Standard-compliant ESD control panels made of special plastics

- Details

- Hits: 5514

An electrostatic discharge can be uncomfortable in everyday life. In industrial production, such discharges can damage or even destroy sensitive electronic devices, components or devices. To prevent such damage, jobs need to be in ESD Zones (electrostatic discharge or electrostatic discharge) down to the smallest component must be equipped in accordance with standards. That Heinrich Kipp Werk offers safe ESD for this keypads.

Content of the technical article

- ESD environments and their effects

- ESD product development and plastics know-how

- ESD portfolio briefly explained - video presentation

ESD environments and their effects

"Most people do not even notice electrostatic discharges of up to 2000 volts," says Andrew Blocher, Project manager pre-development at Kipp. “From around 3000 volts it crackles; Sparks only fly from around 5000 volts. These are surprisingly high tensions. ”However, these are not a problem for humans or animals.

"Most people do not even notice electrostatic discharges of up to 2000 volts," says Andrew Blocher, Project manager pre-development at Kipp. “From around 3000 volts it crackles; Sparks only fly from around 5000 volts. These are surprisingly high tensions. ”However, these are not a problem for humans or animals.

With circuit boards or others electronic components looks different. Electrical components are far more sensitive and can be damaged or destroyed due to electrostatic charging from 100 V upwards. In order to prevent damage from the outset, electrically conductive components in accordance with DIN EN 61340-5-1 must be used in these production environments - from work clothes to furniture and production equipment.

ESD product development and plastics know-how

The market has adapted to this special need and Kipp also received its first inquiries about six years ago. The ESD components are particularly interesting for dealers and export. The product management of the control unit manufacturer took on the topic and checked in a first step which control units are primarily needed in this area. After a selection had been made for the company's own product line, the development team began work. “There are special ones for ESD control panels plastics required ”, describes Andreas Blocher. "They are enriched with fillers in order to achieve electrical conductivity in accordance with DIN EN 61340-5-1."

Calculate fit calculator and roughness easily online

Calculate fit calculator and roughness easily online

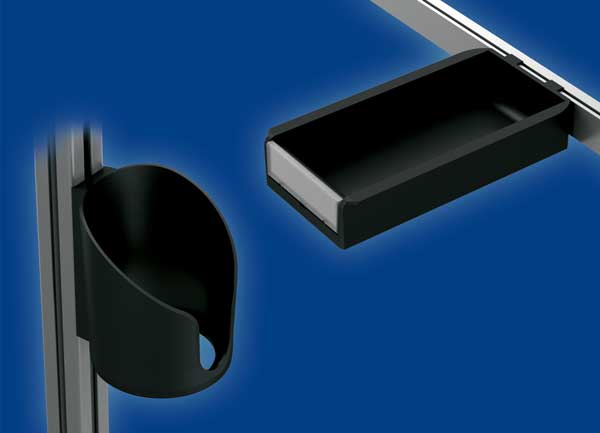

An off-the-shelf plastic could not be used. In terms of development, Kipp has a lot in a short time material Improvement and knowledge has been built up regarding the producibility of the individual products. The development time took almost two years. Today the manufacturer has a bow handle, star handle, wing handle, mushroom button, adjustable foot as well clamping lever Product line in the portfolio. There are also containers or gripping trays. In 2020 knurled screws and knurled nuts were added. Coming up to date ESD quick release added.

Niche application with increasing demand

"ESD control panels are still a niche application, but are enjoying increasing demand," emphasizes Andreas Blocher. "Our customers benefit from the proven Kipp design and guaranteed quality." The products are in terms of electrical conductivity tested by TÜV Süd. In addition, they are tested with a special measuring device after production in Sulz am Neckar. They are finally given the yellow ESD logo for clear identification.

"ESD control panels are still a niche application, but are enjoying increasing demand," emphasizes Andreas Blocher. "Our customers benefit from the proven Kipp design and guaranteed quality." The products are in terms of electrical conductivity tested by TÜV Süd. In addition, they are tested with a special measuring device after production in Sulz am Neckar. They are finally given the yellow ESD logo for clear identification.

Applications can be found in Electrical Engineering, Mechanical and plant engineering, energy and traffic engineering as well as in IT security rooms. Operating parts are required, among other things, in production, assembly and transport. The Electrostatic Discharge products from Kipp also meet the Atex directive 2014/34 / EU. This means that they can also be used in potentially explosive areas. Because an electrostatic spark discharge is prevented, neither gases nor dusts ignite, which can lead to an explosion in closed rooms.

Plastic recycling from and for industry and other uses

Plastic recycling from and for industry and other uses

“With our ESD range, we guarantee a high Security for device manufacturers“, Emphasizes Andreas Blocher. “It is important, however, that we only deliver individual components that conform to standards. Our customers have to make sure that their end product complies with the relevant ESD and ATEX guidelines. "

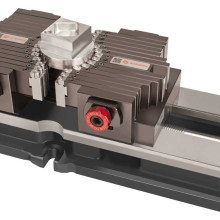

ESD quick release and special solutions

The function of the ESD keypads is the same as that of the standard components. Only the combination of the materials used is different. This can be clearly explained using the new ones ESD quick release. In the regular version, the plastic parts are not conductive or insulating. However, according to the standard, the ESD version must be able to discharge electrostatic charges. Handle elements and protective caps are therefore made of electrically conductive material polyamide or elastomer produced. In this way, the tension is dissipated via the steel frame.

Shim washers to compensate for tolerances in assembly

Shim washers to compensate for tolerances in assembly

The quick releases serve as Assembly and holding device. With them z. B. clamp workpieces for further processing. Functionally, they offer an ergonomic handle, maintenance-free joint bushings and a sustained constant use of force when opening and closing. The conical clamping arm with U-profile makes the quick release very stable.

"In the area of ESD control units, we already offer a large range that covers many applications," concluded Andreas Blocher. “In addition, however, we can also offer other sizes, different threads or even special solutions "If necessary, additional control parts can be manufactured relatively easily with the dissipative plastics. ESD handwheels, for example, are conceivable. Kipp has flexible in-house production for this on site.

ESD portfolio briefly explained - video presentation

You might also be interested in...

This snap lock locks securely

clamping technology | Intelligent, safe, efficient!

Indexing bolts / locking bolts from Kipp

Heinrich Kipp work | Inventor of the spaetzle machine

Clamping lever with safety function or solid plastic handle