yesterday | Electrical Engineering Archives

- Details

- Hits: 1814

Archive for Electrical Engineering...coming soon

BILD

energy chains

The current energy chain information can be found here here.

- How roller energy chains ensure more safety on long journeys

- Configurator for energy supply based on AI and neural networks

- Stable cable routing in commercial vehicles - video

- E2 shackle chain reduces maintenance of mobile work machines

- Powerful energy chains and modular connectors

- Energy chain with automatic retraction prevents loop formation

- Twisterband energy supply for rotary movements up to 7000 degrees

- Installation of transport frame for ready-to-install cable carriers

- Permanently conductive energy chains in Atex design

- World's first circulating energy chain without an empty run

How roller energy chains ensure more safety on long journeys

How roller energy chains ensure more safety on long journeys

16.08.2019/XNUMX/XNUMX | From a technical innovation to the standard to a forward-looking solution: they can do it roller energy chains by Igus. For more than 45 years, the motion plastics specialist has been developing energy supply systems that reliably supply cables for all media such as Ethernet, servo, Motor and also lead hoses.

In the beginning, these were almost exclusively products for mechanical engineering, but the invention of the roller energy chain ensured 20 years ago to break through into other sectors. The technical basis is formed by rollers in the chain links, which reduce the coefficient of friction enormously over long travel distances when the upper run of the chain is placed on the lower run.

How much Energy himself thereby reduce The infographic shows what speeds can be achieved with the roller energy chains.

Configurator for energy supply based on AI and neural networks

29.04.2019/XNUMX/XNUMX | Configure complete cable carriers quickly and easily: The E-chain expert. With the newly developed Online tool the user can design his individual energy chain system in just a few steps.

29.04.2019/XNUMX/XNUMX | Configure complete cable carriers quickly and easily: The E-chain expert. With the newly developed Online tool the user can design his individual energy chain system in just a few steps.

E2 shackle chain reduces maintenance of mobile work machines

01.10.2018 | Support feet on many construction machines, such as concrete pumps or mobile cranes, are characterized by a large variety of variants. With the new one E2 strap chain from igus there is now an energy and media routing in one system for tight installation spaces on support feet. Stable, space-saving and easy to assemble, the e-chain also has two hydraulic hoses in addition to power and control lines. The E2 bow chain saves maintenance in special machine construction and significantly reduces downtimes.

01.10.2018 | Support feet on many construction machines, such as concrete pumps or mobile cranes, are characterized by a large variety of variants. With the new one E2 strap chain from igus there is now an energy and media routing in one system for tight installation spaces on support feet. Stable, space-saving and easy to assemble, the e-chain also has two hydraulic hoses in addition to power and control lines. The E2 bow chain saves maintenance in special machine construction and significantly reduces downtimes.

Energy chain with automatic retraction prevents loop formation

19.08.2015/XNUMX/XNUMX | igus has developed a light and inexpensive concept for the automatic retraction of energy chains, which enables further advances in robotics. Then Industrial robots Today, in addition to power, data and media lines, they also often carry feed hoses for rivets or screws, for example. The new system Triflex RSE prevents the energy chains from forming loops, which means that these solid bodies can be guided safely to the end of the robot arm.

The Triflex R series is specially designed for highly dynamic industrial robots been designed and can move in all directions in space as a 3-axis energy chain. The universally usable Triflex chains made of high-performance plastics also withstand demanding industrial environments, are easy to assemble and can be filled with cables from the outside. They also have high tensile and torsional strength.

Feed hoses for bolts, rivets and screws

"However, since today not only electrical and pneumatic lines, but often also feed hoses for bolts, rivets or screws have to be routed to the robot, too tight bending radii or hanging loops can sometimes cause problems," explains Joerg Ottersbach, Industry Manager Robotics at igus. “Every deflection and every fall below the permissible minimum bending radius of the feed hoses offers a potential point of failure and can have a negative impact on the process. In the worst case, a rivet or a screw gets stuck in the feed hose, which then leads to a system standstill.”

"However, since today not only electrical and pneumatic lines, but often also feed hoses for bolts, rivets or screws have to be routed to the robot, too tight bending radii or hanging loops can sometimes cause problems," explains Joerg Ottersbach, Industry Manager Robotics at igus. “Every deflection and every fall below the permissible minimum bending radius of the feed hoses offers a potential point of failure and can have a negative impact on the process. In the worst case, a rivet or a screw gets stuck in the feed hose, which then leads to a system standstill.”

With its linear retraction of the energy chain, the retraction system offers an efficient and inexpensive solution that does not require any bends, spring bars or deflection rollers. The very light system is based on the tried and tested lubrication and maintenance-free Drylinlinear guide, in which a movable carriage transports the chain over a retraction path of up to 600 mm. Elastic bands automatically pull back the extended chain. This prevents the energy chain from forming loops. The resulting optimization of process reliability can significantly increase service life.

The self-guiding The return system is designed for the closed or hinged Triflex chains TRC, TRE and TRCF in sizes from 60 to 125 mm in diameter. They are locked onto the system using a connecting element and a sliding bushing, which in turn can be variably connected to a large number of robot types using mounting plates. Because the Triflex RSE guides the e-chain directly on the robot and no deflections are necessary, the required cable and chain length is reduced. Thus, the retraction system is not only a space-saving and light but also a cost-effective solution.

Twisterband energy supply for rotary movements up to 7000 degrees

26.03.2015/XNUMX/XNUMX | Rotary movements on machines put a lot of strain on cables and hoses. In order to guide and protect them safely, igus has increased its range of energy supply chains for rotary movements by one Heavy Duty version expanded. The Twisterband HD is an even more stable, but at the same time just as compact, spiral-shaped energy chain for circular movements, with which rotations of up to 20 times around its own axis are possible.

26.03.2015/XNUMX/XNUMX | Rotary movements on machines put a lot of strain on cables and hoses. In order to guide and protect them safely, igus has increased its range of energy supply chains for rotary movements by one Heavy Duty version expanded. The Twisterband HD is an even more stable, but at the same time just as compact, spiral-shaped energy chain for circular movements, with which rotations of up to 20 times around its own axis are possible.

The Twisterband HD combines the construction properties and qualities of the twister chain - a circular energy chain for rotary movements up to a maximum of 360 degrees - with the twister band. The Twisterband HD combines the resilience and stability of the chain with the compactness, flexibility and range of rotation of the band, thus filling a gap between the two products.

For the addition "Heavy Duty (HD)" the designers of the Twisterband HD have the Band segments significantly strengthened and therefore more stable. In addition, a combination of a bolt and hook solution was developed to connect the individual segments, so that the Twisterband HD is extremely resilient and at the same time very flexible and rotatable (up to 20 times around its own axis). With this construction for connecting the elements, the individual parts can be completely injection molded from the stable manufacturer's own standard material for e-chains. The Twisterband HD is therefore suitable for temperatures below 0 °C.

The Twisterband HD is very stable and requires little installation space. The outer diameter is 300 mm, the height starts at 250 mm and varies upwards depending on the angle of rotation required. Due to the construction are also extreme turning angles possible: horizontally up to approx. 7000 degrees, vertically up to approx. 3000 degrees. The modular structure around its own axis of rotation and the entire construction principle even open up potential for larger variants.

But despite this ability to rotate, the cables always remain optimally protected. Tests together with "Chainflex" cables in our own laboratory came to a service life of one million turning cycles and more. This is ensured, among other things, by the predefined minimum bending radius, which prevents the cables from kinking. The special hinge construction protects the Twisterband HD and enables quick filling from the outside. Together with the tribo-optimized high-performance plastic of the tape, a long service life is ensured, even under difficult environmental conditions such as temperatures from -40° to +80°C.

Michael Blass presents the blister tape - video

Installation of transport frame for ready-to-install cable carriers

28.08.2012/XNUMX/XNUMX | It currently takes a few weeks to months from the joint development of a provisional frame at the customer's site through the steel construction to the start of series production. Subsequent changes to the welded frames are then no longer easily possible. That's why igus now has a telescopic transport frame modular developed, which is adapted to the interface of the respective machine with millimeter precision within one working day.

28.08.2012/XNUMX/XNUMX | It currently takes a few weeks to months from the joint development of a provisional frame at the customer's site through the steel construction to the start of series production. Subsequent changes to the welded frames are then no longer easily possible. That's why igus now has a telescopic transport frame modular developed, which is adapted to the interface of the respective machine with millimeter precision within one working day.

It consists of modular supports and struts that fit together perfectly. In addition, these are telescopic, so that a Length adjustment possible at any time is. Various locking mechanisms ensure that components can also be attached later. Thanks to specially developed traversing units, the entire system can be moved and transported with ease.

In cooperation with the customer on site in one day put together the right system. If modifications are necessary due to changes to the machine, they can be implemented at any time without any problems thanks to the variability of the system. If the customer's machine series is phased out, the transport and assembly frame can be dismantled into its individual parts and the individual components can be reused.

Permanently conductive energy chains in Atex design

18.11.2010/10/XNUMX | XNUMX years ago, igus made fully conductive energy chains from the material Igumid ESD before. Since then, the gray-colored energy supply systems have been among the most sought-after special materials from the plastics specialist. To make it easier for designers to complete their machines and systems quickly, a selection of the ESD/Atex range is now available from stock.

The series Zipper e-chains, E2/000, E4.1 and E4/light will be available from stock from January 1st, 2012 and thus almost 280 different versions. Igumid ESD (Electro Static Discharge) was designed for applications in which electrostatic discharges are completely undesirable. This primarily includes the manufacture or handling of sensitive electronic products and components.

As everywhere where movement is involved, friction arises between machine parts, which static electricity can form. When it comes into contact with a grounded body, it can discharge suddenly, as is the case, for example, with gripping a door handle. Voltages of up to 10.000 V can flow. However, since the current is relatively small, in most cases it does not harm people. However, sensitive electronic components can already be irreparably damaged from a voltage of around 20 V.

In order to avoid such damage, all components of a machine must be sufficiently conductive and the entire system must be continuously grounded. When Automation umbilical cord the reliable and permanent conductivity of energy chains, even after years of use, is of particular importance for the avoidance of electrostatic discharges.

Standard-compliant ESD control panels made of special plastics

Standard-compliant ESD control panels made of special plastics

Electrostatic discharges are not only dangerous for electronic components, they can also ignite flammable gases, vapors or dust in hazardous areas. Energy chains made of Igumid ESD are useful wherever such conditions are found, for example in the chemical industry, in bulk goods loading or in painting lines Avoidance of ignitable electrostatic discharges at. They were developed in accordance with the Atex directives 94/9/EG for devices and systems in potentially explosive atmospheres and certified according to the EX II 2 GD classification. This makes the ESD/Atex energy chains suitable for use in areas with a risk of explosion caused by gases or dust.

World's first circulating energy chain without an empty run

22.10.2010/XNUMX/XNUMX | Why hasn't anyone invented this before? That was the first thought when seeing the world's first continuously circulating energy chain, which Igus presented to visitors to the Hannover Messe presented. Managing director Frank Blase was approached by a potential customer with the words that this is exactly what he needed.

Start, brake, start again, brake, drive back at the end. Whether for smaller devices on the robot, pick-and-place applications, fast press feeders, large stacker cranes or classic conveyor belts: Conventional handling and transport applications today cannot do without an empty trip, without an unproductive return trip. For this purpose, igus has developed this surprisingly simple-looking energy chain. The ready-to-install complete module opens up completely new perspectives in machine construction.

The so-called C chain versorgt grab, sensors and other units with energy, data and media. Without superfluous forward and return journeys, the next position can be approached directly in a continuous round trip and loaded and unloaded, glued, drilled, etc. permanently. Lightweight and fail-safe, speeds up to 8 m/s are possible. In this way, the fastest machine cycle times can be achieved.

The C-chain consists of an abrasion-resistant plastic energy chain with connected rotary feedthrough. This moves easily and vibration-free, if necessary with supported upper strand. The system offers sufficient space for filling z. As with a servo / motor cable, a control, bus or fiber optic cable and protects and guides air and gas. All necessary lines and hoses for load, data and media are housed in a compactly built guidance system. This is delivered as a complete module according to the customer-specific key data and attached to the customer directly to the machine, the conveyor belt or another system. It can be used in various mounting positions.

Each car individually addressable

With the circulating chain z. B. a handling, storage and retrieval device or feeder similar to one track chain design. Circulating trolleys with a wide variety of functions can be attached to this. The carriages are supplied with information, energy and media by an energy chain with a rotary feedthrough connected to it. The chain circulates easily and wear-free in the guide housing to the first carriage station. There it feeds a circulating ring line to which all the cars of the "caterpillar" are connected.

With the circulating chain z. B. a handling, storage and retrieval device or feeder similar to one track chain design. Circulating trolleys with a wide variety of functions can be attached to this. The carriages are supplied with information, energy and media by an energy chain with a rotary feedthrough connected to it. The chain circulates easily and wear-free in the guide housing to the first carriage station. There it feeds a circulating ring line to which all the cars of the "caterpillar" are connected.

With modern electronics and bus technology each car individually addressed will. It is supplied with the appropriate signals so that it can then work as desired, e.g. B. by means of a Pneumaticsvalves, electric motors or Sensors. Each trolley can be controlled individually and can immediately take over "its" task in a predefined position.

Depending on the customer specifications is a travel distance of 30 m and more possible. Numerous different carriages can be connected to the continuously circulating chain. This can be rotating grippers, suction cups or electromagnets that permanently pick up, hold, adjust and set down workpieces. Or Tools for machining such as turning, Tighten, Glue and drilling. Regulation and control technology can also be positioned on the trolley, compactly supplied with information and power from a stable management system - from barcode or color recognition readers to RFID readers.

In addition to the central constructive breakthrough - the No empty trips – transport, pick-and-place and other handling systems can now also be built leaner. The C-chain can be easily integrated into small installation spaces. Currently, very large masses often have to be moved at high accelerations in order to meet the specifications for cycles and cycle times. Designers therefore have to build relatively large in order to be able to absorb the corresponding forces that arise due to the dynamic back and forth driving (braking, stopping, etc.). With the C-chain system, on the other hand, you can not only work much more efficiently, according to the manufacturer, but also save space and energy.

Gland

You can find the current cable glands here.

Multiple cable glands for a wide temperature range

20.11.2018/XNUMX/XNUMX | With the invention of the multiple sealing insert Pflitsch A very space-saving cable entry: Depending on the size of the cable gland and the cable diameter used, several cables, including cables of different thicknesses, can be routed through just one housing hole in the UNI multiple cable gland.

20.11.2018/XNUMX/XNUMX | With the invention of the multiple sealing insert Pflitsch A very space-saving cable entry: Depending on the size of the cable gland and the cable diameter used, several cables, including cables of different thicknesses, can be routed through just one housing hole in the UNI multiple cable gland.

The UNI multiple screw connection achieves the high protection classes due to the unique sealing principle IP65 to IP68 (up to 10 bars). The sealing inserts are made from a TPE-V Plastic manufactured, which allows operating temperatures from 40° to +135 °C. With the new, black silicone material variant, -55° to +200 °C are possible for brass and stainless steel cable glands for the first time. In PVDF plastic -40° to +150 °C can be reached. This means that these multiple cable glands can be used reliably and for a long time in cold and heat. The UNI Multiple Silicone is currently available in the four sizes M20 to M40.

With the UNI Dicht cable gland, when the pressure screw is tightened, the sealing insert gently and over a large area around the cables that are fed through, so that there is no irreparable constriction of the cable sheaths and thus long-term leaks.

Animation of the sealing principle of UNI Dicht

cables and wires

You can find the current cable glands here.

- SPE cable with a long service life for the energy chain

- Intelligent bus line with traffic light function for Smart Factory

- Data cable for the smallest bending radii in moving applications

- Ethernet bus cable for the highest mechanical stress

- Twistable Ethernet cable for fast, secure data transfer

- Mechanically flexible Ethernet cable and NFPA 79 solution

- Robust bus cable for all movements

SPE line with a long service life for the energy chain

05.12.2019/XNUMX/XNUMX | the Single-pair Ethernet (SPE) technology offers completely new opportunities to transmit the immense data streams reliably and quickly, even in the smallest area of the machine. For the movement in the energy chain, igus presents the first SPE "Chainflex" cable. Using only one pair of wires reduces the outer diameter by 25%.

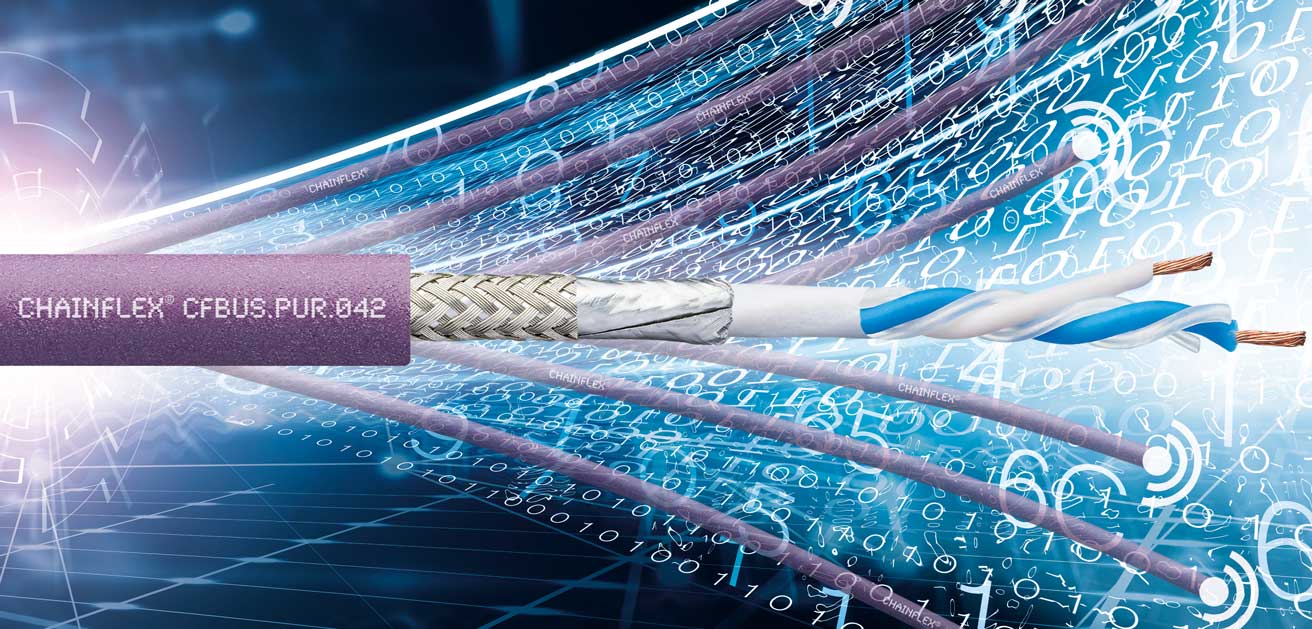

The Chainflex CFBUS.PUR.042 Single pair Ethernet cable was specially developed for flexible, long-lasting use in the energy chain. Because the single pair Ethernet cable only uses one pair of wires instead of the usual four, this reduces the data rate to transmission rates of 10 MBit/s to 1 GBit/s. However, a higher speed is not necessary in many applications. Instead, reducing the number of cores in the CFBUS.PUR.042 enables a 25% smaller outer diameter. It is now at the level of an initiator line.

The new SPE line is a perfect fit for the T1 connector interface constructed specifically for PES was newly developed. As a result, the durable screen is reliably handed over, resulting in high electromagnetic compatibility (EMC). The combination of cable and plug is extremely robust: igus uses a highly abrasion-resistant, notch-resistant PUR jacket and the plug uses robust metal locking with a PCB socket.

Reducing the size of the cable and connector creates additional space even in the smallest e-chain series. The SPE technology is therefore one Alternative to classic serial bus systems in Automotive industry, railway engineering or at industrial robots. The user does not have to do without quality. The oil-resistant and flame-retardant CFBUS.PUR.042 has been extensively tested in the 3800 m² igus test laboratory. As with his entire range of cables, which includes more than 1300 cables, the user also receives a guarantee and 10 million double strokes and 36 months for the SPE cable that can be calculated online.

Intelligent bus line with traffic light function for Smart Factory

04.12.2018 | igus presents a new and globally unique concept for intelligent Monitoring of bus lines in e-chain systems. The "CF.D" system recognizes imminent system downtimes in good time thanks to the early alarming of even the smallest changes in the transmission properties.

04.12.2018 | igus presents a new and globally unique concept for intelligent Monitoring of bus lines in e-chain systems. The "CF.D" system recognizes imminent system downtimes in good time thanks to the early alarming of even the smallest changes in the transmission properties.

Sooner or later, the mechanical loads in energy chains will change the transmission properties of bus lines. In addition to linear traverse paths, this also applies to three-dimensional movements such as hose packages on Robot. The result: disruptions in data transmission or even unforeseen system failures.

The CF.D concept of the "Smart Plastics" developer makes it possible to prevent any impairment of the used Chainflex bus line to recognize in time. The intelligent system consists of an evaluation unit and a response module. These are inserted at the beginning and end of the mechanically stressed bus line. The evaluation unit is usually placed in the control cabinet on the fixed point side, the response module in the distribution box on the driver side. Special data packets are transmitted between the two for measurement purposes and the line quality is constantly evaluated based on the increasing number of lost or damaged packets.

If a predefined value is exceeded, the customer is alerted by a yellow LED and a contact switching. This warning threshold can also be queried via the connected network and the current situation can be displayed in a web browser. Exceeding a second warning threshold is signaled by a red LED and indicates a failure of the bus transmission, so that the error can be identified by looking at the switch cabinet can be located quickly.

For the first time, the new system enables lines to be monitored in dynamic operation, without additional measuring wires or sacrificial lines. CF.D integrates itself into the isense Predictive maintenance environment where different sensors and monitoring modules make Motion Plastics products intelligent. Networking using the "Icom" module enables an online status display with an alarm function or direct integration into the company-wide infrastructure.

The next step in development is increasing integration of the components planned, such as the integration of the receiver in a connector housing.

Data cable for the smallest bending radii in moving applications

24.01.2017/XNUMX/XNUMX | The latest generation of "Chainflex" data cables with a new alloy conductor and a halogen-free TPE outer jacket is ideally suited for the smallest bending radii of up to 4 xd with a number of cycles of over 40 million strokes. The new high-performance conductor alloy qualified by igus is the solution for highly dynamic, fast applications with small radii from 15 mm. This makes the Chainflex series CF298 and CF299 unique cable series available from stock for the highest demands.

24.01.2017/XNUMX/XNUMX | The latest generation of "Chainflex" data cables with a new alloy conductor and a halogen-free TPE outer jacket is ideally suited for the smallest bending radii of up to 4 xd with a number of cycles of over 40 million strokes. The new high-performance conductor alloy qualified by igus is the solution for highly dynamic, fast applications with small radii from 15 mm. This makes the Chainflex series CF298 and CF299 unique cable series available from stock for the highest demands.

Intensively tested in the largest with 2750 m² test laboratory in the industry, the CF298 (unshielded) and the CF299 (shielded) are qualified for continuously moving in the smallest installation spaces. This is made possible primarily by the combination of the new high-performance alloy conductor material and the highly flexible TPE outer jacket, which prevents cracks and breaks. The cover material also offers the highest possible abrasion resistance in combination with energy chains from igus.

Tool-free, secure cable bushing and cable entry

Tool-free, secure cable bushing and cable entry

The new generation of data lines is suitable for short, very fast movements like in Pick and place machines or other very fast handling applications. They are also suitable for indoor and outdoor use due to their UV, low temperature and oil resistance. Because the cables are certified according to ISO Class 1, they can also be used in clean rooms. In energy chains, they are designed for up to 40 million double strokes. The manufacturer guarantees a shelf life of 36 months. The CF298 and CF299 are now available from stock with various core counts and conductor cross-sections.

Ethernet bus cable for the highest mechanical stress

15.11.2016 | igus presents the "CFBUS.LB" bus cable - one of several new high-end cable families for the continuous motion in the energy chain with an outer sheath made of TPE, halogen-free. With these cables, the motion plastics specialist completes its range in the upper range of requirements for energy and data supply, for example in the case of very limited installation space, particularly long travel distances or extremely low temperatures.

15.11.2016 | igus presents the "CFBUS.LB" bus cable - one of several new high-end cable families for the continuous motion in the energy chain with an outer sheath made of TPE, halogen-free. With these cables, the motion plastics specialist completes its range in the upper range of requirements for energy and data supply, for example in the case of very limited installation space, particularly long travel distances or extremely low temperatures.

High-end cables from the "Chainflex" range are suitable for applications where the properties of other cable series are no longer sufficient. For smallest bending radii the new cable series was developed for bus cables of up to 7,5 xd or for temperatures down to -35 °C.

The core structures of the CFBUS.LB, which are optimized for movement, offer a solution for the Ethernet area in combination with an inner sheath and the highly flexible, abrasion-optimized TPE outer sheath. The bus cable family for the highest mechanical stress is suitable for all common bus systems such as Ethernet CAT5, CAT5e, CAT6, Ethercat, Profinet or the common fieldbuses such as Profibus. The 'LB' in the product name stands for 'low bending' – i.e. a particularly low bending radius at which the cables can be moved in energy chains. In addition to the CFBUS.LB, there is also a control and servo cable with the same outer sheath material. The manufacturer guarantees a shelf life of 36 months on all cables.

Twistable Ethernet cable for fast, secure data transfer

02.11.2015 | igus is expanding the range of Ethernet cables for movement with new ones robot lines according to CAT6A and CAT7 standard. This gives users security and fast transmission during operation, even with the highest mechanical demands, for example when supplying data to industrial robots. With the new cables, the motion plastics specialist is expanding what is already the most comprehensive range of Ethernet cables for continuous movement in energy chains.

The three million or so industrial robots that work with increasingly large amounts of data are now indispensable in modern production facilities. Especially here are durable lines with special Materials and constructions for one fail-safe data transmission absolutely necessary to avoid costly production downtimes.

For very complex applications and the latest quality standards, the Cologne-based company is now presenting the world's first cables for three-dimensional movements according to CAT6A and CAT7 standard: The "Chainflex CFROBOT8.050" (CAT6A) and Chainflex CFROBOT8.052 (CAT7) cables ensure fast data transmission according to the latest industry standards. "In contrast to cables for linear movements in energy chains, the 'mechanical stress' for robot cables consists of a combination of bending, torsional and compression forces," explains Rainer Rössel, head of the Chainflex cables division at igus. “It is therefore all the more difficult to determine the design requirements in advance. For this reason, we test all cables not only in isolated torsion but also in application-specific motion sequences on industrial robots.”

The range of Chainflex Ethernet cables now includes 27 different types different qualities and price ranges. All components of the robot cables such as cores, stranded structures, screens and sheathing materials are exposed to strongly changing loads during torsional movements. To ensure that the Chainflex cables remain stable and data security is ensured, the combination of particularly slippery and at the same time highly stable foils and special "soft" filling elements that systematically absorb the forces that occur is used. In particular, the properties such as damping, line capacity and signal quality must remain the same over the entire service life within narrow tolerances. Torsion-optimized insulating materials and mechanical damping elements with coordinated capacitance values guarantee this durability.

Mechanically flexible Ethernet cable and NFPA 79 solution

24.11.2011/2011/XNUMX | At SPS IPC Drives XNUMX, igus is presenting a mechanically flexible Ethernet cable with a wide variety of qualities for mechanical stability. These and other innovations are presented to us Rainer Rössel, Head of the Chainflex Cables Division, igus GmbH in Nuremberg:

Robust bus cable for all movements

04.10.2010 | igus has expanded the "Chainflex" bus cable program with additional quality levels. The are now also available from stock CAT5e/GigE lines "CFBUS.PVC.045" for dry rooms and "CFBUS.PUR.045" for oily environments. With bus cables for energy chains, it is important to mechanically ensure that the transmission properties of the corresponding bus specification are maintained even with several million movement cycles. The company can now offer a solution for almost every bus protocol. From Profibus, DeviceNet, CC-Link to CAN bus, USB to all Ethernet variants including GigE.

04.10.2010 | igus has expanded the "Chainflex" bus cable program with additional quality levels. The are now also available from stock CAT5e/GigE lines "CFBUS.PVC.045" for dry rooms and "CFBUS.PUR.045" for oily environments. With bus cables for energy chains, it is important to mechanically ensure that the transmission properties of the corresponding bus specification are maintained even with several million movement cycles. The company can now offer a solution for almost every bus protocol. From Profibus, DeviceNet, CC-Link to CAN bus, USB to all Ethernet variants including GigE.

This applies to both standard and extreme applications, including torsion. Where copper is not the first choice (huge data rates, long distances), the plastics expert recommends preference Glass and plastic fiber optics.

The outer sheath material plays an important role in the now expanded bus cable range. The sheath material of the CAT5e/GigE cable "CFBUS.PVC.045" is made of a PVC mixture, which is abrasion-optimized for continuously moving use in plastic energy chains. The cable is flame-retardant, suitable for the temperature range from -5° to +70°C and has UL approval. With the tested PVC mixture, a high number of cycles can be achieved at moderate costs in applications without exposure to oil.

The new one too PUR GigE cable "CFBUS.PUR.045", on the other hand, was designed for energy chain applications with machine oil, coolants and lubricants. This highly oil-resistant cable combines flame retardancy and freedom from halogens, can be used at temperatures from -35° to +70 °C and also has UL approval. Here, too, the abrasion behavior of the outer jacket material is matched to the chain material, which leads to a much longer service life.

Connectors

You can find the current connector information here.

- 360 degree connectors for measuring and testing technology

- High speed M12 connector for field installation

- Custom Board-To-Board Connectors

- Circular connectors, rectangular connectors and electrical contacts

- Heavy-duty industrial connectors

- High-pole combination connector for power and signal

- Magnetic connectors with spring contact for special cables

- Hybrid Circular Connectors for machine automation

- Hybrid, miniature and rectangular connectors for a variety of applications

- Power connector with rated voltage up to 630 V and rated current up to 16 A

- Connector combines shielding and plastic housing

360 degree connectors for measuring and testing technology

25.09.2019 | Fischer connectors shows nine product extensions of its multiple award-winning "Freedom" series, which are intended to set new standards in terms of usability, integration capability and versatility in the connectivity of measuring and testing technology devices. The series offers 360° plug freedom.

25.09.2019 | Fischer connectors shows nine product extensions of its multiple award-winning "Freedom" series, which are intended to set new standards in terms of usability, integration capability and versatility in the connectivity of measuring and testing technology devices. The series offers 360° plug freedom.

It features a sealed, blind-mate, non-magnet locking quick release. Thanks to high-quality materials and very good workmanship, the connectors are robust and durable. They optimize cable management.

In addition, they can be easily and completely cleaned and are according to the protection classes IP68 or IP67 for the connectors Plastic sealed. New in the series are, for example, a USB 2.0 adapter, an LED adapter, a robust flash drive and connectors in new sizes and materials (metal and plastic).

The Freedom series supports new developments in connectivity and application design of wearables and IoT applications. It makes devices and electronic systems smaller, faster and more intelligent overall.

The Freedom series is particularly suitable for devices and apparatus in industrial automation, laboratory technology, testing and Measurement Technology as well as process control technology. Likewise she comes in the Robotproduction and condition monitoring are used. chemical analyzers, spectrometer, electron microscopes, calibration systems, vibration testers, heat sensors and cameras and many portable devices are further applications.

High speed M12 connector for field installation

05.04.2019 | Yamaichi Electronics expands its Y-Circ M12 product portfolio with a new, field-assemblable connector for 10 Gigabit Ethernet applications. It is suitable for use in typical CAT6A applications such as in the communication cabling of automation control systems.

The field-terminated variant comes opposite overmolded M12-Cable assemblies for use when the cable, for example, through a Cable channel has to be pulled and would be too bulky with a plug. Even if the exact cable length cannot be defined in advance, field assemblies are an option.

The mating face corresponds to the standardized M12 X-coding DIN EN 61076-2-109. Thanks to its die-cast zinc housing, the Y-Circ M CAT6A field assembly connector offers optimal transmission properties even in demanding environments. When plugged in, it achieves protection class IP67. Thanks to its slim design, it is also suitable for tight installation spaces.

The quick and easy assembly offers a time advantage during installation. The cable simply has to be stripped and the wires of the cable pressed into the color-coded slots in the back of the two-piece connector. After the protruding wires are cut off, the IDC insulation displacement contacts automatically connect when the two parts are screwed together.

Custom board-to-board connectors

13.02.2019/XNUMX/XNUMX | The trend towards digitization in industry requires new solutions, which also applies to previously purely electromechanical components Weidmüller. Because without an efficient, consistent infrastructure, digitization quickly reaches its limits. The infrastructure includes connectors and cables, the importance of which will continue to increase in the future and are reflected, for example, in intelligent connectors.

13.02.2019/XNUMX/XNUMX | The trend towards digitization in industry requires new solutions, which also applies to previously purely electromechanical components Weidmüller. Because without an efficient, consistent infrastructure, digitization quickly reaches its limits. The infrastructure includes connectors and cables, the importance of which will continue to increase in the future and are reflected, for example, in intelligent connectors.

The development of the connectors is carried out by three trends influenced: digitization, decentralization and miniaturization. With decentralization, more and more functions are migrating to the device and field level in the industrial environment, which means there will be an increasing need for consistent connections between devices along the horizontal and vertical axis of the automation pyramid. This also includes the addition of intelligent functions.

An integration of Sensorand diagnostic functions directly in the connector opens up completely new fields of application and makes additional sensors superfluous. Measured variables such as current, voltage, power and temperature can be recorded and via an APP, an ERP/Scada-System or a cloud store and evaluate. Such a intelligent connector is presented by Weidmüller for the first time. The smart connector was created as part of the BMBF funding project "Intelligent electrical connectors and connection technology with electronic signal processing".

Circular connectors, rectangular connectors and electrical contacts

05.11.2018 | ODU presents a newcomer with the "MAC Rapid" which, thanks to a new half-shell principle, offers 50% time savings in assembly and service. There are also many other intelligent features such as high contact density, easy adaptability to rapidly changing requirements, coding and spindle locking.

05.11.2018 | ODU presents a newcomer with the "MAC Rapid" which, thanks to a new half-shell principle, offers 50% time savings in assembly and service. There are also many other intelligent features such as high contact density, easy adaptability to rapidly changing requirements, coding and spindle locking.

The new performance class of the MAC BlueLine with economical and user-friendly assembly and disassembly of the crimp clip contacts. A new combination module now achieves the highest packing density available on the market with a width of only 14,4 mm. A unique selling point is their spindle lock, even in the standard plastic housing.

The robust one Dock Silver Line is another novelty for automatic docking and robotic systems. The new high-performance contact "Lamtac HTC" offers the highest current carrying capacity and is temperature-resistant up to 200°C. The self-locating contact system "Docking Mate" will be presented for autonomous driving in vehicles and automated production.

Hermetic tightness for medical technology, for example, offers a new series of device parts from the "Mini Snap" series. Thanks to glass encapsulation, the high requirements are met Ultra high vacuum suitable interfaces with high-performance data transmission at up to 14,4 Gbit/s. New high-voltage applications for the "Medi-Snap" enable not only the reliable transmission of up to 1000 V (AC), according to IEC 60664-1, but also the avoidance of "hot-plugging" thanks to the specific pin layout design and lagging contacts in the smallest space of approx .20mm.

Heavy-duty connectors for industrial environments

29.10.2018 | RS Components has introduced a new range of RS Pro high performance connectors. It includes screw and cage clamp terminals as well as housings. The components are designed for the industrial environment. Fields of application are in particular in the areas of sound and light as well as in robotics and mechanical engineering.

29.10.2018 | RS Components has introduced a new range of RS Pro high performance connectors. It includes screw and cage clamp terminals as well as housings. The components are designed for the industrial environment. Fields of application are in particular in the areas of sound and light as well as in robotics and mechanical engineering.

The Pro A and B series inserts include screw terminals and cage clamp terminals that offer very good electrical and mechanical protection as well as UL approvals exhibit. All inserts have a grounded contact for reverse polarity protection. In addition, there are already mounted contacts, so no additional tools are required.

Inserts are available in popular sizes including 3PE, 4PE, 6PE, 10PE, 16PE and 24PE. Other features are a insulation resistance of no less than 1010 Ω and the resilience of more than 500 mating cycles. The operating temperature range of -40° to +125°C meets industry standards, as does the UL90V0 flammability rating.

The introduction also includes two series of covers and housings Made of die-cast metal that meets the IP65 standard. RS Pro A-Series enclosures, available in 3A size, are made from die-cast zinc metal and offer options for top or side cable entry, for cable-to-cable connection and for the surface mount. The RS Pro B range of enclosures is constructed from die-cast aluminum metal and includes top and side entry covers.

High-pole combination connector for power and signal

29.05.2017/XNUMX/XNUMX | Of the Combination connector Han K32 / 55 from Harting sets new standards in the field of miniaturization of rectangular connectors. With a combination of 32 power and 55 signal contacts for use in size 10B housings, it offers one thing in particular: 87 pieces in the smallest of spaces.

29.05.2017/XNUMX/XNUMX | Of the Combination connector Han K32 / 55 from Harting sets new standards in the field of miniaturization of rectangular connectors. With a combination of 32 power and 55 signal contacts for use in size 10B housings, it offers one thing in particular: 87 pieces in the smallest of spaces.

The Han Com Product series combines performance and signal in one Connectors and is now growing with the Han K 32/55. In addition to saving space, this connector design also saves time and money, since 2 connectors are combined in one: Crimp contacts from the D and D-Sub series are installed closed in one insert on the Han K32/55 and allow a maximum of 32 power contacts ( 10 A 250 V 4 kV 3) and 55 signal contacts (4 A 50 V 4 kV 3) to connect.

Contact surfaces in silver as well as in gold are available to the user. It can also be used on existing Crimp contacts and thus also use tools. Clear numbering of each individual contact chamber also rules out incorrect wiring during assembly.

The use in size 10B allows, depending on the application and environmental requirements, the flexible installation in the appropriate metal housing. These include, for example, Han B, Han M, Han EMC, Han HPR and Han-Inox.

Magnetic connectors with spring contact for special cables

27.09.2016 | N + H Technology supplies customized cables and magnetic connectors as a complete system. The plug consists of spring contact pins and a permanent magnet. The implementation of a magnet ensures a quick shock and vibration-resistant as well as self-guiding connection or simple solution between plug and device. Through the spring contacts can not only transmit charging current, but also all other types of signals.

27.09.2016 | N + H Technology supplies customized cables and magnetic connectors as a complete system. The plug consists of spring contact pins and a permanent magnet. The implementation of a magnet ensures a quick shock and vibration-resistant as well as self-guiding connection or simple solution between plug and device. Through the spring contacts can not only transmit charging current, but also all other types of signals.

The contact points are in the device soldered to the board. The advantage of this technology is the high functional reliability with a high number of cycles of at least 10.000 reattachments. Magnetic connectors are used in the field of power and data transmission.

Through the magnetically-defined release mechanism is prevented, for example, in the event of an unintentional train on Cables the device is damaged by a fall. In addition, the plug-in socket is prevented from breaking out. Especially with small end devices such as smart watches or in the Medical Technology magnetic connectors are preferred due to their flat and compact design.

Hybrid Circular Connectors for machine automation

27.01.2016 | TTI is the first distributor to introduce the "Circular Hybrid Connector" (CHC) connector TE Connectivity (TE) in the range. With its 8 power and 4 data pins for industrial Ethernet connections, it is suitable for machine automation applications that require more powerful data connections and currents up to 10 A.

27.01.2016 | TTI is the first distributor to introduce the "Circular Hybrid Connector" (CHC) connector TE Connectivity (TE) in the range. With its 8 power and 4 data pins for industrial Ethernet connections, it is suitable for machine automation applications that require more powerful data connections and currents up to 10 A.

The connector offers very reliable connection technology and meets the high demands on durability and quality for Real-time ethernet Applications in industrial automation. The ability to transmit power, signals and data in one connector allows for more flexible machine configuration. The connector, which is compatible with the "Varan" bus standard, enables shorter changeover times for injection molding machine tools, for example, and the simplified cabling means that installation can be completed in half the time.

The CHC has an optional housing with 11+PE (Protective Earth) contact and versions as PCBs, built-in and cable connectors. The robust design of the contacts offers a longer service life with multiple contact points and a stainless steel detent spring. The gold-plated, silver-plated and tin-plated contacts are suitable for the requirements of the Industrial automation.

The seals ensure the appropriate tightness according to protection class IP67. The Circular Hybrid Connector is available with hydraulic oil-resistant Plastichousing or with shielded Metalhousing. A spinsnap lock ensures a safe and durable plug connection even in environments subject to heavy shock and vibration loads (up to 25 g).

Hybrid, miniature and rectangular connectors for a variety of applications

17.10.2015 | ODU presents hybrid connectors, the miniaturized high-density series and the modular rectangular connector "ODU-MAC". Thanks to numerous modules that can be combined according to the modular principle, this is available in almost unlimited variety configurebar. The specialist for electrical connection technology offers six standard docking solutions.

17.10.2015 | ODU presents hybrid connectors, the miniaturized high-density series and the modular rectangular connector "ODU-MAC". Thanks to numerous modules that can be combined according to the modular principle, this is available in almost unlimited variety configurebar. The specialist for electrical connection technology offers six standard docking solutions.

In addition, new HDMI connectors 2.0 and USB 3.0 modules guarantee high-speed data transmission XXL housing gives different module variants even more space. Not only the standard portfolio but also tailor-made plug connection solutions and suitable cable assemblies implement the requirements of the industry precisely.

Power connector with rated voltage up to 630 V and rated current up to 16 A

13.10.2015 | Bumblebee presents the M12 power connector to the public for the first time. The compact power connector transmits power up to a nominal voltage of 630 V and a nominal current of up to 16 A. This development allows completely new applications, especially in cramped installation spaces. This is where the M12 Power makes the use of power connectors possible in the first place.

13.10.2015 | Bumblebee presents the M12 power connector to the public for the first time. The compact power connector transmits power up to a nominal voltage of 630 V and a nominal current of up to 16 A. This development allows completely new applications, especially in cramped installation spaces. This is where the M12 Power makes the use of power connectors possible in the first place.

This results in new challenges in terms of robustness and temperature resistance. By using new Materials the M12 Power works absolutely reliably in the Temperature range up to 125 °C. The stable metal housings are all EMC-compatible as standard and can accommodate cables with a cross-section of up to 11 mm. The M12 Power is available in four codings and meets protection classes IP67 and IP69K.

Connector combines shielding and plastic housing

27.05.2015/XNUMX/XNUMX | The shielded plastic connector "Medi-Snap EMC" complements the push-pull circular connector range ODU. The portfolio expansion of the specialist for electrical connection technology now combines the application-relevant advantages of the materials metal and plastic. The connector is light, autoclavable and sterilizable and offers safe contact protection with reliable shielding at the same time.

27.05.2015/XNUMX/XNUMX | The shielded plastic connector "Medi-Snap EMC" complements the push-pull circular connector range ODU. The portfolio expansion of the specialist for electrical connection technology now combines the application-relevant advantages of the materials metal and plastic. The connector is light, autoclavable and sterilizable and offers safe contact protection with reliable shielding at the same time.

Shielded products are in increasing demand, because applications in medical technology also increasingly require more electronics in the smallest of spaces, according to the manufacturer. The diverse coding options - both in color and mechanically - and the high chemical resistance is retained. The product extension is available in standard size 2.