Plain bearings for applications that are fun

- Details

- Hits: 23461

About 250.000 manufacturers put the igloo bearings from Igus in their constructions. the Plastic-Plain bearings show their advantages wherever the construction between moving components has to be protected from wear caused by friction. The Motion Plastics specialist praises the every two years Manus Award 2023 which selects particularly interesting applications. Below we report on new plain bearings and unusual applications.

Contents

- Maintenance-free plastic plain bearings that are sustainable

- Chemical-resistant plain bearings made from plastic regranulate

- Backlash-free multi-link hinges with self-calibrating plain bearings

- CO2 Footprint proof for Tribo plain bearings

- For the first time, plain bearings made from regranulated Tribo plastics

- Wound tribo plain bearings reduce wear in heavy-duty use

- Customized plain bearings in seven days

- Igus Isense plain bearings are now available for five materials

- Find the right plain bearing material with the Iglidur configurator

- Manus Award for exceptional applications

- Plain bearing applications

- Archive for journal bearings news

Maintenance-free plastic plain bearings that are sustainable

Igidur plain bearings are maintenance-free and require no additional lubricants, making them an efficient and cost-effective alternative to metal plain bearings. With over 10.000 sizes and specialized materials, they are suitable for numerous applications, including high temperature and food contact areas.

Chemical-resistant plain bearings made from plastic regranulate

Oct 19.10.2023, XNUMX | Igus has the new plain bearing for machines that regularly come into contact with chemicals, such as agitators and laboratory mills, filtration systems and car washes Iglidur ECO P210 developed. The maximum recommended surface pressure at room temperature is 50 MPa. This corresponds to a pressure of 5000 kg/cm2. The application temperature is between -40° and +100°C. External lubrication with oil or grease is not necessary because solid lubricants are integrated into the material for low-friction dry running.

“We were able to show in in-house laboratory tests that the plain bearings made of regranulate provide almost the same performance as the conventional Iglidur P210 series,” commented Stefan Loockmann-Rittich, Head of the Iglidur Plain Bearings Division at Igus. "They are similarly resistant to edge pressure as well as shocks and impacts - with only minimal compromises. This means that the ECO version can also cope with the majority of applications."

To precisely calculate the service life, there is a Online tool, with which users can quickly find out whether the ECO variant is worth using. There are now a total of five products in the Iglidur ECO series, in which all materials are made from at least 97% regranulate consist:

- iglidur ECO P210, the material with chemical resistance

- iglidur ECO H, a material for corrosive and hot environments

- iglidur ECO P, a low moisture absorption material for outdoor high humidity applications

- iglidur ECO G, an all-rounder and resistant to high loads

- iglidur ECO A180, a particularly cost-effective plain bearing.

“All ECO materials consist of at least 97 percent regranulate,” emphasizes Loockmann-Rittich. The development of the ECO series is part of the Sustainability strategy by Igus.

Backlash-free multi-link hinges with self-calibrating plain bearings

12.04.2023/XNUMX/XNUMX | The production of multi-joint hinges for spoiler kinematics and top can be expensive. An economical and technically superior construction is possible with an igus plain bearing made of tribologically optimized plastic. The new iglidur F300 is even electrically conductive and can calibrate itself and prevent corrosion using the cathodic dip coating (KTL) process. Complicated recalibration is no longer necessary.

12.04.2023/XNUMX/XNUMX | The production of multi-joint hinges for spoiler kinematics and top can be expensive. An economical and technically superior construction is possible with an igus plain bearing made of tribologically optimized plastic. The new iglidur F300 is even electrically conductive and can calibrate itself and prevent corrosion using the cathodic dip coating (KTL) process. Complicated recalibration is no longer necessary.

A relaxed ride in a convertible undoubtedly includes a mild headwind, sunshine and a lonely, winding road. However, if it starts to wind and rain, the occupants are happy when it improves Close the top quickly leaves. This requires, among other things, low-backlash multi-link hinges.

This aerodynamic components pose great challenges to production. Holes in the handlebars are only roughly punched, fine-cut portions are limited and the plain bearings and rivets should work without play to avoid noise and rattling.

To date, metallic rolled PTFE bearings have been used as standard. These have to be recalibrated very laboriously. The motion plastics specialist offers this with its plastic plain bearings made from the new Iglidur F300 a more efficient alternative. “The disadvantage of plastic plain bearings is that they flow at high temperatures. That difference works to our advantage here,” explains Markus Feth, Head of Automotive at igus.

Self-calibration due to high temperatures

The plain bearing bush made of iglidur F300 is mounted in the bearing point with preload. With the Cathodic dip painting will provide an even coating of the Surfaces achieved. The new plain bearing plastic was developed in such a way that it is electrically conductive and does not insulate the individual parts of the hinge from one another. With the specially designed conductivity, a good painting result can be achieved.

The whole world of igus robots

The whole world of igus robots

However, in contrast to metallic plain bearings, the igus plain bearings are more insulating. This means that there is no significant corrosion of the plain bearings in the usual OEM salt spray and climate change tests. This is particularly important for aerodynamic components such as spoiler kinematics and adjustable diffusers. In addition, the material is extremely wear-resistant and withstands the special thermal requirements during the subsequent curing process. The plain bearing recalibrates itself during the drying process at 180° to 220°C. Despite roughly punched bores and the cold extrusion of bolts, the bearing is smooth-running and has little play.

CO2 Footprint proof for Tribo plain bearings

26.10.2022 | How much CO2 gets into the atmosphere through the production of a plastic plain bearing? igus publishes the exact CO for the first time2 Footprint for many lubrication-free and maintenance-free iglidur polymer plain bearings. Users can enter the values as Scope 3 emissions in the CO2-Include the balancing of climate-neutral products.

In times of climate change, the question arises as to how sustainable the products produced and used are. One focus is on the CO2 emissions. Companies balance, reduce and compensate the so-called Scope-1 Emissions that arise at the site, for example through the operation of delivery vans and machines. Scope 2 emissions, indirect emissions from purchased energy and Scope 3 emissions from suppliers are also of interest.

Bearings for everyone in over 60 industries

Bearings for everyone in over 60 industries

“However, balancing across company boundaries is a real challenge in many cases. For example, when machines are made up of hundreds of components from different manufacturers,” says Stefan Loockmann-Rittich, head of the iglidur plain bearing division at igus. "In order to make this task easier for our customers, we are now assigning the CO for 16 materials in the iglidur plain bearing series2-Footprints in the online shop. Users can see at a glance how much carbon dioxide emissions are caused by the production of a plastic plain bearing.”

By 2025 CO2 neutral production to the target

igus strives for transparency in terms of environmental balance and continuous CO2-Reduction in own production. In 2021, the motion plastics specialist has the CO2 Emissions compared to the previous year reduced by 31,2% – above all by switching to climate-neutral gas and green electricity. Investments in new injection molding machines also require 40% less energy compared to older models. The ambitious goal is: By 2025, the production of components made of high-performance plastic CO2- done neutrally.

Worldwide put more than 250.000 companies on the plastic plain bearings from Cologne, below Automobileists, bicycle manufacturers, aircraft industry and machine builders. And they all improve the ecological balance of their products by switching from classic metal bearings to polymer bearings. They are light and require less drive energy and no lubricant.

For the first time, plain bearings made from regranulated Tribo plastics

19.07.2022/XNUMX/XNUMX | To all customers who are on more sustainable construction pay attention to their moving application, igus now offers four new materials made from recycled plastic. At the main location in Cologne, igus develops and tests tribologically optimized high-performance plastics for moving applications such as plain bearings, linear bearings, ball bearings or spherical bearings, energy chains, Cables, 3D Print materials or Low cost robotics based on plastic.

19.07.2022/XNUMX/XNUMX | To all customers who are on more sustainable construction pay attention to their moving application, igus now offers four new materials made from recycled plastic. At the main location in Cologne, igus develops and tests tribologically optimized high-performance plastics for moving applications such as plain bearings, linear bearings, ball bearings or spherical bearings, energy chains, Cables, 3D Print materials or Low cost robotics based on plastic.

The tribo-polymers are lightweight, low-maintenance and require no additional lubrication during their lifetime. When you consider that in Germany alone, around 1 million tons of lubricating oil is sold and a large part of it ends up in the environment, plastic parts offer advantages here. With Iiglidur plain bearings, contamination can be reduced as the service life increases. With the new plain bearings made of ECO H, ECO P, ECO A180 and ECO G materials, the motion plastics specialist is now starting even earlier in the product life cycle by using 97 to 100% regranulate in the production of new plain bearings.

ECO materials with fewer microplastics

Within the injection molding productionn become e.g. B. Sprues used, which as classic Waste products develop. The four new materials offer the following advantages in a wide variety of applications:

- iglidur ECO H is particularly temperature and media resistant. Therefore it is suitable for highly corrosive and hot environments.

- iglidur ECO P offers high mechanical strength with low moisture absorption. This predestines it for outdoor use.

- iglidur ECO A180 is suitable for price-sensitive use.

- iglidur ECO G is very robust and versatile.

All ECO materials are lubricant-free. Their lifespan can be calculated online. The ECO series and other 58 iglidur materials prove in 15.000 tribological tests annually how resistant to abrasion and wear they are. Reduced abrasion reduces contamination from microplastics and ensures a significantly longer service life. If these components are also "intelligent", they accurately predict their service life in real operation. Then maintenance and replacement intervals can be dispensed with. A plain bearing is only replaced if it is necessary.

Wound tribo plain bearings reduce wear in heavy-duty use

07.05.2021 | Igus has the new tribological material especially for heavy-duty applications in construction machinery or the agricultural sector Iglidur TX2 developed. The material does not require any lubrication. Even small excavators still use 50 liters of lubricant a year. The wound plastic plain bearing bushes withstand particularly strong forces. With loads of more than 100 MPa surface pressure, they increase wear resistance by a factor of 3,5.

07.05.2021 | Igus has the new tribological material especially for heavy-duty applications in construction machinery or the agricultural sector Iglidur TX2 developed. The material does not require any lubrication. Even small excavators still use 50 liters of lubricant a year. The wound plastic plain bearing bushes withstand particularly strong forces. With loads of more than 100 MPa surface pressure, they increase wear resistance by a factor of 3,5.

With the new plastic, igus offers an alternative to what is often in use Mobile work machines metallic solutions used. The extremely high tensile strength filament in its specially interwoven form offers maximum resistance and enables a maximum permissible Compressive strength of 400 MPa. Iglidur TX2 has been extensively tested on the indoor and outdoor test stands in the 3800 m² test laboratory of the Motion Plastics specialist. Swivel tests on hard chrome-plated shafts have shown that Iglidur TX2 is around 3,5 times more wear-resistant than the standard high-load material TX1.

Iglidur is TX2 self-lubricating and dry-running. This means that no dirt can get stuck at the bearing points and maintenance and repair costs are reduced. Machine failures due to insufficient lubrication are a thing of the past. The material is very temperature, chemical and moisture resistant. This means that plain bearings made from iglidur TX2 are suitable for use in many other areas.

Adaptive exoskeleton for the stroke patient

Adaptive exoskeleton for the stroke patient

The corrosion-free and seawater-resistant plain bearings can be used in moving maritime applications, for example. Diameters up to 2800 mm are possible. iglidur TX2 is also very sustainable. "According to the operator, even a small excavator needs between 50 and 60 liters of lubricant per year," says Stefan Loockmann-Rittich, head of the iglidur plain bearing technology division. "Because iglidur TX2 plain bearings do not have to be lubricated, the customer benefits in three ways: He saves the costs for oil or grease, maintenance time and no lubricants get into the environment." iglidur TX2 is available in the standard range in diameters from 20 to 80 mm directly from stock.

Customized plain bearings in seven days

05.02.2021 | Customer-specific parts such as plain bearings in special shapes must be delivered quickly and easily. However, the production of special parts by injection molding often takes several weeks. The new Fastline service from Igus is now possible thanks to the expanded in-house toolmaking facility. Lubricant-free plastic plain bearings in special dimensions can now be delivered in a few days.

05.02.2021 | Customer-specific parts such as plain bearings in special shapes must be delivered quickly and easily. However, the production of special parts by injection molding often takes several weeks. The new Fastline service from Igus is now possible thanks to the expanded in-house toolmaking facility. Lubricant-free plastic plain bearings in special dimensions can now be delivered in a few days.

If the production of a special plain bearing has to be quick, many users think of 3D printing or milling the desired parts from the semi-finished product. In the long run, however, both methods are too expensive for large series of more than 1000 parts. In the Fastline Service, highly wear-resistant plain bearings series from the Injection produced and shipped within a few days. "By investing in our tool shop with our own production line for round parts with modern CNC technology, we are now able to react even faster to the needs of our customers," explains Stefan Loockmann-Rittich. "In addition to our large catalog range of polymer plain bearings from stock, we can now produce customer-specific parts with the appropriate injection molding tool in just a few days."

With the Iglidur designer tool the customer finds out when it is worthwhile to manufacture by injection molding or whether another manufacturing process is cheaper. The user enters the dimensions of his plain bearing in the online tool, selects the required material, defines the quantity and is shown an overview of the manufacturing processes with the corresponding costs.

Ergoline uses special slide bearing service for ergometer series

Ergoline GmbH also uses the Fastline service. The manufacturer of Ergometers was looking for a maintenance-free plain bearing for the height adjustment of its new series. The standard plain bearings were out of the question due to the inner diameter and outer diameter. Ergoline successfully carried out the first attempts with turned bearings made from iglidur semi-finished products. For the start of series production, however, things had to be done quickly due to the high demand on the market.

Material and filament 3D printer - durable!

Material and filament 3D printer - durable!

“Waiting six weeks for a regular tool was too long for us. Turning bearings from semi-finished products over the long term is time-consuming and expensive, ”explains Dominik Huber, developer at Ergoline. “So we were very happy about the Fastline service. It took just four days from ordering to delivery. And the price is three times cheaper than expected.” The injection molding tool was then stored, so Ergoline can continue to benefit from the Fastline service in the future.

Igus Isense plain bearings are now available for five materials

26.05.2020/XNUMX/XNUMX | igus presents the first Isense plain bearing series with five iglidur materials. isense was introduced last year as a prototype for predictive maintenance. The term Isense covers a product family in which different sensors and monitoring modules are used for the Plastics solutions such as energy chains, cables, linear guides, rotary table bearings or plain bearings make them intelligent.

Machine Learning, Big Data and Industry 4.0 – meanwhile, pure buzzwords have long since concealed real concepts. Isense gives users durable and lubrication-free plain bearings in which Sensors inform about their wear. In this way, predictive maintenance can be planned in good time and Avoid machine downtime. The Isense technology integrated in the warehouse detects wear in advance and gives the user a signal in good time when the wear limit is reached.

Materials customized for intelligent condition monitoring

After many test series in the in-house 3800 m² test laboratory, igus has now developed the first Isense standard range for its lubrication-free iglidur bearings. "The catalog range contains five materials with which we can cover a large number of highly stressed applications," says Stefan Loockmann-Rittich, head of the iglidur plain bearing technology division at the motion plastics specialist.

High-quality wheels and castors for industry

High-quality wheels and castors for industry

The FDA-compliant iglidur A180 is also included. It was specially designed for applications in the food technology designed. This is joined by the iglidur Q2E high-load bearing for use in agricultural technology and construction machinery. The all-rounder Iiglidur G three dimensions with 20, 30 and 40 mm inner diameter. Further sizes and materials are planned.

Stand for the connection of the Isense plain bearings four matching lines with an oil and media-resistant PUR outer jacket in four standard lengths from 1 to 10 m. The user can also choose between two connector types. The measured sensor data can be integrated in various ways by the machine and system operators.

The plastics specialist offers this three readout units: read out all plug-in points manually, integrate a control unit with red / green display on the machine, which shows the state of the slide bearings or the connection to the Icom.plus. To do this, a radio module sends the sensor data wirelessly to the Communicationmodule. From here, the data is integrated into the IoT, cloud system or customer network on a wired basis. “The customer is free to choose to read out the data in the way that is best for him,” explains Stefan Loockmann-Rittich.

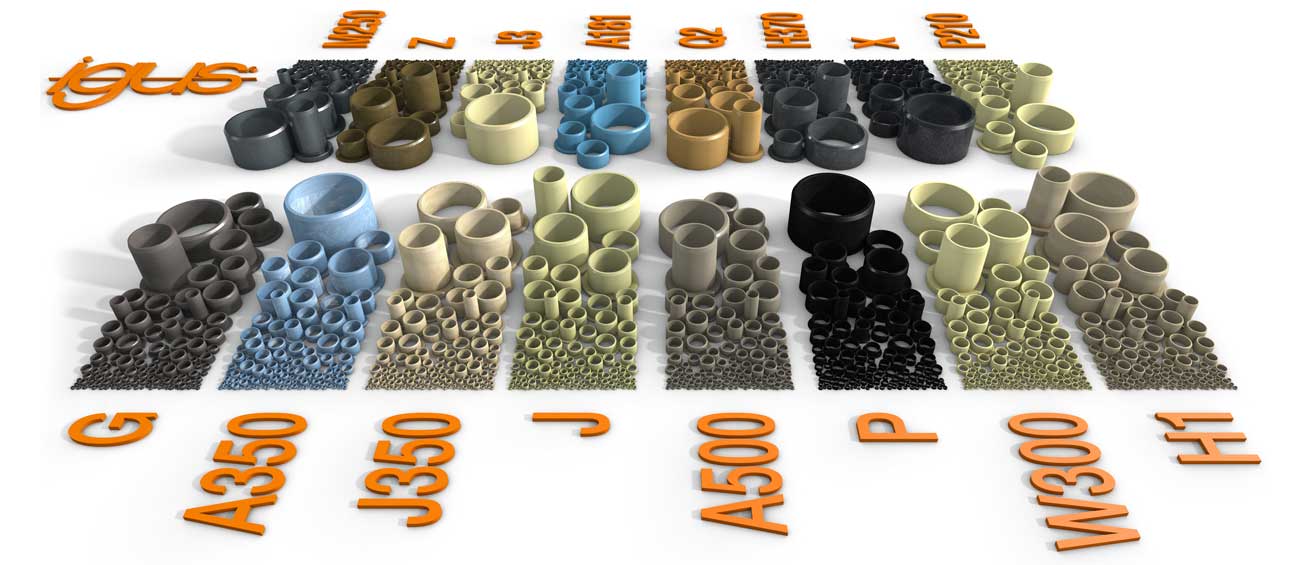

Find the right plain bearing material with the Iglidur configurator

22.01.2020/XNUMX/XNUMX | When it comes to wear-resistant tribo polymers, users at igus havethe agony of choice. The plastics specialist now has one for small series or series production in injection molding, a prototype from the 3D printer or semi-finished products Offline configurator developed for his 39 iglidur standard materials: The user can use templates to determine the right plastic. An iglidur expert system is also available for selecting and calculating the service life.

22.01.2020/XNUMX/XNUMX | When it comes to wear-resistant tribo polymers, users at igus havethe agony of choice. The plastics specialist now has one for small series or series production in injection molding, a prototype from the 3D printer or semi-finished products Offline configurator developed for his 39 iglidur standard materials: The user can use templates to determine the right plastic. An iglidur expert system is also available for selecting and calculating the service life.

"With the help of Sample box users can quickly and easily find the right Iglidur plain bearing material for their individual application, ”explains Stefan Loockmann-Rittich, Iglidur Business Unit Manager bearings. But how does an offline configurator work?

The user sets different stencils about the multitude of materials. For example, if he is looking for a plain bearing with high temperature resistance, he places the appropriate template over the bushings and filters the materials. Other properties such as high loads, dirty surroundings or chemical resistance can also be placed over the plain bearings using templates. Ultimately, there is a corresponding selection that is best suited to the desired applications.

Iglidur from the sample box

The Motion Plastics specialist has been presenting the offline concept since 2013 as Dry-tech sample box. In the compact new variant, users can now see directly which materials are available for free design as semi-finished products.

Also the 3D printing service and that 3D Print Material for the production of prototypes and small series are included in the sample box. "We have the iglidur materials in the new configurator on 39 of the available ones 57 materials limited. The box therefore contains the materials that are used in most plain bearing applications, ”says Mr. Loockmann-Rittich. “In discussions with users and interested parties, we have only received positive feedback on the handy box so far. The configurator can be consulted at any time ".

Manus Award for exceptional applications

The motion plastics specialist draws unusual applications of the plain bearings made of high-performance plastic every two years with the Manus Award in gold, silver and bronze for the most creative, economical and sustainable use of polymer plain bearings.

- Manus Award 2023 is looking for an innovative plain bearing application

- Winner of the Manus Awards 2021

Manus Award 2023 is looking for an innovative plain bearing application

05.10.2022 | For the 11th time, igus is issuing the Manus Award for the most creative, economical and sustainable use of polymer plain bearings. The winners of the golden, silver, bronze and green Manus receive prize money of up to 5000 euros. Until February 10, 2023 users can apply. Everything is possible, from series application to a one-off, as long as at least one built prototype exists. A jury of experts from science, industry and specialist media will then award the four prizes, which will be presented at the Hannover Messe 2023.

Winner of the Manus Awards 2021

11.05.2021/10/2021 | In 5000, the joint initiative was looking for unique applications for the XNUMXth time. These will be awarded up to XNUMX euros. For the anniversary, the jury awards a sustainability prize. For the 10th Manus Award 582 users from 41 countries submitted their designs this year. The jury, consisting of representatives from specialist media, business and research, selected four applications that were able to impress with their technical and economic efficiency and creativity. And these are the winners:

Golden manus for carrier vehicle and off-road vehicle

The winner of the Golden Manus Award is Kässbohrer Geländefahrzeug AG with her Powerbully, for which she received 5000 euros in prize money. The off-road vehicle and carrier vehicle with high payloads is suitable for a wide range of applications wherever roller-driven vehicles fail. With the appropriate superstructure, the vehicle can, for example, lay power and telephone lines, be used for fire protection, carry out mulching work or soil investigations.

The winner of the Golden Manus Award is Kässbohrer Geländefahrzeug AG with her Powerbully, for which she received 5000 euros in prize money. The off-road vehicle and carrier vehicle with high payloads is suitable for a wide range of applications wherever roller-driven vehicles fail. With the appropriate superstructure, the vehicle can, for example, lay power and telephone lines, be used for fire protection, carry out mulching work or soil investigations.

Like all components, the plain bearings must be extremely robust and withstand the high forces that are used in the pendulum axis and clamping axis. For this purpose, the designers, with the support of Igus, have the wound Iglidur TX1 Plain bearings in XXL format selected. Lubrication-free, dust- and dirt-resistant, they withstand use under extreme conditions.

Silver manus for radio-controlled felling wedge

The silver manus is awarded to them Forstreich GmbH from Germany for their radio-controlled felling wedge. The drought of recent years has increased the risk of cutting down trees with a hammer and wedge. That is why Stefan Reichenbach has developed a radio-controlled and battery-operated felling wedge.

The silver manus is awarded to them Forstreich GmbH from Germany for their radio-controlled felling wedge. The drought of recent years has increased the risk of cutting down trees with a hammer and wedge. That is why Stefan Reichenbach has developed a radio-controlled and battery-operated felling wedge.

The forester places the wedge in the saw cut and starts felling with a safety margin. For the Linear movement of the felling wedge the designers use the Drylin W double rails with plastic housing bearings. There are also plain bearings from the Iglidur G series. Over a long service life, the bearings can absorb high radial forces under the influence of dirt, sand and sawdust.

Bronze manus for sun protection facade

The Bronze Manus goes to das French company Arcora for its facade system with a shape memory alloy for sun protection. If the alloy heats up, the sun protection system sets a translation carriage in motion. The carriage transfers the power to the rotating sunshade slats via small connecting rods.

This is how a Standard motorization in building facades substitute. At the interfaces between the moving and stationary elements, the designers use high-performance plastics, including Igubal spherical plain bearings, iglidur J polymer flange bearings and miniature Drylin N guide rails.

This is how a Standard motorization in building facades substitute. At the interfaces between the moving and stationary elements, the designers use high-performance plastics, including Igubal spherical plain bearings, iglidur J polymer flange bearings and miniature Drylin N guide rails.

Green manus for the intelligent garbage can

For the first time this year, the Green Manus was also awarded for the use of polymer plain bearings in particularly sustainable projects. the Finnish company Finbin wins the sustainability award for the development of their intelligent, solar-powered garbage can.

The patented technology in the waste system compresses the waste in a ratio of 6: 1. The garbage can automatically notifies the waste management system of the fill level. Above all, the individual components of the garbage can had to be durable and maintenance-free. That is why slide bearings made of tribo-plastic are used in the clamping rods for hatches, pedals and pedal transmission rods. the Iglidur G Bearings work without external lubrication and are insensitive to dirt.

Applications for plastic plain bearings

- Maintenance-free drone hangar thanks to Igus plain bearings

- Plain bearings adjust weights in new fitness equipment

- Iglidur slide bearings allow solar boats to move easily across the water

- Lubricant-free slide bearings for maintenance-free cultivators + compact disc harrows

- 3022 km through the desert with plain bearings in solar racing cars

- Antibacterial bearings for sterile use in medical and laboratory equipment

Maintenance-free drone hangar thanks to Igus plain bearings

January 08.01.2023, XNUMX | Inspecting gas pipelines with helicopters is expensive and time-consuming. Offers as an alternative Exabotix a drone team that automatically carries out inspection flights. After the missions, every professional drone lands in a remote place drone hangar. These drone ports are thanks Igus Products maintenance-free.

January 08.01.2023, XNUMX | Inspecting gas pipelines with helicopters is expensive and time-consuming. Offers as an alternative Exabotix a drone team that automatically carries out inspection flights. After the missions, every professional drone lands in a remote place drone hangar. These drone ports are thanks Igus Products maintenance-free.

Plain bearings adjust weights in new fitness equipment

21.10.2021/XNUMX/XNUMX | More and more athletes rely on functional training, with which they achieve a more stable core and better muscle interaction. The armbar of Atlas In Gym Needing combines the leverage and pendulum power. Two competitive athletes have developed the compact fitness device that is suitable as a multifunctional device. For the safe storage of the barbell, the engineers relied on durable, lubrication-free and therefore maintenance-free plain bearings made of iglidur G.

21.10.2021/XNUMX/XNUMX | More and more athletes rely on functional training, with which they achieve a more stable core and better muscle interaction. The armbar of Atlas In Gym Needing combines the leverage and pendulum power. Two competitive athletes have developed the compact fitness device that is suitable as a multifunctional device. For the safe storage of the barbell, the engineers relied on durable, lubrication-free and therefore maintenance-free plain bearings made of iglidur G.

The Barbell by Till Nonhoff hangs on one side on a rope and offers so many options for movement. The patented fitness device is ideal for fitness studios, personal training, in the crossfit area and for physiotherapy. With a footprint of only 6 m², the armbar is also suitable for smaller studios.

"The quality and durability of the 150 different components were particularly important to us," explains Til Nonhoff. The engineers were looking for robust and lubricant-free plain bearings especially for the bearing points of the sports equipment. They should be low-friction and maintenance-free. "During our research, we became aware of the plain bearings made of high-performance plastics.

Housing bearing replacement saves significant TCO

Housing bearing replacement saves significant TCO

In the online service life calculator, we could simply enter the data of our armbar and determine the right plastic. When we later had to change the design, the technical sales consultant Gerald Voss advised us. As a small start-up, such a service is not a matter of course for us,” explains the young entrepreneur.

A total of four slide bearings are used. Two bearings are made of the high-performance plastic Iglidur G. They ensure a smooth weight adjustment of the armbar on a stainless steel shaft. The plain bearings are located in a carriage that is acted upon by up to 450 N. Sweat, dirt, magnesium powder and water can get into the bearing points. But the high-performance plastics easily withstand such environmental conditions.

Two more plain bearings made of the same material are located in the rowing handle of the armbar. In addition to its good technical properties, the polymer is also very inexpensive. In first Long-term tests the plain bearings have already proven themselves. Now the sports equipment is about to be launched on the market.

Iglidur slide bearings allow solar boats to move easily across the water

20.07.2021/XNUMX/XNUMX | With the autonomous Solaris racing boat a Polish student team has developed a means of transport of the future. With only solar energy, the boat travels easily and maintenance-free over rivers and lakes. The young engineers use polymer plain bearings made of the high-performance plastic iglidur J in the control system. These provide the necessary strength, make the boat lighter and do not require any lubricant.

The solar powered racing boat was specially developed for use in the water. The student team comes from Wrocław, Poland, the city of a hundred bridges. The Solaris I project is carried out by the PWR Solar Boat Team at the Faculty of Mechanical and Energy Engineering. For the environmentally friendly drive one relies on Photovoltaic cells.

The solar powered racing boat was specially developed for use in the water. The student team comes from Wrocław, Poland, the city of a hundred bridges. The Solaris I project is carried out by the PWR Solar Boat Team at the Faculty of Mechanical and Energy Engineering. For the environmentally friendly drive one relies on Photovoltaic cells.

The project includes development, construction and implementation of the watercraft. It has a system for computer-electronic control and amplification of vehicle movement. This is done analogously to the one used in aviation Fly-by-wire system. The plain bearings used in the control system had to be lubricant-free, seawater-resistant, mechanically robust and easy to assemble - all requirements ideally suited for Iglidur plain bearings.

You can find them Double flange bearings from the high-performance plastic iglidur J in the control system of the yoke. “The use of plain bearings guarantees us flawless durability. They reduce the weight of the entire system, avoid the use of lubricants and enable easy assembly,” says Dominika Dewor from the PWR Solar Boat Team. Igus' young engineers support (yes) sponsored the team for their project. The university initiative supports school and student projects with free samples, sponsoring and advice.

3022 km through the desert with sliding bearings in the solar racing car

23.10.2019/3022/XNUMX | XNUMX km across the Australian desert and only with the power of the sun, that's the challenge of the World Solar Challenge. One of their participants is the Sonnenwagen team from Aachen. When developing their solar car, the students relied on the light, wear-resistant and lubricant-free "Iglidur “plain bearingtechnology made from durable tribo-polymers from Igus and drove successfully in sixth over the finish line.

For the track from Darwin to Adelaide the participants have exactly one week. The student teams from all over the world are developing different vehicle concepts and thus show the colorful variety of sustainable technologies. The Sonnenwagen team took part in the biennial competition for the second time.

"The bearing points are immensely important because they hold the car together," he says Kersten Heckman from the Sonnenwagen team. "If a bearing fails, the repair is extremely expensive." In addition, the bearings used had to be wear-resistant and light. Because the lighter the sun chariot, the more efficiently it can be driven and the longer it can travel.

Sliding bearings everywhere you look

The easy iglidur Plain bearing technology can be found in countless places in the sun chariot. For example, self-adjusting "Igubal" fork heads made of iglidur J are used in the telescopic mechanism for the solar car cover and in the steering wheel. The same plastic can be found in the form of slide bearings in the wheel suspension of the rear wheels and in the steering gear.

The easy iglidur Plain bearing technology can be found in countless places in the sun chariot. For example, self-adjusting "Igubal" fork heads made of iglidur J are used in the telescopic mechanism for the solar car cover and in the steering wheel. The same plastic can be found in the form of slide bearings in the wheel suspension of the rear wheels and in the steering gear.

The wear-resistant and lubricant-free long-distance runner has a very low coefficient of friction on a variety of shaft materials, especially when running dry, and is vibration-damping. An advantage especially for the steering feel. The hinges of the lid lock also contain plain bearings made from the material iglidur G. The tribo-polymer is inexpensive and has a high level of wear resistance.

The Cover of the solar car presented the team with a particular challenge. According to the rules of the challenge, the driver must be able to open and close it independently when getting in and out. A difficult task because the cover is 5 m long, not even a meter wide and weighs 25 kg with the solar cells. Up to now, opening has been jerky and strenuous.

Hybrid regenerative energy generation from sun and wind

Hybrid regenerative energy generation from sun and wind

The problem lay in the stiff ones printed camps from a standard plastic. Therefore, the team ordered the 3D printing of the bearings from the high-performance plastic iglidur I3 from igus at short notice. The material for the laser sintering process is characterized by its low coefficient of friction, is insensitive to dust and dirt like all iglidur materials and is ideal for the desert. By using the printed bearings, the driver only needs a few seconds to get in and out.

University initiative yes

The Motion Plastics specialist supports projects such as the sun car from Aachen as part of the young engineers support (yes). With the university initiative, Igus would like to support pupils, students and lecturers with free samples and sponsoring as well as in the development of innovative projects.

Lubricant-free slide bearings for maintenance-free cultivators + compact disc harrows

March 20.03.2018, XNUMX | Stubble cultivation devices are primarily used to loosen the arable land, mix in organic matter and prepare it for the next sowing. The Karat 9 from Lemken is such an intensive cultivator. Lubrication-free plastic plain bearings do their job at the bearing points.

March 20.03.2018, XNUMX | Stubble cultivation devices are primarily used to loosen the arable land, mix in organic matter and prepare it for the next sowing. The Karat 9 from Lemken is such an intensive cultivator. Lubrication-free plastic plain bearings do their job at the bearing points.

Antibacterial bearings for sterile use in medical and laboratory equipment

21.11.2015/XNUMX/XNUMX | Lubrication-free, media-resistant, non-magnetic, non-corrosive - these are decisive criteria for components in the Medical Technology. The motion plastics specialist has developed the new plain bearing material especially for the industry Iglidur AB developed. Antibacterial plain bearings made from this material help to reduce germ contamination.

21.11.2015/XNUMX/XNUMX | Lubrication-free, media-resistant, non-magnetic, non-corrosive - these are decisive criteria for components in the Medical Technology. The motion plastics specialist has developed the new plain bearing material especially for the industry Iglidur AB developed. Antibacterial plain bearings made from this material help to reduce germ contamination.

Archive for journal bearings news

- Interview: Behind the scenes - bearings and linear technology

- The fast way to individual plain bearings

- Plain bearing material with improved UV resistance

- Linear plain bearings as a better alternative to linear ball bearings

- Tribo Polymer doubles the life of the plain bearing

- Calculate warehouse adjustments using the app on your smartphone

- Over 1300 new standard plain bearings for all industries

- Plastic bearings meet EU directive

- Maintenance-free plain bearings for highly loaded slewing movements

Interview: Behind the scenes - bearings and linear technology

10.07.2019/XNUMX/XNUMX | Every year, igus presents, among other things, numerous new plain bearing innovations. We took a look at where these come from. When we took a look behind the scenes in Cologne, we had an authorized signatory Tobias Vogel Answers to the following questions:

- Which are the bearing and linear technology Highlight 2019?

- 120 innovations again at the Hannover Messe 2019: Where do the ideas come from? and what is the effort behind it?

- Why should users who still use steel bearings, on your Change to the Motion Plastics warehouse?

- which unused potential for your motion plastics warehouse is still slumbering in industry?

- What actually happens to the plastic when the products are worn out - against the background of the general plastic waste problem?

The fast way to manufacture individual plain bearings

22.07.2019/XNUMX/XNUMX | In order to always be able to quickly assemble and deliver the right plain bearing solution to the user, over 12.000 different types of Iglidur plain bearings kept in stock from tribo-polymers. In addition to large series from 500 pieces, the plastics specialist also offers small series up to 500 pieces or prototypes with the "Speedigus" production service with the divisions "Speedimold", "Speedicut", "Speedifit" and the 3D printing service. You can find out what the different processes can do in the video:

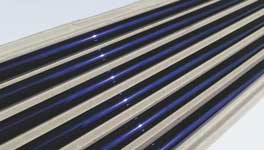

Plain bearing material with improved UV resistance

29.06.2018/XNUMX/XNUMX | Today, plain bearings are not only used as simple press-in bushes, but also in more and more special forms, which are used, for example, in the Solar industry are subject to permanent UV radiation. Especially for such applications, igus has the durable high-performance plastic "iglidur J" in its range. This has now been further developed into "iglidur J UV".

29.06.2018/XNUMX/XNUMX | Today, plain bearings are not only used as simple press-in bushes, but also in more and more special forms, which are used, for example, in the Solar industry are subject to permanent UV radiation. Especially for such applications, igus has the durable high-performance plastic "iglidur J" in its range. This has now been further developed into "iglidur J UV".

Machine elements that offer a long service life and a long service life are required for installation in solar systems. In addition, plain bearings, which are used, for example, in solar tower power plants, parabolic trough power plants or for mounting the axis of rotation for the panel adjustments, be as inexpensive as possible.

The new UV-stabilized high-performance plastic Iglidur JUV is particularly suitable for permanent direct sunlight. Thanks to the incorporated solid lubricants, plain bearings made of this plastic are lubricant-free and therefore maintenance-free and insensitive to dust and dirt. In addition, the long-term mechanical properties of iglidur J UV have been further improved. The user now has the optimal material for extremely smooth-running, lubrication-free and long-lasting solar systems.

solar storage | Products, technologies, innovations and trends

solar storage | Products, technologies, innovations and trends

Due to its freedom from corrosion and good media resistance, moisture and other environmental influences do not prevent the use of iglidur J UV. The tribological properties such as friction and wear of the UV material are comparable to those of the standard material Iglidur J. Its low coefficient of friction when running dry and the extremely low tendency to stick-slip are particularly important at very low speeds, which are common in tracking systems in the solar industry.

But also high Speeds of over 1 m/s are possible. In both cases, the static friction is very low, which avoids stick-slip. Initially, the material will be available with and without a collar up to a shaft diameter of 20 mm. On request, bearings made of iglidur J UV are available in all previous standard dimensions of iglidur J as well as in individually designed special geometries.

Linear plain bearings as a better alternative to linear ball bearings

02.07.2017 | Igus also calls it Slip dry: storing shafts or axles in the Linear Technology and Drive Technology. As with all bearings, a basic distinction is made between the two types of plain bearings and rolling bearings based on their operating principle. The manufacturer about the constantly growing number of applications that speak for linear plain bearings.

02.07.2017 | Igus also calls it Slip dry: storing shafts or axles in the Linear Technology and Drive Technology. As with all bearings, a basic distinction is made between the two types of plain bearings and rolling bearings based on their operating principle. The manufacturer about the constantly growing number of applications that speak for linear plain bearings.

Tribo Polymer doubles the life of the plain bearing

10.05.2017/XNUMX/XNUMX | The Cologne-based company has further improved its bestseller, the all-round plain bearing material iglidur G, and presented it at the Hanover Fair Iglidur G1. The lubrication and maintenance-free tribo-polymer material offers higher temperature resistance, lower moisture absorption and further improved behavior in terms of friction and wear. And that for almost the same price.

10.05.2017/XNUMX/XNUMX | The Cologne-based company has further improved its bestseller, the all-round plain bearing material iglidur G, and presented it at the Hanover Fair Iglidur G1. The lubrication and maintenance-free tribo-polymer material offers higher temperature resistance, lower moisture absorption and further improved behavior in terms of friction and wear. And that for almost the same price.

The wear rates at low Loads up to 5 MPa could be reduced to up to a quarter. The service life at high loads could almost be doubled, depending on the application parameters. At the same time, the all-rounder can now be used permanently at application temperatures of up to 180 ° C (Iglidur G: 130 ° C). In addition, the temperature at which an additional axial securing device is recommended in addition to the press fit has been increased by half to 120 ° C.

With that and with the by more than 50% reduced moisture absorption the new material is suitable for an even wider range of environmental conditions. The new plastic is another, improved alternative in moving applications where steel bearings have been used up to now. Customers can save around 40% in costs, increase service life and benefit from the absence of lubricants, lower weight and corrosion resistance.

Iglidur G1 will initially be made available in 113 standard dimensions as a cylindrical plain bearing and plain bearing with collar.

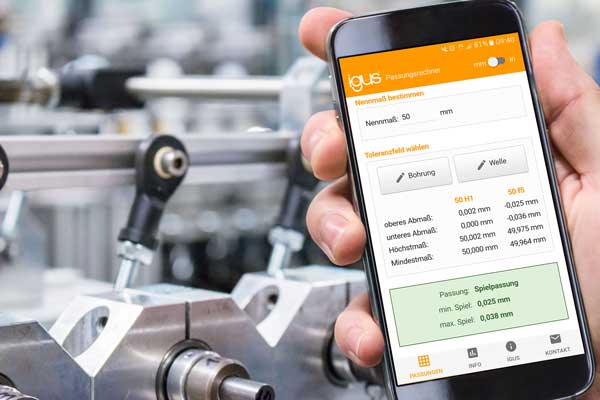

Calculate bearing fits via the app on your smartphone

09.11.2016/XNUMX/XNUMX | From now on, igus offers with the of fits a new smartphone app for iOS and Android. This makes it easy to calculate dimensions and tolerances according to ISO 286 for bearings. Enter nominal dimensions between 0,01 and 500 mm as well as tolerances for bore and shaft and have them calculated - that's how easy the new fit calculator works, with which users can calculate dimensions and tolerances.

09.11.2016/XNUMX/XNUMX | From now on, igus offers with the of fits a new smartphone app for iOS and Android. This makes it easy to calculate dimensions and tolerances according to ISO 286 for bearings. Enter nominal dimensions between 0,01 and 500 mm as well as tolerances for bore and shaft and have them calculated - that's how easy the new fit calculator works, with which users can calculate dimensions and tolerances.

In addition to the output of maximum and minimum dimensions, the associated Type of fit (Clearance or interference fit) output. The tool in the slim smartphone app can also be used offline by users, which is particularly advantageous in isolated machine halls or security areas. At the same time, users can switch between the metric and imperial systems at any time if necessary. In addition to the calculator, the app provides further information and detailed help on the calculation of the tolerance field.

In addition, users can direct Contact the storage specialists or find out about the other available mobile apps. The application is currently available in German and English for devices with Android and iOS. An expansion to include even more languages and operating systems is already in preparation.

Over 1300 new standard plain bearings for all industries

19.01.2015/XNUMX/XNUMX | Designers from a wide variety of industries, from the Automobile- about the packaging and Food industry to chemical plant and pump builders, can now find it even faster dry running bearings for their application. With the addition of five to 16 full-range materials and 1.321 new catalog dimensions, the plastics specialist now covers all imaginable requirements for plain bearings directly from stock.

With the investment, igus is reacting to the enormous progress made in the in-house development of new plain bearing materials. Due to the fact that they were quickly ready for the market, bearings made of the most suitable plastic were not always directly available in the right dimensions. This gap has now been closed - all materials that are optimally suited for an application from a tribological point of view can now also be supplied from stock. For this purpose, the existing range of eleven additional materials was expanded in such a way that for each material more than 110 dimensions up to 50 mm Diameters can be ordered immediately. Both with and without a collar, the DIN-guided dimensions are now available in 16 tribo materials - from a quantity of 1.

Calculate fit calculator and roughness - online for the first time

Calculate fit calculator and roughness - online for the first time

Since the different materials in injection molding require different tools, even with identical dimensions, this new service naturally means that Manufacture of an injection molding tool for each individual dimension of this program extension. Calculation tools are available on his website which, after entering environmental parameters and dimensions, display suitable products with their prices. The service life in hours is precisely calculated for each plastic for the described load.

The full range of materials now includes high-tech polymers such as Iglidur Q2 for high loads or Iglidur Z for very high temperatures. Three new materials have been added to the FDA-approved materials for the packaging industry alone. All 16 materials are now available in the standard dimensions of DIN ISO 3547-1 up to a diameter of 50 mm. For larger DIN dimensions, the tools are manufactured if there is a specific need. In addition, numerous materials are already available from stock in diameters of up to 150 mm.

Plastic bearings meet EU directive

14.07.2014/XNUMX/XNUMX | The extended one has been in effect since the beginning of the year EU Directive 2011/65 / EU (RoHS II) and tightened permissible limit values for hazardous substances in more and more areas. From July 22nd, products with impermissibly high concentrations, such as plain bearings containing lead, will also be on the brink of extinction in the medical technology industry. Iglidur polymer plain bearings are a RoHs-compliant alternative. They promise the manufacturer legal and functional security, the user safe use and disposal.

14.07.2014/XNUMX/XNUMX | The extended one has been in effect since the beginning of the year EU Directive 2011/65 / EU (RoHS II) and tightened permissible limit values for hazardous substances in more and more areas. From July 22nd, products with impermissibly high concentrations, such as plain bearings containing lead, will also be on the brink of extinction in the medical technology industry. Iglidur polymer plain bearings are a RoHs-compliant alternative. They promise the manufacturer legal and functional security, the user safe use and disposal.

Since the mid-1990s, electrical and electronic equipment and its components have been subject to restrictions across Europe with regard to the use of environmentally hazardous substances. This under the Abbreviation RoHS (Restriction of (the use of certain) Hazardous Substances) Constantly stricter guidelines set limit values for the use of industrially necessary but potentially harmful substances such as chromium, lead, mercury or bromine.

With the new RoHS II standard a maximum of 0,1% of the total weight is set for most. Many producers have already had to change their production processes accordingly in the past and others have to react now, as exemptions such as those for medical and control technology expire this month. Since similar regulations are also in force in countries such as the USA, Japan or China, these standards must increasingly be met globally. However, metallic composite bearings often have alloys that are not RoHS compliant.

Customers who take RoHS compliance into account have a direct alternative with Iglidur bearings. Because the substances included in the directive play a role in this thermoplastic plastic compounds existing material basically irrelevant. The iglidur bearing technology based on the principle of incorporated dry lubrication uses only non-metallic and RoHS-safe ingredients for the compounds made of tribologically optimized base polymers, solid lubricants and fillers.

Customers who take RoHS compliance into account have a direct alternative with Iglidur bearings. Because the substances included in the directive play a role in this thermoplastic plastic compounds existing material basically irrelevant. The iglidur bearing technology based on the principle of incorporated dry lubrication uses only non-metallic and RoHS-safe ingredients for the compounds made of tribologically optimized base polymers, solid lubricants and fillers.

Maintenance-free plain bearings for highly loaded slewing movements

16.05.2011/XNUMX/XNUMX | The new lubrication and maintenance-free plastic plain bearing Iglidur Q2 pushes the limits of injection molded bearings even further for highly loaded pivoting movements. This is made possible by a new mix of materials, which the plastics specialist processes into cost-effective polymer bearings using injection molding technology. The iglidur plain bearings are already replacing millions of metal bushings or coated metal bearings that require oiling or greasing.

In the first tests in the company's technical center, it has now been proven that iglidur Q2 e.g. B. with a pivoting movement 76 MPa radial load depending on the shaft used, performs better by a factor of 2 to 5 than all of the company's other 35 catalog materials. The combination of high wear resistance (wear = abrasion) and low deformation is decisive for the superior service life with heavy-duty swivels. The plastics specialist was the first company in the world to offer a service life calculation for plain bearings on the Internet.

The author Oliver Cyrus is Head of Press + Advertising at igus GmbH in Cologne.