3D printing filament and material - durable!

- Details

- Hits: 7474

3D printer at Igus also manufacture components with different filaments. in the 2-component printing Various material properties can be easily combined. For example, B. 3D printed components achieve particular rigidity and high wear resistance. The latest 3D printing materials are temperature-resistant Iglidur i230 for SLS or the resin Iglidur i3000 for DLP printing. The article introduces you to these and other new developments:

Contents

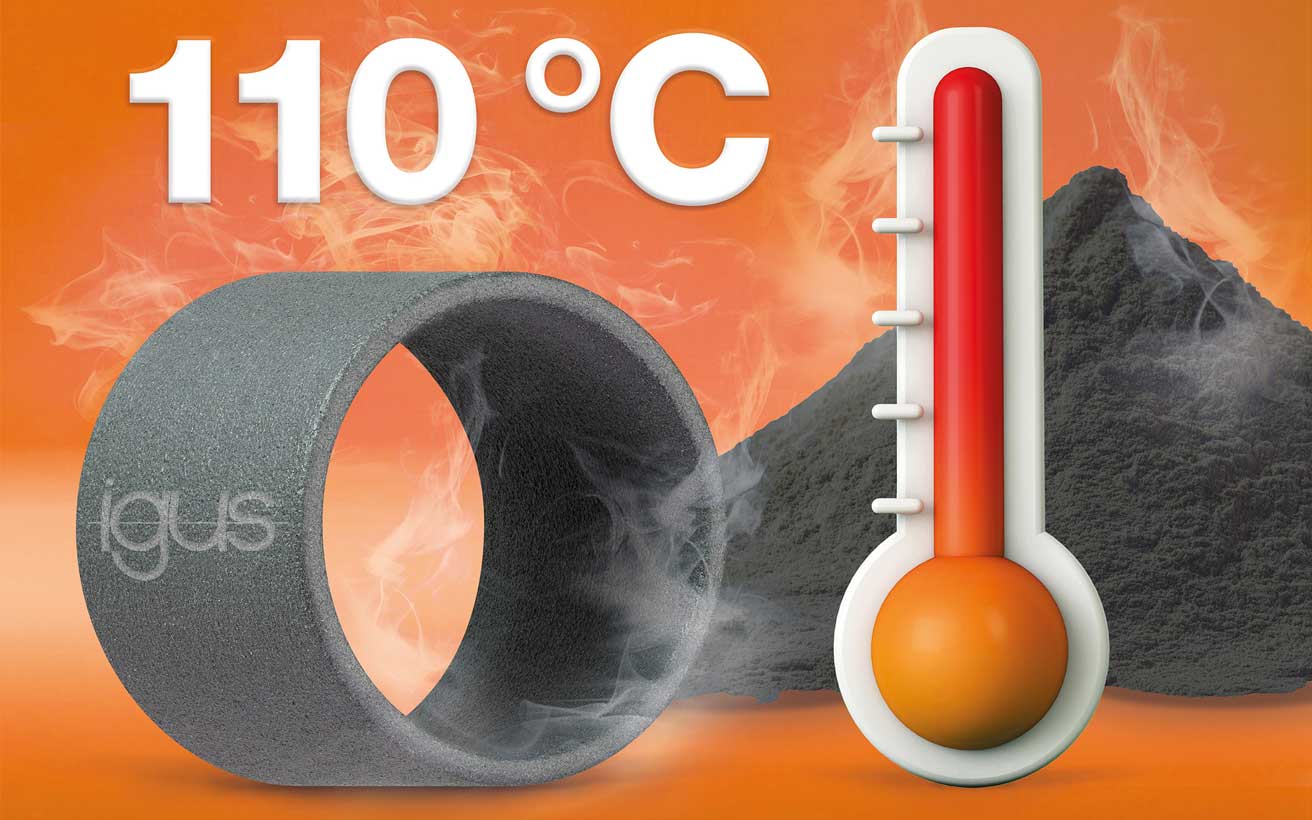

- SLS printing material with 110°C temperature resistance

- 3D printing resin significantly increases service life

- Extremely strong filament 3D printer with fiber reinforcement

- Filaments according to EU regulation and FDA

- New filaments for 2-component 3D printing in one step

- Maintenance-free tribo-filament for food technology

- FAQ

SLS printing material with 110°C temperature resistance

30.01.2024/3/110 | Igus brings the first 3D printing material for polymer components with a temperature resistance of up to 80 °C onto the market. In the future, 230D-printed polymer components will be able to withstand much higher temperatures, such as those generated in the engine compartment of an automobile. Standard SLS printing materials risk deforming at temperatures above XNUMX °C. The new powdered material Iglidur iXNUMX can withstand long-term use at high temperatures. In addition, the material is PTFE-free and approx. 80% more wear-resistant than the classic PA12.

Especially for small series and prototypes, more and more designers are turning to having components manufactured quickly and cost-effectively using 3D printers. Selective laser sintering (SLS) is particularly popular here. To date, standard SLS printing materials have only been used in applications below a maximum of 80 °C. At temperatures above this the material becomes soft and loses its dimensional stability. This is a knockout criterion for bearing points in the engine compartment of a car, industrial systems or many air conditioning and cooling systems.

3D printer | Additive manufacturing of plastic parts

3D printer | Additive manufacturing of plastic parts

“As the demand for 3D printed bearings for such high ambient temperature applications has recently increased, we have developed the new SLS printing material,” says Paul Gomer, material developer in 3D printing at Igus. Tests in certified external laboratories according to DIN EN ISO 75 HDT-A and HDT-B have proven the heat resistance. The material can even withstand extreme temperatures of up to 170 °C for short periods of time without deforming. It is also electrostatically dissipative and protects machines and systems from electrostatic discharges, which in the worst case can cause fires and explosions. Iglidur i230 is PTFE free.

80 percent more wear-resistant than PA12

Iglidur i230 is also constantly moving. Tests in the in-house Igus laboratory have proven this. In addition to the high wear resistance of 80%, the material has a round shape compared to PA12 at room temperature 50% higher mechanical strength. In bending tests, the material withstood a pressure of 94 MPa. User of a 3D printed plain bearing made of Iglidur i230 eliminates the need for time-consuming relubrication work. Solid lubricants are integrated into the SLS printing material for low-friction dry running.

3D printing resin significantly increases service life

July 23.07.2023, XNUMX | Igus presents on the EMO 2023 with Iglidur i3000 the world's first 3D printing resin for DLP 3D printing of wear parts. This gives small and precise components a 30 to 60 times longer lifespan than resins can.

July 23.07.2023, XNUMX | Igus presents on the EMO 2023 with Iglidur i3000 the world's first 3D printing resin for DLP 3D printing of wear parts. This gives small and precise components a 30 to 60 times longer lifespan than resins can.

For components in the millimeter range, 3D printers are particularly suitable Digital Light Processing (DLP)-Process press. This achieves a very fine resolution of just 0,035 mm – around half the thickness of a hair. A projector projects layer by layer from the 3D model onto the surface of a liquid special resin. The corresponding regions network under the influence of light.

After curing, the construction platform is lowered by one layer so that the next exposure can take place. This is how layer by layer is created tiny components like gears with tips measuring only 0,2 mm and which have a very smooth surface without post-treatment. With the new Resin iglidur i3000-PR, users can now significantly increase the service life of their moving application.

Longer service life by a factor of 60

But as precise as DLP 3D printing works, it has had a downside so far. "A common problem is that tiny components made from commercially available 3D printing resins, such as gears for model making, are not particularly robust and fail quickly," makes Tom Krause, Head of Additive Manufacturing at Igus, clearly. “We were able to prove in laboratory tests that the service life of Iglidur i3000 is at least 10 times longer compared to 30 commercially available resins tested. In some applications we even expect an increase in service life by a factor of 60.” The maintenance effort for lubrication work is zero. Microscopically small solid lubricants integrated into the material are released independently during movement.

Tiny special components manufactured quickly

In addition to the resin, customers can also order components made from it directly. The finest details and even internal channels can be easily realized. Work is already underway on an online tool through which STEP files of components can be uploaded or gears made from this material can be configured with just a few clicks.

Extremely strong filament 3D printer with fiber reinforcement

15.08.2022/XNUMX/XNUMX | The new Igus filament Igumid P190 enables an extremely stiff and firm print due to a carbon fiber reinforcement. It is suitable for structural components and special connection elements energy chains as well as 2-component 3D printing in combination with Iglidur i190. Igumid P190 is available as a filament for self-printing and will soon be available as an online service.

15.08.2022/XNUMX/XNUMX | The new Igus filament Igumid P190 enables an extremely stiff and firm print due to a carbon fiber reinforcement. It is suitable for structural components and special connection elements energy chains as well as 2-component 3D printing in combination with Iglidur i190. Igumid P190 is available as a filament for self-printing and will soon be available as an online service.

In the 2-component 3D printing (2K) from igus, different material properties can be easily combined. This idea was also the basis of the new, fiber-reinforced filament Igumid P190. It was specially developed as a material partner for the tribofilament iglidur i190. Thanks to the solid lubricants incorporated in the material, the igus filament offers high wear resistance and an excellent service life. The abrasion resistance of this filament is up to 50 times better than regular 3D printing filaments.

Two times stronger and five times stiffer 3D printer filament

The fiber-reinforced Igumid P190 is 2x stronger and 5x stiffer than the iglidur material. "With the help of multi-material printing, these two filaments can be combined in just one production step to form a highly stable and at the same time friction-optimized component," explains Tom Krause, Head of Additive Manufacturing at igus. The 2K 3D printers work with the "Fused Deposition Modeling" (FDM) process. Both plastics are melted in their own pressure nozzle and built up in layers to form a workpiece. "Both filaments together have a very good material connection. Therefore, they are ideally suited for multi-material printing,” Tom Krause makes clear. 2K components can be found e.g. B. Use in Grippers. This gives them a rigid body and at the same time flexible gripping surfaces for a secure grip.

3D printing service – online and fast

3D printing service – online and fast

Thanks to the high material strength, less material is required. The filament has a low Density of 1,25 g/cm³. The filament is also suitable for lightweight construction and production usually only takes a few hours. Light, high-strength, quickly available and flexible with 3D printing: This also predestines the Igumid P190 for the production of custom-fit special connection elements for energy chains. The individually printed components allow energy chains to be installed in a space-saving manner.

In addition, the new filament has material properties similar to those of injection-moulded energy chains. Thanks to its strength, it also withstands tensile and bending loads. With its high strength and rigidity, the Igumid P190 is also predestined for the production of highly stable structural components. Tests according to DIN EN ISO 178 in the in-house 3800 m² laboratory have shown that the filament, thanks to the fiber reinforcement, can withstand the enormous flexural strength from up to 237 MPa and a flexural modulus of elasticity of 11,5 GPa (printed flat, print lines aligned for optimum strength, optimized filling direction).

Filaments according to EU regulation and FDA

Sep 07.09.2021, 3 | When manufacturing large-format parts from the 150D printer, Igus relies in particular on the Iglidur I151 tribofilaments and the optically detectable Iglidur IXNUMX variant in blue colors. This means that lubrication-free special parts for movement can be produced quickly and cost-effectively.

Sep 07.09.2021, 3 | When manufacturing large-format parts from the 150D printer, Igus relies in particular on the Iglidur I151 tribofilaments and the optically detectable Iglidur IXNUMX variant in blue colors. This means that lubrication-free special parts for movement can be produced quickly and cost-effectively.

New filaments for 2-component 3D printing in one step

22.06.2020 | 32 percent of industrial companies were already using 2019D printing for their component production in 3 as an alternative to abrasive processes such as Turning and Milling. That was 12 percent more than in 2016, shows a study by the industry association Bitkom. The demands of users are increasing.

“More and more designers have asked us in recent years whether it is possible to 3D print components made of several plastics to manufacture in order to achieve special properties, ”says Tom Krause, Head of Additive Manufacturing at igus. With 2-component 3D printing (2K), e.g. B. Combine tribo filaments with carbon fiber reinforced filaments. The result is not only a particularly low-wear component, it is also extremely resilient.

Geometrically everything is feasible with 2-component 3D printing

“We have ours 3D printing service now expanded to include so-called 2-component 3D printers. These work with two different printing materials and thus allow more flexibility in product development,” says Tom Krause.

The 2-component 3D printer works with the FDM process. The two melted plastics each flow through their own pressure nozzle. The 2K 3D printer can switch between the materials at any time during printing, which merge at the transitions. “From a geometric point of view, there are hardly any restrictions,” explains Tom Krause. "The materials can enclose each other, interlock and alternate in layers."

The only exception is when the Melting temperatures of the filaments differ greatly and no material fusion is possible. In this case, designers can create a form-fitting connection like a dovetail. This connects two areas that are different Plastics . there

The Igus filament portfolio includes lubricating plastics and high-performance plastics, among others with hygienic, fire-retardant and antistatic properties. Tom Krause on this: “With the 2-component 3D Print can we the Properties of two filaments process and combine in one component.”

A good example of a 2K part is a gripper element for a machine that makes lids in the Food industry screwed. The body consists of a robust and wear-resistant Iglidur filament. The surfaces, however, are made of a flexible one material made, which ensures slip resistance. “The user benefits from this with this 2K component of materials“, Comments Tom Krause. “In the past, the individual parts could only be printed out and put together one after the other. Now it's much easier and faster. "

Maintenance-free tribo-filament for food technology

14.02.2017/3/XNUMX | The XNUMXD printing material developed by igus Iglidur I150 has now been approved for food contact according to EU regulation 10/2011. The certification of the versatile Tribo-Filament now gives users the opportunity to print special parts for moving applications that are in direct contact with food or cosmetics.

14.02.2017/3/XNUMX | The XNUMXD printing material developed by igus Iglidur I150 has now been approved for food contact according to EU regulation 10/2011. The certification of the versatile Tribo-Filament now gives users the opportunity to print special parts for moving applications that are in direct contact with food or cosmetics.

With the certified Tribo-filaments can be used to quickly and cost-effectively produce lubrication-free special parts for movement in the food industry. The lubrication and maintenance-free iglidur I150 can be processed on any 3D printer where the nozzle temperature can be set to 250 °C.

Since the high-performance plastic has very little shrinkage, it can also be processed on 3D printers that do not have a heatable printing plate. In this case, the adhesive film is recommended as a base for the print bed to ensure good adhesion.

iglidur I150 is extremely versatile and therefore also interesting for many other industries. It is also very tough and the easiest tribo-filament to process. The material offers a high level of wear resistance sliding speeds of up to 0,2 m/s. In the test laboratory, iglidur I150 showed a much higher abrasion resistance than classic 3D printing materials in a large number of different test parameters.

Clutches and brakes Use in food technology

Clutches and brakes Use in food technology

Five more filaments

In addition to iglidur I150, the manufacturer has five other lubrication-free and maintenance-free iglidur tribo-filaments in its range for a wide variety of applications - for example where permanent stress or chemical resistance is required. What they all have in common is that they are characterized by high abrasion resistance and up to 5 times more wear-resistant than standard materials for 3D printing.

3D printing with tribo-filaments is particularly useful in the manufacture of complex moving wear parts in fixture construction, small series and special machine construction. For customers who do not have their own 3D printer, the Motion Plastics specialist offers one 3D Print Service for wear parts, both made from Iglidur Tribo-Filament and also from our own laser sintering material Iglidur I3. Customers can upload their data online, choose the material for the products, calculate prices and order their individual wearing part directly.

3D printer filament is the material used in Fused Deposition Modeling (FDM) 3D printers to create three-dimensional objects. It is a thermoplastic wire that melts when heated and is extruded through a nozzle to build up the desired object layer by layer.

FAQ

What is a filament?

A filament is the material used in Fused Deposition Modeling (FDM) 3D printers to create three-dimensional objects. It is a thermoplastic wire that melts when heated and is extruded through a nozzle to build up the desired object layer by layer.

Which filament for what?

In 3D printing there is a wide variety of filaments that can be selected depending on the specific needs and properties of the object to be printed.

- PLA Filament (Polylactic Acid) is one of the most commonly used filaments. PLA filament is great for prototypes and decorative items because it is easy to print and environmentally friendly.

- ABS Filament (Acrylonitrile Butadiene Styrene) is another popular filament. ABS filament is often used for mechanical parts and toys due to its durability and heat resistance.

- PETG Filament (polyethylene terephthalate glycol) offers a good balance between the lightness of PLA and the strength of ABS. It is weather-resistant and is therefore well suited for outdoor use.

- PVA Filament (polyvinyl alcohol) is filament that is best known for its unique, water-soluble properties. PVA filament is typically used as a support material in 3D printing processes, especially for models with complex geometries, overhangs or internal cavities.

- TPU Filament (Thermoplastic Polyurethane) is a flexible filament for special applications where products such as cell phone cases or shoe soles are used.

There are also filaments with special additives such as wood or wood filament, metal, carbon fiber or conductive particles that provide special aesthetic effects.

What is the difference between PLA filament and PLA+ filament?

PLA and PLA+ are both popular 3D printing filaments, but with some significant differences.

PLA, right Polylactic Acid, is a biodegradable polymer based on corn starch. It is known for its light weight, good printability and low shrinkage. However, it has limited impact resistance and is less durable under high temperatures.

PLA+, also as Premium PLA known, is a modified version of PLA designed to overcome some of these limitations. The addition of additives and polymers improves the durability and impact resistance of PLA+ while still remaining relatively easy to print. PLA+ typically has a smoother surface quality and is more flexible than standard PLA, making it an excellent choice for print projects that require aesthetics and durability.

You might also be interested in...

Sustainability plastics – CO2 neutral with recycling

Igus linear guide quiet, resistant, maintenance-free

Electrical Wires | From cable to assembly

Cobot | Discover collaborative robots as a new employee

Igus energy chain: stable, recyclable, plastic.