Indexing bolts / locking bolts from Kipp

- Details

- Hits: 26171

The group of the rather inconspicuous standard parts and operating parts also include the Locking. The Heinrich Kipp Werk produces them at the location in Germany with a large machine park. Numerous indexing plungers leave the factory here every year. Kipp holds the intellectual property rights for many of the 1300 different designs. In the following we present the new developments of these operating parts such as a locking bolt in hygienic design, a locking bolt with an eccentric lever.

Contents

- Constant expansion of the locking bolt portfolio

- Six new indexing plungers with rotary actuation

- Wired indexing bolts with status sensor

- Locking bolt offer for in hygienic design

- Practical locking bolt with eccentric lever

- Two in one: handle for locking and tensioning

- Locking bolt with integrated condition sensor

- Locking bolt with Bowden cable for remote operation

- Functionally with locking, bevel and compressed air

- Structure and function of indexing bolts | locking bolt

- Areas of application for indexing plungers | locking bolt

- Archive for Indexing Bolts / Locking Bolts Innovations

- How indexing bolts work | locking bolt

Constant expansion of the locking bolt portfolio

“With our developments in the field Workholding, standard parts and operating parts, we set standards in the market,” says Kai Patrick Dahlhaus, Head of Development at Kipp. "In our factory, solutions are created that make a decisive contribution to increasing efficiency in production facilities around the world."

“With our developments in the field Workholding, standard parts and operating parts, we set standards in the market,” says Kai Patrick Dahlhaus, Head of Development at Kipp. "In our factory, solutions are created that make a decisive contribution to increasing efficiency in production facilities around the world."

The large standard parts program currently includes 45.000 parts and is constantly being supplemented with additional components. “We develop new products entirely in-house. Thanks to our high level of vertical integration and seamless quality assurance, high-quality components are created in terms of design, ergonomics, stability and reliability, ”continues Mr. Dahlhaus.

The product group of the Locking, also resilient pressure pieces. The Kipp Werk has around 1300 designs in different types of actuation, sizes, shapes, levels of precision and materials in its program. Special designs can also be implemented on request.

The locking bolts from Kipp Werk are used to lock in swivel and rotating devices and as positioning elements for the stops in machines, furniture and special vehicles. The machine parts can only be moved into a new position after the bolt has been disengaged and then fixed. So a change in the locking position is carried out Lateral forces prevented.

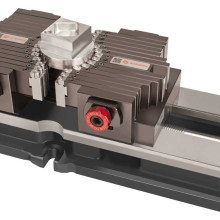

Clamping technology for workpiece, device and tool machine

Clamping technology for workpiece, device and tool machine

"Despite the range of products that are already available, there is still potential for innovations in this area," says Kai-Patrick Dahlhaus. “With the constant further development in mechanical engineering, the requirements for the positioning and fixing of components are also changing. With our new products, we always respond to a clear need. ”The pioneering role of the manufacturer in the market is evident from the large number of products Property rights for innovative locking bolts that Kipp has. Below you will find the innovations from the locking bolt product group:

Six new indexing plungers with rotary actuation

25.04.2023/XNUMX/XNUMX | Kipp has expanded its indexing bolt portfolio with six new versions with rotary actuation. With the practical locking bolts, moving parts can be quickly adjusted and positioned for operation. They are ideal for all applications where the Locked position by lateral forces must not be changed.

25.04.2023/XNUMX/XNUMX | Kipp has expanded its indexing bolt portfolio with six new versions with rotary actuation. With the practical locking bolts, moving parts can be quickly adjusted and positioned for operation. They are ideal for all applications where the Locked position by lateral forces must not be changed.

The indexing bolts are available with bolt diameters from 5 and 7 mm. The locking pins allow a component to be positioned and fixed quickly by rotating or sliding. The products offer an on/off indication or an on/mid/off indication depending on the execution. These markings significantly reduce the risk of incorrect operation.

The housing and the bolts of the indexing bolts are off nickel-plated steel manufactured, the rotary heads consist of thermoplastic plastic. The indexing pin of the indexing bolt is conical. Matching conical steel bushings in both indexing pin diameters are available as accessories.

The range of locking bolts includes a version with a thread and a variant with a flange. In the case of the indexing plunger variant with a thread, it is fastened with a counter nut, the flange product is fixed with three fastening screws.

The indexing plungers with rotary actuation are suitable for positioning on guide rails in mechanical engineering, for fixture construction and packaging systems as well as for locking in the vehicle technology or for locking extensions.

Wired indexing bolts with status sensor

16.05.2022/XNUMX/XNUMX | As an alternative to the wireless Bluetooth variant, Kipp now also has wired locking bolts with a status sensor in its range. This means that users are in mechanical engineering regardless of battery life. Even at longer ranges with obstacles, these indexing bolts guarantee trouble-free signal transmission. The wired locking bolts belong to the Featuregrip product line, which enables intelligent process monitoring.

16.05.2022/XNUMX/XNUMX | As an alternative to the wireless Bluetooth variant, Kipp now also has wired locking bolts with a status sensor in its range. This means that users are in mechanical engineering regardless of battery life. Even at longer ranges with obstacles, these indexing bolts guarantee trouble-free signal transmission. The wired locking bolts belong to the Featuregrip product line, which enables intelligent process monitoring.

The integrated inductive sensor of the locking bolt detects the actuation status. The signal is processed in the mushroom handle and transmitted to the machine control. A three-core, 2 m long cable is provided as standard. As soon as the bolt has been pulled 1 mm, the sensor switches. For example, the control can be used to specify that the processing cycle only begins when all the bolts are in the right place.

The wired ones IP67 Indexing plungers are resistant to splash water, dust-tight and protected against accidental contact. Hardened or non-hardened indexing plungers in stainless steel are also available. They are available with bolt diameters from 5 to 2 mm and thread sizes from M10 to M20.

Locking bolts with status sensors are ideal for Fix and clamp in guidance systems, in monitored assembly facilities, in pivoting or rotating devices or in stop positioning. Machine parts can only be brought into a new position after the bolt has been disengaged and then clamped again. This prevents the locking position from being changed by transverse forces. Heinrich Kipp offers around 1300 versions in different sizes, shapes, types of actuation, materials, levels of precision and special versions on request.

Locking bolt offer in hygienic design

11.01.2022/XNUMX/XNUMX | With locking bolts can be move moving machine components quickly. To do this, the operator pulls a locking pin out of the counterpart on the pull ring or button and thus brings machine parts safely into the desired position in order to then lock them with the locking device.

Kipp is now presenting a detent plunger in hygienic design for increased Hygiene requirements. The indexing bolt was designed according to hygienic design guidelines. As a result, no dirt particles stick to it and cleaning is also simplified. The stainless steel indexing bolt is suitable for the construction of machines and systems food technology, pharmaceutical industry and Medical Technology.

Emka fitting parts for electrical engineering and electronics

Emka fitting parts for electrical engineering and electronics

The new locking bolt was made from high quality stainless steel 1.4404. This stainless steel indexing bolt has a conical collar to hygienically seal the screw point with the associated sealing washers and washers. The component surface with a surface roughness of Ra <0,8 µm prevents the adhesion of dirt particles. The locking bolt is suitable for CIP and SIP cleanings processes.

The indexing bolt in hygienic design FDA compliant materials is resistant to polar and non-polar media and aromatic substances. It is available with a hardened or unhardened indexing pin and with or without an indexing groove. It is available with a locking pin diameter of 6 and 8 mm and with a screw-in standard or fine thread size M10 and M12. The shaft seal of the indexing plunger is optionally available in 70 EPDM 291 (black) or 75 Fluoroprene XP 41 (blue). A sealing and washer Hygienic Usit K1491 made of the same base materials is included in the scope of delivery. If required, it can also be purchased as an accessory.

Practical locking bolt with eccentric lever

02.09.2021 | In addition to the locking bolts from the Heinrich Kipp factory, there are also standard parts in which the bolt is disengaged via an eccentric lever. If the operator moves the eccentric lever over the Dead center of the eccentric, the bolt disengages. The new indexing bolt is ergonomic, flat, temperature-resistant and can be adjusted quickly.

02.09.2021 | In addition to the locking bolts from the Heinrich Kipp factory, there are also standard parts in which the bolt is disengaged via an eccentric lever. If the operator moves the eccentric lever over the Dead center of the eccentric, the bolt disengages. The new indexing bolt is ergonomic, flat, temperature-resistant and can be adjusted quickly.

A big advantage This version with an exender lever is that the locking bolt remains disengaged when the grip lever is moved past the dead point of the eccentric. are e.g. If, for example, several locking pins are fixed to a housing that cannot be reached manually by one person at the same time, this locking pin with extender lever solves the problem. The operator thus easily releases one locking bolt after the other without having to hold all the handles in the extended position. This function is otherwise only available with locking pins with a locking groove, where the handle has to be turned in the pulled position - but the process takes longer as a result. The products with an eccentric lever, on the other hand, are suitable for convenient quick adjustment.

The ergonomic shape of the eccentric handle allows easy handling with little effort. The grip levers are available in black and traffic red and are made of glass-fibre reinforced plastic. The plastic is resistant to high temperatures and allows long-term use temperatures of approx. 160 °C and a maximum of 250 °C for short periods. The threaded sleeves and indexing pins are available in steel and stainless steel.

All threaded sleeves are included fine thread in the four sizes M10 x 1, M12 x 1,5, M16 x 1,5 and M20 x 1,5. The eccentric handles can be rotated 360°. When not actuated, they are significantly flatter than a mushroom handle or T-handle. This enables countersunk installation that avoids interfering contours.

Two in one: handle for locking and tensioning

12.08.2021/XNUMX/XNUMX | The new Combination handle from the Heinrich Kipp factory takes over the tasks of locking bolts and star knobs. Various adjustment elements can be positioned, secured and clamped with just one movement. You can also choose the new locking and cocking handle with an optical locking indicator for additional security.

12.08.2021/XNUMX/XNUMX | The new Combination handle from the Heinrich Kipp factory takes over the tasks of locking bolts and star knobs. Various adjustment elements can be positioned, secured and clamped with just one movement. You can also choose the new locking and cocking handle with an optical locking indicator for additional security.

The locking takes place form-fitting over the bolt. the frictional The face of the sleeve is used for clamping. Rotating the handle in the pulled position will hold the detent pin in the retracted position. On the model with optical lock detection, the protruding signal button indicates when the locking pin connection is not fully locked.

The solution from the series of resilient pressure pads is suitable for the manual operation of assemblies, aggregates, machines and devices or also on sports equipment. The star grip with spring bolt makes operation comfortable and ergonomic. The user pulls on the handle, the locking pin holds the position and locks when released. The support arm is fixed at the desired height. The optical locking identifier is suitable for adjusting the height of monitors. The user can see immediately whether the bolt has engaged. Otherwise, the monitor could unintentionally slide down and change its position.

Select eyebolt, cotter pin, axial joint online

Select eyebolt, cotter pin, axial joint online

The material for the locking and tensioning handles was black thermoplastic used. The red signal button from the same material stands out visually. There are 8 sizes. The diameter of the stainless steel indexing pin varies from 4 to 8 mm. The threaded sleeves are made of steel and are available in sizes M8 to M16 with regular or fine threads.

Locking bolt with integrated condition sensor

19.05.2021/XNUMX/XNUMX | A new development from the Heinrich Kipp factory is a very special locking bolt in the product range Feature grip. An integrated Sensor detects the actuation state. The signal is processed in its mushroom handle and transmitted wirelessly to the machine control or to a mobile device. The feature grip pressure pieces are characterized by the fact that electromechanical and sensory elements are integrated into them. These report certain parameters or states. The locking bolts are therefore suitable for Industry 4.0 applications.

19.05.2021/XNUMX/XNUMX | A new development from the Heinrich Kipp factory is a very special locking bolt in the product range Feature grip. An integrated Sensor detects the actuation state. The signal is processed in its mushroom handle and transmitted wirelessly to the machine control or to a mobile device. The feature grip pressure pieces are characterized by the fact that electromechanical and sensory elements are integrated into them. These report certain parameters or states. The locking bolts are therefore suitable for Industry 4.0 applications.

The locking bolt with status sensor contributes to process safety in mechanical engineering. The user can query centrally whether the catch lock is pulled or not. About the machinessteering it can thus be determined, for example, that the machining cycle only begins when each locking device is in the right place.

Kipp offers the right solution for connecting to the control system Gateway K1494. The locking bolts can be integrated into machines and systems via this interface. This means that the operating states of the elements are displayed, checked and used for process control. Connected to a machine control, information from up to six locking bolts can be processed at the same time. This number can be expanded using additional gateways.

Maintenance-free and ready-to-install rotary dampers from Norelem

Maintenance-free and ready-to-install rotary dampers from Norelem

The actuation status of the locking bolts is transmitted wirelessly via Bluetooth Low Energy. The gateway receives the radio signal and converts it into a standardized output signal. The Communication between the locking bolt and the gateway receiver is encrypted and therefore secure. The range is up to 10 m. The locking bolt is supplied with energy via an integrated button cell that can be replaced. Intelligent energy management increases the battery life.

Locking bolt with Bowden cable for remote operation

29.06.2020/2020/XNUMX | In the summer of XNUMX, Kipp presented a locking bolt made of stainless steel for remote operation. The locking bolt has a Bowden. Machine parts can be positioned and determined using a remote control.

Kipp has it for inaccessible installation spaces or for safe and ergonomic operation from a distance Locking bolt with Remote Control developed. The coupling with the operator takes place via a Bowden cable. Its length can vary between 1000 mm and 5000 mm. The cable can be shortened accordingly for the accuracy of fit.

Calculate fit calculator easily online

Calculate fit calculator easily online

The manufacturer offers a coordinated combination of locking bolts and an actuating element Mushroom handle. The locking pin can be detached from the counterpart using the handle. Alternatively, an individual control element can be integrated into the system via an additional screw nipple with a diameter of 5 x 7 mm.

The locking bolt and the actuating element are made of stainless steel. That guarantees Corrosion Protection even with heavy soiling or intensive cleaning. Wire rope and Bowden cable cover can be exchanged if necessary. The locking bolts are available in various designs. Several thread sizes and stud diameters are available.

Functionally with locking, bevel and compressed air

In 2019, Kipp added three additional types to its range of locking pins. The first version with Locking offers easy handling. The system locks by pressing the push button; a red release button allows the practical release and change of the locking position.

The second locking bolt has a Ramp on the bolt. This is designed to be secured against rotation and allows the bolt to be disengaged automatically by one-sided transverse forces. The angle of rotation can be adjusted in increments of 60 ° and unlocking takes place as usual by pulling the handle.

Kipp has a third version pneumatic locking pin taken into the portfolio. It can be used to automate the process. The bolt is actuated by means of compressed air; it is reset after the air supply has been disconnected by a Compression spring. This version is used, for example, in clocked production systems, assembly facilities or in safety-relevant applications.

Structure and function of indexing bolts | locking bolt

A locking pin always consists of a sleeve, handle, indexing pin and spring. Steel and stainless steel are used as standard materials. Handles can also be made of plastic. "Basically, there are a variety of different designs," explains Kai-Patrick Dahlhaus. "These include standard parts with and without collars, thread locks or lock nuts, short and long versions and various handle variants." Based on the high Variety of variants the components meet a wide variety of requirements. The standardized components can be interchanged at any time.

Adjustable ball lock pins for long distances

Adjustable ball lock pins for long distances

Locking bolt with Locking groove are suitable for applications in which the locking pin is to remain temporarily in the retracted state. To do this, pull the locking bolt out of the locking pin and turn it 90 °. In this position it sits on the hexagon until it retracts again by turning it again.

That is beneficial as soon as Housing are fixed with several locking bolts that cannot be reached manually by one person at the same time. The operator then conveniently releases one locking bolt after the other without having to hold all of the extended handles.

"The rail guidance of an injection molding machine is also one of the application examples," explains Mr. Dahlhaus. “This is where our components fix the rail car. When released, the bolt literally locks onto the groove and the carriage can move. "

Areas of application for indexing plungers | locking bolt

Locking bolts are suitable for applications in which quick loosening, adjusting and locking of components is required. These can be found, for example, in swiveling or rotating devices or as positioning elements for stops. These are standardized Locking boltwith whom Machine Elements After extending the bolt, move it into a new position and then allow it to be reliably fixed again.

Wave spring or not? That is the question of Gutekunst here

Wave spring or not? That is the question of Gutekunst here

Such locking bolts must be easy to handle, durable and of high quality. Also important are one exact run and secure engagement and disengagement in the end position. It does not matter whether the locking bolt is welded on as a smooth version or screwed into the existing thread. Even the strongest lateral forces have no chance of impairing function during application. Another locking position can only be assumed after the locking bolt has been manually extended.

As many different types of locking bolts as there are, the potential applications are so innumerable. In the following we present some applications:

Premium applications

Locking bolts are also suitable for thin-walled parts with wall thicknesses of one to five millimeters. Examples of this are sheet metal housings from Control cabinets or machine covers. With the introduction of such locking bolts, the Kipp factory closed another market niche a few years ago. At around the same time, premium and precision locking bolts were also developed. These are subject to tighter manufacturing tolerances than standard designs. This allows the bolt to be positioned more precisely. This is in demand in applications that require good repeatability.

The premium locking bolts require an exact run in the guide and a secure locking in the end position. They are available in conical and cylindrical designs made of steel or stainless steel. All bolts are with a plastic Mushroom handle made of thermoplastic.

Archive for Indexing Plunger News

First locked, then automated: locking bolt

22.03.2019/XNUMX/XNUMX | The Heinrich Kipp factory is expanding its portfolio of standard parts in the area of locking bolts. These prevent the locking position from being changed Lateral forces. The bolts are fastened and loosened manually or, more recently, via pneumatic control - a further development of the standard parts, especially for automation.

22.03.2019/XNUMX/XNUMX | The Heinrich Kipp factory is expanding its portfolio of standard parts in the area of locking bolts. These prevent the locking position from being changed Lateral forces. The bolts are fastened and loosened manually or, more recently, via pneumatic control - a further development of the standard parts, especially for automation.

The locking bolt with locking is easy to handle. Locking occurs by pressing a push button; a red unlocking button enables the practical loosening and changing of the locking position. The locking bolt is available in steel or stainless steel with bolt diameters of 5, 6, 8 and 10 mm.

Another novelty is the locking bolt with anti-twist device, which is available with fine or coarse thread. The special securing of the standard parts ensures that the position of the bolt relative to the sleeve does not change. A starting bevel allows the bolt to disengage automatically due to one-sided transverse forces. Loosening the screw up to the mark on the bolt allows the chamfer to be rotated in a 60° grid.

Clutches and brakes Use in food technology

Clutches and brakes Use in food technology

The pneumatic locking bolts is important for development tasks in automation. It is actuated by applying compressed air. It is reset by cutting off the air supply. It is used, for example, in clocked production plants or assembly facilities as well as in safety-relevant applications that do not allow manual unlocking. In addition, the manufacturer includes locking bolts with a marking ring for visual status control in the range.

At the show, visitors can get an impression of the product line Feature grip provide. The integrated electromechanical and sensory elements provide immediate and reliable feedback on certain parameters or states such as open or locked via visual signals.

Monitoring of quick releases and locking bolts via app

02.10.2018 | The Heinrich Kipp factory presents the new product line feature grip with quick release, locking bolt and spring pressure pads. Electromechanical and sensory elements are integrated in it. These provide feedback on a specific parameter or status. They enable monitoring and can collect information such as condition or force. By processing and visualizing the information at a central point, time can be saved and process reliability guaranteed.

Belong to the new product line Quick release with force sensor as well as locking bolts and spring pressure pieces with status sensor. Toggle clamps with a force sensor report the force acting on the workpiece. This allows an exact monitoring of the force. Exceeding or falling below are reported based on default values.

Chuck innovations for efficient metal processing

Chuck innovations for efficient metal processing

The status of the locking bolt is displayed using an app. If the green light is on, it is locked. However, if the red light appears, the locking bolt has been pulled and must be checked. That spring pressure piece with status sensor reports whether the pressure pin is pressed or extended. A sensor in the pressure piece processes the signal via the connectioncable. In addition, there is an LED on the pressure piece and indicates the status.

The quick releases, locking bolts and pressure pieces of the Feature Grip line allow a Coupling with individual software, systems, mobile devices or apps. The individual values are saved and can therefore be evaluated. Toggle clamps & Co. give the user access to Industry 4.0.

How indexing bolts work | locking bolt

The functionality of indexing bolts, also known as locking bolts, is based on the use of high-quality materials such as super thermoplastic.

This special thermoplastic mixture ensures high stability and resilience. The intelligent design of the studs allows them to be easily inserted into mini-grids, allowing for precise positioning. Indexing holes ensure easy assembly and disassembly of the bolts. This innovative system ensures reliable and efficient locking in a wide variety of applications.

You might also be interested in...

clamping technology | Intelligent, safe, efficient!

Ergonomic controls and standard parts

Heinrich Kipp work | Inventor of the spaetzle machine

Kipp clamping technology for fixture and machine tool

Standard-compliant ESD control panels made of special plastics

High quality wheels and castors for industrial applications

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.