World's first urban bike made from recycled plastic

- Details

- Hits: 4113

Maintenance-free, lubricant-free, sustainably produced and rustproof sets the new urban bike from Igus new standards in sustainable mobility. The bike off recycled plastic will transport generations of people. On the Hannover Messe The plastic visionary had the new one in 2022 Igus: bike Platform presents the groundbreaking concept. Here you can follow the development to date.

Contents

- The first 100 Igus bikes hit the streets

- From recycling to bicycling for the mobility of tomorrow

- The first urban bike made from recycled plastic

- Platform for bike and component manufacturers

- Frequently asked questions

The first 100 Igus bikes hit the streets

05.03.2024/XNUMX/XNUMX | "The igus:bike is now finally hitting the streets in its first small series under a new name,” says a delighted man Frank Blase. The new branding will be announced at Cyclingworld Europe in Düsseldorf. The Dutch development partner MTRL is currently producing 100 units together with Igus. After the road traffic approval, the rapid delivery of the first, now around 1200 pre-orders, was planned.

“In order to shorten the waiting time for the remaining orders, we are currently building one at our company location in Cologne own production line for the bike. The goal is to produce 10.000 bicycles with the expanded capacities,” says Sven Terhardt, Head of Sales & Marketing igus:bike. The price for the plastic bicycle is around 1200 euros.

92% plastic and some improvements

The few parts that were made of metal in earlier prototypes, such as the seat post or the brake lever, were also made of plastic in the current version. The engineers were also able to increase the steering angle of the handlebars to make cornering easier. Other new features include a freewheel in the drive train so that the wheels turn even without pedal movement.

More wear-resistant Xiros ball bearings are intended to ensure that the wheels run lubrication-free and even more smoothly. A two-legged stand is used to safely park the urban bike. "The igus:bike, which weighs around 17 kg, is now made of 92 percent plastic - from the frame to the bearings to the drive train. For a long time, this was considered almost impossible in the industry," says Sven Terhardt.

50% recycled content – and the trend is rising

The partners use the rotation and injection molding process to produce granules recycled plastic waste, including fishing nets, to manufacture bicycle components. The proportion of new plastic mixed in could be reduced to 50%. “We are now investing further in research and development in order to increase the recycled content to 75 percent as quickly as possible, and in the future even to 100 percent,” emphasizes Mr. Terhardt. “With this high recycled content, we are accelerating the circular economy for plastics. Plastic in the world’s landfills is becoming an increasingly valuable resource.”

From recycling to bicycling for the mobility of tomorrow

June 21.06.2023, XNUMX | In addition to the igus:bike made of plastic, igus is now presenting one additional product line made from high-performance plastics for bicycle manufacturers. These include frames made from one piece or several components, wheels and cranks as well as a handlebar that will be used on the Reco Bike from Advanced. The company has significantly expanded its bicycle laboratory for production. Self-developed and compounded polymers are used and tested. The products are recyclable and partly made from recycled material. Production starts in Cologne and will be expanded to Asia and North America in order to be able to offer local supply chains to bike OEMs.

“We see plastic technology as a new option for the industry, in the future for all components in a wheel. CO2-Reduction“Recyclability, durability and local supply chains are increasingly being demanded by our customers,” commented Jan Philipp Hollmann, Head of the Bicycle Components Division at Igus.

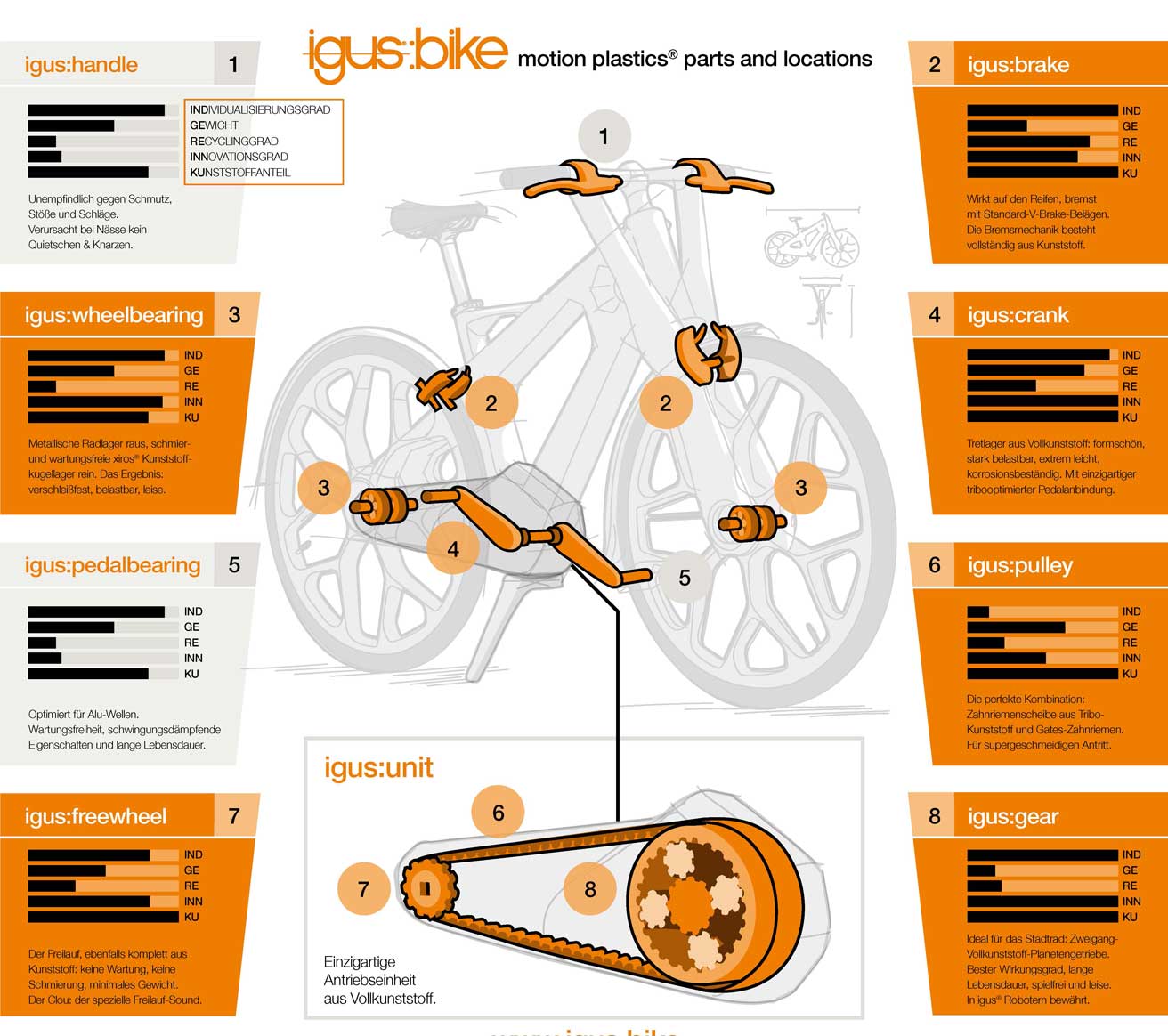

For bicycle manufacturer Igus is now presenting ball bearings, cranks, steering head bearings and a freewheel made of high-performance plastics specially developed for the city bike. Frames, wheels and handlebars will also be available soon. The seat post and saddle frame are already in progress. Igus delivers bearings and other moving components for over 30 years to numerous well-known manufacturers of bicycles and high-quality components. In the future, local supply for bike OEMs will be ensured via 12 factories on four continents.

Recyclable handlebars for the Reco bike

Igus has the first customer project Advanced realized. The bicycle manufacturer is considered a pioneer of the next generation of e-bikes, the special feature of which is the Reco frame. This is made of plastic and is 100% recyclable. The Reco bike now uses a 100% recyclable handlebar developed by Igus. Manufactured using a special manufacturing process from high-performance polymers, the handlebar is just as stable as its aluminum counterpart.

Igus has the first customer project Advanced realized. The bicycle manufacturer is considered a pioneer of the next generation of e-bikes, the special feature of which is the Reco frame. This is made of plastic and is 100% recyclable. The Reco bike now uses a 100% recyclable handlebar developed by Igus. Manufactured using a special manufacturing process from high-performance polymers, the handlebar is just as stable as its aluminum counterpart.

Production needed significantly less energy and takes place at Igus in Cologne. Because the handlebar is manufactured in one piece using an injection molding process, it does not have any annoying weld seams. “We have completely redeveloped this manufacturing process for such curved parts with high stability and cavities. This means we are free to choose the plastics, can create different colors and even have internal bushings for them Cables and create trains,” explains Jan Philipp Hollmann.

Igus Urban Bikes as a test laboratory for the industry

The development of the all-plastic bicycle igus:bike is also progressing successfully in cooperation with the co-developer MTRL. An all-plastic bike with frame and wheels consists of Post-consumer waste like shampoo bottles and fishing nets from the seas. All of the bicycle's wearing parts are made of long-lasting tribo-polymers from Igus, which describes the project as a “live test laboratory for the bicycle industry”. The igus:bike platform is intended to open the doors for further partnerships, impulses and the exchange of knowledge. The motion plastics specialist would like to promote plastics know-how in the bicycle industry and further develop the concept together with many other manufacturers.

The first urban bike made from recycled plastic

30.05.2022/XNUMX/XNUMX | The world is sinking into plastic waste and the mountains on the landfills are getting higher and higher. The plastic also ends up in the sea, gets into the food chain and thus becomes a danger to humans and animals. Therefore, there is an urgent need to move away from the linear economy towards the Recycling to perform. To support this transformation, igus has been developing and investing in ideas related to the recycling of plastics for years.

At the Hanover Fair 2022, the motion plastics specialist presented a world first with the concept of a robust and durable urban bike. The Urban Bike consists of 100% plastic, from the frame to the bearings to the toothed belt. In a planned recycling version, most of the material will come from post-consumer plastics. "The plastic in the world's landfills is becoming a valuable resource," explains Frank Blase, Managing Director of Igus.

Polyamide for electromobility and industrial applications

Polyamide for electromobility and industrial applications

While on vacation on the Atlantic beach, he had the brilliant idea for a bicycle called "Igus:Bike". In a conversation with employees of a bicycle rental company on the beach, he learned of their major problems with the beach bikes. These were permanently exposed to sand, wind and salt water. Sometimes they were already worn out after only three months and had to be replaced. Replacement and maintenance are often expensive and time-consuming in this industry.

The Urban Bike does not rust

The plastic bikes are easier to care for than any other bike. The single-speed bikes can be left outside in wind and weather without worry and can be cleaned in seconds with a garden hose. “Since all components are made of plastic, nothing on the bike will rust,” emphasizes Mr. Blase. “Even that Transmission is spared. A bicycle gear was made out of plastic unthinkable for a long time. "

Of the 2 components Ball bearings in the wheel bearings to the plain bearings Lubrication-free and light high-performance plastics are used in the seat post, brake levers and pedals. All components provide with their integrated solid lubricants for low-friction dry running – without a single drop of lubricating oil. Dirt, sand and dust cannot settle. The manufacturer's tribo-plastics have long been used successfully in more than 70 industries such as in automobiles, farm tractors or robots. Even in the bicycle industry, they have had many fans for decades. Here they prove themselves in mountain bikes and e-cargo bikes, for example.

Platform for bike and component manufacturers

Eight developers are currently working on all the moving components of the all-plastic urban bike. Andrew Hermey, longtime head of development for energy chains, coordinates the development. He also works by bike Startup MTRL from the Netherlands together. As part of this cooperation, ball bearings have already been Brakes, pinions, gears and Drives. Existing and proven industrial developments have been adapted to the new application. As a result, suppliers worldwide can benefit from the smooth-running, quiet and durable plastic parts within the igus:Bike platform.

Reading tip: Reaching CO2 neutrality with plastic recycling

Reading tip: Reaching CO2 neutrality with plastic recycling

The Cologne-based company gives bicycle manufacturers all over the world the opportunity Igus: bike Platform to advance urban bicycle technology together. On the platform you can see the current status and progress of all components. It also explicitly invites market competitors to participate.

“We want to enable the bicycle industry to produce bicycles made of plastic,” explains Frank Blase. He sees the platform that has been set up as a contact point for manufacturers who want to build a bicycle out of plastic and for component manufacturers of, for example, frames, wheels and drives and sprockets made of plastic. There are already initial collaborations in this context, such as with Helix.Eco for recycled plastics. More are to follow.

First urban bike planned for the end of the year

The Partners MTRL has already brought 400 bicycles with frames and wheels made of plastic onto the streets of his home country. "In the founders Johannes and Benjamin Alderse Baas, we have found partners who share our vision 1:1," says the managing director, who is himself an investor in MTRL. "Together we are tackling the further development of all-plastic bicycles."

The whole world of igus robots

The whole world of igus robots

The startup will until the end of 2022 start the production and sale of an adult city bike and a children's bike. The market launch in Germany is Beginning 2023 planned. Will there also be an e-bike? Of course, other versions such as an e-bike are also planned for the future. The igus bike will be available in two variants: made of new plastic and made of 100% Recycling Material. First prototypes were successfully produced and tested, including a version made from old fishing nets.

MTRL plans local production facilities worldwide near plastic waste dumps. "From Ocean Plastics to Motion Plastics, the concept of the igus bike has what it takes to become an ecological high-tech product," enthuses Frank Blase. “We still have a lot of ideas like condition monitoring going through Smart Plastics, where you can see on your smartphone how many thousands of kilometers the bike has left. And with that we can hopefully convince many people who are still skeptical about plastic today.”

Infographic for the igus:bike platform

Frequently asked questions

What is meant by urban bike?

An urban bike is a bike specifically designed for riding in the city or urban environments. It is characterized by its robustness, maneuverability and comfort for everyday use. Urban bikes are often equipped with practical features such as mudguards, lights and luggage racks to make everyday rides easier. They offer an efficient and environmentally friendly alternative for commuters and city explorers. Their design combines functionality with a modern look, making them a popular choice for urban cyclists looking for simplicity.

You might also be interested in...

Igus linear guide quiet, resistant, maintenance-free

Electrical Wires | From cable to assembly

Cobot | Discover collaborative robots as a new employee

Igus energy chain: stable, recyclable, plastic.

linear guide | Precise, light, durable

Fit calculator | Tools for fits and tolerances

The author Oliver Cyrus is Head of Press + Advertising at igus GmbH in Cologne.