Nord Antriebstechnik solutions for food technology

- Details

- Hits: 7963

Thousands Drive Technology Systems for the Food technology from Bakery machines up to processing fish and seafood NORD already successfully installed. Based on this industry know-how and an extensive product kit, users in the industry receive complete solutions from a single source.

Content of the technical article

Requirements of the food industry

The entire value chain in the beverage and food technology requires a reliable mechanical and electrical Drive Technology with Engines, Transmission, Frequency converter. The special requirements for the products in terms of hygiene, energy efficiency, gentle treatment and demanding environmental conditions such as cold, heat and moisture are in the components economically in harmony bring to. The portfolio of Getriebebau Nord consists of high quality and reliable gear motors, frequency convertern as well as intelligent software.

Hygienic drive technology as a complete solution

One of the building blocks of the kit are Pump Drives. Getriebebau Nord adapts the drive to the respective conveying medium and realizes z. B. high starting torques or a soft start. Frequency converters mounted on the wall and motor facilitate this decentralized automation and enable mobile pumps with sophisticated controls.

Decentralized drive technology for the digital factory of the future

Decentralized drive technology for the digital factory of the future

The drive specialist combines his Smooth engines with two-stage bevel gears and the Surface finishing NSD Tuph. The result is a versatile and lightweight drive technology with a high degree of efficiency. Thanks to the smooth surfaces, the drive systems are easy to clean. Even without a fan, they achieve significantly better heat dissipation than stainless steel drives with comparable corrosion protection. These properties are also used in drive technology in systems and mechanical engineering for dosing and cutting or in CIP and SIP Cleaning required.

The electrical and mechanical drive technology from Nord also meets all of the requirements Temperatures stand - applications in hot or cold environments as well as freezer zones alike. Extreme environmental conditions such as cooking zones, baking lines or freezer systems do not cause any problems for the drive technology.

Gear motor for stirring technology and mixing technology

For processes such as stirring, mixing and kneading, Getriebebau Nord builds geared motors of all sizes. The bearings installed in it for the output shaft can withstand particularly high loads. The Maxxdrive is particularly suitable for mixed technology applications industrial gear. They offer output torques from 15 to 282 kNm. The new SafomiAdapter was developed especially for you. This is a flange with an integrated oil expansion tank. It improves operational reliability and uses fewer wearing parts. Especially for pumps, stirring and mixing technology, Nord equips its drive technology with a process-related high radial and axial load capacity.

For processes such as stirring, mixing and kneading, Getriebebau Nord builds geared motors of all sizes. The bearings installed in it for the output shaft can withstand particularly high loads. The Maxxdrive is particularly suitable for mixed technology applications industrial gear. They offer output torques from 15 to 282 kNm. The new SafomiAdapter was developed especially for you. This is a flange with an integrated oil expansion tank. It improves operational reliability and uses fewer wearing parts. Especially for pumps, stirring and mixing technology, Nord equips its drive technology with a process-related high radial and axial load capacity.

Drive technology for packaging and intralogistics

At the end of every baking process etc., the packaging technology is ready to connect the food hygienic to the consumer to be able to bring. synchronous motors with frequency converter and encoderFeedback via absolute or incremental encoders allow precise positioning and dynamic movement of packaging of all sizes.

Getriebebau Nord builds flexible drive technology solutions for horizontal conveyors, vertical conveyors, inclined conveyors and palletizing systems. Custom-made drives for filling systems are of course also possible.

With intelligent frequency converter soft start, braking ramp function, braking process and STO function (Safe Torque Off) can be implemented. Multi encoder operation is also possible. Here the electrical components control up to four motors with rotary encoders.

For the Intralogistik offers north with the Logidrive concept a modular system for individual, economical drive concepts that achieve an optimal balance between energy efficiency and fewer variants.

Application examples food and beverage

Whole individually tailoredNord Drivesystems offers drive systems for the industry from storage, conveying and processing of raw materials to process technology and filling to packaging and logistics. The following applications give a little insight:

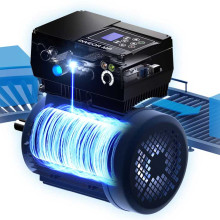

Water-cooled electric motors: compact, powerful, quiet

Water-cooled electric motors: compact, powerful, quiet

Chocolate production at Zotter Schokolade

This application shows how Getriebebau Nord works at Zotter Schokolade numerous process steps covered with just one drive technology solution.

Can filling of powder and dry products at Swiss can Machinery

This application illustrates how the drive specialist at Swiss Can Machinery uses a hygienic motor-gearbox combination for transporting, filling and closing 4000 cans per hour realized.

Grain storage at Lachenmeier Monsum

In this application, Nord equips a grain terminal with storage capacity for 40.000 tons of grain at Lachenmeier Monsum with its drive technology.

Getriebebau Nord is an exhibitor at FMB 2020.

General technical knowledge

Clean in Place (CIP) is a mostly fully automatic cleaning process in the food industry, in which internal surfaces of closed systems can be cleaned with little or no dismantling.

Sterilization in Place (SIP) is an extension of CIP cleaning to include additional sterilization. The sterilization takes place after the CIP cleaning. It kills microorganisms that are still active in the system.

You might also be interested in...

Frequency inverter | For the optimal speed on the electric motor

Frequency converter from the modular system for control cabinet + field

Gear motor integrated IE5 + motor in spur gear

Transmission North | The Block Case Inventor

IE5 + synchronous motor for variant reduction and TCO reduction

Easy-to-install IE3 asynchronous motor in eco-design

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.