Easy-to-install IE3 asynchronous motor in eco-design

- Details

- Hits: 6025

Electric drives have a large share in industrial electrical energy consumption. According to Nord Drivesystems, up to 60 percent can be saved together with the application. Therefore supported NORD its customers with energy-efficient drives to tap this potential for savings. Below we present the innovations in the area Asynchronous motor.

Contents

Effects of the new ecodesign regulation

15.09.2021: An Efficiency optimization of a drive system including its application offers a significant energy saving potential, which here is around 30 to 60%. Getriebebau Nord committed itself to this task several decades ago with the emergence of the energy debate. With every product development, the drive specialist looks at sustainability, economy, energy efficiency, functionality and performance.

Implementation of the current efficiency regulations in practice

Since July 1, 2021 the legal requirements regarding the energy efficiency of electric motors and speed control have tightened. This makes the use of IE3 motors in additional power ranges more economically attractive and in some cases also imperative. Among other things, the energy efficiency class IE3 now applies to 3-phase asynchronous motors for rated outputs from 0,75 kW to 1000 kW and now also for 8-pole motors Engineswhich were previously excluded.

Frequency converter innovations: decentralized, networked with app and much more.

Frequency converter innovations: decentralized, networked with app and much more.

There are also new specifications for the smaller 3-phase asynchronous motors with rated outputs of 0,12 kW to <0,75 kW. Such an asynchronous motor must now comply with energy efficiency class IE2. Nord Drivesystems examines the topic in detail in a free white paper with the title Energy efficiency with three-phase motors. It contains important detailed knowledge about the design more energy efficient gearmotors and frequency converters as well as the current international efficiency regulations

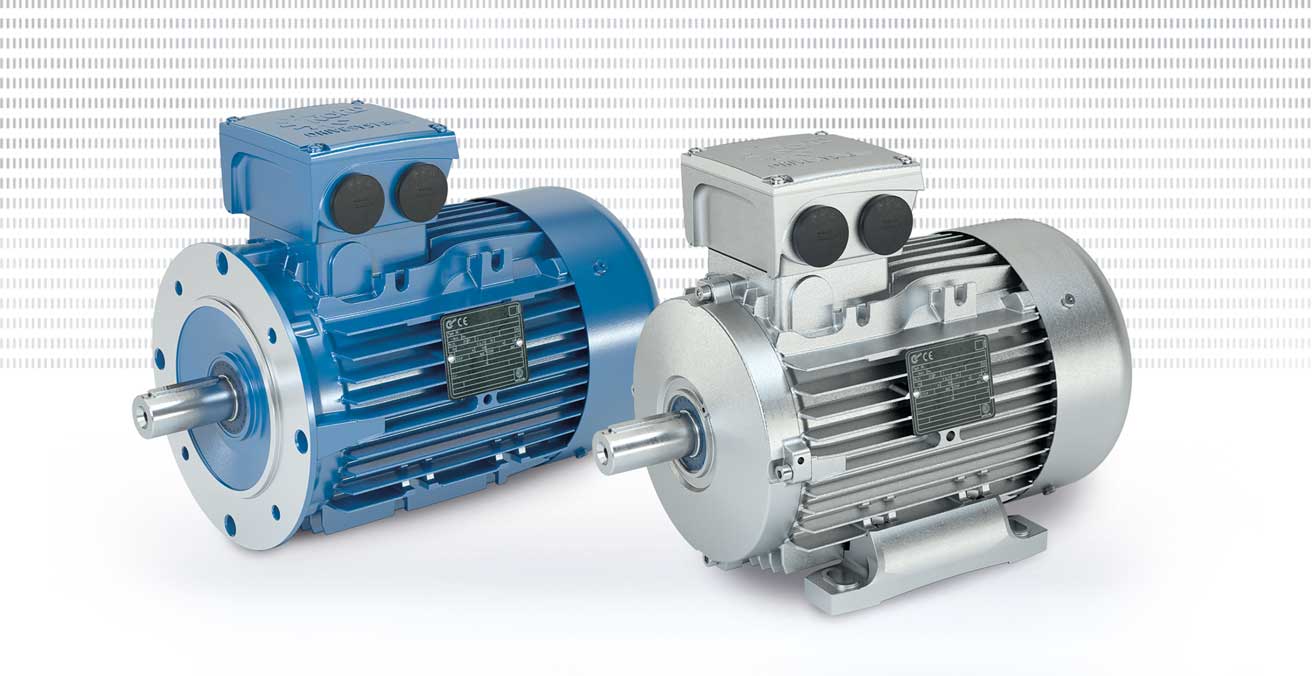

IE3 asynchronous motor design optimized

11.12.2019: Nord Drivesystems has the design of its proven IE3 asynchronous motor Optimized series. Numerous details improve the function, assembly and operation of the asynchronous machine. The electrical data and the mechanical dimensions remain unchanged with the facelift of the IE3 asynchronous motors from Nord.

They can be used seamlessly without adjustments in any existing application with Nord IE3 asynchronous motors. The optimized cooling fin shape, an assembly-optimized fan and a new fan cover in a modern design ensure better heat dissipation and assembly. The fan cover can also be used when using a motor-mounted Frequency converter easy to assemble.

Universal motor in 20 variants for worldwide use

Universal motor in 20 variants for worldwide use

Through the new Cooling fin design the result is a flowing air flow around the terminal box. The revised terminal box no longer has pronounced corners and edges and reinforced feet provide the Engines better stability.

The optimized Incremental is completely protected against impacts by the fan cover and is no longer in the air flow. This increases the cooling capacity. It can also be retrofitted thanks to a slip-on shaft.

Getriebebau Nord is exhibiting at FMB 2021 and the SPS 2021.

You might also be interested in...

Frequency inverter | For the optimal speed on the electric motor

Frequency converter from the modular system for control cabinet + field

Transmission North | The Block Case Inventor

Modular industrial gear units for heavy-duty tasks

Surface finishing + other protection for the drive technology