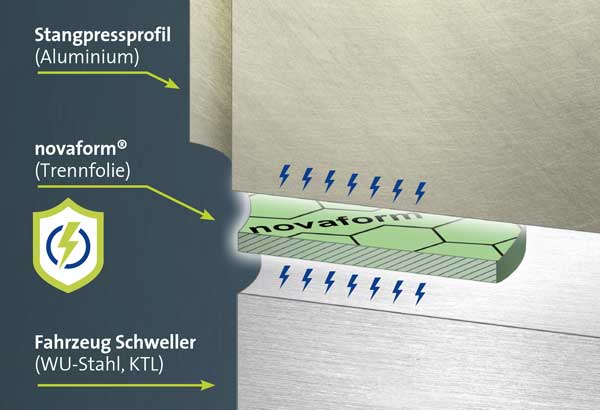

The molding is a release film, which decouples two metal surfaces from each other. Different alloyed metals always seek equipotential bonding when in contact with one another. In the process, electrons from the lower alloyed metal are transferred to the higher alloyed metal. As a result, the lower alloyed metal corrodes.

Galvanic corrosion in electric vehicles

Galvanic corrosion also plays a role in Electric car a role. In particular, they require a reliable galvanic protection against galvanic corrosion when separating the rocker panel and the battery housing block. External influences such as water as spray in rainy weather or salt from the grit in winter may accelerate contact corrosion.

NBR bonded fiber gasket

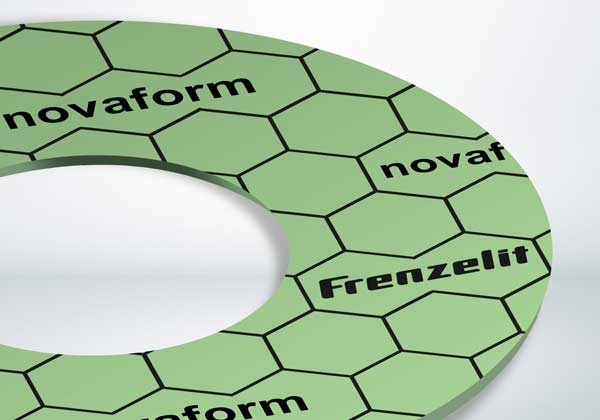

For a Customer project Frenzelit has developed rings from Novaform. Novaform consists of nitrile butadiene rubber and belongs to the family of NBR bonded fiber gaskets. The material offers a low compression with a high volume resistance.

For a Customer project Frenzelit has developed rings from Novaform. Novaform consists of nitrile butadiene rubber and belongs to the family of NBR bonded fiber gaskets. The material offers a low compression with a high volume resistance.

That is a decisive criterion for the application. The non-conductive molded part serves as a separating film between the Body and the high-voltage required for the electric carBattery. Novaform prevents a conductive connection between the components and thus prevents galvanic corrosion.

Methods of protection against galvanic corrosion

In order to protect components on the car from galvanic corrosion, a Lacquer sealing performed. However, this can be insufficient at the contact points between two different metals in the car. The former had such a seal galvanizing the entire steel body replaced. The so-called is also a way of avoiding galvanic corrosion.

Surface finishing + other protection for the drive technology

Surface finishing + other protection for the drive technology

The component sacrifices itself in favor of higher quality metals, which it separates from each other. The sacrificial anode consists of an even less noble metal than the one to be protected Materials. It attracts galvanic corrosion and slowly decomposes. Disadvantages of the sacrificial anode: It is more complex to use because it has to be replaced more frequently depending on the geometry and size of the application.

Novaform molded parts pre-cut from the roll

The Novaform molded part from Frenzelit holds maintenance-free over the entire service life. It is cheaper and can be supplied as a roll. When delivering in bulk, the protective film must be removed from each self-adhesive part before use, which is quite impractical. As an assembly aid, Frenzelit supplies the molded parts on rolls, on which the individual rings have already been pre-cut using the kiss-cut process. This variant is also very suitable for automated production processes.

The Novaform molded part from Frenzelit holds maintenance-free over the entire service life. It is cheaper and can be supplied as a roll. When delivering in bulk, the protective film must be removed from each self-adhesive part before use, which is quite impractical. As an assembly aid, Frenzelit supplies the molded parts on rolls, on which the individual rings have already been pre-cut using the kiss-cut process. This variant is also very suitable for automated production processes.

"Ideally, the delivery form is tailored directly to the customer's assembly process," explains Christian Kraus, Head of Sales Mobility at Frenzelit “Although we are purely a parts supplier with regard to the Novaform rings, we are characterized by our integrative thinking, which includes the entire process. How is the component processed further by the customer, by hand or automated, how should our components then be delivered? We think about how we can support the customer's processes and optimize his assembly times in the best possible way. "

World's first urban bike made from recycled plastic

World's first urban bike made from recycled plastic

As a Other Partners Frenzelit brings extensive expertise to a development project from the fiber to the finished part. The company not only punches and manufactures the parts, it also has the necessary know-how of the materials. This includes our own formulation of the fiber mixture of aramid fibers as well as fillers and functional materials that are bound with NBR. The result is the exclusive Novaform material for prefabricated seals.