Housing bearing exchange saves significant total cost of ownership

- Details

- Hits: 6354

It is often enough to exchange a small component in a large machine and you already have yours Total Cost of Ownership (TCO) under control. This is the experience that customers of NSK. The optimal housing bearing in the right quality can save up to almost 300.000 euros a year. A new example reduces bearing failures at a manufacturer of vibrating screens. He saves 117.000 euros a year here. You can find this and other examples below:

Contents

- Bearing housing for vibrating screens saves 6-digit amounts annually

- Housing bearings withstand the cleaning process in the dairy

- Durable housing bearing for lettuce harvester

- Stahlwerk replaces housing bearings and saves €292.000

- Bearing housing exchange in recycling plant saves 50.000 euros

Bearing housing for vibrating screens saves 6-digit amounts annually

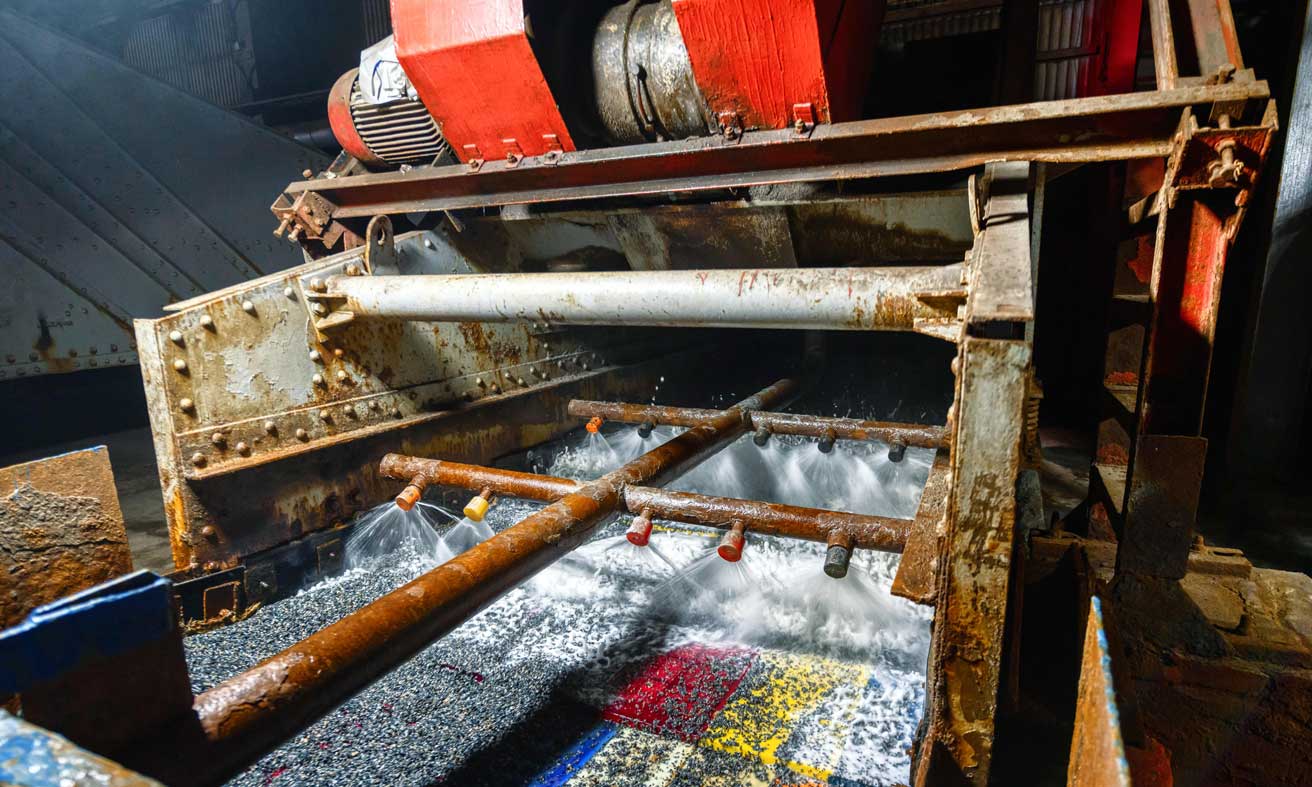

28.02.2023/XNUMX/XNUMX | A manufacturer of vibrating screens approached NSK because it repeatedly Problems with the bearing attachment recorded in the sieve units. He also wanted to reduce manufacturing costs and increase the overall performance of the screens. The vibrating screens are used in mining and quarries. They are used to classify the material, which puts a lot of strain on them every day. In particular, the drive and bearing units of the screens are affected.

NSK specialist engineers examined both the complete screening plant and the affected bearings. The problems were evident in the bearings of the vibration drives, because the mounting of the bearings was insufficient. In this situation, the company approached NSK with the task of proposing an optimized bearing design. The experts' suggestion for improvement: The highly stressed, constantly vibrating bearing should be designed as a complete, ready-to-mount housing bearing assembly. This housing bearing can then be easily attached to the machine frame without the need for complex assembly of the individual parts such as the housing, bearings and seals.

The NSK engineers designed a tailor-made housing bearing assembly, which the customer checked and approved using CAD drawings. The bearing specialist took over the assembly of the housing made of high-strength spheroidal graphite iron, labyrinth and contact seals as well as the CAM-VS type bearings. The bearings were specially developed for use in vibrating screens, among other things. The housing bearing is supplied as a complete unit - packaged, pre-greased and ready for installation with bearing support. The alternative design has meanwhile been adopted for series production.

The NSK engineers designed a tailor-made housing bearing assembly, which the customer checked and approved using CAD drawings. The bearing specialist took over the assembly of the housing made of high-strength spheroidal graphite iron, labyrinth and contact seals as well as the CAM-VS type bearings. The bearings were specially developed for use in vibrating screens, among other things. The housing bearing is supplied as a complete unit - packaged, pre-greased and ready for installation with bearing support. The alternative design has meanwhile been adopted for series production.

50 to 60% lower noise level

With the new design, not only has the performance and reliability of the housing bearings been improved under the harsh operating environments of the vibrating screen insert, the manufacturer also benefits from significantly reduced production and assembly costs for the housing bearings. The Fatigue strength against vibration and shock loads has also been increased. Wear and corrosion were reduced and the noise level was reduced by 50 to 60%. The integrated housing bearing can be greased if necessary.

The advantages of the simplified installation can even be represented in euros and cents: With the previous solution, the vibrating screen manufacturer had to budget for high expenses for housing production, stock purchase and assembly costs. He now obtains the pre-assembled bearing units from a single source and at significantly lower costs. The savings amount to around 117.000 euros annually.

Housing bearings withstand the cleaning process in the dairy

29.04.2022/XNUMX/XNUMX | More and more food and beverage manufacturers are using the Silver-Lube pillow block unit from NSK one. The housing bearings protect against the ingress of cleaning agents and washing water. At the same time, they are very resistant to corrosion. This large dairy, for example, benefits from this. The market-leading milk processing and bottling company repeatedly experienced bearing failures on five conveyor lines in its bottling plant. The housing bearings had to be replaced every sixteen weeks on average. This took about 1 hour each time. The dairy asked the NSK experts for a solution.

Clutches and brakes Use in food technology

Clutches and brakes Use in food technology

The engineers then analyzed the failed pillow block bearings. These corroded because of water during the fairly frequent washes corrosion in the bearing and also washed out the fat. The premature failures were the result. After further review of the applications and operating conditions, NSK engineers recommended replacing the existing pillow block bearings with Silver-Lube pillow block units.

In the beginning there was the housing bearing test

The plant started with a test: Silver-Lube bearings were fitted to one of the conveyor belts food grade grease assembled. This resulted in an immediate improvement and extended service life.

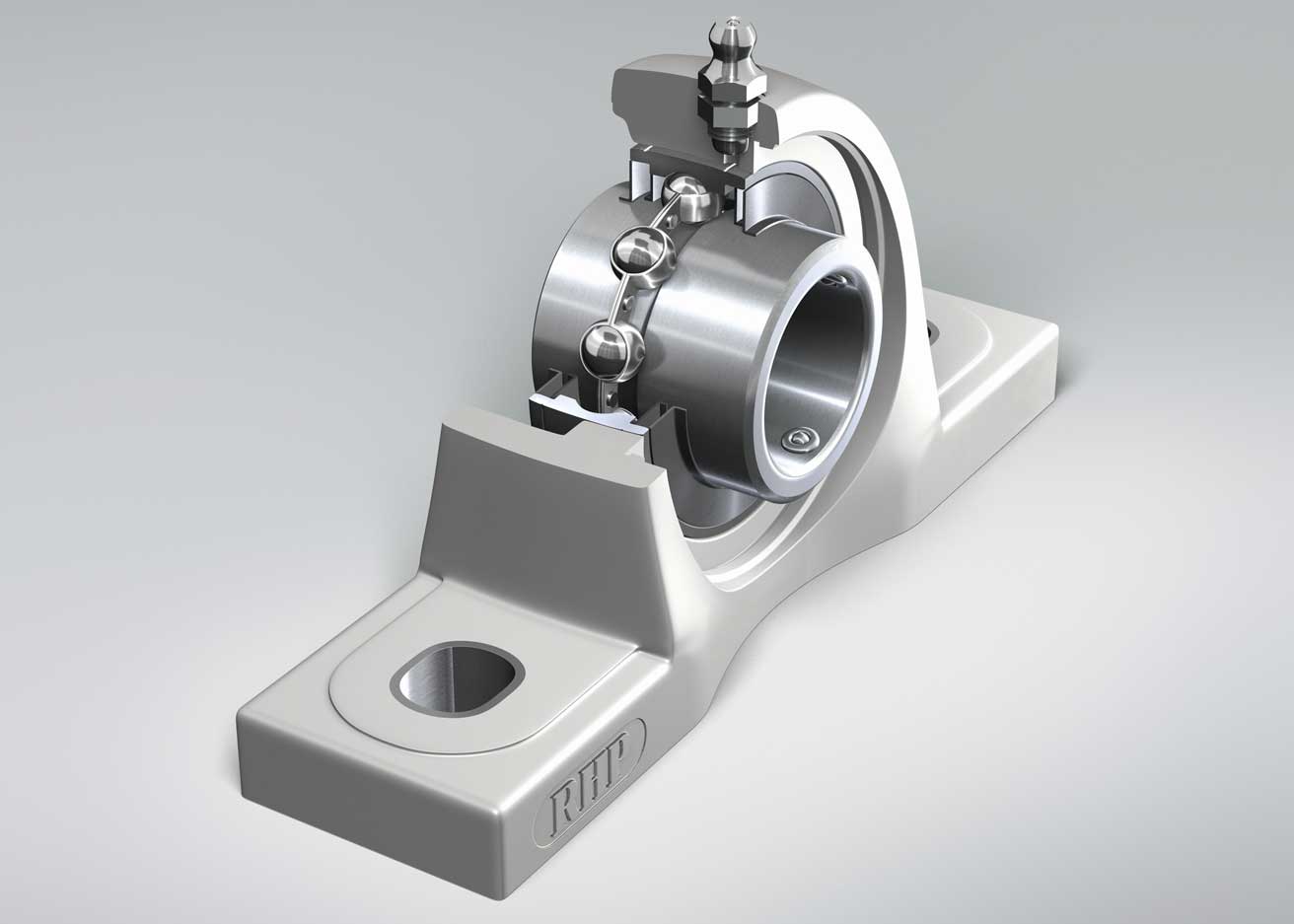

The Silver-Lube ball bearings have highly effective, heat-resistant silicone seals. These prevent the ingress of liquid and dirt. The lubricating grease also remains in the pillow block bearing. A stainless steel flinger completes the seal. This avoids contamination and protects the seal from mechanical damage. The rolling elements and rings of the bearing inserts as well as the cage, flingers and set screws are made of stainless steel. The bearing insert is mounted in a high strength PBT thermoplastic housing with a stainless steel grease fitting.

Roller chain for the high demands of food technology

Roller chain for the high demands of food technology

After successful testing, the dairy exchanged the existing bearings on all of them milk bottle conveyor systems against Silver-Lube cartridge bearings. Machine downtimes, maintenance work and bearing replacement costs are reduced. The resulting annual savings are €7625. In addition, there have been no bearing failures on the conveyor systems for more than five years.

The Silver-Lube bearing units also automatically compensate for misalignments. This is advantageous when used on filling machines and conveyor systems in the food and beverage industry. It eliminates peeling of coatings, because the plastic housing is unpainted. The dead space-free and therefore hygienic design and smooth surfaces prevent dirt from settling. The bearings withstand temperatures from -20° to +90 °C, which also makes them ideal for applications in food production and filling technology.

Durable housing bearing for lettuce harvester

21.02.2022/XNUMX/XNUMX | Machines and plants of food technology need robust and reliable Rolling from harvest to processing to packaging. These must work at consistently high speeds under often adverse operating conditions and at the same time meet high hygiene standards. The housing bearings Silver Lube from NSK meet these requirements. The following example of a harvester for lettuce shows this.

Thin section bearings as a better alternative to standard ball bearings

Thin section bearings as a better alternative to standard ball bearings

A farm that grows and packs young, small-leaved lettuce, including lettuce for picking, was having problems with a lettuce harvester. This was equipped with many inexpensive housing bearings, which the located in it shafts of different diameters store and support. Dirt and water often got into these housing bearings. This led to machine malfunctions and production losses. Sometimes the harvest was no longer even for sale.

The supplier of well-known supermarket chains turned to NSK. The storage specialists then offered, as part of the AIP (Added Value Programme) to check the application and operating conditions. As a result, they recommended replacing the pillow block bearings with NSK Silver-Lube pillow block bearings.

Housing storage free of dirt and moisture

The Silver-Lube ball bearings are robust and corrosion-resistant cartridge bearings. Your camp assignments are out Stainless Steel and are protected against the ingress of dirt and moisture by centrifugal discs and silicone seals. The seal also avoids washing out of the food-grade USDA H1 grease. The bearing housing is made of high-strength thermoplastic Plastic PBT.

The Silver-Lube ball bearings are robust and corrosion-resistant cartridge bearings. Your camp assignments are out Stainless Steel and are protected against the ingress of dirt and moisture by centrifugal discs and silicone seals. The seal also avoids washing out of the food-grade USDA H1 grease. The bearing housing is made of high-strength thermoplastic Plastic PBT.

This construction of the bearing housing protects very well against Corrosion, detergents and chemicals. Even the harsh conditions of agricultural and food technology with their dirt, dust and moisture environment as well as frequent washdown processes cannot harm the housing bearing units. A long bearing life is guaranteed.

The NSF certified Silver-Lube Pillow Block Bearings feature a paint-free polymer housing that eliminates the possibility of chipping or flaking. The smooth surface of the pillow block bearings prevents dirt from adhering, they offer a hygienic design with no dead space and withstand operating temperatures from -20° to +90 °C. The NSF certificate documents that the unit bearing units meet the strict requirements and standards of food safety.

Plain bearings novelties and applications that are fun

Plain bearings novelties and applications that are fun

Apart from the life characteristics, these ball bearings can compensate for alignment errors. They are therefore also suitable for use in conveyor systems, centrifugal separators and filling systems. In this application, downtime costs have been cut in half after converting to Silver-Lube bearings. Thanks to significantly reduced production losses and reduced service costs, the company has Savings of €63.300 to record. The Silver-Lube housing bearings are available in four housing versions: pedestal bearings, radial insert bearings and flanged bearings with two and four mounting holes.

Stahlwerk replaces housing bearings and saves €292.000

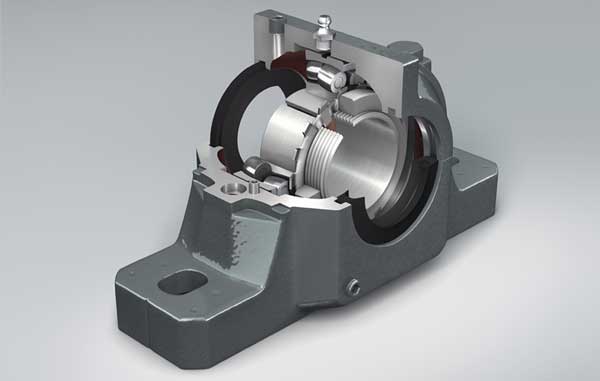

03.08.2021/XNUMX/XNUMX | In steel production, extreme temperatures, contamination, shock, moisture, vibrations and high radial and axial forces all affect the service life of the rolling bearings used here. The NSK housing bearings also came under these conditions RHP Self Lube by NSK replacing conventional bearings in a steel mill.

03.08.2021/XNUMX/XNUMX | In steel production, extreme temperatures, contamination, shock, moisture, vibrations and high radial and axial forces all affect the service life of the rolling bearings used here. The NSK housing bearings also came under these conditions RHP Self Lube by NSK replacing conventional bearings in a steel mill.

In this steel mill, up to three bearing failures on a rotary valve used to occur each year. The sluice is used to dose coal during ore processing. In addition to costs for replacement bearings, there were expenses for machine downtimes, production losses and damage to neighboring components. These added up to just under 293.000 euros annually.

The steel mill managers contacted NSK with a request for an analysis. To do this, the bearing experts checked the condition of the housing bearings and the environmental conditions on site. They found out that the housing bearings used were not suitable for the high process temperatures suit. In addition, the lubricant quantities and deadlines of the bearings were incorrect.

The NSK specialists quickly found a solution: They recommended replacing the existing pillow block bearings with customer-specific RHP Self-Lube HLT bearing inserts in Self-Lube FC cast iron housings. For mounting the pillow block they recommend a heat insulating spacer as well as a tailor-made adapter plate.

Housing bearing compensates for misalignment

The RHP Self-Lube bearing inserts consist of a housing and a bearing insert. The pillow block bearing is a sealed one single row ball bearing with spherical outer diameter and widened inner ring. It is mounted in a high-quality flange housing, which is one-piece and stable. The spherical seat of the cartridge bearing compensates for any initial misalignment during assembly.

The RHP Self-Lube bearing inserts consist of a housing and a bearing insert. The pillow block bearing is a sealed one single row ball bearing with spherical outer diameter and widened inner ring. It is mounted in a high-quality flange housing, which is one-piece and stable. The spherical seat of the cartridge bearing compensates for any initial misalignment during assembly.

The inner and outer rings of the Self-Lube pillow block unit are off hardened, high quality steel manufactured. The inner geometry has been optimized. The two-piece, riveted cage is made of high-strength sheet steel, is supplied with high-performance grease and sealed with durable silicone. The Self-Lube HLT bearing inserts withstand operating temperatures of up to 180 °C and the bearings can always be relubricated.

For the rotary valves For housing bearings in the steelworks, the NSK engineers have suggested further optimizations such as changes in the lubrication quantities and lubrication intervals. First, the engineers carried out a test. Then they monitored the installation and implementation of the recommendations given.

Product piracy: WBA app detects counterfeit rolling bearings

Product piracy: WBA app detects counterfeit rolling bearings

After more than twelve months there was still no bearing failure. This resulted in annual cost savings for the user of 292.136 €. Downtimes had previously caused the largest share of this. Further cost reductions resulted from the reduced maintenance effort and the omission of the compressed air cooling, which had controlled overheating of the pillow block unit previously used. The investment for storage optimization was more than manageable.

Bearing housing exchange in recycling plant saves 50.000 euros

24.08.2020/XNUMX/XNUMX | When operating a recycling plant, the pillow block units on the conveyor belt of the waste sorting plant have been failing for a long time and regularly. After using the plant on SNN bearing housing NSKHPS spherical roller bearings converted by NSK is what the system operator saves every year 51.174 Euros of spare parts, downtime and maintenance costs.

24.08.2020/XNUMX/XNUMX | When operating a recycling plant, the pillow block units on the conveyor belt of the waste sorting plant have been failing for a long time and regularly. After using the plant on SNN bearing housing NSKHPS spherical roller bearings converted by NSK is what the system operator saves every year 51.174 Euros of spare parts, downtime and maintenance costs.

The problem became apparent very quickly. Five housing bearings failed just 3 months after installation and commissioning. Because these failures caused costly repairs and unplanned downtime, the operator asked NSK to analyze and solve the problem.

As part of the value-added program AIP, an NSK application engineer examined the system on site. He found that improper lubrication and vibration that caused premature bearing failures. The vibrations caused the grub screws to loosen. That is why the inner ring of the bearing had turned on the shaft. In addition, the housing bearing did not offer an outlet for excess grease. As a result, the grease had collected, causing excessive heat build-up in the bearing.

Collet and mis-exit hole for problem solving

Based on these results, NSK recommended replacing the bearings with NSKHPS (High Performance Standard) spherical roller bearings with adapter sleeves in SNN bearing housings are mounted. The adapter sleeve secures the bearing so that it cannot become detached from the shaft, even if there are vibrations. The SNN bearing housings are equipped with a grease drain hole as standard. An accumulation of excess grease in the bearing is now also a thing of the past.

Based on these results, NSK recommended replacing the bearings with NSKHPS (High Performance Standard) spherical roller bearings with adapter sleeves in SNN bearing housings are mounted. The adapter sleeve secures the bearing so that it cannot become detached from the shaft, even if there are vibrations. The SNN bearing housings are equipped with a grease drain hole as standard. An accumulation of excess grease in the bearing is now also a thing of the past.

With the SNN series, NSK offers bearing housings for use under unfavorable environmental conditions. For example, they are suitable for use in conveyors the steel industry, recycling industry and mining industry. Massive corners in the bottom part of the bearing housing offer locating pins an optimal hold. A center mark ensures easy alignment. The split housing allows for easy bearing replacement. There are two lubrication holes for relubrication.

The SNN housing bearings out precision casting have high rigidity. This prevents deformation of the seal. The housing bearings also offer very good heat distribution and the choice of numerous seal variants. They can be used with either double-row self-aligning roller bearings or double-row self-aligning ball bearings. The diameter of the shaft can vary between 20 mm and 140 mm.

Bearings for everyone in over 60 industries

Bearings for everyone in over 60 industries

The NSKHPS spherical roller bearings used in the sorting plant are suitable for operation at high speeds and high loads. They are available with steel and brass cages. An optimized running surface contour, temperature stability up to 200 °C and the special surface treatment make the bearings robust. Compared to conventional bearings, these bearing housings have a 25% higher dynamic load rating on. The limit speed is 20% higher and the service life has been doubled.

By using these NSKHPS spherical roller bearings in combination with the SNN bearing housings, the operator of the recycling plant was able to reduce the number of unplanned breakdowns in the sorting plant from ten per year to zero. 50.000 Euros thus had less impact on the TCO costs.

You might also be interested in...

linear guide | Precise, light, durable

Reduce carbon footprint | That's how it's done!

Ball screw drive | Rotating ball screw

Product piracy | Protect your copyright!