Igus energy chain: stable, recyclable, plastic.

- Details

- Hits: 21099

The portfolio of Igus Energy chain is happy about the first rack from the 3D printer and a world first: With the first fully recycled fully recycled cradle chain the circular economy is promoted. The smallest pluggable Readychain Micro speedMicro speed can also be connected 80% faster. We have compiled these and other new energy chains and applications for you below.

Contents

- Innovations in energy chain systems

- First e-chain rack from the 3D printer

- World's first 100 percent recycled e-chain

- Small pluggable energy chain installed 80% faster

- Igus energy chain for rotational movements saves 73% costs

- Rollers and sliding shoes increase the service life of the E4.1

- 83% lighter telescopic energy chain for robots

- Energy chain E4Q with new interior layout

- Energy chain delivered completely with a click in three days

- Put together energy chains optimally for clean room technology

- Hybrid energy chains made of plastic and steel for height

- Autoglide energy chain without guide trough saves 88% installation time

- World's first recycling program for energy and drag chains

- Behind the Scenes - Cables and Wires - Interview

- applications and users

- Energy chain in pipeline maintenance robots

- Energy chains defy dust and dirt in aluminum oxide production

- 25 energy chains for de-icing aircraft

- Powerful energy chain meets modular connector

- Igus-Harting technology cooperation at SSI Schaefer

- Energy chains for cables and hoses in cutting systems

- Heavy bridge slightly lifted with safe energy supply

- Vector Award

- Archive for energy chain innovations

Innovations in energy chain systems

No sooner have you become familiar with a new development at igus than the Cologne-based company is already bringing the next innovation onto the market. And if you think plastic isn't exactly environmentally friendly, then you haven't found out about the wide range of recycling activities at the Motion Plastics specialist. Even composting is already possible today. But discover the innovations for yourself:

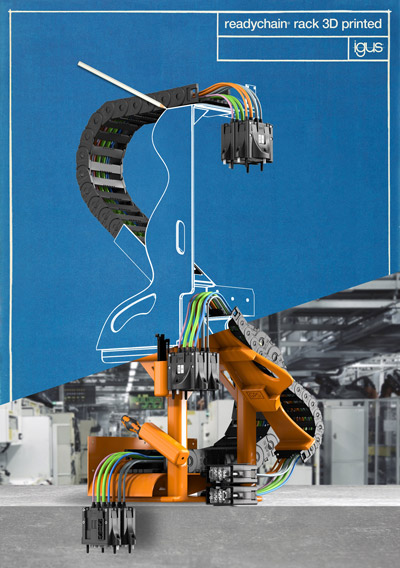

First e-chain rack from the 3D printer

25.08.2023/XNUMX/XNUMX | igus has for its proven assembly and transport frame Ready chain rack developed an even simpler, faster and unlimited customer-specific solution: The Readychain P-Rack (printed rack) manufactured using 3D printing can be adapted to the respective customer requirements with millimeter precision.

25.08.2023/XNUMX/XNUMX | igus has for its proven assembly and transport frame Ready chain rack developed an even simpler, faster and unlimited customer-specific solution: The Readychain P-Rack (printed rack) manufactured using 3D printing can be adapted to the respective customer requirements with millimeter precision.

"The P-Rack is a very flexible and simple addition for Readychain customers to be able to use the advantages of an individual solution even faster. Because all add-on parts are printed within 36 hours," says Christian Stremlau, Head of the Readychain and Readycable division at igus.

From batch size 1 and significantly lighter

“So customers are completely free in design of the P-Rack. With the 3D printer an ergonomic design with round shapes can also be implemented - without interfering contours or risk of injury from sharp edges. Additional elements such as tool holders, holders for small parts or lettering can be printed as required.” This optimal built-in solution pays off from just one piece.

That by up to 80% reduced Weight saves resources and makes handling much easier and safer. The smooth-running construction saves up to 66% installation effort. Assembly and disassembly are tool-free. Despite the lightweight construction, the 3D-printed frame is highly resilient. This has been extensively tested in our in-house laboratory. All add-on parts can also be printed from corn starch. The material is very robust and absolutely "rustproof". The material is compostable and 100% regranulatable and reusable.

World's first 100 percent recycled e-chain

11.05.2022/XNUMX/XNUMX | 'From the cradle to the cradle' is the principle of the circular economy, which is based on nature. Consumables and consumer goods should be returned to the biological or technical cycle. With the new one Cradle chain E2.1.CG Energy chain igus once again saves resources and extends the product life cycle. The world's first energy chain made from recycled material was developed on the basis of our own energy chain recycling program chainge

“The purchasing decisions of our customers are increasingly influenced by ecological considerations. That's why we put a lot of effort into our product development to be able to produce even more resource-efficiently - without sacrificing product quality," explains Joerg Ottersbach, Head of the E-Chain Division.

CNC control for retrofitting machine tools

CNC control for retrofitting machine tools

The Cradle-Chain E2.1.CG is a complete range of energy chains made from the new material Igumid CG. The new energy chain has almost the same technical properties and load limits as the energy chain made from the standard material Igumid G and is priced the same. The new portfolio includes five series and 28 chain types from stock.

Sustainable raw material cycle and 28% CO2 saving

As part of the Chainge recycling program, over 32 tons of material from 13 countries collected. For 2022, igus has set itself the goal of increasing this sum to 500 t. The old material is sorted according to type, cleaned, regranulated and processed to new quality. This is possible with the help of a chemical analysis and the so-called formulation tuning. In this process, the material is optimized with regard to the desired properties, resulting in constant product quality. The cradle chain has no loss of quality in terms of wear, stability or bending fatigue.

According to the Environment Product Declaration, the sustainable raw material cycle saves 28% CO2 saved. “The focus should not only be on the first use of products, but also the use of raw materials after use must receive more attention. We see a lot Cradle to Cradle potential and strive to recycle as many raw materials and discarded products as possible so that valuable resources are not wasted but used sensibly for as long as possible," comments Jörg Ottersbach.

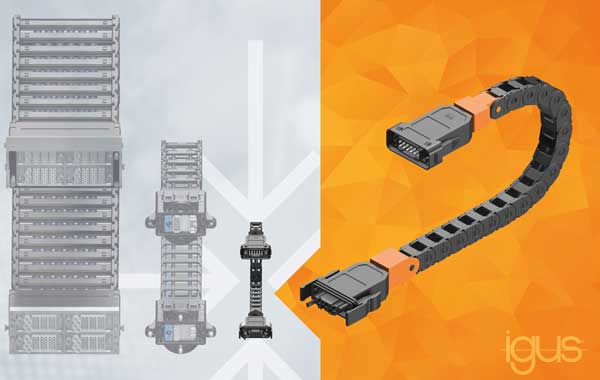

Small pluggable energy chain installed 80% faster

21.01.2022/XNUMX/XNUMX | The pluggable Readychain Speed system from igus connects a ready-made energy chain within seconds without tools. With that you can Lines just as quickly as the power cord of a laptop. This reduces assembly throughput times, machine downtime and maintenance work to a minimum. The new Readychain Micro speed Chain is suitable for particularly small applications and really tight installation spaces.

21.01.2022/XNUMX/XNUMX | The pluggable Readychain Speed system from igus connects a ready-made energy chain within seconds without tools. With that you can Lines just as quickly as the power cord of a laptop. This reduces assembly throughput times, machine downtime and maintenance work to a minimum. The new Readychain Micro speed Chain is suitable for particularly small applications and really tight installation spaces.

The Ready Chain Micro-speed energy chain is only 20 mm wide and high (inside). An example of use with little space is a door lock in the machine tool. When using the Ready Chain Micro-speed, the cores of a cable do not have to be separated from the terminal strips using tools before they can be changed. For this purpose, the energy chain has integrated Plug and the line is fully connected on both sides. The entire assembly is therefore pluggable.

As a counterpart, an add-on housing with socket can be flanged onto the machine housing. If a change is required, the energy chain is simply replaced after the Plug-in principle exchanged. Any employee can do this without having to worry about making mistakes. “Thanks to this flexibility, the reaction speed increases in the event of failures, so that downtimes can be reduced many times over. And that with little investment, says Markus Hueffel, Product Manager Readychain at igus.

Safety brake protects Robco robot kit

Safety brake protects Robco robot kit

The interface tailored exactly to the application is almost freely configurable. Like the larger Readychain speed chain, it can be combined with Chainflex cables such as fiber optic cables, power cables, Ethernet cables or bus cables. "The necessities Plug, housing and connections can be planned individually,” emphasizes Mr. Hüffel. "In this way, the customer gets everything from a single source and every energy chain becomes a tailor-made machine part."

Igus energy chain for rotational movements saves 73% costs

23.09.2021/XNUMX/XNUMX | The small Rotary module PRM (Polymer Rotation Module) has Igus for Robot, handling and camera systems were developed in which media guides perform tight rotational movements. The new energy chain is light, compact and consists entirely of Plastic in the form of a polymer energy chain and a low-friction plastic guide channel. With the rotary energy supply, users can increase the service life of their machine and system and save up to 73% in purchasing costs compared to a comparable steel guide trough. The e-chain expands the range of complete sets that can be ordered directly online.

So that cameras Robotic or handling systems can do their work in 24/7 operation in production, their media must be well protected. In addition to slip rings, rotary energy supply systems are often used, which move cables and hoses safely in rotation at 360 degrees. "In our previous rotary modules, the chain was always placed in a steel channel," says Michael Berteit, Sales Manager Engineering Projects and Assembly Service at Igus GmbH. "The channel constituted a high cost factor, which was not always attractive for users of smaller applications in particular."

Specially for compact rotary movements the motion plastics specialist has now developed a channel made entirely of plastic, relying on wear-resistant and therefore durable high-performance plastics. As a result, the user receives a system that is up to 73% more cost-effective and is also up to 85% lighter than a steel channel. The plastic channel is protected against corrosion. The new energy chain has already proven its high stability in the test laboratory by over three million double strokes withstood.

Can be ordered online as a complete package

Compared to slip rings, the cables in the PRM energy chain are given a defined movement. Several media can also be managed at the same time. The chain can be adjusted and media guides can be quickly exchanged in the event of maintenance. The new e-chain is available as a complete set with an outer diameter of 200 mm to 0,5 meters in the online shop.

There are also linear traverse paths from 8 to 200 meters in length finished kits. They consist of an energy chain from the robust E4.1 series, the corresponding connection elements, strain relief, dividers, guide trough with or without slide rail, suitable assembly sets and a screwdriver. If the energy chain is no longer in use due to the service life of the machine, igus takes it back and ensures that it is sorted for recycling. The user receives a credit note for this.

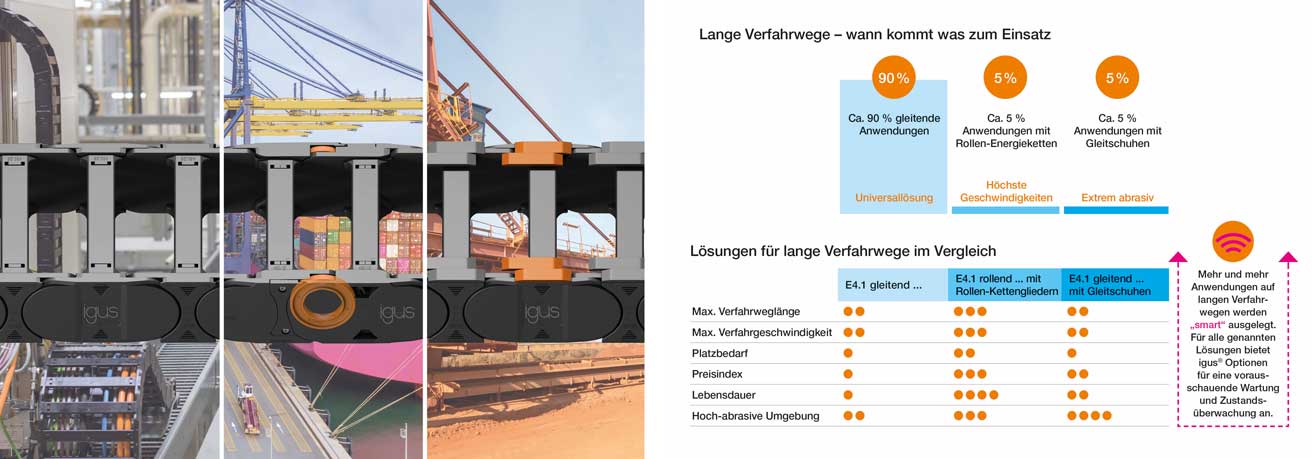

Rollers and sliding shoes increase the service life of the E4.1

28.05.2021/XNUMX/XNUMX | on long travels an energy chain is the method of choice for guiding media safely. In most applications, customers rely on the stable modular system of the E4.1 universal energy chain. igus has now expanded the system with sliding shoes and roller chain links for quick retrofitting. In abrasive environments and at very high speeds or with an extreme travel length, the durability of the systems can be increased quickly and cost-effectively.

More than 25.000 Igus energy chains move along long distances every year Storage and retrieval machines, STS cranes or portal robots. The modular and robust energy chain E4.1 is suitable for this. Their rear grip ensures high torsional rigidity. The energy chain runs quietly and is variable in height and width. The E90 is a universal solution in 4.1% of gliding applications.

Tool-free and safe cable entry and entry

Tool-free and safe cable entry and entry

Especially for extending the life of the energy chain in abrasive environments the sliding shoes were developed. With them, the chain can be easily upgraded. The wear-optimized sliding elements can be easily attached to the chain links on the inner radius. They consist of a highly abrasion-resistant Igumid polymer, which can double the service life of the energy supply system at travel speeds of 1 m/s to 3 m/s.

Gliding, rolling, condition monitoring on long travels | seminar

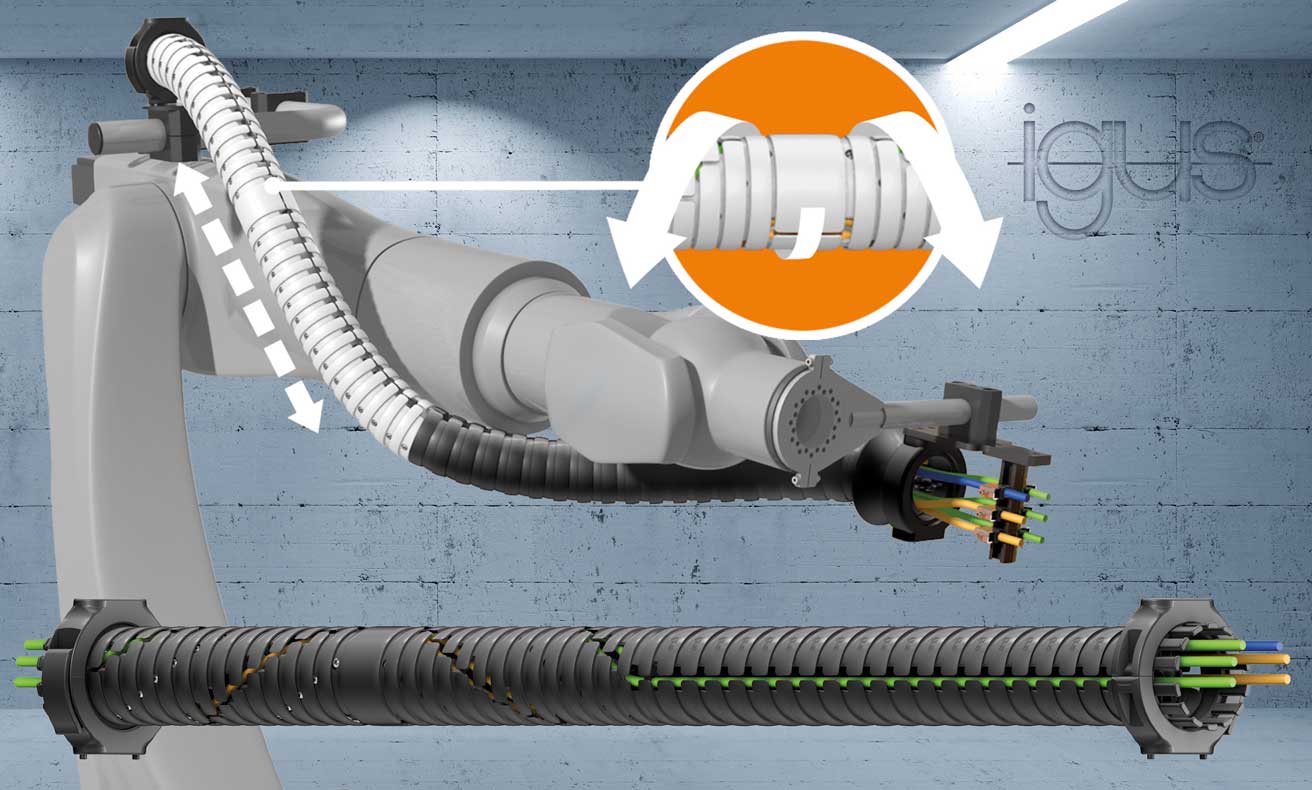

Telescopic energy chain for robots

06.05.2021 | For safe, easy and compact guiding of the cables and wires Igus presents the four-dimensional energy chain in motion Triflex TRX. This new design study replaces classic robotic hose packages and retraction systems. A special telescopic mechanism inside the chain enables a retraction path of 40%. This allows users to save up to 83% weight on the third robot axis and the high costs for retraction systems.

The three-dimensional Triflex R energy chains are in the Manufacturing Already widely used for routing cables, lines and hoses on robots in a fail-safe manner. So far come Withdrawal systems on the third robot axis to prevent loops when the energy chains move.

Function of the Triflex R energy chain

"The axles on the robots offer less and less space, so a new solution had to be found," says Joerg Ottersbach, Head of the E-Chain Business Unit at Igus. So the developers developed the Triflex TRX system based on the Triflex R energy chain. This is a four-dimensional energy chain in which the retraction system is already integrated. “With TRX we are creating a space-saving energy chain that can be fixed directly and compactly on the third axis. The energy supply twists, lengthened and shortened spirally like a telescopic extension by up to 40 percent, ”says Ottersbach.

To this end, the plastics specialist relies on unique mechanism on a Screw connection and an integrated reset strap. The band always leads the chain links to their starting point, the retraction force is adjustable. The cables and lines are laid in the form of a helix in the chain and safely guided in movement by means of the e-chain. The cables and hoses are also fixed in the middle of the TRX so that they do not leave their position when the cable guide is pulled.

83% lighter and more than half the space savings

Compared to retraction systems from other manufacturers save users with the Triflex TRX up to 83% weight. They also take up less than half the space. The performance of the robot can be further improved in this way. The costs of doing without an additional retraction system are significantly reduced. TRX can be easily connected to the existing Triflex R energy chain from the TRE series. The cables can be quickly inserted into the cable duct from the outside.

Energy chain E4Q with new interior layout

27.01.2021/XNUMX/XNUMX | To ensure lines at long travels to lead, igus has developed the self-supporting energy chain E4Q. Their lightweight design is bionic inspired. It should be simple and easy to assemble and master unsupported and long distances. Thanks to the naturalistic design, material and 10% weight are saved. The new energy chain is also more robust than its predecessor series E4.1. The energy chain can be opened and closed without tools using a special opening bar. The user saves 40% in assembly time.

27.01.2021/XNUMX/XNUMX | To ensure lines at long travels to lead, igus has developed the self-supporting energy chain E4Q. Their lightweight design is bionic inspired. It should be simple and easy to assemble and master unsupported and long distances. Thanks to the naturalistic design, material and 10% weight are saved. The new energy chain is also more robust than its predecessor series E4.1. The energy chain can be opened and closed without tools using a special opening bar. The user saves 40% in assembly time.

The jury of the German Design Awards 2021 convinced. So that the E4Q can be filled with cables and lines even faster, it has also been given a new, flexible interior division, consisting of universal dividers and lockable intermediate shelves. The cable-friendly dividers have a grid for inserting the shelves. To assemble the interior separation, the dividers are first placed on the opening bars. The shelves can then be pushed into the required level on both sides.

Slide and crossbar make assembly easier

The Lock the shelves positively. So they stay safely in place even at high accelerations. “Even if the fitter forgot to secure the shelf, that's no problem,” explains Jörg Ottersbach. "When the crossbar is inserted, the lock is automatically activated. A very easy and safe concept for all cases. "

To change the internal division of the energy chain, the user opens the crossbar in the inner or outer radius, whichever is more accessible. He unlocks the intermediate floor using the slide on the side and pulls it out. The new interior layout is available in four E4Q sizes with different widths.

The E4Q energy chain is available in the online shop. You can im Energy chain experts can be configured with cables and the interior layout. The complete energy supply has a guarantee of up to 36 months. The customer can generate the certificate online using the lifespan calculator. If the energy chain is no longer needed due to the service life of the machine and system, the manufacturer takes it back and guarantees pure recycling. The user receives a credit for this based on the net weight.

Energy chain complete as a set delivered in three days with a click

23.11.2020/XNUMX/XNUMX | Users can now easily and quickly create their Energy chain in the online shop Order from Igus and assemble it yourself. Such a kit consists of an E4.1 energy chain, aluminum channel, separators, strain relief and screwdriver. The time-consuming configuration of the energy supply in the complete set, which is available from stock in three interior heights for travels from 8 to 24 m, is no longer necessary.

In the Purchase of an energy chain For cables and wires, the user often has to go through several steps in the ordering process in order to put together the shopping cart correctly for his energy supply. Usually he can find the right type of chain quickly, but often needs accessories such as a gutter or suitable connection elements.

"Any Chain configuration is individual like every application, so the customer has a large selection with us. The energy chain expert helps to configure and order the energy supply, ”explains Jörg Ottersbach. "However, there are also customers, for example in the field of sewage treatment plants, in sawmills or in the chemical industry, who are looking for a simple, complete solution that can be ordered quickly."

What the complete energy chain set contains

For them, the Motion Plastics specialist now offers Travels from 8 to 24 m a complete energy chain set directly from stock. Longer travels can be ordered with the help of the energy chain expert. The kits consist of an energy chain from the robust E4.1 series, strain relief, dividers, the corresponding connection elements, an aluminum guide trough with and without a slide rail, suitable assembly sets and a screwdriver.

The energy chain in the set is available in three different interior heights from 32 mm to 56 mm. The ordering process is easy: In the online shop, the customer only has to decide on the inside height of the chain and the desired total length, inside width and bending radius. With one click, the energy chain kit ends up in the shopping cart.

Put together energy chains optimally for clean room technology

13.08.2020/XNUMX/XNUMX | For the almost particle-free guidance of cables in clean room technology, igus has the energy chain e-skin flat developed. This is available as a version with single pods or single chambers. This means that the chain can be fitted more quickly and cables can be easily replaced.

13.08.2020/XNUMX/XNUMX | For the almost particle-free guidance of cables in clean room technology, igus has the energy chain e-skin flat developed. This is available as a version with single pods or single chambers. This means that the chain can be fitted more quickly and cables can be easily replaced.

Hybrid energy chains made of plastic and steel for height

08.04.2020 | The energy chains Hybrid series YE from igus is 50% lighter than conventional steel chains and offers 50% more unsupported length than a plastic cable carrier. The hybrid chains made of steel and plastic are therefore particularly stiff.

08.04.2020 | The energy chains Hybrid series YE from igus is 50% lighter than conventional steel chains and offers 50% more unsupported length than a plastic cable carrier. The hybrid chains made of steel and plastic are therefore particularly stiff.

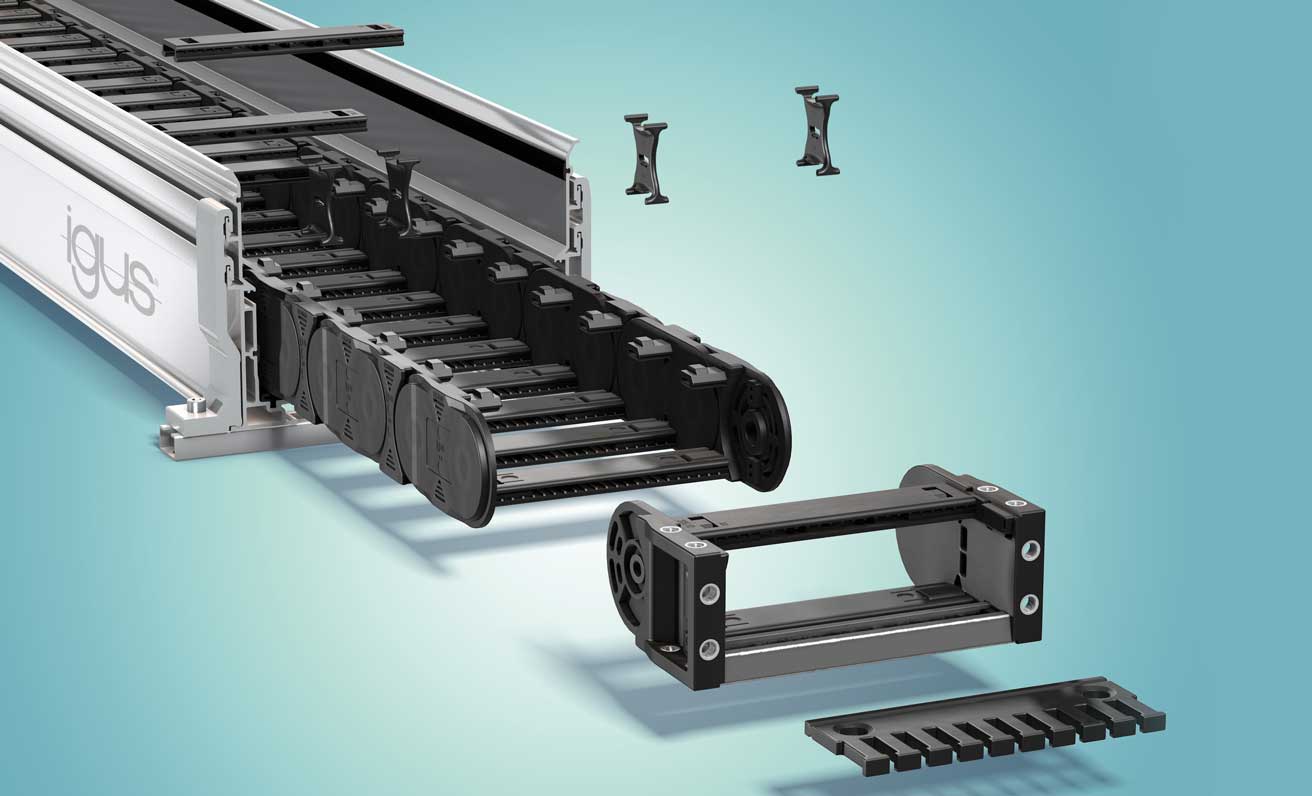

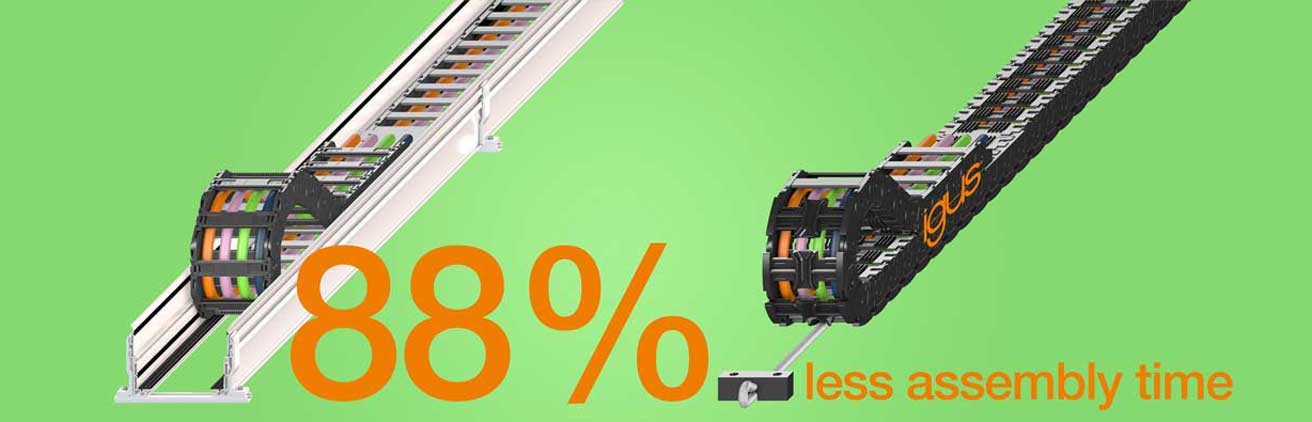

Energy chain without a guide trough saves 88% assembly time

24.03.2020/XNUMX/XNUMX | Transporting energy safely and inexpensively over long distances was the goal when developing the energy chain autoglide by Igus. The new energy chain was specially designed for horizontal applications in intralogistics and on crane systems. The energy supply lies on a tensioned cable with the help of a special underside construction. Compared to cable carriers in a trough system, the Autoglide 5 saves 88% time during installation.

For the Energy and data transmission in confined spaces and on fast aisle journeys such as those of the storage and retrieval machines, many users use power rails. However, they are difficult to maintain, can only be used for energy transmission as standard and must be cleaned regularly to avoid contact faults.

In order to be able to safely route horizontal cables and lines at speeds of up to 4 m/s and a travel distance of up to 80 m without a trough, the Cologne-based company has developed a new energy supply system. “The Autoglide 5 is easy to set up in the aisle on a rope or profile. This design is inexpensive and reduces installation time by 88% compared to gutter systems. In addition, it is maintenance-free,” explains Christian Strauch, branch manager intralogistics at the motion plastics specialist. "This means that the energy chains for routing horizontal cables and lines are a real alternative to conductor rails."

Conduct electricity and data safely without a gutter

To install the Autoglide 5, the intralogistics specialist only needs the one supplied Metal rope, which he stretches on the floor of the alley. Alternatively, it can also be guided using a plastic cable or a profile. The energy chains can move safely on the rope because the developers have come up with a special guide concept.

To install the Autoglide 5, the intralogistics specialist only needs the one supplied Metal rope, which he stretches on the floor of the alley. Alternatively, it can also be guided using a plastic cable or a profile. The energy chains can move safely on the rope because the developers have come up with a special guide concept.

The underside of the chain link has a guide element in the middle, via which the energy chain is placed securely on the rope. For a wear-resistant and precise rolling of the chain's upper run on the lower run, the developers relied on the Autoglide elements. Comb-like splash guard bars prevent the cable guide from breaking out in this system.

Energy chain with convenient maintenance

busbars or the contacts of the pantograph are very susceptible to wear and have to be replaced after just one to two years. The durable and maintenance-free cable carrier Autoglide 5 consists of high-performance plastics and has a long service life. The plastics specialist is currently checking these in its own 3800 m² test laboratory. Here the chain already convinced with its quiet running. At a speed of 2 m/s, the measured value was 63 dB(A).

"Since the Autoglide 5 has no open contacts in contrast to the power rail, the aisle is easy to clean," says Christian Strauch happily. The energy chain is available as a fully assembled system as a readychain with highly flexible Chainflex cables.

World's first recycling program for energy and drag chains

06.11.2019 | What happens when the maximum service life of a plastic energy or drag chain is reached? In most cases, it is simply disposed of with other plastic waste. With Green chain recycling the motion plastics specialist is now going down a new path.

06.11.2019 | What happens when the maximum service life of a plastic energy or drag chain is reached? In most cases, it is simply disposed of with other plastic waste. With Green chain recycling the motion plastics specialist is now going down a new path.

Interview: Behind the scenes - cables and wires

10.07.2019/XNUMX/XNUMX | Every year, igus presents, among other things, numerous new energy chain innovations. We took a look at where these come from. During our look behind the scenes at the Motion Plastics specialist in Cologne, we were Rainer Rössel, Head of GB Cainflex cables, speech and answers to the following questions:

- You bid with the Chainflex-Leads for moving applications a whole tangle of cables. How extensive and special is your range?

- What Highlight 2019 stand out among this diversity?

- Some companies are currently dealing with the Single-pair Ethernet-Technology: To what extent are you on board here?

- Ready-made, assembled drive lines ready for dispatch in up to 2 days Quantity 1: How does the ordering process take place from receipt of order to delivery?

- They ran a great test laboratory: What stress do you put your cables there?

Applications for igus energy chains

The list of industries for which igus energy chains supplies is long. Listing them all would go beyond the scope. So we've selected a few for you. The users also have their say in the reports.

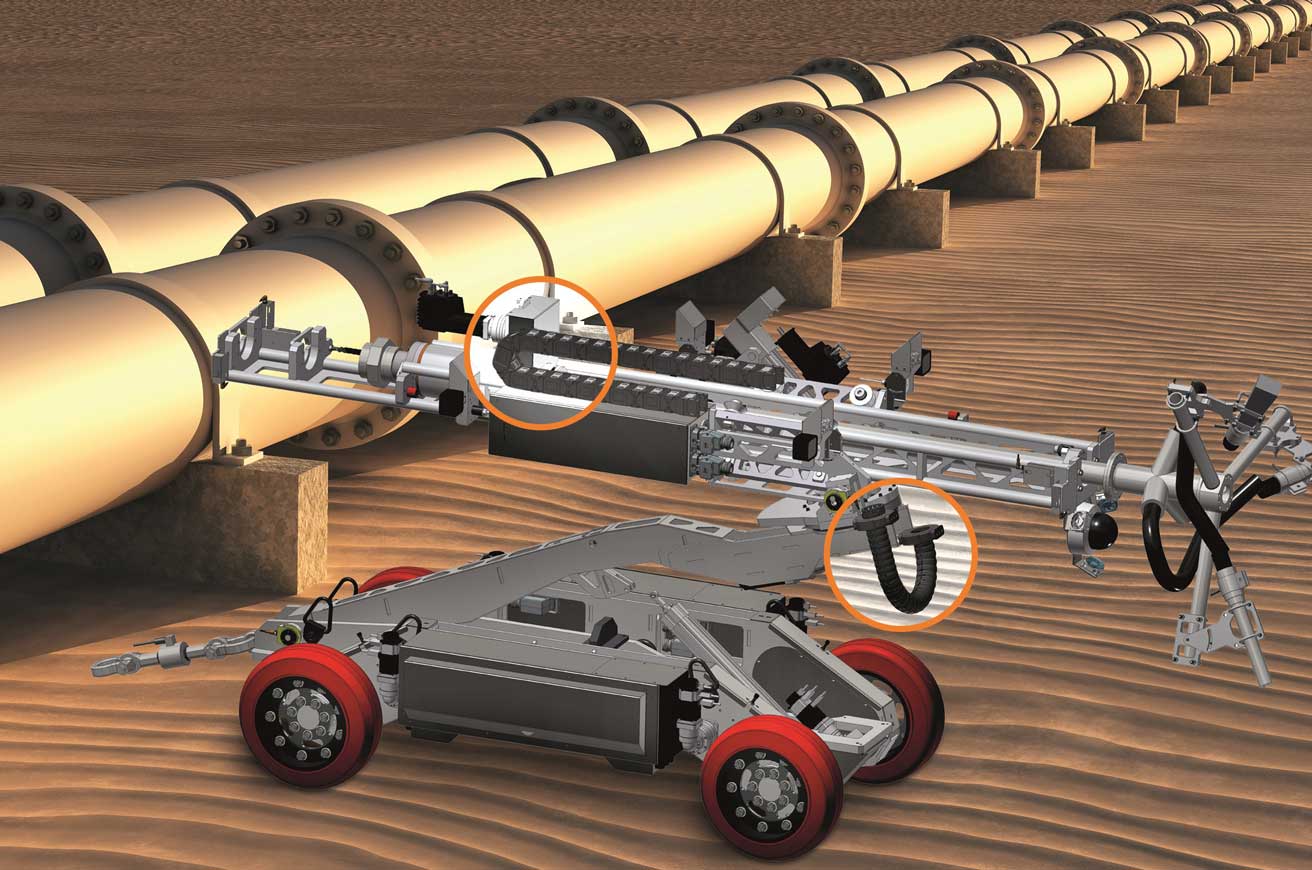

Energy chain in pipeline maintenance robots

11.01.2022/XNUMX/XNUMX | The remote controlled Robot crawler takes on work that would be life-threatening for humans. He rehabilitates the inner walls of pipelines in power plants. Automation works reliably, among other things, because the power and data lines are protected from the harsh environment. the Remote Orbital Installations LLC from the USA relies on the energy chains from igus.

A tragic accident in 2007 shows just how dangerous working in pipelines can be. He has himself in one power station in Colorado happened. Workers have one inside a penstock that carries water to the turbines epoxy resin coating applied. A flammable solvent ignited, killing five people. Such a fate would like Remote Orbital Installations (LLC) and Big Sky Engineering spare other workers.

The two US companies have the maintenance robot developed crawlers. The remote-controlled robotic platform on four wheels drives through pipelines, cleaning the inner walls with a blasting tool and then lining them with epoxy resin. Meanwhile, the workers are safe at the other end of the control line. Before the robot was ready for use, the engineers had to overcome a number of challenges. Amongst other things, it was necessary to find components that would withstand the humid environment inside the pipeline. These include guides that protect the crawler's energy and data lines from damage caused by uncontrolled movements.

The energy chains of the Motion Plastics specialist take over this leadership in several places power and data lines. For example, they run the lines from the mechanism that adjusts the wheel width of the crawler to the diameter of the pipe and that of the boom for adjusting the height of the tools. energy chains of Triflex series ensure the safety of hanging lines. Thanks to twistable chain links, they enable controlled, three-dimensional movements.

All energy chains used are made of a robust, wear-resistant, chemical-resistant and corrosion-free high-performance plastic. It reliably withstands even the most adverse environments for years. "The longevity of the products from igus was crucial to the success of the crawler," confirms Ingenieur Mike Kronz. "We've done several projects and haven't had a single failure."

Energy chains defy dust and dirt in aluminum oxide production

13.05.2019/XNUMX/XNUMX | When dismantling Bauxite, a sedimentary rock for aluminum oxide production, a lot of dust forms, which poses a major challenge, especially for the moving machine parts of the conveyor units. TO uses energy chains from igus in its systems.

13.05.2019/XNUMX/XNUMX | When dismantling Bauxite, a sedimentary rock for aluminum oxide production, a lot of dust forms, which poses a major challenge, especially for the moving machine parts of the conveyor units. TO uses energy chains from igus in its systems.

25 energy chains for de-icing aircraft

25.02.2019/XNUMX/XNUMX | In order to reduce the time, delays and thus costs involved in de-icing and washing aircraft, the MSG Production AS a fully automatic one All in one concept, which can de-ice and wash aircraft. The company relied on energy chains from igus.

25.02.2019/XNUMX/XNUMX | In order to reduce the time, delays and thus costs involved in de-icing and washing aircraft, the MSG Production AS a fully automatic one All in one concept, which can de-ice and wash aircraft. The company relied on energy chains from igus.

Powerful energy chain meets modular connector

29.11.2018/XNUMX/XNUMX | In order to ensure that the interface assembly for power and signal transmission can be efficiently and safely integrated into the company's own production processes for energy chains and Cablessystems can be integrated, igus cooperates with Harting as a supplier and design-in partner of modular "Han" industrialConnectors.

29.11.2018/XNUMX/XNUMX | In order to ensure that the interface assembly for power and signal transmission can be efficiently and safely integrated into the company's own production processes for energy chains and Cablessystems can be integrated, igus cooperates with Harting as a supplier and design-in partner of modular "Han" industrialConnectors.

Igus-Harting technology cooperation at SSI Schaefer

23.10.2018 | SSI Shepherd relies largely on standardized assemblies in order to optimize procurement processes, streamline internal logistics and reduce assembly and maintenance times. The intralogistics company relies on suppliers such as Harting and igus.

23.10.2018 | SSI Shepherd relies largely on standardized assemblies in order to optimize procurement processes, streamline internal logistics and reduce assembly and maintenance times. The intralogistics company relies on suppliers such as Harting and igus.

Energy chains for cables and hoses in cutting systems

12.09.2018/XNUMX/XNUMX | the Multitherm system from Knife Cutting Systems allows, in addition to cutting sheet metal, the integration of an additional device to cut unalloyed strip steel according to the specifications of manufacturers in the construction sector. Included are energy chains from igus.

12.09.2018/XNUMX/XNUMX | the Multitherm system from Knife Cutting Systems allows, in addition to cutting sheet metal, the integration of an additional device to cut unalloyed strip steel according to the specifications of manufacturers in the construction sector. Included are energy chains from igus.

Heavy bridge slightly lifted with safe energy supply

03.06.2018/XNUMX/XNUMX | the Memorial bridge spans the Piscataqua River on the east coast of the USA between Portsmouth in New Hampshire and Kittery in Maine. It replaced the original bridge, built in 1923 to commemorate local sailors and soldiers who died in World War I. Pre-assembled energy chains from igus reliably ensure a safe energy supply in the lifting bridge.

You might also be interested in...

Sustainability plastics – CO2 neutral with recycling

Igus linear guide quiet, resistant, maintenance-free

Cobot | Discover collaborative robots as a new employee

linear guide | Precise, light, durable

Fit calculator | Tools for fits and tolerances