solar storage | Products, technologies, innovations and trends

- Details

- Hits: 5699

In Germany, heat accounts for 55% of final energy consumption out. In order to achieve the goal of carbon neutrality by 2050, there is an urgent need to avoid using fossil fuels to meet this demand as much as possible. Instead, on the energy supplier sun be resorted to. In order to use the energy obtained effectively, it takes Solar storage. Below we report on new products and technologies that store solar power.

Contents

- Electric cars as buffer storage for solar power

- Solar storage based on optimized high-performance layers

- Archive for solar storage innovations

Electric cars as buffer storage for solar power

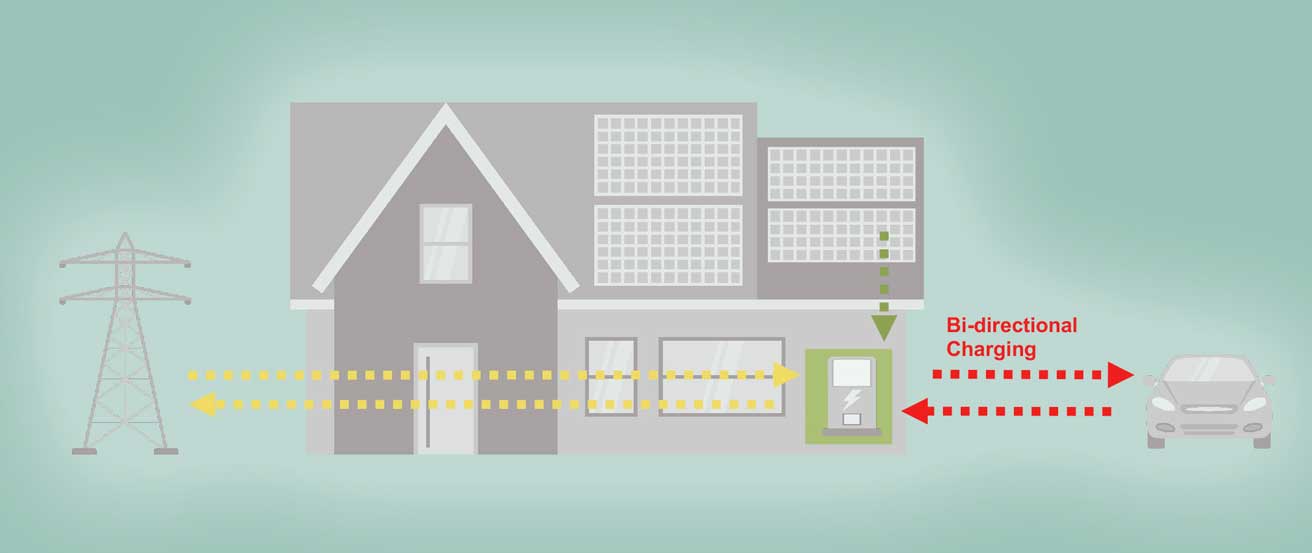

27.07.2022/XNUMX/XNUMX | On hot summer days, the share of solar power in the energy mix achieves record values. But the sun doesn't shine, let me bidirectional charging the solar power from the PV system in Electric Cars and store house batteries. If required or in the evening hours, this is then fed back into the home network for the operation of household appliances. This creates incentives for switching to zero-emission electromobility.

27.07.2022/XNUMX/XNUMX | On hot summer days, the share of solar power in the energy mix achieves record values. But the sun doesn't shine, let me bidirectional charging the solar power from the PV system in Electric Cars and store house batteries. If required or in the evening hours, this is then fed back into the home network for the operation of household appliances. This creates incentives for switching to zero-emission electromobility.

Infineon Technologies and delta electronics have developed a three-in-one system for this. It integrates solar system, home storage and charging station. The electric car is charged via a bidirectional inverter and can also be used as a buffer storage for the emergency power supply in your own home. More and more electric cars are equipped for this. In perspective, new Vehicle-to-Grid (V2G) and Vehicle-to-Home (V2H) solutions can also be implemented with bidirectional energy flows.

"In order to make a sustainable contribution to decarbonization, we have to think about electromobility holistically: from the generation of green electricity to a stable, efficient grid infrastructure to storage and consumption," says Peter Wawer, Head of Infineon's Industrial Power Control division. "With our solutions for bidirectional charging, the electric car can be charged at home with solar power at low cost and also serve as a buffer storage."

A pair of Detached consumes an average of 10 to 15 kWh of energy per day. A fully charged car battery with a capacity of 30 to 100 kWh could theoretically bridge a few days as an emergency power solution. Homeowners can thus secure cheap electricity and gain more independence in the home Power Supply.

Charging plug, charging cable | For the electric car

Charging plug, charging cable | For the electric car

This allows for an output power of around 10 kW Three-in-one system a maximum continuous current of 34 A. The peak efficiencies are more than 97,5%. Energy-efficient silicon carbide (SiC) semiconductors from Infineon are used to increase the power density. Compared to silicon-based semiconductors, the compound semiconductor SiC reduces the energy losses when converting electricity by about half. Charging stations could build about 30% smaller. With SiC, the PV system becomes more efficient. The charging times at fast charging stations and wall boxes are reduced. The range of electric cars increases by 5 to 10%.

By the end of the decade, more than half of the newly registered vehicles will be partially or fully electric. the green mobility but can only be implemented with climate-neutral energy such as wind and solar energy. For stable grids, the volatile availability of these energy sources must therefore be compensated for by electrical wind or solar storage.

Infineon will be exhibiting at the Electronica 2022.

Solar storage based on optimized high-performance layers

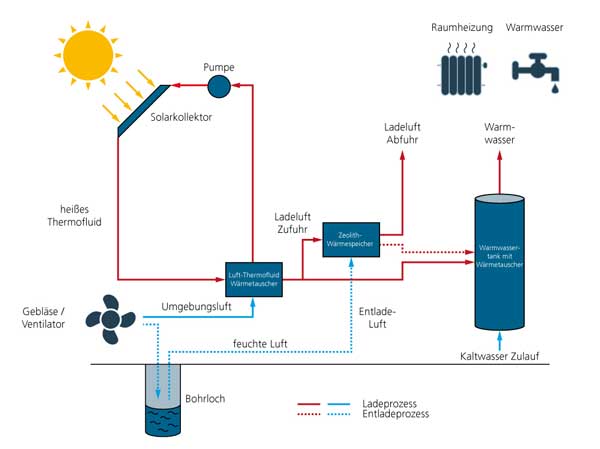

12.10.2021 | Thin film systems for Photovoltaic system and Solar Thermal help collect a broad spectrum of solar radiation for power generation and in the form of heat. The Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP vacuum technologies developed, with which layers and layer systems for the use of solar energy and the storage of heat are deposited.

Electric vehicles worldwide wireless charging with open standards

Electric vehicles worldwide wireless charging with open standards

The radiant energy of the sun, which the earth receives within 90 minutes, corresponds approximately to the worldwide energy consumption in one year. (Source: AEE). For effective absorption of the solar radiation, special layer systems are required for photovoltaics or solar thermal energy. In photovoltaics, these include semiconductor layers and electrode layers. Solar thermal requires absorber layers with high absorption in the visible and UV range and low emission in the infrared spectral range (IR) in order to minimize heat radiation losses.

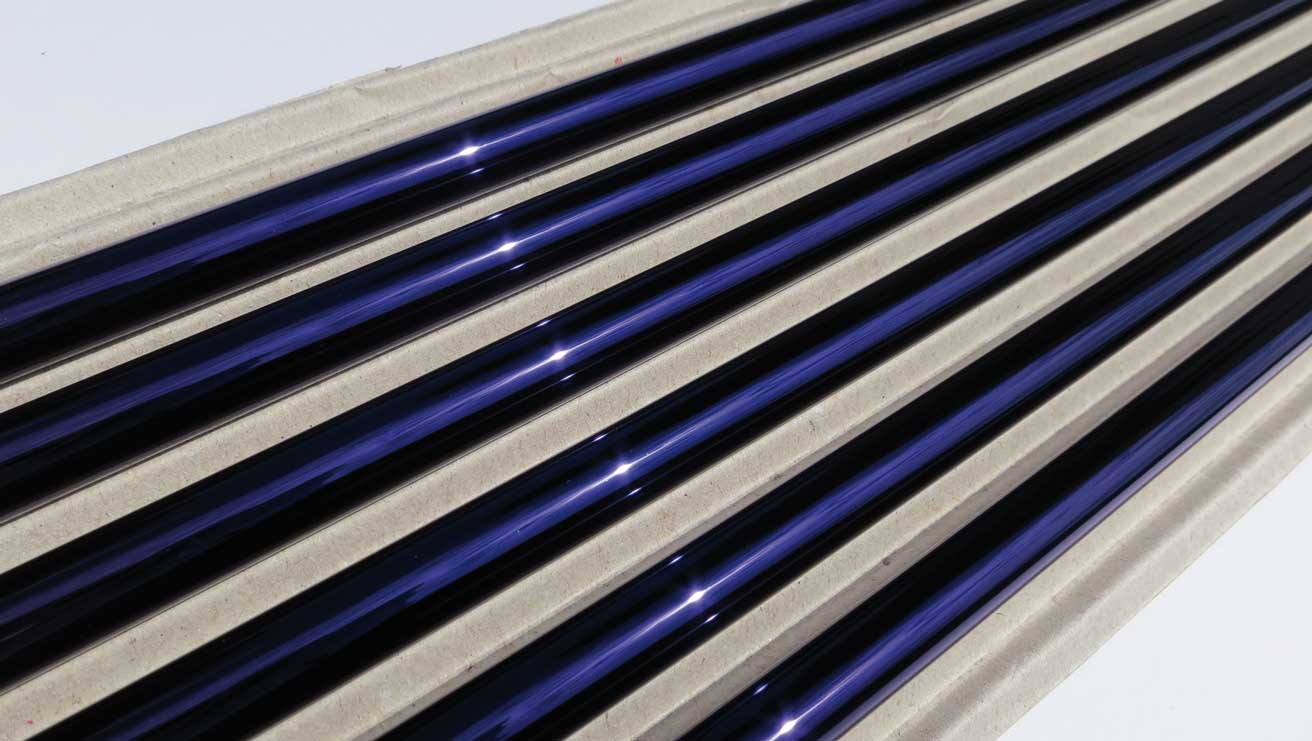

Optimized layer systems for effective solar absorbers

In order to implement such optical functions, a Layer system made up of several individual layers necessary. Their thicknesses must be matched very precisely and they must be deposited reproducibly on the absorber tubes of the low-heat-loss solar tube collectors. The absorber tube is located in an evacuated cladding tube. This protects the layer system from contamination and possible degradation from air components. The layer system has to withstand the permanently high temperatures that the absorber pipe takes on. It must be stable over the long term, even under cyclic temperature loads. The higher the temperature in the heat cycle, the more versatile and better it can be used. It can be used as process heat or is used to charge heat accumulators at high temperatures.

In order to implement such optical functions, a Layer system made up of several individual layers necessary. Their thicknesses must be matched very precisely and they must be deposited reproducibly on the absorber tubes of the low-heat-loss solar tube collectors. The absorber tube is located in an evacuated cladding tube. This protects the layer system from contamination and possible degradation from air components. The layer system has to withstand the permanently high temperatures that the absorber pipe takes on. It must be stable over the long term, even under cyclic temperature loads. The higher the temperature in the heat cycle, the more versatile and better it can be used. It can be used as process heat or is used to charge heat accumulators at high temperatures.

Coatings are also suitable for the development of more efficient solar storage systems. Extensive research is currently being carried out on electrical power storage to use the energy generated by photovoltaic systems variable in time close. The power storage should compensate for the time lag between power generation and power consumption.

Coating processes for solar storage tanks with zeolite granules

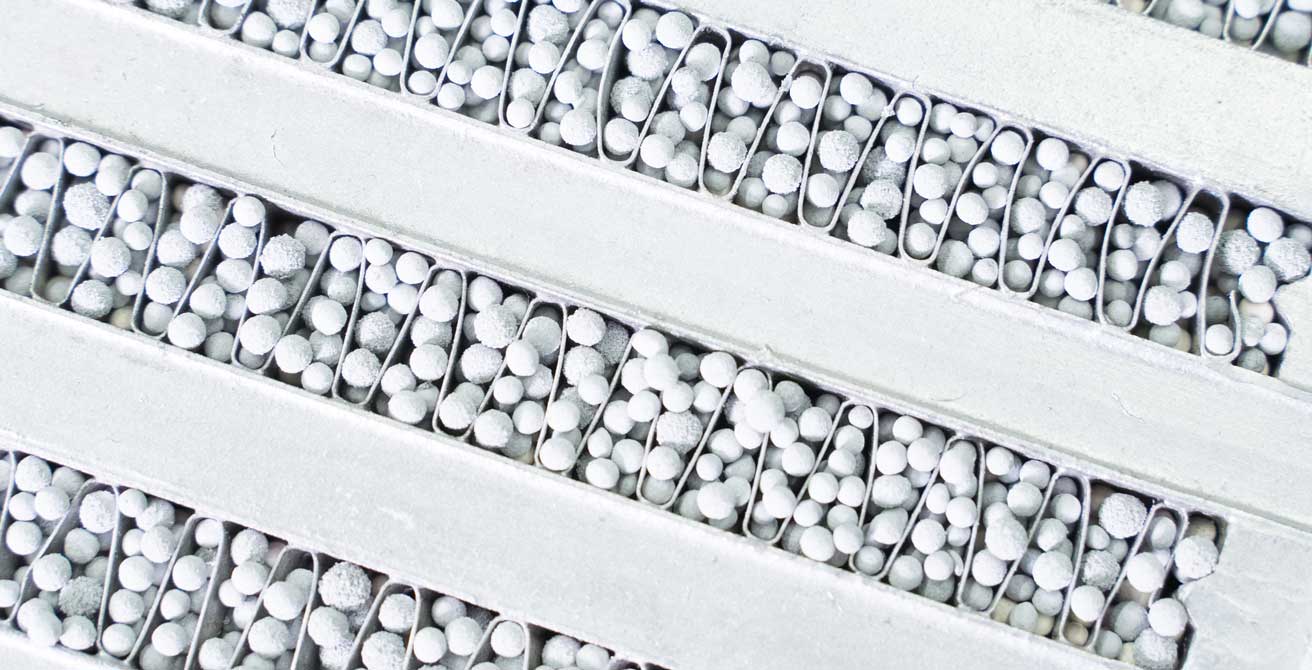

In the heating sector, this function is performed by a water storage tank in many heating circuits. However, here too better memory concepts worked. Such reservoirs are said to have a higher storage capacity than water. The storage should be installed in a space-saving and low-loss manner. For example, in adsorption heat storage nanoporous zeolite granules, water is expelled while the heat to be stored is supplied. This then corresponds to the loading of the store with energy.

"When air containing water vapor flows through the storage material, it adsorbs water and releases heat that can be used in heating circuits," explains dr Heiderun Klostermann, scientist at the Fraunhofer FEP. "In order for this to work, however, the heat exchange with the storage material must also be designed efficiently, which itself does not have good heat conduction. This can be achieved with layers of aluminum that encase the material. They ensure good heat transport and efficient heat transfer at the heat exchanger.” In addition to the adsorption and desorption dynamics of the storage material, this is an important aspect of the performance of a storage system. It has a major influence on its maximum and average specific heat output.

The granular storage material zeolite is vapour-deposited with aluminum in bulk in a vacuum. Good heat conduction requires an even, sufficiently thick layer. The FEP researchers are experimenting with layers more than 20 µm thick. The technology used for this is otherwise used to coat films. Beds of highly porous Materials Applying thick layers evenly is therefore a major challenge. Fraunhofer's previous developments are unique in this respect.

The process must be designed in such a way that the layers do not impede the exchange of substances between the storage material and the environment. After all, the material must continue to be able to absorb and release water, otherwise the storage principle will not work. Comparative adsorption curves of coated and uncoated material show that this mass transport is not hindered by the layer.

Solar storage developments for tomorrow

Developers of novel storage materials with a focus on increasing storage capacity are particularly interested in these innovative layers from Fraunhofer FEP. Such new materials are primarily hybrids that are not yet being mass-produced, as is already the case with zeolites. As a rule, these powdered hybrid materials are only produced in small quantities. In the future, these new materials will be treated in the metallization plant at the Fraunhofer FEP. Storage manufacturers are already hoping for these new classes of material higher storage density and smaller storage volumes.

Archive for solar storage innovations

- The right solar system memory: Lead versus lithium

- Solar storage provides electricity around the clock

The right solar system memory: Lead versus lithium

23.10.2013/XNUMX/XNUMX | When asked about the difference between a lithium-ion and a lead-gel battery, the user first sees the price and weight differences. It is also important to clarify questions such as: How do the two types of batteries work? Why does one last longer than the other? Why does one weigh more than the other? All of these questions will be examined Ikratos in more detail below:

23.10.2013/XNUMX/XNUMX | When asked about the difference between a lithium-ion and a lead-gel battery, the user first sees the price and weight differences. It is also important to clarify questions such as: How do the two types of batteries work? Why does one last longer than the other? Why does one weigh more than the other? All of these questions will be examined Ikratos in more detail below:

Lead-acid battery

A pair of lead acid battery consists of an acid-proof housing and two lead plates, which serve as positive and negative polarized electrodes. In addition, there is a filling of 38 percent sulfuric acid H2SO4 as an electrolyte.

With lead-gel batteries, as used in the IBC Solstore Pb Home, the sulfuric acid is bound by adding silicic acid and the battery is sealed. Because of that he is almost completely maintenance free, since it is no longer necessary or possible to add water. In the discharged or neutral state, a layer of lead(II) sulfate (PbSO4) on. When charged, the positive electrodes are lead (IV) oxide (PbO2), the negatively polarized electrodes of finely distributed porous lead, also called lead sponge. By the chemical reaction during the charging and discharging electrical energy can be stored or delivered.

Lithium-ion battery

In lithium-ion accumulators There are lithium atoms on the negative electrode and transition metal ions on the positive electrode. Electrical energy is stored as the lithium in ionized form moves back and forth through the electrolyte between the two electrodes. Hence the name of the lithium-ion battery.

Drives for extending and retracting a solar folding roof

Drives for extending and retracting a solar folding roof

In contrast to the migrating lithium ions, the transition metal ions are stationary. When discharging, lithium atoms at the negative electrode give off an electron, which flows to the positive electrode via the external circuit. At the same time, the same number of lithium ions migrate through the electrolyte from the negative to the positive electrode. At the positive electrode, however, it is not the lithium ions that take up the electron again, but the ones that are present there and are strongly ionized in the charged state and therefore right electron hungry transition metal ions. Depending on the battery type, this can be cobalt, nickel, manganese, iron ions and so on.

Decades long life

High-quality lead-acid batteries, which are used in solar power storage systems, can be quite long life span of around 10 years before there is a significant drop in performance. The aging and thus the wear and tear of the lead-acid battery is primarily due to the internal corrosion of the electrodes. In addition, there are always fine short circuits. The sulphation of the lead also causes the PbSO4 Merge crystals into larger and larger alliances.

However, sulfation can be counteracted with the right charging and discharging strategies. That is why it is important for solar storage systems to use the charge controller and batteries as a complete system optimally matched are. With current lithium-ion batteries, the cycle life determines how long the battery can be used. This depends on the type and quality of the battery, the temperature and the type of use - in particular (dis)charge stroke, end-of-charge voltage and strength of the charging and discharging currents.

Facts and components from and for battery production

Facts and components from and for battery production

As with lead-gel batteries, lithium-ion batteries are the right ones battery management system of great importance in order to achieve the desired service life. There are already cells for special applications that only lose a very small part of their capacity and performance even after several years of use and several 10.000 charging and discharging cycles.

Weight difference up to factor 6

The energy density of lead-acid batteries is around 30 Wh/kg. The energy density of lithium-ion batteries, on the other hand, is between 95 and 190 Wh/kg, i.e. 3 to 6 times higher than that of a conventional lead-acid battery. As a result, lithium-ion batteries are significantly lighter than lead-acid batteries with the same capacity. In a practical comparison: The 4 batteries of an IBC Solstore Pb with a nominal capacity of 8 kWh together weigh 300 kg, with the housing 350 kg. The battery block (battery, battery management and housing) of the IBC Solstore Li (nominal capacity 5 kWh) weighs 122 kg.

Newcomer versus the proven

It is up to each customer to decide which battery to use. On the one hand there is the classic lead-gel battery, which has been tried and tested for decades and will certainly continue to shape the image of the battery market for years to come. On the other hand, there is the newcomer lithium-ion battery. With different electrode materials, he unsettles the consumer with regard to reliability and dangerous goods regulations as well as the wealth of information. However, the lithium-ion battery is already bringing technology enthusiasts to their side.

In summary, one can say that both battery technologies are very suitablen in order to promote the maximization of the use of the self-generated energy from our own photovoltaic system and the needs of consumers for independence in the purchase of electricity.

Solar storage provides electricity around the clock

13.03.2013 | Centrosolar offers storage systems for solar power from April. This means that the electricity produced by photovoltaic systems is available around the clock. The "Cenpac Storage" system is based on battery storage, a battery inverter and an intelligent energy manager. Depending on requirements, the solar power supplies electrical consumers, charges the battery or flows into the public grid. While households without storage can typically use a maximum of 30% of the solar power themselves, the proportion can be more than doubled with storage support.

13.03.2013 | Centrosolar offers storage systems for solar power from April. This means that the electricity produced by photovoltaic systems is available around the clock. The "Cenpac Storage" system is based on battery storage, a battery inverter and an intelligent energy manager. Depending on requirements, the solar power supplies electrical consumers, charges the battery or flows into the public grid. While households without storage can typically use a maximum of 30% of the solar power themselves, the proportion can be more than doubled with storage support.

The batteries used are based on the Lead Gel Technology and are available in usable sizes of 3,7, 6,0 and 7,4 kWh. The sizes are predestined for single-family households with PV system sizes of up to 6, 9 and 10,5 kWp. The batteries have a service life of approx. 2500 cycles at 50% depth of discharge and are therefore particularly suitable for use in solar applications with high charging and discharging loads.

A family of four with an annual electricity consumption of 4000 kWh can use Cenpac Storage with a battery size of 7,4 kWh up to 85% of the daily electricity requirement cover with solar power. Thanks to storage, the system operator can call up the electricity when he needs it – regardless of whether the sun is shining.

Air circuit breaker, digital protection relay and soft starter

Air circuit breaker, digital protection relay and soft starter

The battery storage is supplemented by the one specially developed for self-consumption battery inverter Sunny Island from SMA. This can be installed like a PV inverter and can be used flexibly for different battery sizes. The Sunny Home Manager takes care of the interaction of the entire system.

This energy management system regulates the flow of energy between the solar system, storage system, household and public grid. The system monitors all system components and ensures intelligent energy management. The Sunny Home Manager determines recommendations for action based on the household's consumption profile, the location-based weather forecast and the resulting PV generation forecast.

You might also be interested in...

Infrared camera optimizes Laser Powder Bed Fusion 3D printing

Artificial Intelligence | trends and developments

3D printer | Additive manufacturing of plastic parts

3D printer metal | Amazing Possibilities

Programming Robots | software and controls

Plastics development: Bio-based, circular plastics for more sustainability

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.